Académique Documents

Professionnel Documents

Culture Documents

Mirafi 600X: Minimum Average Roll Value Mechanical Properties Test Method Unit MD CD

Transféré par

Gautam RaiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mirafi 600X: Minimum Average Roll Value Mechanical Properties Test Method Unit MD CD

Transféré par

Gautam RaiDroits d'auteur :

Formats disponibles

Mirafi® 600X

Mirafi® 600X is composed of high-tenacity polypropylene yarns, which are woven into a

stable network such that the yarns retain their relative position. 600X is inert to biological

degradation and resistant to naturally encountered chemicals, alkalis, and acids.

Minimum Average

Mechanical Properties Test Method Unit Roll Value

MD CD

Grab Tensile Strength ASTM D 4632 kN (lbs) 1.40 (315) 1.40 (315)

Grab Tensile Elongation ASTM D 4632 % 15

Trapezoid Tear Strength ASTM D 4533 kN (lbs) 0.53 (120) 0.53 (120)

Mullen Burst Strength ASTM D 3786 kPa (psi) 4134 (600)

Puncture Strength1 ASTM D 4833 kN (lbs) 0.65 (145)

CBR Puncture Strength ASTM D 6241 kN (lbs) 5.3 (1200)

mm 0.425

Apparent Opening Size (AOS) ASTM D 4751

(U.S. Sieve) (40)

Permittivity ASTM D 4491 sec-1 0.05

l/min/m2 163

Flow Rate ASTM D 4491

(gal/min/ft2) (4.0)

% strength

UV Resistance (at 500 hours) ASTM D 4355 70

retained

1

ASTM D 4833 has been replaced with ASTM D 6241

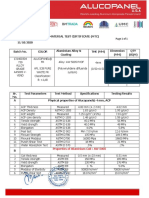

Physical Properties Test Method Unit Typical Value

Weight ASTM D 5261 g/m2 (oz/yd2) 203 (6.0)

Thickness ASTM D 5199 mm (mils) 0.64 (25)

Roll Dimensions -- m 3.8 x 110 5.3 x 78.7

(width x length) (ft) (12.5 x 360) (17.5 x 258)

Roll Area -- m2 (yd2) 418 (500) 418 (500)

Estimated Roll Weight -- kg (lb) 109 (240) 109 (240)

Disclaimer: TenCate assumes no liability for the accuracy or completeness of this information or for the

ultimate use by the purchaser. TenCate disclaims any and all express, implied, or statutory standards,

warranties or guarantees, including without limitation any implied warranty as to merchantability or fitness

for a particular purpose or arising from a course of dealing or usage of trade as to any equipment,

materials, or information furnished herewith. This document should not be construed as engineering advice.

FGS000393

ETQR6

Vous aimerez peut-être aussi

- TDS 140N - TipicosDocument2 pagesTDS 140N - TipicosCristian Ariel Araneda MarquezPas encore d'évaluation

- Geotubo GT-500Document1 pageGeotubo GT-500Juan AceitunoPas encore d'évaluation

- Mirafi S800: Gai-LapDocument1 pageMirafi S800: Gai-LapRamiro ChambiPas encore d'évaluation

- Miratech GT500: Technical Data SheetDocument3 pagesMiratech GT500: Technical Data SheetNicolás CanoPas encore d'évaluation

- Mirafi-500X PDSDocument1 pageMirafi-500X PDSLarry Wayne Sumpter, JrPas encore d'évaluation

- G&G-TDS 160NDocument2 pagesG&G-TDS 160NCostos y PresupuestosPas encore d'évaluation

- FW300Document1 pageFW300miroslava mondragonPas encore d'évaluation

- Tencate Mirafi HP 370Document1 pageTencate Mirafi HP 370Tony_candyPas encore d'évaluation

- TDS RS580iDocument1 pageTDS RS580iforismei5644Pas encore d'évaluation

- TDS - N AllDocument14 pagesTDS - N AllJoel AlvaradoPas encore d'évaluation

- GRI-GM30 Specification Coated Tape Polymeric BarriersDocument28 pagesGRI-GM30 Specification Coated Tape Polymeric BarriersГригорий ЛевашовPas encore d'évaluation

- SKAPS M330 SpecDocument1 pageSKAPS M330 SpectranoPas encore d'évaluation

- Ccis 200Document1 pageCcis 200bbomersbackPas encore d'évaluation

- Ccis 315Document1 pageCcis 315bbomersbackPas encore d'évaluation

- Property Test Method English Metric: US Fabrics, Inc. - 3904 Virginia Avenue - Cincinnati, OH 45227Document1 pageProperty Test Method English Metric: US Fabrics, Inc. - 3904 Virginia Avenue - Cincinnati, OH 45227Chrislet VaelPas encore d'évaluation

- Pultruded Composites Material Property ComparisonDocument5 pagesPultruded Composites Material Property ComparisonJohn WycliffePas encore d'évaluation

- US 350 Woven Geotextile Filtration Fabric SpecificationsDocument1 pageUS 350 Woven Geotextile Filtration Fabric SpecificationsChrislet VaelPas encore d'évaluation

- US 160NW: Property Test Method English MetricDocument1 pageUS 160NW: Property Test Method English MetricChrislet VaelPas encore d'évaluation

- NTPEP Approved Geotextile US 4800Document1 pageNTPEP Approved Geotextile US 4800Chrislet VaelPas encore d'évaluation

- Titan Wickdrain - Sept2022 FICHA TECNICA MECHAS DRENANTESDocument1 pageTitan Wickdrain - Sept2022 FICHA TECNICA MECHAS DRENANTESJean CausilPas encore d'évaluation

- PAVCO Perú - Geotextil NT - NW011 - Marv - Abril - 13 Eng PDFDocument1 pagePAVCO Perú - Geotextil NT - NW011 - Marv - Abril - 13 Eng PDFArmandoPas encore d'évaluation

- Ficha Tecnica Agru - Geotextil NT Ambiental (2018)Document1 pageFicha Tecnica Agru - Geotextil NT Ambiental (2018)Edward Jose Quispe BaldarragoPas encore d'évaluation

- Product Datasheet PP-200 MARV - TYPE - 2 - BHIMJI - RAMESH HADIYADocument1 pageProduct Datasheet PP-200 MARV - TYPE - 2 - BHIMJI - RAMESH HADIYARamesh HadiyaPas encore d'évaluation

- Astm D 4632Document24 pagesAstm D 4632Yus wantoPas encore d'évaluation

- Woven polypropylene geotextile TG-706 specificationsDocument1 pageWoven polypropylene geotextile TG-706 specificationsMarvin WilliamsPas encore d'évaluation

- MIRAFI G100N Drainage CompositeDocument1 pageMIRAFI G100N Drainage CompositeHardeo Dennis ChattergoonPas encore d'évaluation

- Hoja Técnica Mirafi Hp370Document1 pageHoja Técnica Mirafi Hp370Marcos GallardoPas encore d'évaluation

- Technical Data Sheet Nonwoven Geotextile: Specifications: SpecificationsDocument1 pageTechnical Data Sheet Nonwoven Geotextile: Specifications: SpecificationsAnang BagusPas encore d'évaluation

- High-capacity drainage geocompositeDocument1 pageHigh-capacity drainage geocompositeThameem SharaafPas encore d'évaluation

- Winfab 200W - T1700Document1 pageWinfab 200W - T1700Mónica Maria VillaPas encore d'évaluation

- CC - GCCM Data SheetDocument2 pagesCC - GCCM Data SheetLarizza TesicoPas encore d'évaluation

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonPas encore d'évaluation

- Styroflex 2G66: Styrene Butadiene Copolymer (SBC)Document3 pagesStyroflex 2G66: Styrene Butadiene Copolymer (SBC)Ronaldo CamargoPas encore d'évaluation

- PP Nonwoven Geotextile 542gsmDocument1 pagePP Nonwoven Geotextile 542gsmSuntharathevan RamasamyPas encore d'évaluation

- Nilex Woven 2006 Product SpecificationsDocument1 pageNilex Woven 2006 Product SpecificationstranoPas encore d'évaluation

- PDF DownloadDocument4 pagesPDF DownloadAnonymous deAxFjPas encore d'évaluation

- Data Sheet-Pr-25 (Type I) 18.10.19.Document1 pageData Sheet-Pr-25 (Type I) 18.10.19.SubhamPas encore d'évaluation

- Polygomma EPDM Pond Liner BrochureDocument4 pagesPolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdPas encore d'évaluation

- POM Delrin 500CLDocument2 pagesPOM Delrin 500CLcountzeroaslPas encore d'évaluation

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875Pas encore d'évaluation

- SEASHIELD HDPE OUTERCOVER MATERIAL SPECIFICATIONSDocument1 pageSEASHIELD HDPE OUTERCOVER MATERIAL SPECIFICATIONSJorge QuintanaPas encore d'évaluation

- Powder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialDocument1 pagePowder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialLuiskar MedinaPas encore d'évaluation

- Nilex Woven Geotextile SpecificationsDocument1 pageNilex Woven Geotextile SpecificationsAbdullah BasalamahPas encore d'évaluation

- Dupont Fr50 Nc010 2Document2 pagesDupont Fr50 Nc010 2mariano310570Pas encore d'évaluation

- GRI-GM 28 Specification: Scrim Reinforced Chlorosulfonated Polyethylene (CSPE-R) GeomembranesDocument27 pagesGRI-GM 28 Specification: Scrim Reinforced Chlorosulfonated Polyethylene (CSPE-R) GeomembranesГригорий ЛевашовPas encore d'évaluation

- Product Specification: Interax™ Foundation NXF-FG GeogridDocument1 pageProduct Specification: Interax™ Foundation NXF-FG GeogridRobert Gomez FlorPas encore d'évaluation

- ELITE™ AT 6111: Enhanced Polyethylene ResinDocument3 pagesELITE™ AT 6111: Enhanced Polyethylene ResinRoberto De Mesa PPas encore d'évaluation

- General PropertiesDocument2 pagesGeneral PropertiesIsrael ExporterPas encore d'évaluation

- Especificación LLDPEDocument1 pageEspecificación LLDPERainer TerronesPas encore d'évaluation

- High Density Polyethylene HDPE Properties ApplicationsDocument1 pageHigh Density Polyethylene HDPE Properties ApplicationsEleannys GarciasPas encore d'évaluation

- SPECSPEADM5370Document1 pageSPECSPEADM5370nicolas yoris marcogliesePas encore d'évaluation

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsPas encore d'évaluation

- Non Woven, Needle Punched, Staple FiberDocument2 pagesNon Woven, Needle Punched, Staple FiberAnonymous MAQrYFQDzVPas encore d'évaluation

- Data Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFDocument1 pageData Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFErnie ErniePas encore d'évaluation

- For - Geocells Made From HDPE Strips: GTI-GS15 SpecificationDocument33 pagesFor - Geocells Made From HDPE Strips: GTI-GS15 SpecificationГригорий ЛевашовPas encore d'évaluation

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsD'EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsPas encore d'évaluation

- Shielding of Electromagnetic Waves: Theory and PracticeD'EverandShielding of Electromagnetic Waves: Theory and PracticePas encore d'évaluation

- Reverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsD'EverandReverberation Chambers: Theory and Applications to EMC and Antenna MeasurementsPas encore d'évaluation

- IIT Connection Strength Final ReportDocument2 pagesIIT Connection Strength Final ReportGautam RaiPas encore d'évaluation

- ACE Case Study BookletDocument40 pagesACE Case Study BookletGautam RaiPas encore d'évaluation

- Chap 8Document4 pagesChap 8Gautam RaiPas encore d'évaluation

- Geotube Dewatering For45Document2 pagesGeotube Dewatering For45Gautam RaiPas encore d'évaluation

- Classic Installation Guide EnglishDocument32 pagesClassic Installation Guide EnglishGautam RaiPas encore d'évaluation

- Stress DistributionDocument44 pagesStress DistributionebalicPas encore d'évaluation

- Design and Construction Guidelines For Geosynthetic Reinforced Soil AbutmentsDocument152 pagesDesign and Construction Guidelines For Geosynthetic Reinforced Soil AbutmentsJosué QuesadaPas encore d'évaluation

- Internal Design of Mechanically Stabilized Earth (MSE) RetainingDocument138 pagesInternal Design of Mechanically Stabilized Earth (MSE) Retainingboris1516Pas encore d'évaluation

- Ztech Intro PDFDocument18 pagesZtech Intro PDFGautam RaiPas encore d'évaluation

- MSE Wall Spreadsheet Users ManualDocument55 pagesMSE Wall Spreadsheet Users Manualscribd_geotec100% (1)

- MSE Wall Engineering - A New Approach to Design and ConstructionDocument18 pagesMSE Wall Engineering - A New Approach to Design and ConstructionUlissipo1955Pas encore d'évaluation

- CED39 (7739) - Retaining Wall EarthquakeDocument55 pagesCED39 (7739) - Retaining Wall EarthquakeNaga Manikanta TatikondaPas encore d'évaluation

- MSE Wall Inspectors HandbookDocument45 pagesMSE Wall Inspectors HandbookGihan KayPas encore d'évaluation

- Is 6403 1981 PDFDocument24 pagesIs 6403 1981 PDFjaikrishnaPas encore d'évaluation

- CRRI Presentation On GeosyntheticsDocument51 pagesCRRI Presentation On GeosyntheticsGautam RaiPas encore d'évaluation

- Coir BhoovasthraDocument172 pagesCoir BhoovasthraGautam RaiPas encore d'évaluation

- Fault Database - Flat TVDocument3 pagesFault Database - Flat TVZu AhmadPas encore d'évaluation

- Oxford EQ ManualDocument29 pagesOxford EQ ManualCasar1973Pas encore d'évaluation

- Sl1000 MLT User Guide v1 Key TelephoneDocument24 pagesSl1000 MLT User Guide v1 Key TelephoneRavi Sudharsan0% (1)

- Selecting Arrester MCOV-UcDocument9 pagesSelecting Arrester MCOV-Ucjose GonzalezPas encore d'évaluation

- Host 1Document6 pagesHost 1Lukman FafaPas encore d'évaluation

- MS Gree Aircon Midwall Service Manual PDFDocument55 pagesMS Gree Aircon Midwall Service Manual PDFMacSparesPas encore d'évaluation

- Request Documents or InfoDocument6 pagesRequest Documents or InfoRashika RampalPas encore d'évaluation

- 16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalDocument34 pages16BBG - Sec17 - NPR NPRHD NQR NRR Diesel Cab Chassis Electrical Revision 3 100115 FinalJou Power50% (2)

- Online Ticket Reservation SystemDocument100 pagesOnline Ticket Reservation SystemPiya SharmaPas encore d'évaluation

- Track roller repairDocument2 pagesTrack roller repairKhincho ayePas encore d'évaluation

- Catalogue PDFDocument5 pagesCatalogue PDFumeshgcPas encore d'évaluation

- Linear Loaded Vert 80-40Document14 pagesLinear Loaded Vert 80-40Claudio ChiconPas encore d'évaluation

- 17012EDocument7 pages17012EAVINASHRAJPas encore d'évaluation

- Blast Furnace Cooling System MonitoringDocument27 pagesBlast Furnace Cooling System MonitoringAnil MistryPas encore d'évaluation

- AT-8600 Series Switch: Hardware ReferenceDocument30 pagesAT-8600 Series Switch: Hardware ReferenceSubbuPas encore d'évaluation

- Abb CatDocument9 pagesAbb CatMukesh Kumar MeenaPas encore d'évaluation

- Synopsis Mobile Banking AdministrationDocument24 pagesSynopsis Mobile Banking AdministrationRaj BangalorePas encore d'évaluation

- ACAS II Operations in The European RVSM EnvironmentDocument45 pagesACAS II Operations in The European RVSM Environmentali4957270Pas encore d'évaluation

- IEEEtran HOWTO PDFDocument28 pagesIEEEtran HOWTO PDFMario CruzPas encore d'évaluation

- Spec - LA 11,22,33 KV LA R1 Sep10Document14 pagesSpec - LA 11,22,33 KV LA R1 Sep10Amarjit KulkarniPas encore d'évaluation

- 3D PrintingDocument32 pages3D Printing9700216256Pas encore d'évaluation

- AGA3Document1 pageAGA3Alan BkPas encore d'évaluation

- Design of Water Cooled Electric Motors Using CFD and Thermography TechniquesDocument6 pagesDesign of Water Cooled Electric Motors Using CFD and Thermography TechniquesNicolas JerezPas encore d'évaluation

- MS 1472-2017Document65 pagesMS 1472-2017Thinagaran100% (2)

- KTS Quotation Meidan Building Plumbing Works PDFDocument1 pageKTS Quotation Meidan Building Plumbing Works PDFShakeel Ahmad100% (1)

- Hydran 201ti Gea12933 HRDocument2 pagesHydran 201ti Gea12933 HRlxd.hepPas encore d'évaluation

- CV for Mechanical Inspector and Welding InspectorDocument28 pagesCV for Mechanical Inspector and Welding InspectorAJMAL KAREEMPas encore d'évaluation

- Staggered Truss System - Wikipedia, The Free EncyclopediaDocument3 pagesStaggered Truss System - Wikipedia, The Free EncyclopediashawnideaPas encore d'évaluation

- NETWORKING Top 100 interview questionsDocument22 pagesNETWORKING Top 100 interview questionsyrikki0% (1)

- Jinal Black BookDocument7 pagesJinal Black Bookhardik patel0% (1)