Académique Documents

Professionnel Documents

Culture Documents

CPT To CBR

Transféré par

Gumbert Maylda Pratama0 évaluation0% ont trouvé ce document utile (0 vote)

649 vues2 pageskonversi cpt ke cbr

Titre original

CPT to CBR

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentkonversi cpt ke cbr

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

649 vues2 pagesCPT To CBR

Transféré par

Gumbert Maylda Pratamakonversi cpt ke cbr

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

66 Handbook of Geotechnical Investigation and Design Tables

5.13 CBR value from DCP data

• The DCP is often used for the determination of the in situ CBR.

• Various correlations exist depending on the soil type. A site specific correlation

should be carried out where possible.

• The correlation is not as strong for values ≥ 10 blows/100 mm (10 mm/blow),

i.e. CBR > 20%.

Table 5.13 Typical DCP–CBR relationship.

Blows/100 mm mm/blow In situ CBR (%)

<1 >100 mm <2%

1–2 100–50 mm 2–4%

2–3 50–30 mm 4–6 %

3–5 30–20 mm 6–10%

5–7 20–15 mm 10–15%

7–10 15–10 mm 15–25%

10–15 10–7 mm 25–35%

15–20 7–5 mm 35–50%

20–25 5–4 mm 50–60%

>25 <4 mm >60%

◦ For clays CBR ≤ 10%.

◦ This a generalisation often used for a typical soil. Specific soil types shown

below.

5.14 CBR values from DCP data specific to soil type

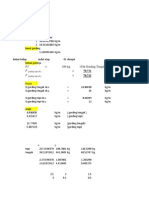

• General soils – Log(CBR) = 2.465 – 1.12(Log(DCP)) – Webster et al. (1992)

• For various soils types Webster et al. (1994) suggests

– Gravel, sand, and silt – CBR = 292/(DPI)1.12 . This is similar to Austroads.

– High plasticity clays CBR = 1/0.002871 DCP. CBR values above 25% not

shown in table.

– Low plasticity clays – CBR = 1/(0.017 DCP)2 .

Table 5.14 DCP–CBR relationships for varying soil types (Webster et al. (1992).

Blows/100 mm mm/blow In situ CBR (%)

Austroads General Gravel, sand, Low High

and silt plasticity clay plasticity clay

<1 >100 mm <2% <1% <2% <1% <3%

1–2 100–50 mm 2–4% 1–3% 2–4% ∼1% 3–7%

2–3 50–30 mm 4–6% 3–4% 4–6% 1–3% 7–10%

3–5 30–20 mm 6–10% 4–8% 6–10% 3–9% 10–15%

5–7 20–15 mm 10–15% 8–11% 10–15% 9–17% 15%

7–10 15–10 mm 15–25% 11–20% 15–25% 17–25% 15%

10–15 10–7 mm 25–35% 20–30% 25–35% 25% 15%

15–20 7–5 mm 35–50% 30–40% 35–50% 25% 15%

>20 <5 mm >50% >40% >50% 25% 15%

Soil strength parameters from classification and testing 67

◦ For subgrades CBR ≤ 25% and 15% for low and high plasticity clays,

respectively. Hence upper limit despite above equations.

◦ Webster’s work is based on the 8 kg cone as per Figure 4.3 while Austroads

is the 9 kg cone. The energy is similar but cone tip is different.

5.15 Allowable bearing capacity from DCP tests

• The DCP may be used as in the field assessment of allowable bearing capacity for

shallow footings.

• Indicative values will vary with soil type.

• Factor of safety of 3 used in Table.

Table 5.15 Allowable bearing capacity from DCP.

Blows/100 mm Allowable bearing capacity (kPa) Typical material

≤1 ≤50 kPa Very soft to soft clays, very loose sands

1–2 50–100 kPa Firm clays, loose sands

2–5 100–200 kPa Stiff clays, medium dense sands

6–9 200–400 kPa Very stiff clays, medium dense to dense sands

≥10 >400 kPa Hard clays, dense to very dense sands

◦ For high and low plasticity clays the allowable bearing capacity may be lower

and higher, respectively.

5.16 Soil classification from cone penetration tests

• This is an ideal tool for profiling to identify lensing and thin layers.

• It is most useful in alluvial areas.

• The table shows simplified interpretative approach. The actual classification and

strength is based on the combination of both the friction ratio and the measured

cone resistance, and cross checked with pore pressure parameters.

Table 5.16 Soil classification (adapted from Meigh, 1987 and Robertson et al., 1986).

Parameter Value Non-cohesive soil type Cohesive soil type

Measured cone <1.2 MPa – Normally to lightly over consolidated

resistance, qc >1.2 MPa Sands Over consolidated

Friction Ratio <1.5% Non-cohesive –

(FR) >3.0% – Cohesive

Pore pressure 0.0 to 0.2 Dense sand (qT > 5 MPa) Hard/stiff soil (O.C) (qT > 10 MPa)

parameter, Bq 0.0 to 0.4 Medium/loose sand Stiff clay/silt

(2 MPa < qT < 5 MPa) (1 MPa < qT < 2 MPa)

0.2 to 0.8 Firm clay/fine silt (qT < 1 MPa)

0.8 to 1.0 Soft clay (qT < 0.5 MPa)

>0.8 Very soft clay (qT < 0.2 MPa)

(Continued)

Vous aimerez peut-être aussi

- As 1289.7.1.1-2003 Methods of Testing Soils For Engineering Purposes Soil Re Activity Tests - Determination ofDocument2 pagesAs 1289.7.1.1-2003 Methods of Testing Soils For Engineering Purposes Soil Re Activity Tests - Determination ofSAI Global - APAC0% (1)

- Correlation Between Soaked CBR Value and CBR Obtained With DCPDocument8 pagesCorrelation Between Soaked CBR Value and CBR Obtained With DCPIvan MasubaPas encore d'évaluation

- Geosythetic Reinforced Unpaved RoadDocument10 pagesGeosythetic Reinforced Unpaved RoadPalak ShivharePas encore d'évaluation

- Settlement Prediction of Spread FoundationDocument31 pagesSettlement Prediction of Spread Foundation류태하Pas encore d'évaluation

- New Irish Geo TechDocument61 pagesNew Irish Geo TechgabemzamanPas encore d'évaluation

- The Use of Field Geophysical Techniques To Determine Geotechnical Stiffness ParametersDocument12 pagesThe Use of Field Geophysical Techniques To Determine Geotechnical Stiffness ParametersoldinaPas encore d'évaluation

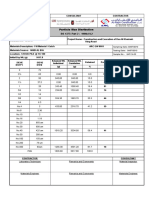

- Project Title: TBA: Client: ContractorDocument4 pagesProject Title: TBA: Client: ContractorIzza Halim100% (2)

- Field Guide Sheet Description of Soil and Rock 2005Document2 pagesField Guide Sheet Description of Soil and Rock 2005paramarthasom1974Pas encore d'évaluation

- SAFE TutorialDocument113 pagesSAFE TutorialNodizc ForMih100% (1)

- COLTO SPECIFICATIONS - MARCH 1998 REVIEWDocument2 pagesCOLTO SPECIFICATIONS - MARCH 1998 REVIEWMaria Fernanda MurilloPas encore d'évaluation

- Flexible PavementDocument148 pagesFlexible Pavementlalo198Pas encore d'évaluation

- UGS2011 Application of The Hardening Soil Model in Deep Excavation AnalysisDocument14 pagesUGS2011 Application of The Hardening Soil Model in Deep Excavation AnalysisfreezefreezePas encore d'évaluation

- Ussocom 006Document52 pagesUssocom 006RTSLLCPas encore d'évaluation

- ACI EB E1-07 Aggregates For ConcreteDocument29 pagesACI EB E1-07 Aggregates For ConcretewjzabalaPas encore d'évaluation

- Triaxial Testing of Granular Soil (Colliat-Dangus, 1988)Document21 pagesTriaxial Testing of Granular Soil (Colliat-Dangus, 1988)Abraham FIgueroa ARevaloPas encore d'évaluation

- Diaphragm WallDocument28 pagesDiaphragm WallTiong V YenPas encore d'évaluation

- Definition of PavementDocument7 pagesDefinition of PavementSujon AhmmedPas encore d'évaluation

- Giignl Custody Transfer Handbook 6.0 - May 21 0Document195 pagesGiignl Custody Transfer Handbook 6.0 - May 21 0Александр КарташовPas encore d'évaluation

- Impact of Gadgets on Learning in Senior High StudentsDocument16 pagesImpact of Gadgets on Learning in Senior High StudentsBlessing Joy Capiz83% (36)

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsDocument10 pagesThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalPas encore d'évaluation

- RE wall review checklistDocument21 pagesRE wall review checklistGDRPL NHAIPas encore d'évaluation

- Load Transfer, Settlement of Embankments on Deep-Mixing ColumnsDocument35 pagesLoad Transfer, Settlement of Embankments on Deep-Mixing ColumnsBeer PhermphornPas encore d'évaluation

- Weathered Rock Mass Classification of ISRMDocument1 pageWeathered Rock Mass Classification of ISRMFebrianto MangopoPas encore d'évaluation

- 05 Mazier Retractable Core BarrelsDocument1 page05 Mazier Retractable Core BarrelsJuan100% (1)

- CPT To CBRDocument2 pagesCPT To CBRGumbert Maylda PratamaPas encore d'évaluation

- CIRCLY 7.0 Workshop September 2018 ONE - Slide - Per - Page PDFDocument264 pagesCIRCLY 7.0 Workshop September 2018 ONE - Slide - Per - Page PDFAdy Nugraha100% (1)

- StateOfPracticeInSoilLiquefactionMitigation PDFDocument29 pagesStateOfPracticeInSoilLiquefactionMitigation PDFpkPas encore d'évaluation

- Temperature Prediction ModelsDocument9 pagesTemperature Prediction Modelsgonzalez_m_aPas encore d'évaluation

- Comparison of CMC Rigid Inclusions and Deep FoundationsDocument10 pagesComparison of CMC Rigid Inclusions and Deep FoundationsAnonymous MklNL77Pas encore d'évaluation

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- Micro Pile Liquefaction MitigationDocument6 pagesMicro Pile Liquefaction MitigationViswanathan NaraPas encore d'évaluation

- Detailed Site Investigation PDFDocument303 pagesDetailed Site Investigation PDFAbdulrahman AlnagarPas encore d'évaluation

- BBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)Document14 pagesBBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)sandycastlePas encore d'évaluation

- Aashto T 180-74Document9 pagesAashto T 180-74ORUSPas encore d'évaluation

- Rock Bolts Increase Shear Resistance of JointsDocument29 pagesRock Bolts Increase Shear Resistance of JointsgianniorlatiPas encore d'évaluation

- Sheet Pile Wall Design and CostDocument6 pagesSheet Pile Wall Design and CostAli Zakariya75% (4)

- Presented at Aust Geomechanics Society, Sydney Chapter, Symposium “Engineering Advances in Earthworks”10 Oct 2007Document7 pagesPresented at Aust Geomechanics Society, Sydney Chapter, Symposium “Engineering Advances in Earthworks”10 Oct 2007Scooby Doo0% (1)

- En 14490 After CEN Enquiry (Soil Nailing)Document59 pagesEn 14490 After CEN Enquiry (Soil Nailing)Abraham FIgueroa ARevaloPas encore d'évaluation

- 12 The Shrink Swell TestDocument10 pages12 The Shrink Swell Testhitman48Pas encore d'évaluation

- Astm D-5239 PDFDocument3 pagesAstm D-5239 PDFgtorrentes1Pas encore d'évaluation

- Nondestructive Testing of Concrete Leg FoundationsDocument5 pagesNondestructive Testing of Concrete Leg Foundationsأحمد دعبسPas encore d'évaluation

- Proportioning Concrete Mixtures With Graded AggregatesDocument86 pagesProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (1)

- PreviewpdfDocument51 pagesPreviewpdfIrfan WiranataPas encore d'évaluation

- Ic 8758Document6 pagesIc 8758Nurali MamenPas encore d'évaluation

- Geotechnical Porject On S ADocument24 pagesGeotechnical Porject On S Aapi-319627739Pas encore d'évaluation

- Construction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsDocument7 pagesConstruction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsamesbPas encore d'évaluation

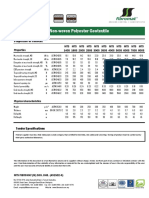

- Brosur Tensar Ground Stabilisation With Geogrid BiaxialDocument5 pagesBrosur Tensar Ground Stabilisation With Geogrid BiaxialIsparmoPas encore d'évaluation

- US 0702-3A Design and Execution-F3Document42 pagesUS 0702-3A Design and Execution-F3almirante_andrePas encore d'évaluation

- Geotechnical Hazards Associated With DesertDocument15 pagesGeotechnical Hazards Associated With DesertSalam LabadiPas encore d'évaluation

- Cement-Treated Base (CTB)Document2 pagesCement-Treated Base (CTB)bunkun100% (1)

- Remedial Measures To A Building Settlement ProblemDocument5 pagesRemedial Measures To A Building Settlement ProblemEswara PrasadPas encore d'évaluation

- The Direct Shear Strength and Dilatancyof Sand-Gravel MixturesDocument27 pagesThe Direct Shear Strength and Dilatancyof Sand-Gravel MixturesPipatpong NookhaoPas encore d'évaluation

- Improvement of Soft Clay With Cement and Bagasse Ash WasteDocument11 pagesImprovement of Soft Clay With Cement and Bagasse Ash WasteAnonymous NxpnI6jC100% (1)

- Standard Penetration Test Method for Soil SamplingDocument9 pagesStandard Penetration Test Method for Soil SamplingFranco PretellPas encore d'évaluation

- A Comparative Evaluation of Various AdditivesDocument11 pagesA Comparative Evaluation of Various Additivesagus_ip3808Pas encore d'évaluation

- As 1289.6.2.1-2001 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsDocument2 pagesAs 1289.6.2.1-2001 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsSAI Global - APACPas encore d'évaluation

- Design MixDocument7 pagesDesign MixMohammad Hafiz MahadzirPas encore d'évaluation

- Effects of Fines On Compaction Characteristics of Poorly Graded SandsDocument7 pagesEffects of Fines On Compaction Characteristics of Poorly Graded SandsJawad AbidiPas encore d'évaluation

- Specification of Gabion WallsDocument2 pagesSpecification of Gabion WallsAnam JabbarPas encore d'évaluation

- Safe Bearing Capacity of Soil at SiteDocument3 pagesSafe Bearing Capacity of Soil at SiteTravel With EvonPas encore d'évaluation

- CompactionDocument118 pagesCompactionSaleh HassanPas encore d'évaluation

- As 1289.6.9.1-2000 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation Test - DDocument2 pagesAs 1289.6.9.1-2000 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation Test - DSAI Global - APACPas encore d'évaluation

- QUALITY TESTS & LIMITS FOR NHA ROAD SPECIFICATIONSDocument18 pagesQUALITY TESTS & LIMITS FOR NHA ROAD SPECIFICATIONSBilal KhanPas encore d'évaluation

- TabelDocument2 pagesTabeldickyPas encore d'évaluation

- Tabel RMRDocument2 pagesTabel RMRAida Rafrin0% (1)

- Rock Mass Classification: Ashok Kumar Director Geological Survey of IndiaDocument44 pagesRock Mass Classification: Ashok Kumar Director Geological Survey of IndiazmnerPas encore d'évaluation

- Global Land Cover 2014Document40 pagesGlobal Land Cover 2014Yvette CarrilloPas encore d'évaluation

- 27 Import-Txt enDocument10 pages27 Import-Txt enNoel IbrahimPas encore d'évaluation

- Price List for Geo Software Modules and PackagesDocument1 pagePrice List for Geo Software Modules and PackagesGumbert Maylda PratamaPas encore d'évaluation

- ReportDocument6 pagesReportGumbert Maylda PratamaPas encore d'évaluation

- sSLOPE Slope Stability Analysis Settings & ResultsDocument2 pagessSLOPE Slope Stability Analysis Settings & ResultsGumbert Maylda PratamaPas encore d'évaluation

- MOM FormDocument2 pagesMOM FormGumbert Maylda PratamaPas encore d'évaluation

- Hal 271/904 - Design of Small DAMSDocument2 pagesHal 271/904 - Design of Small DAMSGumbert Maylda PratamaPas encore d'évaluation

- Release Notes Safe 2016 V 1601Document2 pagesRelease Notes Safe 2016 V 1601Nick BesterPas encore d'évaluation

- G Surf Before Failure MeshDocument62 pagesG Surf Before Failure MeshGumbert Maylda PratamaPas encore d'évaluation

- Pengukuran AirDocument42 pagesPengukuran AirGumbert Maylda PratamaPas encore d'évaluation

- Hardening & Softening Soil ModelsDocument2 pagesHardening & Softening Soil ModelsGumbert Maylda Pratama0% (1)

- !rangkuman UCS With Strain GaugeDocument8 pages!rangkuman UCS With Strain GaugeGumbert Maylda PratamaPas encore d'évaluation

- Stirrrd Logo Full RedDocument1 pageStirrrd Logo Full RedGumbert Maylda PratamaPas encore d'évaluation

- Mucking Loader QuestionaireDocument1 pageMucking Loader QuestionaireGumbert Maylda PratamaPas encore d'évaluation

- Beban AtapDocument2 pagesBeban AtapGumbert Maylda PratamaPas encore d'évaluation

- Tugas Felenius Dan BishopDocument38 pagesTugas Felenius Dan BishopGumbert Maylda PratamaPas encore d'évaluation

- Excel LongsorDocument12 pagesExcel LongsorGumbert Maylda PratamaPas encore d'évaluation

- Laboratory Test List: Universitas Gadjah MadaDocument4 pagesLaboratory Test List: Universitas Gadjah MadaGumbert Maylda PratamaPas encore d'évaluation

- Catalogue Cable Tray RevDocument40 pagesCatalogue Cable Tray RevhardiyantodonniPas encore d'évaluation

- Lars Part Ix - Safety Managment System Requirements-SmsDocument24 pagesLars Part Ix - Safety Managment System Requirements-SmssebastienPas encore d'évaluation

- Lab 02 - Boundary Layer-2Document21 pagesLab 02 - Boundary Layer-2Walid El AhnafPas encore d'évaluation

- Compressed Air SystemDocument372 pagesCompressed Air SystemMauricioPas encore d'évaluation

- Coils TransponderDocument4 pagesCoils TransponderGuadalajara JaliscoPas encore d'évaluation

- Group Presentation on CIM, Database Systems and Product Life CyclesDocument23 pagesGroup Presentation on CIM, Database Systems and Product Life Cyclesশাহীন আহেমদPas encore d'évaluation

- OpenDSS Level 1 TrainingDocument85 pagesOpenDSS Level 1 Trainingraul_bsu100% (1)

- ION Enterprise 6.0 System RequirementsDocument2 pagesION Enterprise 6.0 System RequirementsAlberto SalazarPas encore d'évaluation

- Environmental Engineering - Civil Engineering - McGill UniversityDocument4 pagesEnvironmental Engineering - Civil Engineering - McGill Universityamrin jannatPas encore d'évaluation

- Heliobond GI WE3Document24 pagesHeliobond GI WE3jarodzeePas encore d'évaluation

- FibrotexDocument2 pagesFibrotexMan ChupingPas encore d'évaluation

- Mazinoor EN Mini G PDFDocument154 pagesMazinoor EN Mini G PDFBalamurugan ArumugamPas encore d'évaluation

- Alpha Eritrean Engineers Community's Magazine (October's Issue)Document8 pagesAlpha Eritrean Engineers Community's Magazine (October's Issue)meharigrwPas encore d'évaluation

- Um String Code 2 0 eDocument46 pagesUm String Code 2 0 ehydrasearchPas encore d'évaluation

- TAICDocument8 pagesTAICparthPas encore d'évaluation

- Spec Oem National 300qDocument2 pagesSpec Oem National 300qJose Javier GamaPas encore d'évaluation

- Solid WastesDocument47 pagesSolid WasteskevinjorgeramosPas encore d'évaluation

- RCP-15 Drilling Fluid Agitator Parts ListDocument5 pagesRCP-15 Drilling Fluid Agitator Parts ListwaleedPas encore d'évaluation

- Tsi 20040109 PDFDocument2 pagesTsi 20040109 PDFenache_marian0% (1)

- Semiconductive Shield Technologies in Power Distribution CablesDocument6 pagesSemiconductive Shield Technologies in Power Distribution CablesA. HassanPas encore d'évaluation

- Home water pressure booster pumpDocument3 pagesHome water pressure booster pumpbadaasaabPas encore d'évaluation

- LDRDocument4 pagesLDRRaymond ValdezPas encore d'évaluation

- Geotech Civ150 CompressDocument4 pagesGeotech Civ150 CompressismaeelPas encore d'évaluation

- Cathode Ray Oscilloscope (Cro)Document2 pagesCathode Ray Oscilloscope (Cro)jesunathan44@yahoo.comPas encore d'évaluation

- Connector CatalogDocument60 pagesConnector CatalogYadira De De Ciam100% (1)