Académique Documents

Professionnel Documents

Culture Documents

WPS - 0601 00112 01 PDF

Transféré par

Anonymous zzMwR2aNTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WPS - 0601 00112 01 PDF

Transféré par

Anonymous zzMwR2aNDroits d'auteur :

Formats disponibles

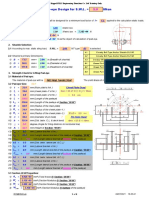

WPS no Rev.

WPS

0601-00112 01

135-HY7-BW/PA-mb

Page 1 of 1

Location: Lengau Examiner or test centre:

WPQR No.: 0601-00069 Method of preparation and cleaning: Mechanical processing

Welder qualification: ÖN EN ISO 9606-1 Processing the root weld: none

Welding process: 135-(MAG) Parent material specification: Group no ISO 15608:

Joint type: see specific joint details S690QL 3.1

Customer: S690QL 3.1

Order no.: Material thickness: 10 mm

Drawing no.: Outside diameter:

Part no.: Welding position: PA

Dimensions: Joint design Welding sequence

t1=10mm

t2=8mm

α = 30°

Remark:

HY= 7 mm

Job.Nr.: HXV-2065_ID10-32

Welding details

Welding pass Process Ø weld filler Current Voltage Current / Wire feed rate Travel speed Heat input

Polarity

A Cap pass 135 1,2 mm Base1: 190 A 22 V =/+ 7 m/min 32 cm/min

Welding filler / welding flux Special regulations for drying

Designation Brand name Manufacturer Time Temperature

A EN ISO 16834-A - G 69 5 M21 Mn3Ni1CrMo BÖHLER X 70-IG böhler welding

Shielding gas

Type Brand name Manufacturer Volume Pre-purge time Post-purge

time

A Shielding: M20 - ArC-10 CORGON 10 Linde Gas 15 l/min 1s 1s

Further information

Parameter Value Weld bead form stringer bead

A Nozzle /gas cup size 17 Preheat temperature: 20 °C

A Material transfer Pulslichtbogen Interpass temperature:

A Distance contact tube/work piece 13-15 mm

Date, prepared: Date, checked: Date, released:

08.01.2018 Strasser Raphael 08.01.2018 Wegscheider Josef

Signature Signature Signature

Palfinger AG; Lamprechtshausener Landesstraße 8; A-5101 Bergheim/Austria

Created with weldassistant® by hsk-welding solutions

Vous aimerez peut-être aussi

- Is 11006 2011 PDFDocument16 pagesIs 11006 2011 PDFAnantha NarayananPas encore d'évaluation

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanPas encore d'évaluation

- Warren SM ch.18 FinalDocument35 pagesWarren SM ch.18 FinalAli Butt50% (2)

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsGia Minh Tieu TuPas encore d'évaluation

- 1622-DES-CR-01 - Gas Cylinder Basket Design Report - R0Document25 pages1622-DES-CR-01 - Gas Cylinder Basket Design Report - R0Aditya Jain100% (2)

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperPas encore d'évaluation

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityPas encore d'évaluation

- WPS-Shell To Tubesheet (CS-SS)Document1 pageWPS-Shell To Tubesheet (CS-SS)suria qaqcPas encore d'évaluation

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Hazardous Area Guide: For Atex & Iecex (Zones/Groups)Document1 pageHazardous Area Guide: For Atex & Iecex (Zones/Groups)Sandra Yadhit Higuera ArchilaPas encore d'évaluation

- CHG 55B2Document1 pageCHG 55B2Nhien ManPas encore d'évaluation

- LPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewDocument13 pagesLPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewabdiPas encore d'évaluation

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetPas encore d'évaluation

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387Pas encore d'évaluation

- Alvaer DNV2.7-3 PDFDocument23 pagesAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Document2 pagesWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiPas encore d'évaluation

- Welding Repair ProcedureDocument4 pagesWelding Repair ProcedureRiky SumantriPas encore d'évaluation

- North Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5Document3 pagesNorth Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5farshid KarpasandPas encore d'évaluation

- Weld Repair AWS D1.1Document3 pagesWeld Repair AWS D1.1Hemant PatelPas encore d'évaluation

- WPS ExampleDocument2 pagesWPS ExampleMarcio Jr.Pas encore d'évaluation

- 8615 Nozzle Orientation Report 01Document4 pages8615 Nozzle Orientation Report 01Bsc Aditya Singh Dinkar100% (1)

- G - 1 - A1 General Arrangment DrawingDocument1 pageG - 1 - A1 General Arrangment Drawingjonodo89Pas encore d'évaluation

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusPas encore d'évaluation

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertPas encore d'évaluation

- QP STD R 009Document104 pagesQP STD R 009p.abdulameen1234Pas encore d'évaluation

- Welding Consumable ChartDocument2 pagesWelding Consumable ChartAfetPas encore d'évaluation

- Esab E7018-1-H4r Ebds1-Ok 55Document2 pagesEsab E7018-1-H4r Ebds1-Ok 55PubcrawlPas encore d'évaluation

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizPas encore d'évaluation

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Document17 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Ulviyye ElesgerovaPas encore d'évaluation

- API 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As NecessaryDocument3 pagesAPI 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As NecessaryBilel NajjarPas encore d'évaluation

- Installation of T1501 PIPE ProcedureDocument6 pagesInstallation of T1501 PIPE Procedure1339979Pas encore d'évaluation

- PVG PDFDocument40 pagesPVG PDFArindam DasPas encore d'évaluation

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefPas encore d'évaluation

- Appendix 1 - Technical SpecificationDocument119 pagesAppendix 1 - Technical SpecificationMarleneLopes100% (1)

- WPQDocument10 pagesWPQayoki100% (3)

- KranDocument7 pagesKranMarioPas encore d'évaluation

- Wps (Gtaw & Smaw)Document3 pagesWps (Gtaw & Smaw)Ramadhan AdityaPas encore d'évaluation

- Gate & Globe PDFDocument0 pageGate & Globe PDFZoebairPas encore d'évaluation

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitPas encore d'évaluation

- DVS 2207-3Document12 pagesDVS 2207-3gura9054Pas encore d'évaluation

- ST 37-2 Steel, ST 37-2 Structure Steel, ST 37-2 Equivalent-Seed SteelDocument1 pageST 37-2 Steel, ST 37-2 Structure Steel, ST 37-2 Equivalent-Seed SteelPeddi Raja MohanPas encore d'évaluation

- Agoco Welding Procedure Specification: Smaw Manual JOINTS (QW-402)Document3 pagesAgoco Welding Procedure Specification: Smaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- LTA and Dryer Cylinders - Applying Mandatory Appendix 32Document2 pagesLTA and Dryer Cylinders - Applying Mandatory Appendix 32GTpianomanPas encore d'évaluation

- SWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Document2 pagesSWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Paulo MoreiraPas encore d'évaluation

- Weight For Bolt With Nut PDFDocument1 pageWeight For Bolt With Nut PDFRam RajaramanPas encore d'évaluation

- 1012835-NEROMASTIC 400 (I) Component (B)Document4 pages1012835-NEROMASTIC 400 (I) Component (B)Srikanth GantaPas encore d'évaluation

- AnilDocument7 pagesAnilanil kumarPas encore d'évaluation

- As 4458 - Amd1Document9 pagesAs 4458 - Amd1Nang TruongPas encore d'évaluation

- Described As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Document2 pagesDescribed As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Trịnh Quốc TuyếnPas encore d'évaluation

- Method of Statement PDFDocument7 pagesMethod of Statement PDFSakib AyubPas encore d'évaluation

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533Pas encore d'évaluation

- Pad Eye Calculation AllDocument3 pagesPad Eye Calculation Alldsn_sarmaPas encore d'évaluation

- Mobile Crane Set Up Ckeck List: PROJECT TITLE: OG119-Design & Construction of KIZAD Gas Network DateDocument3 pagesMobile Crane Set Up Ckeck List: PROJECT TITLE: OG119-Design & Construction of KIZAD Gas Network DateImran KhanPas encore d'évaluation

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad RizkiPas encore d'évaluation

- Figure UCS-66 Impact Test Exemption Curves (Cont'd) : ASME BPVC - VIII.1-2019 UCS-66Document2 pagesFigure UCS-66 Impact Test Exemption Curves (Cont'd) : ASME BPVC - VIII.1-2019 UCS-66MechanicalPas encore d'évaluation

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadPas encore d'évaluation

- WPS SertipDocument3 pagesWPS SertipMassimo FumarolaPas encore d'évaluation

- A53 WPSDocument1 pageA53 WPSNaqqash SajidPas encore d'évaluation

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaPas encore d'évaluation

- TS en 10120 - 2010Document12 pagesTS en 10120 - 2010Çağlar EbeperiPas encore d'évaluation

- JVK Filter Elements enDocument16 pagesJVK Filter Elements enArun GuptaPas encore d'évaluation

- Daftar Nomor Sertifikat 2018Document73 pagesDaftar Nomor Sertifikat 2018Bagus SatriyoPas encore d'évaluation

- New PDD 4Document27 pagesNew PDD 4Anand KesarkarPas encore d'évaluation

- FW Solvent DeasphaltingDocument11 pagesFW Solvent Deasphaltingapminshull100% (1)

- FM RequirementDocument7 pagesFM RequirementKurtney V. Rule100% (1)

- VA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1Document20 pagesVA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1MungNguyenDinhPas encore d'évaluation

- Fly Ash PET CompositeDocument8 pagesFly Ash PET CompositeSachin WazalwarPas encore d'évaluation

- Welding Parameters of XABO 890 960Document11 pagesWelding Parameters of XABO 890 960Tomáš BrtníkPas encore d'évaluation

- Southern Company/MHI Ltd. Plant Barry CCS DemonstrationDocument23 pagesSouthern Company/MHI Ltd. Plant Barry CCS Demonstrationrecsco2100% (1)

- Chapter 6 Inventory Control Models: Quantitative Analysis For Management, 11e (Render)Document27 pagesChapter 6 Inventory Control Models: Quantitative Analysis For Management, 11e (Render)Jay BrockPas encore d'évaluation

- Causes and Repair of CracksofDocument16 pagesCauses and Repair of CracksofBharath PbbpPas encore d'évaluation

- 1Document6 pages1Vignesh VickyPas encore d'évaluation

- Metal Forming Processes: PresentationDocument16 pagesMetal Forming Processes: PresentationBahrul HayatPas encore d'évaluation

- Bunshah - Mechanical Properties of Thin FilmsDocument10 pagesBunshah - Mechanical Properties of Thin FilmsJulien MartegouttePas encore d'évaluation

- Engineering GraphicsDocument4 pagesEngineering GraphicsfreemanokPas encore d'évaluation

- Mobile Crusher Plant IntroductionDocument6 pagesMobile Crusher Plant IntroductionsunndyPas encore d'évaluation

- 16699EN Spherical ShimsDocument6 pages16699EN Spherical ShimsCarlos PinnaPas encore d'évaluation

- Turning Tools - Tooling SystemsDocument94 pagesTurning Tools - Tooling Systemssaotinhyeu307783Pas encore d'évaluation

- Preferred Tol and FitsDocument9 pagesPreferred Tol and Fitsananda_beloshe75Pas encore d'évaluation

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONPas encore d'évaluation

- Toyota & GM - Group 1Document12 pagesToyota & GM - Group 1Aditi MurarkaPas encore d'évaluation

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDocument15 pagesIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedPas encore d'évaluation

- Ejb EnclosuresDocument8 pagesEjb EnclosuresMarito VallejitosPas encore d'évaluation

- Resume Mei Chiao Lin Dec 2014Document3 pagesResume Mei Chiao Lin Dec 2014api-272656739Pas encore d'évaluation

- CAK50 MechanicalDocument37 pagesCAK50 Mechanicals_barriosPas encore d'évaluation

- A 484 - A 484m - 03Document16 pagesA 484 - A 484m - 03etwcPas encore d'évaluation

- Bead Room EstimateDocument6 pagesBead Room EstimatedanysubashPas encore d'évaluation

- Econ 101 Sample Quiz Ques 4Document8 pagesEcon 101 Sample Quiz Ques 4choppersurePas encore d'évaluation