Académique Documents

Professionnel Documents

Culture Documents

00 Manuale G3-Short Eng

Transféré par

ElioArmasCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

00 Manuale G3-Short Eng

Transféré par

ElioArmasDroits d'auteur :

Formats disponibles

_

GB

USE AND MAINTENANCE

HANDBOOK FOR ELECTRIC

BOARD

G3

MADE FOR :

MO1/G3SHORT 12/’08

This handbook should be kept in a safe place to allow rapid consultation during the whole life cycle

of the electric board. This handbook and the conformity statement are an integrating part of the

generating set. Read use and maintenance handbooks before using the generating set.

MARGEN srl

Plant 1 and Headquarters: Plant 2:

Via Dino Ferrari ,50 Via Bucciardi,33

41053 MARANELLO (MO) ITALY 41042 FIORANO

Modenese (MO) ITALY

Tel. +39 0536 94.36.15 FAX +39 0536 94.35.81

e-mail: info@margen.it www.margen.it

Handebook G3SHORT versione 0.1 15/12/2008 1

Handbook G3_SHORT

Version 0.1 del 20/04/2006

REDUCED VERSION FOR THE COMPLETE VERSION MAKE REFERENCE TO ANNEX CD

G3 CPU has a backlighted alphanumeric LCD with 2 lines of 16 characters on its front side. This display

allows surfing the menu freely except for configuration that is strictly reserved to Margen staff and therefore

protected through a password. To surf this menu you have to use the 8 eight keys under the display.

Enter/ESC Configuration: allows entering protected configuration menu and exit

Scroll down menu/decrease: allows scrolling down menu pages and decreasing figures from

configuration menu.

Scroll UP menu/increase: allows scrolling up menu pages and increasing figures from configuration

menu.

enter/esc SUB Menu: allows entering visualisation sub menus, confirming visualisation and exiting.

Back to main menu/alarm reset: you can go back to main page from any menu page, in manual mode

you can reset alarms.

function key/manual starting: in manual mode it allows manual generating set starting, it has different

functions according to different options.

function key/manual stop: in manual mode it allows manual group stopping, it has different functions

according to different options.

function key/generating set commutation: in manual mode it allows group commutation (with net

open), it has different functions according to different options.

Led: LED on “Enter/Esc configuration” key blinks with 0.5 s ON/OFF frequency to show that the program is

in execution. If the LED is off or steady on there is a system or program malfunctioning.

For a complete description of the menu see attachment “G3CPU Menu”

Use of panel keys

All G3Panel keys have a red led that shows state or functioning of the function linked to it. During the first

functioning cycle the system is always preset in LOCK mode for security reasons, therefore key LED must be

on. System presetting also includes TEST, AUTO and MANUAL keys.

LOCK: after blocking all generating set functions, if generating set is on you will have immediate lock

by pressing this key. All manual functions are cut out too (except starting from local: see chapter G3 CPU),

buzzer and alarms are cut out in LOCK mode until different setting.

TEST: it makes the unit start immediately but if there is net tension no control on commutation is

possible. If net tension fails during the test there would be commutation net / unit as in automatic mode; in

order to arrest generating set select AUTO (but only if there is net tension) or manual mode by switching

suitable keys. All protections are active.

AUTO: it activates Standby mode, i.e. generating set is waiting for the control of net tension

missing. All automatic functions are on including periodical test; in case net tension fails the generating set

Handebook G3SHORT versione 0.1 15/12/2008 2

starts automatically. As soon as nominal parameters are reached, generating set net contact maker closes.

When net tension is back again and after a programmable time there will be opposite commutation

generating set / net, after a cooling time (which is also programmable) generating set stops. All protections

are active.

MANUAL: In this position the system becomes semi-automatic, i.e. generating set starting and

arrest are voluntary and controlled by the operator, all alarms and protections are on. In manual mode button

controls for starting, arrest and net / power unit commutation are on. In manual mode, when the machine is

stopped and the key START is pressed and no lock alarms are on, the generating set starts. You just

need to press this key for a second to start a complete starting cycle with preset duration. You can interrupt

this cycle any time by pressing the key STOP . In manual mode you must be particularly careful with the

key MS (net contact maker) : if you press this key when the light is on you release load on the net

(provided you have not disabled the software upon request thus making it impossible to use the key MS); in

the same way, only if it is open (led off) it is possible to close that of the GS pressing the key when the

machine is working. The light in the key GS confirms that load on GS has been closed. Commutation keys

work in set-reset mode: every time you press them you close and open the control alternatively. Also in

manual mode controls are interlocked, so it is not possible to have a contemporary lock. With manual control

of Margen motorised commutators you have to press the key of the generating set contact maker only once

then press the net contact maker to go back from GS or net manually, or act manually on commutator from

GS to net position.

NOTE: Control system for net commutation is operated through NC logics in order to safeguard the load, as

soon as there is net tension you can have net remote control switch; this means that also in case the CPU is

replaced or Battery tension is disconnected the working of the machine is still granted. The same happens

when you want to open net load, i.e. you have to keep pertinent control fuse open (see diagram).

ACK: the key ACK or implied alarm lights up every time there is a new alarm and it shows that

active acoustic alarm has been activated (led with steady light). To silence the acoustic alarm, press ACK

key. If the function automatic alarm silencing is on, the acoustic alarm will be automatically silenced after pre

set time but the led of the key ACK will be blinking (the last alarm has not been recognised yet). NB at first

starting up and in LOCK mode both led and siren are OFF.

RESET: Alarm reset key lights up each time there is a new alarm and shows that there are alarm pages in

the alarm section. Once alarms have been solved the reset key has the function of resetting all solved

alarms. To see what alarms are still on press the key , alarm pages will be displayed alternatively

every 2 seconds.

FUEL PUMP MAN/OFF: if there is a fuel pump as a system for tank filling you can use this key to

control the pump manually. Press this key for a second, its LED will light up to show that the pump is in

manual mode, if the led blinks it means that the control contact maker is fed and presumably that the pump

is filling the tank. When the pump is in Manual mode only the alarm of overfilling can stop the pump

automatically, to stop it manually press the key MAN/OFF for 2 seconds, when the LED turns off it means

that the pump has stopped.

FUEL PUMP AUTO: if you press the fuel pump key AUTO this will start working automatically (LED with

steady light); this means that you can or cannot control the fuel pump according to the position of the floats.

When the pump is working, pump LED AUTO blinks; you can stop the pump any time by pressing the key

MAN/OFF at least for 2 seconds.

Handebook G3SHORT versione 0.1 15/12/2008 3

Starting up

Connections

Once you have completed all power and auxiliary connections (as explained in engine installation handbook)

you can apply voltage to electric board.

Presence of electric network: usually referred to as L1R, L2R, L3R, NR (Neutral wire) except different

directions in electric diagram of connections. The reference of presence of electric network has to be taken

from a point in the system where, once there is no tension, you want to control unit starting up; usually the

power of such line does not exceed one kW.

Privileged service line: usually L1P, L2P, L3P, NP (Neutral wire) except different directions in electric

diagram of connections. Privileged line usually has to be taken in common point usually fed through the net,

while it is fed through GS during emergency functioning. The power of this line varies from GS to GS. Keep

to directions given in the electric diagram of connections for line dimension. All input lines to Margen electric

board must be limited to 10kA short circuit current.

Always open all fuses and circuit breakers or sectioning devices before giving power to the lines or

connecting batteries. Use an instrument to measure input AC tension to the lines of Presence of net and of

auxiliary services to privileged line. Check that neutral wire position is correct and that tension corresponds

to the nominal one reported in electric diagrams; always make sure that PE earth wire is connected before

feeding the panel. Electric wiring installation must be performed workmanlike.

Further controls: Check that there is a special liquid in cooling circuit and that taps that might be in water

heating device are open. In case of remote board you have to connect all wires given for connection

between electric board and machine. It is forbidden to modify, even partially, all wires supplied by Margen or

to use other non prescribed wires because this may cause guarantee invalidation in case of malfunctioning.

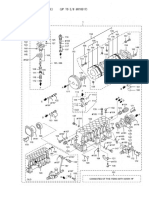

Installation and connections among units/Wires Specifications

For connections between G3PLC and G3Panel use given wires or, in case of remaking on site, you have to

respect some rules given each time by UT Margen according to installation distance. For serial connection

diagram you have to use Belden wire with 4-screened conductors specially designed for RS422/RS485

communication.

4

3

G3CPU

2

1

J17

J2 _

CONNECTION IN RS422

CONN. 9 POLES FEMALE CONN. 9 POLES FEMALE

In addition to this there are 24Vdc feeding connection for terminal and two wires for emergency button; (this

is a standard specification, for specific cases always refer to attached electric wire diagram).

These wires must not be laid next to wires with high current or/and distorting currents or power

wires in general or with middle tension. It is advisable to follow independent paths or near other

signal wires always keeping to regulation in force in the country where installation is carried out.

Panel Installation

Remote controlled G3Panel can be installed without any particular precaution (as far as communication is

concerned) up to a distance of 100 m (as wire length). For longer distances special precautions are

necessary and they will be discussed together with UT Margen.

Anyway we advise that installation should be made in places with little dust, with temperatures between 0

and 55°C, humidity below 80%, not exposed to drippi ng water and not in open air, and lift from the ground at

a height that allows correct display reading at right angle at eyes height (about 1.70-1.80 m). Panel cannot

be installed in a place with explosion risks (except in case of particular installation that must be always

checked before). As for wiring from and to the device follow regulation in force in the country where it is

Handebook G3SHORT versione 0.1 15/12/2008 4

installed. Make sure that there is earth connection before you put device under tension. Electric wiring must

be performed workmanlike.

Starting up

Starting up a generating set is always a very critical operation especially with the first starting up.

Therefore in case your contract foresees starting up by Margen staff, the installer should wait before

feeding the board either through battery or Motive power in order to avoid possible problems that

could partially jeopardize manufacturer’s guarantee. If it is the installer himself that carries out the

first starting up, he has to read following paragraphs carefully to accomplish a faultless test. In

addition we wish to remind you that each power unit is tested in our factory and that system

presetting is tested according to customer’s and system requirements; the customer shall assume

full responsibility for any further change in configuration parameters made by the customer or by

third parties on customer’s behalf. Margen owns equipments that can check what parameters have

been changed after factory test and how.

Preliminary fundamental parameters before starting up

1. read all generating set installation handbook thoroughly, finish all building, hydraulic and electric

works (for ex.: exhaust and suction air conveyance, exhaust gas system, tank installation and

hydraulic connections from and to GS, completion of auxiliary and power electric connection, etc.

…). Once you have completed connections of this book, you can feed pre-heating circuit considering

all possible protection organs from electric diagram including circulator.

2. The poles of the batteries can be connected only after charge reaction has ended. Match the

symbols in the poles with the symbols printed on batteries carefully.

3. Measure actual tension in the ends of the terminal board and check that it matches the one written

on electric diagram for polarity and absolute value (usually higher than 24Vdc).

4. Close the fuses with battery tension one by one and feed all equipments (except that of G3Panel if it

has not been connected yet). Insert the switch of the battery charger/chargers and check that LEDs

above them are lighted.

5. Wait until engine temperature has reached at least 30° C before any start.

6. Check that machine switch is open, check that power connections before the switch (if this is not

installed on the edge of the machine) are correct and that there are no terminals in short circuit;

ATTENTION!: if the generating set has not been used for more than 6 months and it has been stored in a

particularly wet place you have to carry out an isolation test before starting it up! An isolation fault could

destroy alternator at the starting up. Test rules are in alternator handbook, as for the electric panel you have

to open all fuses and disconnect all equipments that are directly connected after the alternator, open GS

cutout switch; do not exceed 1kV test tension. If the results of the test do not comply with data reported in

alternator handbook do not start the machine up and contact Margen assistance.

Check levels of cooling liquid and lubricating oil again. Check the presence of suitable and clean fuel in the

tank and that feeding pipes are filled and deaerated up to engine injection pump (see engine handbook for

this). If fuel tank has a security solenoid valve on delivery circuit to the engine you have to open it to fill the

pipes; disconnect the wire that controls unit starting up, set up Manual mode and press Start for a second.

After this the valve is open for 60 seconds to deaerate the circuit. After 60 seconds the solenoid valve shuts

again. If for any reason you want to shut the valve before this time you have to press STOP. Connect the

wire of starting up control again. Go to G3 panel if it is near the GS, otherwise it is advisable to carry out the

first starting up directly with manual procedure from G3CPU (for details see G3CPU Menu).

Manual starting up from G3CPU: press the key until you visualize “Manual Functions”, press

ENTER, on the display you will see the list of the options you can activate with the keys F1, F2, F3. At this

point you cannot change system set up on the display but you can only activate or control manual mode. If

you press F1 you will start the GS up, if you press F2 you lock the GS. If you press F3 when the GS is

working and the net is not present you can control GS commutation. To exclude GS commutation press F3

again.

Equipment set up from G3CPU: press the key until you visualize “Functioning mode” press

ENTER. On the display you will see the list of options you can activate with keys F1, F2, F3. If there is no

communication with the terminal you can modify set up: if you press F1 you set up EXCLUDED (LOCK), if

you press F2 you set up AUTOMATIC (AUTO), if you press F3 you set up TEST. To check correct selection

press the key ENTER again to exit menu and the key RESET to go to main visualization. For further

information see the handbook see G3CPU Menu.

Handebook G3SHORT versione 0.1 15/12/2008 5

Before starting the GS up, read the remaining paragraphs of this handbook carefully in order to learn

the meaning of some terminologies and procedures that have not been put in this section to make

reading easier.

Check that all lock alarms have been solved then press RESET.

Set up Manual mode and check that the led of the key Manual is on.

Press START for a second. If the system does not start try again at least 2/3 times (that is to say 2/3

complete starting cycles). Check if there are any alarms and check again if there is fuel in the feeding circuit.

Try to start it up again. If for any reason and after you have tried several times you still cannot start the

system up, contact Margen assistance. If the system has started to work correctly press the key STOP to

stop the machine. Check the level of liquids again. Then go to G3 panel. We suggest opening the page of

generator/engine parameters or INFO page, start the GS again and check electrical and physical

parameters.

Put the board in AUTO mode and simulate net absence, check the correct starting up of the GS and check

that consent to commutation arrive at commutation system correctly; reset net tension to correct values and

wait for exchange GS-net. The GS will keep on working for the time necessary to cool down then it will

automatically turn off. Put G3Panel in Test mode. The GS will start immediately but if the net is present it will

not make any commutation to the unit. Simulate absence of net and check that there is a commutation net

GS. Give net presence again and wait for inverse commutation GS-net as in automatic mode; to stop the GS

you have to put the presetter in AUTO mode again. When the net is present the GS will stop after cooling.

Switch to LOCK mode then repeat simulation of net absence. The GS should not start even if you press

Start and Stop G3Panel.

If the system has electro pump control to load fuel, you have to check that it is functioning: press FUEL

PUMP MAN/OFF. Blinking LED shows that the contact maker is feeding the pump. Check that the pump

turns in the direction of the arrow on the pump itself. If not, invert two phases after excluding tension. Press

the key for 2 seconds to stop it. Put pump control in AUTO mode and wait until fuel reaches preset maximum

stop level. In the menu “Machine parameters” you can visualize reached fuel level.

If it is possible you should carry out a load test as the last test: close the GS switch (if it is not motorised),

then simulate net absence in AUTO mode as done before, increase load gradually and check electric and

physical parameters to see if they remain normal and correct. Check above all engine temperature that

should not normally exceed 90°C at full load, while pressure depends on the type of engine but usually it

should not go under 2 bar.

Contacts available to the customer for remote controls are usually cleared contacts (with no tension) with 6A,

400V so it is necessary to avoid exceeding absorption or tension values as indicated in the diagram; input

contacts to the board should normally be cleared (with no tension) but they have to bear board tension as

indicated in the diagram.

Safety measures

For safety measures we mean all necessary precautions to safeguard machine operators (electric board and

power unit).

If the presetter is set up in LOCK mode (excluded) you have all guarantees that the machine will not start.

However if somebody could change this setting from a remote control, the operator would be in potential

danger. Therefore we advise pressing local emergency button, too. In this case you would never have an

unexpected GS starting up even with a remote change in presetter set up.

Problem solving

In this section you can find some problems that may occur and how to solve them:

Problem Possible Cause Solution Notes

G3CPU has no feeding 1) there is no tension 1) check general feeding fuse

2) connector J2 not and CPU fuse

inserted properly 2) check and insert connector J2

3) G3CPU is damaged 3) call assistance

G3CPU keyboard led is 1) controller failure 1) switch CPU off and on again

steady on or off 2) no feeding opening and closing its fuse

2) check feeding

No control from connector 1) emergency pressed 1) remove emergency alarm

J4 outputs 2) no output common 2) check presence of common

3) lock alarms active +24Vdc

3) reset lock alarms

Handebook G3SHORT versione 0.1 15/12/2008 6

Terminal keyboard does 1) No communication with 1) check that there is no alarm of

not function G3CPU. no communication with G3CPU

2) Manual mode from check wires.

G3CPU 2) quit manual mode from

G3CPU

Generating set starts 1) there is at least one 1) check input tension to J 24

when net is present net phase missing connector CPU

2) net presence has been 2) check that net input is

activated from an external deactivated in configuration.

contact

Red led is on in this 1) some alarms are still 1) press indicated key to check

on which alarms are still on

2) no communication with 2) check that communication is

key

G3CPU present by pressing the key

repeatedly.

Terminal display is off but 1) automatic switching off 1) press a key to switch display

LEDs are on has been activated to on again

preserve the lamp 2) if you press the keys but the

2) lamp is burnt-out lamp still does not switch on

replace it as it is damaged.

Pre-heating system is on 1) 24vdc feeding is 1) if 24Vdc is missing there is no

but the engine is cool missing control to pre-heating control

2) pre-heating device is system.

damaged Check that tension gets to pre-

heating device.

Following message is 1) it is a lock alarm of the Contact Margen for the solution

displayed ”Severe Lock operating system of this problem

contact MARGEN”

Alarm message “no COM 1) no feeding for the 1) check instrument feeding

with multimeter” device 2) check connection of com

2) connector of module on the instrument and

COM module position of DIP switch

disconnected 3) communication parameters

3) error in serial should be the same as shown on

configuration diagrams.

Handebook G3SHORT versione 0.1 15/12/2008 7

Vous aimerez peut-être aussi

- 3.2 Powercommand 3.3 Spec Sheet S-1570Document11 pages3.2 Powercommand 3.3 Spec Sheet S-1570akheel201Pas encore d'évaluation

- ts300 Mosa PDFDocument50 pagests300 Mosa PDFzanioPas encore d'évaluation

- SAMSUN, TURKEY 2x GPE-1900 EWS TRAININGDocument33 pagesSAMSUN, TURKEY 2x GPE-1900 EWS TRAININGTuncay Özgür TaşdemirPas encore d'évaluation

- 928-0222-Supl Onan ES Genset 04146 WOODWARD TQ-125 CONTROLER MANUALDocument4 pages928-0222-Supl Onan ES Genset 04146 WOODWARD TQ-125 CONTROLER MANUALfararPas encore d'évaluation

- Kea 071 AnlDocument12 pagesKea 071 Anlamin shirkhaniPas encore d'évaluation

- Deep Sea Electronics: Complex Solutions Made SimpleDocument57 pagesDeep Sea Electronics: Complex Solutions Made SimpleRobertPas encore d'évaluation

- Technical Manual HPUX5 REV.0 PDFDocument47 pagesTechnical Manual HPUX5 REV.0 PDFFadi MuhamedPas encore d'évaluation

- Kit NEXYS To APM303 - Install Procedure-EnglishDocument7 pagesKit NEXYS To APM303 - Install Procedure-Englishzawmintun zpePas encore d'évaluation

- Enclosed Are The October 2020 Incal Dvd-RomsDocument4 pagesEnclosed Are The October 2020 Incal Dvd-RomsRobertoGomezPas encore d'évaluation

- C13 TE3A: 1/ GeneralDocument3 pagesC13 TE3A: 1/ GeneralPowerTechPas encore d'évaluation

- Fuel System 4Document5 pagesFuel System 4Falgon IslamPas encore d'évaluation

- Sync Step Speed Adj Motor For UG Govs 03027 - BDocument8 pagesSync Step Speed Adj Motor For UG Govs 03027 - Bcrazycanuck100% (1)

- Installation and Adjustments Manual Incorporating The Commissioning ProceduresDocument54 pagesInstallation and Adjustments Manual Incorporating The Commissioning ProceduresSimion Cosmin - AlinaPas encore d'évaluation

- Cummins Actuator PDFDocument3 pagesCummins Actuator PDFLuciano PereiraPas encore d'évaluation

- MX-321Document6 pagesMX-321Akun BackupPas encore d'évaluation

- 6125HF070CDocument2 pages6125HF070ClilirenePas encore d'évaluation

- Coolmay: EX3G PLC/HMI All in One Programming ManualDocument95 pagesCoolmay: EX3G PLC/HMI All in One Programming ManualMarcos Luiz Alves100% (1)

- DYNA 8000, 8200 & 8400 Series Electronic Governor Systems: Product Manual 36569 (Revision A, 02/2014)Document33 pagesDYNA 8000, 8200 & 8400 Series Electronic Governor Systems: Product Manual 36569 (Revision A, 02/2014)عمار العماريPas encore d'évaluation

- CPGK S 00000207 - I0 - 201504 VTA28 G5 Frequency ConversionDocument3 pagesCPGK S 00000207 - I0 - 201504 VTA28 G5 Frequency ConversionPieroPas encore d'évaluation

- TCG914 Series Brochure PDFDocument7 pagesTCG914 Series Brochure PDFFranco MayangaPas encore d'évaluation

- Fuel Optimized: Specification SheetDocument3 pagesFuel Optimized: Specification SheetArslan AnnaPas encore d'évaluation

- Gu301 ADocument3 pagesGu301 AJosé Da Silva MataPas encore d'évaluation

- Manual - 489 Generator Management RelayDocument308 pagesManual - 489 Generator Management RelayKiko OliveiraPas encore d'évaluation

- GCP 30 Series User ManualDocument47 pagesGCP 30 Series User ManualMelissa Carter100% (1)

- Eaom-36r Eng v05Document8 pagesEaom-36r Eng v05Khaled KamelPas encore d'évaluation

- Be142 Genset Controller ManualDocument28 pagesBe142 Genset Controller ManualSousaFVPas encore d'évaluation

- UC22/UC27: Aftermarket Parts ListDocument14 pagesUC22/UC27: Aftermarket Parts Listshinichie100% (1)

- EG-3000 Governor Controller Operation ManualDocument7 pagesEG-3000 Governor Controller Operation ManualrepelindPas encore d'évaluation

- PCC1301 Modbus Register Map - Cph031105Document8 pagesPCC1301 Modbus Register Map - Cph031105Gabriel CarvalhoPas encore d'évaluation

- GVSP Governor Spec ReportDocument2 pagesGVSP Governor Spec ReportJohn100% (1)

- Deep Sea Electronics: DSEP100 Configuration Suite PC Software ManualDocument30 pagesDeep Sea Electronics: DSEP100 Configuration Suite PC Software ManualalexanderPas encore d'évaluation

- 6es7 151 1aa04 Oabo Et 200s Im 151 1 Profibus DP Siemens ManualDocument650 pages6es7 151 1aa04 Oabo Et 200s Im 151 1 Profibus DP Siemens ManualRowell AutomationPas encore d'évaluation

- Trans-Auto Eng Man v16Document77 pagesTrans-Auto Eng Man v16asif MehmoodPas encore d'évaluation

- Fault Code 196 (3-Wire Sensor) : Coolant Level Sensor 1 Circuit - Voltage Below Normal or Shorted To Low SourceDocument3 pagesFault Code 196 (3-Wire Sensor) : Coolant Level Sensor 1 Circuit - Voltage Below Normal or Shorted To Low SourceHamilton MirandaPas encore d'évaluation

- DTSC-200 ATS Controller: InstallationDocument41 pagesDTSC-200 ATS Controller: InstallationRafael FernandoPas encore d'évaluation

- LLC Water Contentas For MGS Ver7Document2 pagesLLC Water Contentas For MGS Ver7saiful islam100% (1)

- 1306C-E87TAG3 ElectropaK Pn1613 PDFDocument2 pages1306C-E87TAG3 ElectropaK Pn1613 PDFPebrian SyaferiPas encore d'évaluation

- B2-Lehe4748-01 - Emcp3.3Document8 pagesB2-Lehe4748-01 - Emcp3.3Ali H. Al-ZowayedPas encore d'évaluation

- MMC-4000 ManualDocument94 pagesMMC-4000 ManualTalha Asad0% (1)

- 924S-86 To 88 Parts ListDocument0 page924S-86 To 88 Parts ListMelissa Cargill PernellPas encore d'évaluation

- General: Technical Data TAD1641GEDocument9 pagesGeneral: Technical Data TAD1641GEBill CastilloPas encore d'évaluation

- DCA-25ESK: DenyoDocument1 pageDCA-25ESK: DenyoAdeelPas encore d'évaluation

- DX330 Manual EngDocument45 pagesDX330 Manual EngKM KarthikPas encore d'évaluation

- Engine AlarmsDocument27 pagesEngine AlarmsaupPas encore d'évaluation

- Asco Serie 5200Document44 pagesAsco Serie 5200Miguel Eliezer Sequeira100% (1)

- CT365 CT400S (QSG12 50Hz)Document3 pagesCT365 CT400S (QSG12 50Hz)Md ShPas encore d'évaluation

- 1306C E87tag6 PDFDocument2 pages1306C E87tag6 PDFMarran Almarrani100% (1)

- Motor Cummins X2,5-G2: Kit Mantenimiento y RepuestosDocument1 pageMotor Cummins X2,5-G2: Kit Mantenimiento y RepuestosJulio Felipe Miranda MarzanPas encore d'évaluation

- Yanmar 4tne84-Eds 0CV10-G48601Document27 pagesYanmar 4tne84-Eds 0CV10-G48601Sergio Urquizo100% (1)

- Inst Manual Engine General 47706356Document164 pagesInst Manual Engine General 47706356giri_placid100% (1)

- Ecp ManualDocument22 pagesEcp Manualகோவி கோபால் ஆர்ட்ஸ்100% (1)

- Ecp-4083935oampmecpg PDFDocument100 pagesEcp-4083935oampmecpg PDFP.p. Arul Ilancheeran100% (1)

- TP 6929Document180 pagesTP 6929Egberto Pino GuerreroPas encore d'évaluation

- I-Panda Specification of MPPT Solar Charge ControllerDocument6 pagesI-Panda Specification of MPPT Solar Charge ControllernextgenpowerPas encore d'évaluation

- Kipor KDE Silent GeneratorDocument4 pagesKipor KDE Silent GeneratorbacPas encore d'évaluation

- 4008TAG2 Electro Unit PN2199Document2 pages4008TAG2 Electro Unit PN2199RioPas encore d'évaluation

- Product Data Sheet: Motor-Mechanism - MT400/630 - 208..277 V 60Hz / 220..240 V 50/60HzDocument1 pageProduct Data Sheet: Motor-Mechanism - MT400/630 - 208..277 V 60Hz / 220..240 V 50/60HzPuwa CalvinPas encore d'évaluation

- S12A2-PTA: Specifcation SheetDocument3 pagesS12A2-PTA: Specifcation Sheetjabed habib100% (1)

- LexySync Paralel Control BoardDocument13 pagesLexySync Paralel Control Boardkarimakki0% (1)

- Roller 230 enDocument4 pagesRoller 230 enillemariusPas encore d'évaluation

- O&M Manual Service Compressed Air SystemDocument12 pagesO&M Manual Service Compressed Air SystemElioArmasPas encore d'évaluation

- Interruptor Alta TensionDocument22 pagesInterruptor Alta TensionElioArmasPas encore d'évaluation

- 02bis - Alternator - Es (REGULADORES 4531e - Es) PDFDocument20 pages02bis - Alternator - Es (REGULADORES 4531e - Es) PDFElioArmasPas encore d'évaluation

- 04a Engine MaintDocument30 pages04a Engine MaintElioArmasPas encore d'évaluation

- NFS-3030 Operations ManualDocument70 pagesNFS-3030 Operations ManualElioArmasPas encore d'évaluation

- The Reliability HandbookDocument50 pagesThe Reliability Handbookcar_linPas encore d'évaluation

- Tmax T5 - Circuit Diagram - 1SDM000030R0001 PDFDocument18 pagesTmax T5 - Circuit Diagram - 1SDM000030R0001 PDFCristina MarchisPas encore d'évaluation

- 02bis - Alternator - Es (REGULADORES 4531e - Es) PDFDocument20 pages02bis - Alternator - Es (REGULADORES 4531e - Es) PDFElioArmasPas encore d'évaluation

- QUIT1-IEM-3266-RevA-Documento de Pruebas PDFDocument21 pagesQUIT1-IEM-3266-RevA-Documento de Pruebas PDFElioArmasPas encore d'évaluation

- Revision Description Is Fully Stated On First Sheet of DocumentDocument7 pagesRevision Description Is Fully Stated On First Sheet of DocumentElioArmasPas encore d'évaluation

- S 1551 PDFDocument5 pagesS 1551 PDFDeco DluxePas encore d'évaluation

- No Dust and Dirt Solar Panel Increases Power by 6Document2 pagesNo Dust and Dirt Solar Panel Increases Power by 6AlexPas encore d'évaluation

- OCTF Capacitor Voltage Transformers PDFDocument8 pagesOCTF Capacitor Voltage Transformers PDFRakesh ShinganePas encore d'évaluation

- Factors Affecting Leakage Current on Polymeric InsulatorsDocument5 pagesFactors Affecting Leakage Current on Polymeric Insulatorsyudd hiPas encore d'évaluation

- Athens TCS122/64-AN: Install SpeakerDocument6 pagesAthens TCS122/64-AN: Install SpeakergakbaPas encore d'évaluation

- Fluke 187-189Document96 pagesFluke 187-189MetalloyPas encore d'évaluation

- SD SDH Folder Emea EngDocument4 pagesSD SDH Folder Emea Engfirman pahrizalPas encore d'évaluation

- Physics of Radio Frequency Plasmas PDFDocument395 pagesPhysics of Radio Frequency Plasmas PDFdada12100% (1)

- Astat - CD Plus Solid-State Starters: Size F, G, H or I Cover Removal Instructions For Changing Circuit Boards and ScrsDocument32 pagesAstat - CD Plus Solid-State Starters: Size F, G, H or I Cover Removal Instructions For Changing Circuit Boards and ScrslekavetosPas encore d'évaluation

- Leading Manufacturer Automatic Control PanelsDocument12 pagesLeading Manufacturer Automatic Control PanelsKanul RiyazPas encore d'évaluation

- 150 Watt Generator: Homebuilt Electric MotorsDocument1 page150 Watt Generator: Homebuilt Electric Motorsreboi larebilPas encore d'évaluation

- 5 HP Quick Prime Pompe de 5 CH Quick Prime 5 HP de Cebadura RápidaDocument28 pages5 HP Quick Prime Pompe de 5 CH Quick Prime 5 HP de Cebadura RápidaboyPas encore d'évaluation

- G4 - Sample ExamsDocument8 pagesG4 - Sample ExamsLeeSM JacobPas encore d'évaluation

- TI 200F W Spec SheetDocument1 pageTI 200F W Spec SheetKumar AmbujPas encore d'évaluation

- Work Methodology (LBS)Document2 pagesWork Methodology (LBS)Callista CollectionsPas encore d'évaluation

- DN 790R ManualDocument16 pagesDN 790R Manualdonvincent1Pas encore d'évaluation

- 750-234 CB780E - 784E ManualDocument44 pages750-234 CB780E - 784E ManualDaɳɳy ElSamPas encore d'évaluation

- Libro VerdeDocument778 pagesLibro VerdeCarlos Callupe100% (3)

- Acm CetDocument2 pagesAcm CetFahad Al AjmiPas encore d'évaluation

- 78M15G T60 KDocument10 pages78M15G T60 KMalek KamelPas encore d'évaluation

- Energy and WorkDocument24 pagesEnergy and Workapi-285179261100% (1)

- Belmont Belray 096 Dental X-Ray - Installation Manual PDFDocument32 pagesBelmont Belray 096 Dental X-Ray - Installation Manual PDFIsmael CassiPas encore d'évaluation

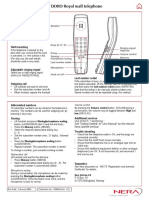

- Using DORO Royal Wall Telephone: ConnectionDocument1 pageUsing DORO Royal Wall Telephone: ConnectionBhavin DoshiPas encore d'évaluation

- Automated Handheld Dishwasher ReviewDocument1 pageAutomated Handheld Dishwasher ReviewKyle Brian Lacson EscarillaPas encore d'évaluation

- Rehs3668 Instalacion VR6Document10 pagesRehs3668 Instalacion VR6julio cesarPas encore d'évaluation

- Three Days Training On Relay CoordinationDocument3 pagesThree Days Training On Relay Coordinationdeepu kumarPas encore d'évaluation

- Electrical Safety Lab ManualDocument28 pagesElectrical Safety Lab Manualrishika chhibberPas encore d'évaluation

- KEDL Electricity Bill Details for HARIRAM HOUSEDocument1 pageKEDL Electricity Bill Details for HARIRAM HOUSEVikas GuptaPas encore d'évaluation

- Pw455r With STTDocument24 pagesPw455r With STTharoub_nasPas encore d'évaluation

- Electric Current and Its 14 EffectsDocument5 pagesElectric Current and Its 14 Effectsraja_tanukuPas encore d'évaluation