Académique Documents

Professionnel Documents

Culture Documents

5 Tejinder Singh

Transféré par

Varun Kumar0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues2 pagesjh

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentjh

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues2 pages5 Tejinder Singh

Transféré par

Varun Kumarjh

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print) IJRMET Vol.

6, Issue 1, Nov 2015-April 2016

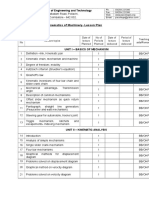

Various Techniques Used in Plant Layout

1

Tejinder Singh, 2Harvinder Lal

1,2

Ramgarhia Institute of Engineering & Technology, Phagwara, Punjab, India

Abstract representing graphically in flow process chart. The flow process

The objective of this research to focus on the various techniques chart real work is to tracing the actual flow of work occurring and

is used in plant layout these techniques are used to improve the the time required for the operation. It works on transportation,

productivity of layout. These techniques is work on tools are used storage and delay.

in layout planning. These tools are used to improve the production The complete information for the analysis and improvement of

time, material, man power, machine and equipment. This research plant operation is provided by flow process chart. The result of

paper aim to study to how these techniques are effective to improve analysis operation may be eliminated, combined or rearranged. The

the arrangements and production rate by using the techniques of work station, storage area can be rearranged to reduce traveling

plant layout distance and labour time. The flow process chart also checks and

verify the efficiency of proposed floor plan for a new layout.

Keywords

Plant Layout, Plant Layout Tools and Techniques C. Flow Diagram

The flow diagram is used to supplement of the flow process chart.

I. Meaning of Plant Layout it is graphically representing of work area, machinery, storage

Plant layout is most effective in physical arrangement machine, area, gang way etc. which path is followed by men or materials

equipment, material and facilities of plant. Plant layout maintains is marked on flow diagram. All the symbols and straight lines are

the co-ordination in between of 4M’s (men, material, machine and joining with each other and make routes to follow by different

method). In every plant there are some problems are come to face item are shown in flow diagram.

to solve the problems plant layout techniques are used. To set up In flow process chart will trace out the undesirable characteristic of

a plant layout orderly the techniques are use to help to improve layout which is responsible for delay and increasing transportation

or deal with problems. The plant layout arranges the machine, by study the process flow diagram and flow process chart.

processing equipment and service department. It is also show nature of back tracking to help on improving the

layout and easy to trace and present layout attractive.

II. Plant Layout Tools and Techniques

In plant layout various types of techniques are used to arrange D. String Diagram

the work in co-ordination manner. The techniques arrange the The string diagram is one of the simplest techniques. String

quickest flow of material at lower cost and with lesser handling in diagram is a model or scale plan which thread is used to trace

processing the product from the acknowledged of the raw material and measuring the path of workers, material or equipment.

to the shipment of finished product. The technique arrange that

which method is done, which material is used to performed in E. Machine Data Cards

which machine all the process are arranged by the plant layout This is effective tool to provide full information for placement

technique. There are some types of tools and techniques are or layout of equipment. The card shows the machine capacity,

discussed below. space and power requirement, handling devices and corresponding

The following tools are used, in layout planning: dimensions.

• Operation process charts

• Flow process charts F. Templates

• Flow diagrams The area taken by a machine is cut to scale from a thick paper is cut

• String diagram to scale from a thick paper to form a template. Not only machine

• Machine data cards but space covered by furniture, equipment and other components

• Templates can also form a template these can be shown the well arranged

• Scale models actual plan of layout to be undertaken. The template technique is

• Layout drawings an important technique because

Unnecessary handling is eliminated, backtracking of materials

A. Operation Process Chart is minimized, the mechanical handling is possible, and it

With the help of operation process chart we can separate and offers flexibility to meet future changes in the production

arrange the process of materials moving to which machine and requirements.

work done under which method all types of operation are arranged

by operation process chart. G. Scale Models

The operation process chart is mainly used when a new plant is to Scale model provide a three-dimensional layout it is better

be laid out. This process chart shows basic activities for producing understanding models are used to represent real situation the

a product. These carts show the overall visualization with help color cording can be used to define the plant perfectly and easily

of elimination, combination, rearrangement or simplification of understand. The scale model is available for large range of machine

process and basis for studying possibilities for the improvement tools, equipment, bench, storage cupboard etc. the typical type

operation. of models are shown in three-dimensional layout. The model

is expensive in this model reduce explanation since the other

B. Flow Process Chart layout.

All the production activities occurring on the floor of the plant are

w w w. i j r m e t. c o m International Journal of Research in Mechanical Engineering & Technology 33

IJRMET Vol. 6, Issue 1, Nov 2015-April 2016 ISSN : 2249-5762 (Online) | ISSN : 2249-5770 (Print)

H. Layout Drawings

Complete layout are shown in drawing walls, columns, stairways,

machines and other equipment, storage areas and office areas. All

are shown in respective manner.

References

[1] Agarwal, Atul,"Industrial Engineering", Rohilla Publication,

Chandigarh, 2012.

[2] Chand, Smriti,"Tools and Techniques used for Industrial

Layout Planning".

[3] [Online] Available: http://www.mbaknol.com/operations-

management/techniques-or-tools-used-for-the-design-of-

good-plant-layouts/

Er. Tejinder Singh have done Diploma

in Mechanical Engineering from

Lord Krishna Polytechnic College,

Kapurthala and after I done my

B-Tech in Mechanical Engineering

from Anand College Engineering

and Management, Kapurthala under

Punjab Technical University, Jalandhar

INDIA. Currently I am pursuing

M.Tech from RIET Phagwara under

Punjab Technical University, Jalandhar INDIA.

Er. Harvinder Lal have done my B.E

in Mechanical Engineering from

G.Z.S.C.E.T. Bathinda, Punjab,

INDIA. And I had completed my

M.Tech in Industrial engineering

from Dr. Ambedkar National Institute

of Technology. Now I am HOD in

RIET Phagwara. Qualification: B.E

in Mechanical engineering, M.Tech

in Industrial engineering.

34 International Journal of Research in Mechanical Engineering & Technology w w w. i j r m e t. c o m

Vous aimerez peut-être aussi

- Manufacturing Facilities Design & Material Handling: Sixth EditionD'EverandManufacturing Facilities Design & Material Handling: Sixth EditionPas encore d'évaluation

- Admission LetterDocument2 pagesAdmission LetterVarun KumarPas encore d'évaluation

- BHEL BHOPAL Vocational Training Report - 1301Document31 pagesBHEL BHOPAL Vocational Training Report - 1301Shubham yadav100% (3)

- Effective Improvement of A Plant Layout Using Pugh Matrix ApproachDocument5 pagesEffective Improvement of A Plant Layout Using Pugh Matrix ApproachAbhishek NanavatePas encore d'évaluation

- Plant Layout Analysis For Effective Prod 31567191Document4 pagesPlant Layout Analysis For Effective Prod 31567191shambel kipPas encore d'évaluation

- MBA 2nd Sem Lacture Note - 01Document4 pagesMBA 2nd Sem Lacture Note - 01GOURAB ROYPas encore d'évaluation

- A Typical Manufacturing Plant Layout Design Using CRAFT AlgorithmDocument7 pagesA Typical Manufacturing Plant Layout Design Using CRAFT AlgorithmgocoolonPas encore d'évaluation

- Computer Aided Process Planning For Milling Operation: September 2016Document9 pagesComputer Aided Process Planning For Milling Operation: September 2016guptaamitalwPas encore d'évaluation

- Cop Milling 4Document9 pagesCop Milling 4Naseeb Ullah TareenPas encore d'évaluation

- Computer Aided Process Planning For Milling Operation: PritiDocument8 pagesComputer Aided Process Planning For Milling Operation: PritiWahyu WidiantoPas encore d'évaluation

- Increasing Productivity of Busbars Manufacturing in Switch Board IndustryDocument7 pagesIncreasing Productivity of Busbars Manufacturing in Switch Board IndustryDave IringcoPas encore d'évaluation

- Unit-1 PpceDocument29 pagesUnit-1 PpceDivyamsi KPas encore d'évaluation

- FP Lec 4 (Compatibility Mode)Document52 pagesFP Lec 4 (Compatibility Mode)yehyaPas encore d'évaluation

- Techniques For Solving Facility Layout Problem: A Survey: Nitish D.Patil Jaivesh Gandhi Vivek DeshpandeDocument9 pagesTechniques For Solving Facility Layout Problem: A Survey: Nitish D.Patil Jaivesh Gandhi Vivek DeshpandellsloiPas encore d'évaluation

- Process Layout On Advance CNG Cylinder ManufacturingDocument4 pagesProcess Layout On Advance CNG Cylinder ManufacturingInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- String Diagram and Plant Layout: Group - 2Document25 pagesString Diagram and Plant Layout: Group - 2VaanazhaganPas encore d'évaluation

- Plant Layout Optimization in Crane Manufacturing Using Craft: Literature SurveyDocument4 pagesPlant Layout Optimization in Crane Manufacturing Using Craft: Literature Surveyfiqri asrulPas encore d'évaluation

- Optimization of Facility Layout For Improvement in ProductivityDocument7 pagesOptimization of Facility Layout For Improvement in ProductivityTania MajumderPas encore d'évaluation

- Tool Management System Incorporated With Skill Matrix: Labade Saurabhvikas, Shewale Nikhil Subhash, Prof. M.S. RohokaleDocument3 pagesTool Management System Incorporated With Skill Matrix: Labade Saurabhvikas, Shewale Nikhil Subhash, Prof. M.S. RohokaleerpublicationPas encore d'évaluation

- Articulo DRA 2da PropuestaDocument4 pagesArticulo DRA 2da PropuestaFabricio Vásquez SolisPas encore d'évaluation

- Akshay Research PaperDocument6 pagesAkshay Research PaperTansen ChaudhariPas encore d'évaluation

- Tools and Techniques of Plant LayoutDocument24 pagesTools and Techniques of Plant LayoutNikhil Sankhe80% (5)

- Industrial Engineering - Lab Manual - 06052016 - 054139AM PDFDocument58 pagesIndustrial Engineering - Lab Manual - 06052016 - 054139AM PDFSaya100% (1)

- Literature Review For Designing of Portable CNC MachineDocument3 pagesLiterature Review For Designing of Portable CNC MachineIJIRSTPas encore d'évaluation

- Tool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesDocument8 pagesTool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesODEH ABU YAHIAPas encore d'évaluation

- Facility Layout Design by CRAFT Technique: September 2005Document7 pagesFacility Layout Design by CRAFT Technique: September 2005Brute1989Pas encore d'évaluation

- 4 - Aldep Corelap and CraftDocument7 pages4 - Aldep Corelap and CraftBalamurugan P100% (1)

- Chandigarh Conference Paper IC-2Document7 pagesChandigarh Conference Paper IC-2Juby JoyPas encore d'évaluation

- Ijiset V2 I1 50Document6 pagesIjiset V2 I1 50yetsedawPas encore d'évaluation

- Methods Engineering Topics: Project SelectionDocument1 pageMethods Engineering Topics: Project SelectionMayurRawoolPas encore d'évaluation

- October 2019process PlaningstionqueDocument8 pagesOctober 2019process Planingstionquekandasamy sivamuruganPas encore d'évaluation

- Me8793 Qb.Document38 pagesMe8793 Qb.YUVA RAJA BPas encore d'évaluation

- Question # 1 DefineDocument17 pagesQuestion # 1 DefineHayyaAli100% (2)

- 1709-Article Text-3215-1-10-20210224Document6 pages1709-Article Text-3215-1-10-20210224Seshank SubuPas encore d'évaluation

- Materials Today: Proceedings: Suthep Butdee, Siridech KunhirunbawonDocument6 pagesMaterials Today: Proceedings: Suthep Butdee, Siridech KunhirunbawonDániel TokodyPas encore d'évaluation

- Continious Processing StudyDocument16 pagesContinious Processing StudyHarshith ShettyPas encore d'évaluation

- 2005 VD Conference CRAFTDocument7 pages2005 VD Conference CRAFTDaniel IlievskiPas encore d'évaluation

- Experimental Investigation On Minimizing Cycle Time and Cost of Radial Drill Head Feed Box Housing in Vertical Machining Centre VMC Using Optimized Canned Cycles IJERTV5IS080451Document6 pagesExperimental Investigation On Minimizing Cycle Time and Cost of Radial Drill Head Feed Box Housing in Vertical Machining Centre VMC Using Optimized Canned Cycles IJERTV5IS08045121P113 - MOHAMMED FAHAD APas encore d'évaluation

- Dr. Goutam Sen: Indian Institute of Technology (IIT) Kharagpur West Bengal, IndiaDocument39 pagesDr. Goutam Sen: Indian Institute of Technology (IIT) Kharagpur West Bengal, IndiaSiddharthPutuvelyPas encore d'évaluation

- InternshipDocument33 pagesInternshipsravankumarPas encore d'évaluation

- EfficiencyimprovementofaplantlayoutDocument8 pagesEfficiencyimprovementofaplantlayoutmhabibiePas encore d'évaluation

- Cim Unit 4 PDFDocument20 pagesCim Unit 4 PDFSarthak KingerPas encore d'évaluation

- Systematic Layout PlanningDocument5 pagesSystematic Layout PlanningNishant1993Pas encore d'évaluation

- Presentation Chapter 5 Plant Layout 1516079587 20707Document27 pagesPresentation Chapter 5 Plant Layout 1516079587 20707itsnithin_tsPas encore d'évaluation

- 2020A4PS1917H MidSem Report Format (31-10-2022)Document15 pages2020A4PS1917H MidSem Report Format (31-10-2022)Ayush jhaPas encore d'évaluation

- Presentaion ProjectDocument15 pagesPresentaion ProjectAyush jhaPas encore d'évaluation

- Craft y Aldep Ejemplo PaperDocument18 pagesCraft y Aldep Ejemplo PaperEs EstebanPas encore d'évaluation

- Plant Layout Optimization Using CRAFT and ALDEP Methodology: June 2016Document18 pagesPlant Layout Optimization Using CRAFT and ALDEP Methodology: June 2016swarajPas encore d'évaluation

- Final Plant LayoutDocument6 pagesFinal Plant Layoutiampradnyesh 05Pas encore d'évaluation

- Unit Ii: Process Planning by Dr. A. Asha Professor/Mechanial Engineering Kamaraj College of Engineering & TechnologyDocument28 pagesUnit Ii: Process Planning by Dr. A. Asha Professor/Mechanial Engineering Kamaraj College of Engineering & TechnologyShailesh ShirguppikarPas encore d'évaluation

- Unit 3 Charting and Diagramming Techniques For Operations AnalysisDocument19 pagesUnit 3 Charting and Diagramming Techniques For Operations Analysisleonard dela cruzPas encore d'évaluation

- Unit 3Document28 pagesUnit 3Ian Lee LuguePas encore d'évaluation

- Jurnal Ilmiah Widya Teknik: Redesign Facility Layout With Quantitative and Qualitative Method On Printing IndustryDocument5 pagesJurnal Ilmiah Widya Teknik: Redesign Facility Layout With Quantitative and Qualitative Method On Printing IndustryLazuardy Hasan PratamaPas encore d'évaluation

- Plant Layout Optimization Using CRAFT and ALDEP Methodology: June 2016Document18 pagesPlant Layout Optimization Using CRAFT and ALDEP Methodology: June 2016Vedant KarnatakPas encore d'évaluation

- Plant LayoutDocument13 pagesPlant LayoutLukka KarthikPas encore d'évaluation

- Unit 3 Charting and Diagramming Techniques For Operations AnalysisDocument19 pagesUnit 3 Charting and Diagramming Techniques For Operations AnalysisVictoria Asuncion RodriguezPas encore d'évaluation

- Recent Trends in CappDocument23 pagesRecent Trends in CappharimankadaPas encore d'évaluation

- Analysis and Simulation Application For Manual Work Performance ImprovementDocument4 pagesAnalysis and Simulation Application For Manual Work Performance ImprovementzainPas encore d'évaluation

- Prayer Paper Production FLP Using SLP and CRAFTDocument9 pagesPrayer Paper Production FLP Using SLP and CRAFTswarajPas encore d'évaluation

- CNC TrainingDocument19 pagesCNC TrainingMahipal Singh RanawatPas encore d'évaluation

- Facility and Process Layout Analysis of An SME Using Simulation: A Case Study of A Manufacturing CompanyDocument11 pagesFacility and Process Layout Analysis of An SME Using Simulation: A Case Study of A Manufacturing CompanyJon GatesPas encore d'évaluation

- Pip PH DDocument316 pagesPip PH DVarun KumarPas encore d'évaluation

- Development of Checklist For Evaluating Sustainability Characteristics of Manufacturing ProcessesDocument21 pagesDevelopment of Checklist For Evaluating Sustainability Characteristics of Manufacturing ProcessesVarun KumarPas encore d'évaluation

- Table 4.1 Definition of Agility Evolution by Various AuthorsDocument6 pagesTable 4.1 Definition of Agility Evolution by Various AuthorsVarun KumarPas encore d'évaluation

- Integration of Lean and Agile Manufacturing Based On Principles From WikinomicsDocument9 pagesIntegration of Lean and Agile Manufacturing Based On Principles From WikinomicsVarun KumarPas encore d'évaluation

- Onion Rs7 Low Price Than Market Rate, Price Negotiable in Saravanampatti Contact 8220609999Document1 pageOnion Rs7 Low Price Than Market Rate, Price Negotiable in Saravanampatti Contact 8220609999Varun KumarPas encore d'évaluation

- 7 Vol 2 No 2Document11 pages7 Vol 2 No 2Varun KumarPas encore d'évaluation

- #CustomizedDocument1 page#CustomizedVarun KumarPas encore d'évaluation

- TQM Internal Mark 2014-2018 BatchDocument2 pagesTQM Internal Mark 2014-2018 BatchVarun KumarPas encore d'évaluation

- Some Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationDocument6 pagesSome Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationVarun KumarPas encore d'évaluation

- Regulation 2008 - Lab Course - Criterion III - TemplateDocument78 pagesRegulation 2008 - Lab Course - Criterion III - TemplateVarun KumarPas encore d'évaluation

- Some Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationDocument6 pagesSome Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationVarun KumarPas encore d'évaluation

- Summary of Surface Finish ParametersDocument3 pagesSummary of Surface Finish ParametersVarun KumarPas encore d'évaluation

- 5B-01-P96 (Malaysia)Document7 pages5B-01-P96 (Malaysia)Varun KumarPas encore d'évaluation

- Kinematics of Machinery-Lesson Plan: P.A. College of Engineering and TechnologyDocument4 pagesKinematics of Machinery-Lesson Plan: P.A. College of Engineering and TechnologyVarun KumarPas encore d'évaluation

- ASSIGNMENT II Answer KeyDocument3 pagesASSIGNMENT II Answer KeyVarun KumarPas encore d'évaluation

- Sub: To Honor Our Alumnus Reg.: Place: Pollachi Date: 26-09-2016Document1 pageSub: To Honor Our Alumnus Reg.: Place: Pollachi Date: 26-09-2016Varun KumarPas encore d'évaluation

- Mech & AutoDocument92 pagesMech & AutoVarun KumarPas encore d'évaluation

- B.Tech ECE 028 05 DEC12Document407 pagesB.Tech ECE 028 05 DEC12Prateek GuptaPas encore d'évaluation

- MD Isocracking v2Document2 pagesMD Isocracking v2Materia GrisPas encore d'évaluation

- Biogastrain Produktblad 2005Document2 pagesBiogastrain Produktblad 2005adamyogiPas encore d'évaluation

- Kashif NoorDocument4 pagesKashif NoorHaseebPirachaPas encore d'évaluation

- P2-FYP2-Conformity of Thesis FormatDocument2 pagesP2-FYP2-Conformity of Thesis FormatMuhd Ashraf AzmiPas encore d'évaluation

- 030 PDFDocument4 pages030 PDFherrerafaridPas encore d'évaluation

- Microcontroller Based Trainer Kit by Vrushank and RushviDocument74 pagesMicrocontroller Based Trainer Kit by Vrushank and Rushvivrushank100% (8)

- Numerical Overcurrent Time Protection and Thermal Overload Relay With Auto-Reclosure 7SJ600Document184 pagesNumerical Overcurrent Time Protection and Thermal Overload Relay With Auto-Reclosure 7SJ600Miguel AngelPas encore d'évaluation

- Mrs Comp Manual T-BTD-RMDocument98 pagesMrs Comp Manual T-BTD-RMkatepol82640% (1)

- Utkarsh India Limited - Best Swaged Pole Manufacturer in IndiaDocument8 pagesUtkarsh India Limited - Best Swaged Pole Manufacturer in IndiaUtkarsh India LTD.Pas encore d'évaluation

- Daftar Pengiriman DokumenDocument1 pageDaftar Pengiriman DokumenIhwan AsrulPas encore d'évaluation

- Unitiiie 170911085503 PDFDocument84 pagesUnitiiie 170911085503 PDFDevanshu SahayPas encore d'évaluation

- GP3000Document32 pagesGP3000JerPas encore d'évaluation

- Conformity of Structural Steel Products and StructuresDocument5 pagesConformity of Structural Steel Products and StructuresStephen HicksPas encore d'évaluation

- Microwave and Radar Engineering M KulkarniDocument3 pagesMicrowave and Radar Engineering M KulkarniAnmol Sood50% (2)

- MateriDocument3 pagesMateriTeuku Rahmad MauliddinPas encore d'évaluation

- Aftercooler - Test PDFDocument6 pagesAftercooler - Test PDFDaniel Castillo Peña100% (1)

- Joinery and Fitting (Wooden Windows Detail - Casement) : Department of Interior & Furniture Design LsadDocument19 pagesJoinery and Fitting (Wooden Windows Detail - Casement) : Department of Interior & Furniture Design LsadAnmol MehanPas encore d'évaluation

- Sulfur Recovery Unit: Specialty Wavelength Industrial Infrared ThermometersDocument2 pagesSulfur Recovery Unit: Specialty Wavelength Industrial Infrared ThermometersAndrew Kevin ThilaksPas encore d'évaluation

- ECM Service GuideDocument18 pagesECM Service Guidemegan1407Pas encore d'évaluation

- History of Computer DevelopmentDocument3 pagesHistory of Computer DevelopmentRoy Isaac Sillador100% (1)

- Design and Analysis of Navigator Quad Copter For Autonomous VehiclesDocument3 pagesDesign and Analysis of Navigator Quad Copter For Autonomous VehiclesInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- E52 Ca1dy 247682 PDFDocument34 pagesE52 Ca1dy 247682 PDFvũ văn đăngPas encore d'évaluation

- Catalogo XMDocument42 pagesCatalogo XMAlejandro Saco HerreraPas encore d'évaluation

- International Journal of Fatigue: C.M. Manjunatha, Ramesh Bojja, N. Jagannathan, A.J. Kinloch, A.C. TaylorDocument7 pagesInternational Journal of Fatigue: C.M. Manjunatha, Ramesh Bojja, N. Jagannathan, A.J. Kinloch, A.C. TaylorAnonymous 7hZOclPas encore d'évaluation

- Final Project Report: Bottle Cap OpenerDocument13 pagesFinal Project Report: Bottle Cap OpenertylerPas encore d'évaluation

- Younis and Abdelati With HeaderDocument6 pagesYounis and Abdelati With HeaderScott MelgarejoPas encore d'évaluation

- Limit State of ServiceabilityDocument20 pagesLimit State of ServiceabilityNavi RengarajanPas encore d'évaluation

- ECSCADA Presentation NRB 120816Document36 pagesECSCADA Presentation NRB 120816Mohit Sharma100% (1)