Académique Documents

Professionnel Documents

Culture Documents

MC-J-09 Unit Control Panel, System and Termination Cabinet

Transféré par

Miftah Masrur0 évaluation0% ont trouvé ce document utile (0 vote)

37 vues1 pageThis document is an inspection and test record for an MC unit control panel, system, and termination cabinet. It lists 15 items to check including verifying nameplate data and tag numbers, checking for mechanical damage, proper cable and wiring installation, cleanliness, accessibility, and compliance with design specifications. The inspector and contractor sign off to accept the results, which are also checked and accepted by the company's quality control inspector and lead and witnessed by an operator.

Description originale:

itr

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document is an inspection and test record for an MC unit control panel, system, and termination cabinet. It lists 15 items to check including verifying nameplate data and tag numbers, checking for mechanical damage, proper cable and wiring installation, cleanliness, accessibility, and compliance with design specifications. The inspector and contractor sign off to accept the results, which are also checked and accepted by the company's quality control inspector and lead and witnessed by an operator.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

37 vues1 pageMC-J-09 Unit Control Panel, System and Termination Cabinet

Transféré par

Miftah MasrurThis document is an inspection and test record for an MC unit control panel, system, and termination cabinet. It lists 15 items to check including verifying nameplate data and tag numbers, checking for mechanical damage, proper cable and wiring installation, cleanliness, accessibility, and compliance with design specifications. The inspector and contractor sign off to accept the results, which are also checked and accepted by the company's quality control inspector and lead and witnessed by an operator.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

MC Inspection & Test Record

MC-J-09 Unit Control Panel, System and Termination Cabinet

Tag No:

Description:

Subsystem:

System:

Manufacturer: Vendor Terminations: Schematic Dwg No:

Vendor GA:

Item Description OK N/A PL Comments

1 INSPECTION CHECK LIST

Check nameplate data against datasheet.

Check equipment tag number is correctly tagged

Check equipment label is installed as per design.

1.01 Check cabinet is correctly installed, confirm mounting secure and aligned

1.02 Check cabinet is in accordance with the vendor GA drawing.

1.03 Check there is no mechanical damage (internal & External)

1.04 Check all cables are correctly installed.

1.05 Check correct segregation between powers, IS and non-IS instrument wiring.

1.06 Check door seals in good condition and spare entries plugged or sealed.

1.07 Check all cable earthing and bonding is correctly installed. (Max value 0.33 Ohm).

1.08 Ensure the spare cable as per design specification

1.09 Check internals of the cabinet are clean, free of dust and debris.

1.10 Check all doors/removable sides are free from obstruction and accessible.

1.11 Check all pneumatic and hydraulic connections are correct.

1.12 Check hazardous area equipment certification as per design.

1.13 Where the panel is exposed to direct sunlight check that a sunshade is fitted

1.14 Ensure seal or gasket are in good condition for IP rated panel

1.15 Ensure surge arrestor is properly installed as per design

Check installed correctly/secure including anti vibration mounts

Note: Tick all check item under OK - Satisfactory; N/A - Not Applicable; Punch items(s) are to be PL.

Comments:

Contractor Company

Checked By Accepted By Checked By Accepted By Witnessed By Data Input

Company / Dept : QC Inspector QC Lead QC Inspector QC Lead Operation CCMS Coord./ Operator

Name:

Signature:

Date:

Vous aimerez peut-être aussi

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaPas encore d'évaluation

- Testing & Commissioning Checklist For Fire PumpDocument2 pagesTesting & Commissioning Checklist For Fire PumpOanh Nguyen86% (7)

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- PC-J-95 Instrument Loop Check (Analogue Inputs)Document1 pagePC-J-95 Instrument Loop Check (Analogue Inputs)Memyhu MahmudahPas encore d'évaluation

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriPas encore d'évaluation

- Check List For Installation of Cooling TowersDocument2 pagesCheck List For Installation of Cooling TowersGirithar M Sundaram67% (3)

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishPas encore d'évaluation

- Auxiliary Relay Test Report: Sheet 1 of 1Document1 pageAuxiliary Relay Test Report: Sheet 1 of 1TariqMalikPas encore d'évaluation

- Checklist For Above Ground Water Piping InstallationDocument1 pageChecklist For Above Ground Water Piping InstallationBelal Alrwadieh50% (2)

- Well Testing Project Management: Onshore and Offshore OperationsD'EverandWell Testing Project Management: Onshore and Offshore OperationsPas encore d'évaluation

- Itp Installation of Fiber Optic CablesDocument4 pagesItp Installation of Fiber Optic Cablesqasim078100% (2)

- Checklist For Installation of Pressurization UnitDocument1 pageChecklist For Installation of Pressurization Unitvictor100% (3)

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunPas encore d'évaluation

- A705F Schematic Circuit Diagram HALABTECHDocument11 pagesA705F Schematic Circuit Diagram HALABTECHbcscneg0% (1)

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhPas encore d'évaluation

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (9)

- Attachment 12.7 - QA - QC Checklist - MCC & CBDocument6 pagesAttachment 12.7 - QA - QC Checklist - MCC & CBehteshamPas encore d'évaluation

- MC L 01A Pre Hydrotest LinewalkDocument1 pageMC L 01A Pre Hydrotest LinewalkMemyhu MahmudahPas encore d'évaluation

- 10.a. Welding Machine Inspection (Electric, Travo Type)Document1 page10.a. Welding Machine Inspection (Electric, Travo Type)Adhy DarmawanPas encore d'évaluation

- Precommissioning Checklist of Pa SystemDocument1 pagePrecommissioning Checklist of Pa SystemTamer EidPas encore d'évaluation

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000Pas encore d'évaluation

- Excel VBA Programming For Solving Chemical Engineering ProblemsDocument42 pagesExcel VBA Programming For Solving Chemical Engineering ProblemsLeon FouronePas encore d'évaluation

- SDV, BDV, Esdv ChecklistDocument2 pagesSDV, BDV, Esdv ChecklistMusab Shabbir67% (3)

- Fire Fighting PipesDocument1 pageFire Fighting PipesMIDHUN RAJPas encore d'évaluation

- PRES-E-04 Electrical Equipment - Oil & TransformerDocument2 pagesPRES-E-04 Electrical Equipment - Oil & TransformersalamlinPas encore d'évaluation

- MC-L-02 Pipework After TestDocument1 pageMC-L-02 Pipework After TestMemyhu MahmudahPas encore d'évaluation

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- PC-J-94 Instrument Loop Check (Analogue Inputs)Document1 pagePC-J-94 Instrument Loop Check (Analogue Inputs)Memyhu MahmudahPas encore d'évaluation

- Checklist For Installation of BMS M Tower PDFDocument2 pagesChecklist For Installation of BMS M Tower PDFAndrew Hiv100% (1)

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunPas encore d'évaluation

- Checklist For Testing Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing Commissioning of Sprinkler SystemMuhammad Fathullah bin SuhailiPas encore d'évaluation

- MC-J0-03 Tubing - TemplateDocument4 pagesMC-J0-03 Tubing - TemplatePipin AripinPas encore d'évaluation

- Mechanical Completion Check Sheet Electrical: Lighting & Power CircuitDocument2 pagesMechanical Completion Check Sheet Electrical: Lighting & Power CircuitYadira Centanaro GutierrezPas encore d'évaluation

- Checklist For Access Control System InstallationDocument1 pageChecklist For Access Control System InstallationRommel Espinosa ParasPas encore d'évaluation

- Sample CBAP Elicitation Scenario Based Questions Set 01Document31 pagesSample CBAP Elicitation Scenario Based Questions Set 01Rubab Javaid100% (1)

- Checklist For T&C of CCTV SystemDocument2 pagesChecklist For T&C of CCTV Systemsheb_khaleelPas encore d'évaluation

- Final Exam DiassDocument9 pagesFinal Exam Diassbaby rafa100% (3)

- Interior Plains Unit PlanDocument6 pagesInterior Plains Unit Planapi-256482747Pas encore d'évaluation

- Checklist For Installation of Chemical Fire Suppression SystemDocument1 pageChecklist For Installation of Chemical Fire Suppression Systembeho2000100% (1)

- Safety Relief ValveDocument76 pagesSafety Relief ValveMiftah MasrurPas encore d'évaluation

- PRES-J-02 Instrument EquipmentDocument2 pagesPRES-J-02 Instrument EquipmentsalamlinPas encore d'évaluation

- MC-B-01 MC Inspection & Test Record BuildingDocument1 pageMC-B-01 MC Inspection & Test Record BuildingMemyhu MahmudahPas encore d'évaluation

- In-Process Inspection ChecklistsDocument1 pageIn-Process Inspection ChecklistsPritam MitraPas encore d'évaluation

- ElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check ListDocument2 pagesElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check Listhuseyinyuksel1903Pas encore d'évaluation

- Test Forms - Water Based Fire Suppression SystemDocument14 pagesTest Forms - Water Based Fire Suppression SystemBan DodoyPas encore d'évaluation

- No. Items To Be Checked Main Contractor Client's Consultant Remarks PreparatoryDocument1 pageNo. Items To Be Checked Main Contractor Client's Consultant Remarks PreparatoryKuljinder VirdiPas encore d'évaluation

- Test Sample FormatsDocument13 pagesTest Sample FormatsMohamed AshrafPas encore d'évaluation

- Cathodic Protection Inspection ChecklistDocument1 pageCathodic Protection Inspection ChecklistVPN NetworkPas encore d'évaluation

- Itr Ew 07a - EngDocument1 pageItr Ew 07a - Engwassim nasriPas encore d'évaluation

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriPas encore d'évaluation

- PRES-E-02 Electrical Equipment - DC Supply & BatteryDocument2 pagesPRES-E-02 Electrical Equipment - DC Supply & BatterysalamlinPas encore d'évaluation

- Mechanical: Itr A Item Description of CheckDocument2 pagesMechanical: Itr A Item Description of Checkmohamed khayrallaPas encore d'évaluation

- ElectroMechanical Completion-INSTRUMENT INSTALLATIONDocument1 pageElectroMechanical Completion-INSTRUMENT INSTALLATIONhuseyinyuksel1903Pas encore d'évaluation

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemPas encore d'évaluation

- Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument6 pagesCheck List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunPas encore d'évaluation

- Satr A 2006Document8 pagesSatr A 2006Shahzad HussainPas encore d'évaluation

- Installation Check List For ATSDocument1 pageInstallation Check List For ATSJohnna CenaPas encore d'évaluation

- SKN Jambimerang Construction Checksheet E20-A Gas Turbine: InformationDocument1 pageSKN Jambimerang Construction Checksheet E20-A Gas Turbine: InformationsuparnaPas encore d'évaluation

- Elm 1950060 CV K24 0001Document8 pagesElm 1950060 CV K24 0001Amin GPas encore d'évaluation

- 1.mechanical - Electrical Completion Inspection Checklist - E20812Document3 pages1.mechanical - Electrical Completion Inspection Checklist - E20812Lulu ChaniagoPas encore d'évaluation

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSDocument37 pagesRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaPas encore d'évaluation

- Subcon ItpDocument6 pagesSubcon ItpManu MohanPas encore d'évaluation

- Suspended Ceiling ChecklistDocument1 pageSuspended Ceiling ChecklistVPN NetworkPas encore d'évaluation

- Cathodic Protection ItpDocument9 pagesCathodic Protection ItpHarmalPas encore d'évaluation

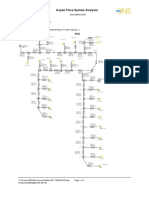

- Aspen Flare System AnalyzerDocument1 pageAspen Flare System AnalyzerMiftah MasrurPas encore d'évaluation

- Aspen Flare System AnalyzerDocument1 pageAspen Flare System AnalyzerMiftah MasrurPas encore d'évaluation

- Rreport NSF BDocument38 pagesRreport NSF BMiftah MasrurPas encore d'évaluation

- List of Straight-Chain Alkanes - WikipediaDocument6 pagesList of Straight-Chain Alkanes - WikipediaMiftah MasrurPas encore d'évaluation

- Aspen Flare System AnalyzerDocument1 pageAspen Flare System AnalyzerMiftah MasrurPas encore d'évaluation

- Report NSF ADocument38 pagesReport NSF AMiftah MasrurPas encore d'évaluation

- HYDROCYCLONEDocument1 pageHYDROCYCLONEMiftah MasrurPas encore d'évaluation

- Aspen Flare System Analyzer V10 - AspenoneDocument7 pagesAspen Flare System Analyzer V10 - AspenoneMiftah MasrurPas encore d'évaluation

- Aspen Flare System Analyzer V10 - AspenoneDocument38 pagesAspen Flare System Analyzer V10 - AspenoneMiftah MasrurPas encore d'évaluation

- PFD 8Document1 pagePFD 8Miftah MasrurPas encore d'évaluation

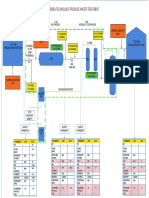

- Nov Technology Produce Water Treatment: T-101 A/B Produced Water Tank T-102 A/B Treated Water TankDocument1 pageNov Technology Produce Water Treatment: T-101 A/B Produced Water Tank T-102 A/B Treated Water TankMiftah MasrurPas encore d'évaluation

- Report IgfDocument38 pagesReport IgfMiftah MasrurPas encore d'évaluation

- Case 23 FixDocument3 pagesCase 23 FixMiftah MasrurPas encore d'évaluation

- Core TanDocument1 pageCore TanMiftah MasrurPas encore d'évaluation

- Material Stream: 78: ConditionsDocument2 pagesMaterial Stream: 78: ConditionsMiftah MasrurPas encore d'évaluation

- Skematik Siemen ModelDocument1 pageSkematik Siemen ModelMiftah MasrurPas encore d'évaluation

- Suction Pipe To Header 10": KeyplanDocument1 pageSuction Pipe To Header 10": KeyplanMiftah MasrurPas encore d'évaluation

- Corrosion PipingDocument13 pagesCorrosion PipingMiftah MasrurPas encore d'évaluation

- Stream Transfer Pump1Document2 pagesStream Transfer Pump1Miftah MasrurPas encore d'évaluation

- Schematic Technology Produce Water Treatment: Skimming Tank T-010Document3 pagesSchematic Technology Produce Water Treatment: Skimming Tank T-010Miftah MasrurPas encore d'évaluation

- Tag Apar PDFDocument1 pageTag Apar PDFMiftah MasrurPas encore d'évaluation

- Primary Treatment Secondary TreatmentDocument2 pagesPrimary Treatment Secondary TreatmentMiftah MasrurPas encore d'évaluation

- M 02 0001Document3 pagesM 02 0001Miguel ruizPas encore d'évaluation

- Universal Human Values NotesDocument13 pagesUniversal Human Values NotesS RamPas encore d'évaluation

- KaranDocument4 pagesKarancristioronaldo90Pas encore d'évaluation

- Business Design Thinking - Nguyễn Quang MinhDocument39 pagesBusiness Design Thinking - Nguyễn Quang MinhbuikimhoangoanhtqkPas encore d'évaluation

- Strata Ene 2023Document8 pagesStrata Ene 2023gabyPas encore d'évaluation

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDocument3 pagesIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriPas encore d'évaluation

- Module-2: SolidificationDocument16 pagesModule-2: SolidificationSachin AgnihotriPas encore d'évaluation

- Heat Power Lab ManualDocument68 pagesHeat Power Lab ManualRaghu KrishnanPas encore d'évaluation

- Command Center Processing and Display System ReplacementDocument2 pagesCommand Center Processing and Display System ReplacementImranPas encore d'évaluation

- Detail Project Report: (Heidelberg Cement Group)Document42 pagesDetail Project Report: (Heidelberg Cement Group)saravananPas encore d'évaluation

- Disconnect Cause CodesDocument2 pagesDisconnect Cause Codesdungnt84Pas encore d'évaluation

- Waste Heat BoilerDocument7 pagesWaste Heat Boilerabdul karimPas encore d'évaluation

- Question 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound CompoundDocument4 pagesQuestion 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound Compoundالموعظة الحسنه chanelPas encore d'évaluation

- Entrepreneurial BehaviourDocument16 pagesEntrepreneurial Behaviournonalyn tomboconPas encore d'évaluation

- Low Invasion CoringDocument4 pagesLow Invasion CoringKHALEDFEKAIRPas encore d'évaluation

- Project Scheduling: Marinella A. LosaDocument12 pagesProject Scheduling: Marinella A. LosaMarinella LosaPas encore d'évaluation

- Floor DiaphragmDocument24 pagesFloor DiaphragmChristian LeobreraPas encore d'évaluation

- Vocabulary: Activity 1Document18 pagesVocabulary: Activity 1Aurora GonzalezPas encore d'évaluation

- Final ExaminationDocument15 pagesFinal ExaminationMAY ANN CATIPONPas encore d'évaluation

- Oracle Pac 2nd KeyDocument48 pagesOracle Pac 2nd KeyKrishna Kumar GuptaPas encore d'évaluation

- Sources of LawDocument27 pagesSources of LawIshita AgarwalPas encore d'évaluation

- (Dust of Snow) & 2 (Fire and Ice) - NotesDocument3 pages(Dust of Snow) & 2 (Fire and Ice) - NotesdakshPas encore d'évaluation

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Document2 pagesBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoPas encore d'évaluation

- Faculty of Civil Engineering and Planning Civil Engineering Department Petra Christian UniversityDocument59 pagesFaculty of Civil Engineering and Planning Civil Engineering Department Petra Christian Universitykenny liePas encore d'évaluation

- Employment Under Dubai Electricity & Water AuthorityDocument6 pagesEmployment Under Dubai Electricity & Water AuthorityMominur Rahman ShohagPas encore d'évaluation