Académique Documents

Professionnel Documents

Culture Documents

RB Standard - Engineering - Data PDF

Transféré par

Imam SitumeangTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

RB Standard - Engineering - Data PDF

Transféré par

Imam SitumeangDroits d'auteur :

Formats disponibles

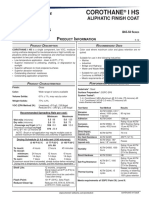

ENGINEERING DATA SHEET

Weight per gallon: 9.0 – 9.2 lbs. Typical Uses

Pigment type: Aluminum High performance rust inhibitive coating to stop existing

Color/Finish: Metallic Gray corrosion and prevent its return. Also prevents the formation of

Flash Point: 123°F rust and corrosion on new metal. Uses consist of mostly all

Volatile Organic Content (VOC): 277 g./liter metal surfaces including commercial/industrial, marine, and

Viscosity: 420-500 cP home and farm applications. If it is made of iron or steel, it will

Theoretical coverage: Approx. 350-400 ft²/ rust and corrode if left unprotected. Rust Bullet Standard is the

Gallon @ 3 mil/coat complete multi-coat system, used as the base, intermediate

Solids by Volume: 70% +/- 2% and top coats.

Recommended DFT: Min. 6 mil; 12 mil for

commercial, industrial or marine applications Product Description

Temperature Resistance: 314°F continuous, Patented, rust inhibitive, MCU coating. Easily applies to rusted,

625oF up to 72 hours clean, or new metal. After curing, Rust Bullet Standard leaves

Application Methods: Brush, Roll, or Airless a super tough, protective coating film, killing existing corrosion

Spray Equipment and preventing any further moisture or oxygen from reaching

Cure Times: Varies with relative humidity, the substrate. Due to its excellent UV resistance and adhesion

temperature and thickness of film;

properties, Rust Bullet Standard requires no topcoat or

Dry-to-Recoat: 2-6 hours, up to 12;

Dry-to- Handle: Up to 6 hours; base/primer coat. Attractive metallic gray finish. Apply by

Dry-to-Touch: Up to 6 hours; brush, roller, or airless spray equipment.

Full Cure: 72 hours

Shelf Life: Approx. 2 years un-opened; 1 month Advantages

for opened containers; Up to 6 months if sealed Easy to Apply – Ready to Use; No Messy Mixing

with Bloxygen Can be Applied to Rusted, Clean or New Metal

Application Temp: 35oF-110oF (2oC-43oC) Single Component

Compatibility: With most other coatings; Always Excellent Resistance to Extreme Atmospheric Conditions

refer to the coating manufacturers guidelines for Excellent Chemical and Abrasion resistance

application and compatibility. Excellent Adhesion and Flexibility

Testing: UV Resistant – No Top Coat Required

ASTM B117- Salt/Fog Spray 1000 hours Contains No Lead, Chromates or Other Heavy Metals

No effect

ASTM D4060 - Abrasion Resistance

14,000 Cycles

ASTM D4541 - Pull off Adhesion Test

7.58 MPa (1100 psi.)

Safety Information

Avoid ingestion, contact with skin or eyes. The use of all personal protective equipment such as, gloves, eye protection, clothing,

appropriate NIOSH approved respirator, etc., is recommended during set up, application and clean-up. Please refer to the Safety Data

Sheet for complete safety data before use, available at www.RustBullet.com. It is the applicator’s responsibility to understand these

safety precautions and the work environment, to protect themselves and/or others.

Surface Preparation

Surface must be free of loose paint and rust, oil, grease, wax, moisture, chlorides and any other contaminates that may affect adhesion

or performance. Methods include chemical cleaning (SSPC-SP1), tool cleaning (SSPC-SP 2 &3), high-low or combinational pressure

water cleaning (SSPC-SP 12) and/or abrasive blast cleaning (SSPC-SP5). Do not use other products with Rust Bullet without

consulting Rust Bullet Technical Support. For more information contact us at:

Rust Bullet, LLC ~ 300 Brinkby Avenue, Suite 200, Reno, NV 89509 USA 1(800) 245-1600, 1(775) 829-5606 www.RustBullet.com

LIMITATION OF LIABILITY: All recommendations or suggestions relating to the use of the products, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge is reliable. The products and information are designed for users having the requisite knowledge and

industrial skills, and the end-user has the responsibility to determine the suitability of the product for its intended use. Conditions of use are beyond our control, Rust Bullet,

LLC (the Company), disclaims any liability incurred in connection with the use of our products and information contained herein. No person is authorized or empowered to

make any statement or recommendation not contained herein, any such statement or recommendation so made shall not bind The Company. Furthermore, nothing contained

herein shall be construed as a recommendation to use any product in conflict with existing patents Rust Bullet, LLC has no control over either the quality of condition of the

substrate, or the many factors affecting the use and application of the product. Therefore, Rust Bullet, LLC does not accept any liability arising from loss, injury, or damage

resulting from such use or the contents of this data sheet. The information contained in this data sheet is subject to modification as a result of practical experience and

continuous product development. This data sheet replaces and annuls all previous issues and the user has the responsibility to ensure that this sheet is current prior to using

the product.

10/16 arn

Vous aimerez peut-être aussi

- Consumption Calc CarbolineDocument10 pagesConsumption Calc CarbolineImam Situmeang100% (1)

- Barrier 80 PDFDocument5 pagesBarrier 80 PDFBalaji GuruPas encore d'évaluation

- RB Engineering Data PDFDocument1 pageRB Engineering Data PDFImam SitumeangPas encore d'évaluation

- Zinc Rich Cold Galvanizing (UZZIEL 215) : Product DescriptionDocument1 pageZinc Rich Cold Galvanizing (UZZIEL 215) : Product DescriptionImam SitumeangPas encore d'évaluation

- Interthane 990 Test Data PDFDocument2 pagesInterthane 990 Test Data PDFImam Situmeang100% (2)

- UNISEAL GALVA ZN B (New EN)Document1 pageUNISEAL GALVA ZN B (New EN)ramdhaniPas encore d'évaluation

- Intergard 251HS - Test DataDocument1 pageIntergard 251HS - Test DataImam Situmeang100% (1)

- Interzinc 52+td+eng PDFDocument2 pagesInterzinc 52+td+eng PDFImam Situmeang100% (1)

- CV Imam 2017Document2 pagesCV Imam 2017Imam SitumeangPas encore d'évaluation

- Data Persiapan Panel Uji (Pelat 3Mm) Pull Off TestDocument1 pageData Persiapan Panel Uji (Pelat 3Mm) Pull Off TestImam SitumeangPas encore d'évaluation

- Engineering Data Sheet: UST Ullet TandardDocument1 pageEngineering Data Sheet: UST Ullet TandardImam SitumeangPas encore d'évaluation

- Environment Test Sheet: Waktu Item TanggalDocument3 pagesEnvironment Test Sheet: Waktu Item TanggalImam Situmeang100% (1)

- QCPC Pmi FanDocument44 pagesQCPC Pmi FanBagas Dewo septian100% (1)

- Rounded Brush (Kuas Bulat) Diameter " 10pcsDocument1 pageRounded Brush (Kuas Bulat) Diameter " 10pcsImam SitumeangPas encore d'évaluation

- PPG PMC Sigmaprime Brochure A4 Feb2016 Glob en LRSPDocument8 pagesPPG PMC Sigmaprime Brochure A4 Feb2016 Glob en LRSPImam SitumeangPas encore d'évaluation

- Rounded Brush (Kuas Bulat) Diameter " 10pcsDocument1 pageRounded Brush (Kuas Bulat) Diameter " 10pcsImam SitumeangPas encore d'évaluation

- Galvanized Steel Vs Zinc Rich PaintDocument2 pagesGalvanized Steel Vs Zinc Rich PaintImam SitumeangPas encore d'évaluation

- RB Standard Engineering Data PDFDocument1 pageRB Standard Engineering Data PDFImam SitumeangPas encore d'évaluation

- Corrothane I Zinc PrimerDocument4 pagesCorrothane I Zinc PrimerImam SitumeangPas encore d'évaluation

- Trial Repair Galvanized Surface of Box Girder: Use Zinc Rich Primer PaintDocument4 pagesTrial Repair Galvanized Surface of Box Girder: Use Zinc Rich Primer PaintImam SitumeangPas encore d'évaluation

- RB Standard Engineering Data PDFDocument1 pageRB Standard Engineering Data PDFImam SitumeangPas encore d'évaluation

- Protective & Marine Coatings: Corothane IHSDocument4 pagesProtective & Marine Coatings: Corothane IHSImam SitumeangPas encore d'évaluation

- PPG PMC Sigmaprime Offen Case Study A4 Jun2016 Glob en LRDocument2 pagesPPG PMC Sigmaprime Offen Case Study A4 Jun2016 Glob en LRImam SitumeangPas encore d'évaluation

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Painting Istructions Accroding ISO 12944-5Document40 pagesPainting Istructions Accroding ISO 12944-5giulioiussich100% (5)

- Penguard Universal PDFDocument5 pagesPenguard Universal PDFImam SitumeangPas encore d'évaluation

- Interseal 670 HSDocument4 pagesInterseal 670 HSFikru DdienPas encore d'évaluation

- Corrothane I Zinc PrimerDocument4 pagesCorrothane I Zinc PrimerImam SitumeangPas encore d'évaluation

- Penguard Express PDFDocument5 pagesPenguard Express PDFImam SitumeangPas encore d'évaluation

- Rust Bullet AI & GuideDocument32 pagesRust Bullet AI & GuideImam SitumeangPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- BituflamepDocument2 pagesBituflamepnkhhhPas encore d'évaluation

- Scissor Platforms For Goods & VehiclesDocument2 pagesScissor Platforms For Goods & VehiclesKleemmann Hellas SA0% (1)

- Nas 4703 Thrunas 4716Document1 pageNas 4703 Thrunas 4716tangyuPas encore d'évaluation

- Biodiesel in ThailandDocument32 pagesBiodiesel in Thailandinfo_thesisPas encore d'évaluation

- Lintel Design ExampleDocument8 pagesLintel Design ExamplemmediboyinaPas encore d'évaluation

- DS-003-2-En - Exertherm - IR06EMSC Sensor - ScreenDocument2 pagesDS-003-2-En - Exertherm - IR06EMSC Sensor - ScreenMohammad AsifPas encore d'évaluation

- Catalogo Hino 700 - ZF 16s151Document54 pagesCatalogo Hino 700 - ZF 16s151Lucio Pando100% (2)

- Mugen MBX5TDocument1 pageMugen MBX5Tbc24flPas encore d'évaluation

- Godrej Appliance Case Study Q99QZxmze5Document5 pagesGodrej Appliance Case Study Q99QZxmze5Harsh ShahPas encore d'évaluation

- 2G Gas EngineDocument32 pages2G Gas EngineQaiser IqbalPas encore d'évaluation

- Design of Railway Structures To The Structural Eurocodes - Part 1Document88 pagesDesign of Railway Structures To The Structural Eurocodes - Part 1Ion Pusculita100% (1)

- Hand Grinding MachinesDocument2 pagesHand Grinding MachinesFrianPas encore d'évaluation

- Saic Q 1015Document2 pagesSaic Q 1015Hussain Nasser Al- Nowiesser100% (1)

- Governing System of 210mw KwuDocument21 pagesGoverning System of 210mw KwuNitesh Rasekar100% (3)

- DC Power-System-Design-for-Telecommunications PDFDocument512 pagesDC Power-System-Design-for-Telecommunications PDFgirm2002100% (3)

- Mass-10 14 1 - May-2016Document14 pagesMass-10 14 1 - May-2016ianfldPas encore d'évaluation

- Insulation Resistances and Polarization Index Test of Electric MotorDocument19 pagesInsulation Resistances and Polarization Index Test of Electric MotorKrishna Jasha100% (1)

- RC Example-Problems Canete PDFDocument45 pagesRC Example-Problems Canete PDFRhonoelle Reevenujlah100% (1)

- D4008Document3 pagesD4008ChienPas encore d'évaluation

- Scale Free Heat Treatment - Images & ArticleDocument5 pagesScale Free Heat Treatment - Images & ArticleSrikar ShenoyPas encore d'évaluation

- OSST Know Your Steel Guide January 2010Document61 pagesOSST Know Your Steel Guide January 2010vikzefgPas encore d'évaluation

- As71164a CHECK LISTDocument9 pagesAs71164a CHECK LISTJulio HernandezPas encore d'évaluation

- Diesel Fuel : Click On The Applicable Bookmark To Selected The Required Model YearDocument67 pagesDiesel Fuel : Click On The Applicable Bookmark To Selected The Required Model YearRogério MorenoPas encore d'évaluation

- SHC AluminiumDocument2 pagesSHC Aluminiumsylent gohPas encore d'évaluation

- 95CBM020Document6 pages95CBM020Saša OljačaPas encore d'évaluation

- EconomicDocument19 pagesEconomicEarl HernanePas encore d'évaluation

- Pressure Table-Nvk Portion IsolatedDocument42 pagesPressure Table-Nvk Portion IsolatedVasanthakumarPas encore d'évaluation

- Appendix E: Load Values, in Water Supply Fixture Units (Wsfu) Type of Supply Fixture Occupancy Control Cold Hot TotalDocument1 pageAppendix E: Load Values, in Water Supply Fixture Units (Wsfu) Type of Supply Fixture Occupancy Control Cold Hot Totalbilal almelegyPas encore d'évaluation

- Maco 6 Element Beam ManualDocument8 pagesMaco 6 Element Beam Manualw8ddw100% (1)

- Volkswagen Polo 1.2 TSI BrochureDocument2 pagesVolkswagen Polo 1.2 TSI BrochureBtiarAshariImanuddin100% (1)