Académique Documents

Professionnel Documents

Culture Documents

1 s2.0 S0022391316305108 Main

Transféré par

Novita RTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1 s2.0 S0022391316305108 Main

Transféré par

Novita RDroits d'auteur :

Formats disponibles

RESEARCH AND EDUCATION

Three-dimensional finite element analysis of implant-assisted

removable partial dentures

Ju-Won Eom, DDS, MS,a Young-Jun Lim, DDS, MS, PhD,b Myung-Joo Kim, DDS, MS, PhD,c and

Ho-Beom Kwon, DDS, MS, PhDd

Various treatment options have ABSTRACT

been developed using dental Statement of problem. Whether the implant abutment in implant-assisted removable partial

implant systems, including dentures (IARPDs) functions as a natural removable partial denture (RPD) tooth abutment is

implant-retained overden- unknown.

tures, implant-supported

Purpose. The purpose of this 3-dimensional finite element study was to analyze the biomechanical

overdentures, and implant- behavior of implant crown, bone, RPD, and IARPD.

supported fixed prostheses.1,2

Recently implant-supported Material and methods. Finite element models of the partial maxilla, teeth, and prostheses were

generated on the basis of a patient’s computed tomographic data. The teeth, surveyed crowns, and

fixed restorations have been

RPDs were created in the model. With the generated components, four 3-dimensional finite

used in combination with element models of the partial maxilla were constructed: tooth-supported RPD (TB), implant-

removable partial dentures supported RPD (IB), tooth-tissue-supported RPD (TT), and implant-tissue-supported RPD (IT)

(RPDs) as an alternative treat- models. Oblique loading of 300 N was applied on the crowns and denture teeth. The von Mises

ment for patients with partial or stress and displacement of the denture abutment tooth and implant system were identified.

3

complete edentulism. The Results. The highest von Mises stress values of both IARPDs occurred on the implants, while those

benefits of implant-assisted of both natural tooth RPDs occurred on the frameworks of the RPDs. The highest von Mises stress of

RPDs have been described by model IT was about twice that of model IB, while the value of model TT was similar to that of model

several authors.3-7 An implant- TB. The maximum displacement was greater in models TB and TT than in models IB and IT. Among

assisted removable partial den- the 4 models, the highest maximum displacement value was observed in the model TT and the

lowest value was in the model IB.

ture (IARPD) is different from

an implant-retained RPD in Conclusions. Finite element analysis revealed that the stress distribution pattern of the IARPDs was

that the implant provides different from that of the natural tooth RPDs and the stress distribution of implant-supported RPD

an RPD abutment in an was different from that of implant-tissue-supported RPD. When implants are used for RPD

abutments, more consideration concerning the RPD design and the number or location of the

IARPD.7-10 The implant in an

implant is necessary. (J Prosthet Dent 2017;117:735-742)

IARPD provides retention and

support, which improves

masticatory efficiency and patient comfort and satisfac- IARPDs is also cost-effective as the number of implants is

tion.11 In addition, the implants protect the remaining reduced.15 Furthermore, by transforming Kennedy class I

natural teeth and preserve bone.12,13 Clasp arms can be RPDs to Kennedy class III through the placement of distal

replaced by retentive attachments to the implant abutment, implants, IARPDs can provide better support and increased

improving patients’ appearance.13,14 Treatment with masticatory force.16,17

Supported by grant 2015R1D1A1A01060940 from the National Research Foundation of Korea.

a

Graduate student, Dental Research Institute and Department of Prosthodontics, School of Dentistry, Seoul National University, Seoul, Republic of Korea.

b

Professor, Dental Research Institute and Department of Prosthodontics, School of Dentistry, Seoul National University, Seoul, Republic of Korea.

c

Associate Professor, Dental Research Institute and Department of Prosthodontics, School of Dentistry, Seoul National University, Seoul, Republic of Korea.

d

Associate Professor, Dental Research Institute and Department of Prosthodontics, School of Dentistry, Seoul National University, Seoul, Republic of Korea.

THE JOURNAL OF PROSTHETIC DENTISTRY 735

736 Volume 117 Issue 6

structures.22-27 It provides useful information that is

Clinical Implications difficult to measure intraorally, including the results of

When implants were used as abutments for the different component sizes and material changes, the

calculation of preload, the effect of implant-abutment

removable partial denture (RPD) design, the highest

connections, and the influence of parafunctional

stress was concentrated on the implants in

habits.22,24,25,28 Although several studies have described

implant-assisted removable partial dentures. To

the use of RPDs in conjunction with implant prostheses,

avoid possible implant complications such as

few studies have used 3D finite element analysis to

prosthesis fracture, marginal bone loss, or implant

evaluate the use of implant prostheses as abutments for

failure related to this stress concentration, it might

RPDs.19,29,30 Therefore, the purpose of this 3D finite

be necessary to consider the placement of multiple

implants, splinted prostheses, or the extension of element analysis study was to analyze the biomechanical

behavior of implant, bone, and RPD in different types of

the RPD base to cover the maximum supporting

IARPDs.

area.

MATERIAL AND METHODS

Implant placement on the maxillary or mandibular Three-dimensional finite element models of an IARPD

posterior regions is sometimes restricted by anatomic or and a tooth-supported RPD were constructed based on a

financial limitations. Some patients with complete patient’s computed tomography (CT) image. Four 3D

edentulism are unwilling to have extensive surgical pro- finite element models of an implant-supported RPD (IB), a

cedures. In these situations, anterior implant-supported tooth-supported RPD (TB), an implant-tissue-supported

fixed restorations in conjunction with RPDs can be an RPD (IT), and a tooth-tissue-supported RPD (TT) were

effective treatment option.18 Chronopoulos et al3 constructed to simulate RPDs combined with implant

described a patient with RPDs in which Kennedy class I prostheses or natural teeth as abutments on the partially

RPDs were used on the maxilla and mandible in combi- edentulous maxilla. An oblique load of 300 N was applied

nation with anterior fixed implant prostheses with semi- on the crowns and denture teeth. The maximum von

precision attachments. The authors concluded that the use Mises stresses and the displacements of the denture

of a dental implant as an abutment for a mandibular abutment teeth, implants, bone, and RPDs were identi-

extension RPD was an effective clinical solution. fied. This study was approved by the institutional review

Cunha et al19 demonstrated that the placement of a board of Seoul National University Dental Hospital.

dental implant diminished the tendency for intrusion of The geometry of the maxilla was extracted from CT

RPDs. The authors constructed a 2-dimensional (2D) data. The individual was healthy and had normal

finite element model of a partially edentulous mandible craniofacial structures. The left side of the maxilla was

and RPD models combined with an implant and used to build a finite element model. The CT scans were

concluded that locating the implant near the abutment segmented using an image processing software (Amira;

tooth positively influenced the distribution of stresses on FEI) and then exported into a meshing program (Visual-

the analyzed structures. Pellizzer et al20 studied the Mesh; ESI Group), which produced the tetrahedral

association between a distal extension RPD and an volumetric meshes of the partial maxilla.

osseointegrated implant using 2D finite element analysis. Four 3D finite element models representing half of

The authors reported that implants associated with a the maxilla, abutments, and half of the RPD were con-

healing abutment, Sterngold ERA overdenture attach- structed. Two models had natural teeth, and the other 2

ment (Sterngold), or a ball attachment exhibited favorable models had implant-supported surveyed crowns. The

stresses with an RPD. In contrast, distal extension RPDs model TB consisted of 2 surveyed crowns supported by

associated with a single implant-supported prosthesis in natural teeth in the area of the maxillary first premolar

the posterior area were not favorable. Shahmiri et al21 and the second molar combined with the RPD. A

analyzed a Kennedy class I implant-assisted removable partially edentulous maxilla was created by removing the

prosthesis using finite element analysis. They constructed second premolar and the first molar in the original model

a 3-dimensional (3D) human mandible model with an and by replacing the first premolar and second molar

RPD and an implant and analyzed the maximum defor- with the scan data of artificial teeth in the replica model

mation and stress distribution of a framework and acrylic (Nissin D50-555; Nissin). The final model TB was

resin in the RPD, cortical or cancellous bone, and implants. composed of palatal mucous membrane, cortical bone

The authors reported the deformation that might lead to and cancellous bone, periodontal ligaments, abutments,

acrylic resin fracture in the prosthesis. surveyed crown, and RPD. The surveyed crowns had rest

Finite element analysis has frequently been used in seats and were modeled on the properties of a gold alloy.

dentistry to analyze the biomechanical behavior of The RPD had 2 Akers clasps.

THE JOURNAL OF PROSTHETIC DENTISTRY Eom et al

June 2017 737

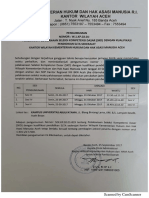

Figure 1. Structure of finite element models. A, Implant-supported RPD (IB). B, Tooth-supported RPD (TB). C, Implant-tissue-supported RPD (IT).

D, Tooth-tissue-supported RPD (TT). RPD, removable partial denture.

The model TT was created by removing the second Table 1. Finite element models

molar of the model TB and by covering edentulous area Removable

Partial No. of No. of

with denture base. Except for the difference in the second Model Abutment Denture Nodes Elements

molar region, all of the components of the model TT were TB Maxillary first premolar and maxillary Tooth 34 120 114 197

identical to those of the model TB. In the model IB, the second molar supported

natural tooth abutments of the model TB were replaced TT Maxillary first premolar Implant tissue 33 024 111 110

supported

with implants. In the model IT, the first premolar of the IB Implant-supported maxillary first Implant 39 902 140 223

model TT was replaced with an implant (Fig. 1). The premolar and implant-supported supported

maxillary second molar

models are summarized in Table 1.

IT Implant-supported maxillary first Implant tissue 36 048 124 373

The geometries of the dental implant system (Osstem premolar supported

US system; Osstem Implant Co) of all models were

provided by the manufacturer. The implant was 10 mm

long and 4 mm in diameter. The abutments and the Meshes of teeth, surveyed crowns, and RPDs were

abutment screws were designed independently and were created with 3D computer-aided design software (Visual-

assembled. The abutment screw was simplified and was Mesh; ESI Group) (Fig. 2). The meshes for the roots of the

in contact with the implant screw hole. The inferior teeth were surrounded by meshes of the periodontal liga-

surface of the abutment was in contact with the top of the ment that were 0.5 mm thick. The RPD model was composed

implant. The preload on the abutment screw was of a metal framework, acrylic resin base, and denture teeth.

generated to simulate screw tightening by using the bolt- The acrylic resin base was considered to be completely

pretension mechanism, which is included in the finite bonded with the denture tooth and metal framework.

element analysis software (ANSYS 14.5; Swanson Anal- All materials were assumed to be linearly elastic,

ysis Systems Inc).31 The preload used was 825 N.25 The homogenous, and isotropic to simplify the calculations.

implant was considered to be bonded with cancellous The elastic modulus and the Poisson ratio for each ma-

and cortical bone to simulate complete osseointegration. terial are summarized in Table 2.

Eom et al THE JOURNAL OF PROSTHETIC DENTISTRY

738 Volume 117 Issue 6

Figure 2. Coronal section of meshes. A, Coronal section of implant-supported removable partial denture (model IB). B, Coronal section of model TB.

C, Coronal section of model IT. D, Coronal section of model TT.

Finite element analysis was performed with software Table 2. Material properties of finite element models31,32

(ANSYS 14.5; Swanson Analysis Systems Inc). The inter- Material Elastic Modulus (GPa) Poisson Ratio

faces between the surveyed crowns and the clasps of the Titanium 110 0.33

RPDs were modeled as frictional contacts with appropriate Acrylic resin 2.2 0.31

friction coefficients (m=0.10).8 Contact analysis was also RPD framework (cobaltechromium) 211 0.3

applied to the interfaces between implant components. Tooth dentin 41 0.3

The coefficient of friction value between the abutment and Gold alloy 91 0.33

Periodontal ligament 3×10−5 0.45

implant was 0.16, and that between the abutment and

Cortical bone 13.7 0.3

abutment screw was 0.2.8 On the basis of previous studies,

Cancellous bone 1.37 0.33

oblique loading of 300 N was applied on the crown and

Mucosa 0.001 0.37

denture tooth to simulate masticatory loading.23,33 Oblique

RPD, removable partial denture.

force was directed at 14.04 degrees to the long axis of the

crown from the buccal to the lingual direction and

distributed to the central fossa and the lingual slopes of the Table 3. Highest von Mises stress values for each finite element model

Model IB TB IT TT

buccal cusps of all maxillary premolars and molars in the

Von Mises stress value (MPa) 120.6 279.7 252.5 307.4

models.34 All nodes of the most medial and most distal

surfaces in the models were constrained in all directions.

The von Mises stress value was used for the analysis, investigated. Maximum displacement of the finite element

appropriate for predicting failure of ductile materials such model was used to verify which compartments moved.

as titanium, cobalt-chromium, and gold alloy.24 Higher

RESULTS

von Mises stress values represent higher risk of fail-

ure.22,34,35 The von Mises stress values of the cortical bones, The highest von Mises stress values were observed on

cancellous bones, RPD frameworks, and implants in the different positions and compartments of each model

different types of IARPDs or natural tooth RPDs were (Table 3). The maximum von Mises stress values of the

THE JOURNAL OF PROSTHETIC DENTISTRY Eom et al

June 2017 739

Figure 3. Von Mises stress (GPa) of removable partial denture framework of finite element models. Red arrows indicate area of maximum von Mises

stress. A, Framework of model IB. B, Framework of model TB. C, Framework of model IT. D, Framework of model TT.

Table 4. Highest von Mises stress values (MPa) in each compartment

With regard to the IARPDs, the maximum von Mises

Model IB TB IT TT

stress values of the cancellous bone and cortical bone,

Cortical bone 33.5 6.5 61.4 6.1

RPD framework, and implant were about twice as high in

Cancellous bone 3.2 0.8 7.5 0.7

model IT as in model IB. For the tooth-supported RPDs,

RPD framework 72.7 279.7 163.1 307.4

Implant 120.6 - 252.4 -

the maximum von Mises stress values of the cortical bone

and cancellous bone were slightly higher in model TB

RPD, removable partial denture.

than those in model TT, while the maximum von Mises

stress value of the RPD framework was higher in model

Table 5. Highest maximum displacement value (mm) for each finite TT (307.4 MPa) than that in model TB (279.7 MPa)

element model (Table 4).

Model IB TB IT TT The maximum displacement values of each model are

Maximum displacement 0.05 1.05 0.36 1.08 summarized in Table 5. The maximum displacement of

models IT and TT occurred in the distal area of each RPD

(Fig. 4). The maximum displacement value that occurred

cancellous and cortical bone were higher in IARPDs (models

in the RPD framework of model TT was the highest

IB and IT) than in the tooth-supported RPDs (models TB and

among the models, while the maximum displace-

TT). However, the maximum von Mises stress values of the

ment value in the RPD framework of model IB was the

RPD framework were higher in the tooth-supported RPDs

lowest.

than in the IARPDs (Fig. 3). Both of the maximum stress

values of models TB (279.7 MPa) and TT (307.4 MPa)

DISCUSSION

occurred on the minor connector of the RPD, while both of

the maximum stress values of models IB (72.7 MPa) and IT The highest von Mises stress value in each IARPD model

(163.1 MPa) occurred on the distal side of the first thread of was located at the implant, and the implants were

the implant in the area of the first premolar in both models. assumed to bear most of the loading in models IB and IT.

Eom et al THE JOURNAL OF PROSTHETIC DENTISTRY

740 Volume 117 Issue 6

Figure 4. Maximum displacement of finite element models. Red arrows indicate area of maximum displacement. A, Maximum displacement of model

IB. B, Maximum displacement of model TB. C, Maximum displacement of model IT. D, Maximum displacement of model TT.

The highest von Mises stress of the implant was about those of model IT were no more than 40 mm. These

twice as great in model IT as in model IB, which might be values are within the normal range, which is about 10 to

explained by the absence of the distal implant in model 50 mm as lateral force is loaded.36 It was assumed that as

IT. This result indicates that the tissue underlying the the RPD in model IT moved downward to the tissue

RPD provided less support under loading than in model under occlusal loading the tissue underneath the RPD

IT and that the use of an implant affected the behavior of base resisted the occlusal loading.37 Thus, the IARPD in

the RPD. However, the models where implants were not model IT should have the maximum support-bearing

used showed different results. The highest von Mises area underneath the base to distribute the total load

stress values in the models TB and TT were observed on from the RPD abutment to the supporting tissue because

the RPD framework, and it was assumed that the RPD the stress around the implant and cortical bone was

framework, which had the highest elastic modulus, found to be higher in model IT than in any other model

experienced the greatest stress because the tooth abut- (Table 4). In addition, the use of multiple splinted im-

ments were mobile because of the presence of the peri- plants instead of a single implant as an RPD abutment

odontal ligament. These results are consistent with those might decrease loading to the implants and thus reduce

of a previous study in which the metal framework of a the risk of complications.38

mandibular RPD showed the highest strain patterns on The reason that the implant models and natural tooth

the major and minor connectors in a mandible model.21 models had different maximum displacement values was

Maximum displacement values varied for each model that the abutment teeth of the natural tooth RPDs were

depending on the presence or absence of the distal more displaceable than those of IARPDs because of the

implant. The maximum displacement value of model IT periodontal ligament, which had a much lower elastic

was 7 times larger than that of model IB. The maximum modulus than any other component in the model. The

displacement values of the implant and the abutment of displacement of model TT was about three times as large

the implant of model IB were no more than 25 mm, while as that of model IT. The displacement of model TT was

THE JOURNAL OF PROSTHETIC DENTISTRY Eom et al

June 2017 741

attributed to tooth-abutment mobility, the elasticity of 6. Mijiritsky E, Ormianer Z, Klinger A, Mardinger O. Use of dental implants to

improve unfavorable removable partial denture design. Compend Contin

the RPD framework, and slipping of the RPD framework Educ Dent 2005;26:744-6.

from the surveyed crown. The displacement of model IT 7. Yeung S, Chee WW, Torbati A. Design concepts of a removable partial dental

prosthesis with implant-supported abutments. J Prosthet Dent 2014;112:

was attributed to the elasticity of the RPD framework and 99-103.

slipping of the RPD framework from the surveyed crown. 8. Shahmiri R, Das R, Aarts JM, Bennani V. Finite element analysis of an

implant-assisted removable partial denture during bilateral loading: occlusal

In this study, a preload of 825 N in the implant system rests position. J Prosthet Dent 2014;112:1126-33.

was created by using the bolt-pretension mechanism in 9. Gharehchahi J, Asadzadeh N, Mirmortazavi A, Shakeri MT. Maximum dis-

lodging forces of mandibular implant-assisted removable partial dentures:

the ANSYS program.31 The 825-N preload was regarded in vitro assessment. J Prosthodont 2013;22:543-9.

as the optimum preload, which was 75% of the yield 10. Wismeijer D, Tawse-Smith A, Payne AG. Multicentre prospective evaluation

of implant-assisted mandibular bilateral distal extension removable partial

strength as recommended for the implant screwejoint dentures: patient satisfaction. Clin Oral Implants Res 2013;24:20-7.

assembly.25 Lang et al25 reported that 75% of the yield 11. Mijiritsky E. Implants in conjunction with removable partial dentures: a

literature review. Implant Dent 2007;16:146-54.

strength of the abutment screw was equal to using a 12. Werbitt MJ, Goldberg PV. The immediate implant: bone preservation and

torque of 32 Ncm applied to the abutment screws in bone regeneration. Int J Periodontics Restorative Dent 1992;12:206-17.

13. Keltjens HM, Kayser AF, Hertel R, Battistuzzi PG. Distal extension removable

implant assemblies with a coefficient friction of 0.12 be- partial dentures supported by implants and residual teeth: considerations and

tween the implant components. case reports. Int J Oral Maxillofac Implants 1993;8:208-13.

14. Budtz-Jorgensen E, Bochet G, Grundman M, Borgis S. Aesthetic consider-

In the present study, several assumptions were made ations for the treatment of partially edentulous patients with removable

to simplify the calculation. It was assumed that the dentures. Pract Proced Aesthet Dent 2000;12:765-72.

15. de Carvalho WR, Barboza EP, Caula AL. Implant-retained removable pros-

cortical and cancellous bones were isotropic, that the thesis with ball attachments in partially edentulous maxilla. Implant Dent

mucosa was linearly elastic, and that all the interfaces 2001;10:280-4.

16. Shahmiri RA, Atieh MA. Mandibular Kennedy Class I implant-tooth-borne

were bonded states except for the 2 frictional contact removable partial denture: a systematic review. J Oral Rehabil 2010;37:

interfaces between the surveyed crowns and the clasps of 225-34.

17. Ohkubo C, Kobayashi M, Suzuki Y, Hosoi T. Effect of implant support on

the RPDs and between implant components. Some distal-extension removable partial dentures: in vivo assessment. Int J Oral

components of the finite element models were simpli- Maxillofac Implants 2008;23:1095-101.

18. Pellecchia M, Pellecchia R, Emtiaz S. Distal extension mandibular removable

fied.22,28 In addition, only half of the maxilla and partial denture connected to an anterior fixed implant-supported prosthesis:

the partial RPD were generated and used in the a clinical report. J Prosthet Dent 2000;83:607-12.

19. Cunha LD, Pellizzer EP, Verri FR, Pereira JA. Evaluation of the influence of

present study. The contralateral side might have affected location of osseointegrated implants associated with mandibular removable

the results. Further studies on RPD design, other partial dentures. Implant Dent 2008;17:278-87.

20. Pellizzer EP, Verri FR, Falcon-Antenucci RM, Goiato MC, Gennari Filho H.

implanteabutment connection types, and the use of at- Evaluation of different retention systems on a distal extension removable

tachments with more sophisticated models are required. partial denture associated with an osseointegrated implant. J Craniofac Surg

2010;21:727-34.

21. Shahmiri R, Aarts JM, Bennani V, Atieh MA, Swain MV. Finite element

CONCLUSIONS analysis of an implant-assisted removable partial denture. J Prosthodont

2013;22:550-5.

22. Geng JP, Tan KB, Liu GR. Application of finite element analysis in

Within the limitation of this 3D finite element analysis, implant dentistry: a review of the literature. J Prosthet Dent 2001;85:

the following conclusions were drawn: 585-98.

23. Mericske-Stern R, Assal P, Mericske E, Burgin W. Occlusal force and oral

1. The highest stress was concentrated on the implants tactile sensibility measured in partially edentulous patients with ITI implants.

Int J Oral Maxillofac Implants 1995;10:345-53.

in both IARPDs. 24. Baggi L, Cappelloni I, Di Girolamo M, Maceri F, Vairo G. The influence of

2. Because the stress from the occlusal loading was implant diameter and length on stress distribution of osseointegrated im-

plants related to crestal bone geometry: a three-dimensional finite element

concentrated primarily on the implant when im- analysis. J Prosthet Dent 2008;100:422-31.

plants were used for the RPD abutments, more 25. Lang LA, Kang B, Wang RF, Lang BR. Finite element analysis to determine

implant preload. J Prosthet Dent 2003;90:539-46.

considerations concerning the RPD design and the 26. Anitua E, Tapia R, Luzuriaga F, Orive G. Influence of implant length,

number or location of the implant are necessary. diameter, and geometry on stress distribution: a finite element analysis. Int J

Periodontics Restorative Dent 2010;30:89-95.

27. Murakami N, Wakabayashi N. Finite element contact analysis as a critical

technique in dental biomechanics: a review. J Prosthodont Res 2014;58:

REFERENCES 92-101.

28. Torcato LB, Pellizzer EP, Verri FR, Falcón-Antenucci RM, Santiago Júnior JF,

1. Mentag PJ, Kosinski TF, Sowinski LL. Fabrication of a maxillary prosthesis de Faria Almeida DA. Influence of parafunctional loading and prosthetic

using dental implants and an “overdenture” attachment. A clinical report. connection on stress distribution: a 3D finite element analysis. J Prosthet

J Prosthet Dent 1991;65:331-5. Dent 2015;114:644-51.

2. Zitzmann NU, Marinello CP. Treatment plan for restoring the edentulous 29. Topkaya T, Solmaz MY. The effect of implant number and position on the

maxilla with implant-supported restorations: removable overdenture versus stress behavior of mandibular implant retained overdentures: a three-

fixed partial denture design. J Prosthet Dent 1999;82:188-96. dimensional finite element analysis. J Biomech 2015;48:2102-9.

3. Chronopoulos V, Sarafianou A, Kourtis S. The use of dental implants in 30. Nakamura Y, Kanbara R, Ochiai KT, Tanaka Y. A finite element evaluation of

combination with removable partial dentures: a case report. J Esthet Restor mechanical function for 3 distal extension partial dental prosthesis designs

Dent 2008;20:355-64. with a 3-dimensional nonlinear method for modeling soft tissue. J Prosthet

4. Sato M, Suzuki Y, Kurihara D, Shimpo H, Ohkubo C. Effect of implant Dent 2014;112:972-80.

support on mandibular distal extension removable partial dentures: rela- 31. Montgomery J. Methods for modeling bolts in the bolted joint. Paper pre-

tionship between denture supporting area and stress distribution. sented at: ANSYS User’s Conference 2002. Available at: http://server2.docfoc.

J Prosthodont Res 2013;572:109-12. com/uploads/Z2015/12/22/nLEFnyDdtB/3f012e1c82f1b6f7f034b0c2fcd09d06.

5. Jang Y, Emtiaz S, Tarnow DP. Single implant-supported crown used as an pdf. Accessed November 7, 2016.

abutment for a removable cast partial denture: a case report. Implant Dent 32. Wang HY, Zhang YM, Yao D, Chen JH. Effects of rigid and nonrigid

1998;7:199-204. extracoronal attachments on supporting tissues in extension base partial

Eom et al THE JOURNAL OF PROSTHETIC DENTISTRY

742 Volume 117 Issue 6

removable dental prostheses: a nonlinear finite element study. J Prosthet 38. Sano M, Ikebe K, Yang TC, Maeda Y. Biomechanical rationale for six splinted

Dent 2011;105:338-46. implants in bilateral canine, premolar, and molar regions in an edentulous

33. O’Mahony AM, Williams JL, Spencer P. Anisotropic elasticity of cortical and maxilla. Implant Dent 2012;21:220-4.

cancellous bone in the posterior mandible increases peri-implant stress and

strain under oblique loading. Clin Oral Implants Res 2001;12:648-57.

34. Van Staden RC, Guan H, Loo YC. Application of the finite element method in Corresponding author:

dental implant research. Comput Methods Biomech Biomed Engin 2006;9:257-70. Dr Ho-Beom Kwon

35. Himmlova L, Dostalova T, Kacovsky A, Konvickova S. Influence of implant Dental Research Institute and Department of Prosthodontics

length and diameter on stress distribution: a finite element analysis. School of Dentistry

J Prosthet Dent 2004;91:20-5. Seoul National University

36. Kim Y, Oh TJ, Misch CE, Wang HL. Occlusal considerations in implant 101, Daehak-ro, Jongno-gu, Seoul 110-744

therapy: clinical guidelines with biomechanical rationale. Clin Oral Implants REPUBLIC OF KOREA

Res 2005;16:26-35. Email: proskwon@snu.ac.kr

37. LaVere AM, Krol AJ. Selection of a major connector for the extension-base

removable partial denture. J Prosthet Dent 1973;30:102-5. Copyright © 2016 by the Editorial Council for The Journal of Prosthetic Dentistry.

Noteworthy Abstracts of the Current Literature

Grinding damage assessment for CAD-CAM restorative materials

Curran P, Cattani-Lorente M, Anselm Wiskott HW, Durual S, Scherrer SS

Dent Mater 2017;33:294-308

Objectives. To assess surface/subsurface damage after grinding with diamond discs on five CAD-CAM restorative

materials and to estimate potential losses in strength based on crack size measurements of the generated damage.

Methods. The materials tested were: Lithium disilicate (LIT) glass-ceramic (e.max CAD), leucite glass-ceramic (LEU)

(Empress CAD), feldspar ceramic (VM2) (Vita Mark II), feldspar ceramic-resin infiltrated (EN) (Enamic) and a

composite reinforced with nano ceramics (LU) (Lava Ultimate). Specimens were cut from CAD-CAM blocs and

pair-wise mirror polished for the bonded interface technique. Top surfaces were ground with diamond discs of

respectively 75, 54 and 18 mm. Chip damage was measured on the bonded interface using SEM. Fracture mechanics

relationships were used to estimate fracture stresses based on average and maximum chip depths assuming these to

represent strength limiting flaws subjected to tension and to calculate potential losses in strength compared to

manufacturer’s data.

Results. Grinding with a 75 mm diamond disc induced on a bonded interface critical chips averaging 100 mm with a

potential strength loss estimated between 33% and 54% for all three glass-ceramics (LIT, LEU, VM2). The softer

materials EN and LU were little damage susceptible with chips averaging respectively 26 mm and 17 mm with no loss in

strength. Grinding with 18 mm diamond discs was still quite detrimental for LIT with average chip sizes of 43 mm and a

potential strength loss of 42%.

Significance. It is essential to understand that when grinding glass-ceramics or feldspar ceramics with diamond discs

surface and subsurface damage are induced which have the potential of lowering the strength of the ceramic. Careful

polishing steps should be carried out after grinding especially when dealing with glass-ceramics.

Reprinted with permission of The Academy of Dental Materials.

THE JOURNAL OF PROSTHETIC DENTISTRY Eom et al

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- 1.1 Original ResearchDocument8 pages1.1 Original ResearchNovita RPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Jhfdbcsss TFVCBVC FFHGHDocument5 pagesJhfdbcsss TFVCBVC FFHGHNovita RPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- 1 s2.0 S0022391314003606 MainDocument4 pages1 s2.0 S0022391314003606 MainNovita RPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- KKJKKKDocument10 pagesKKJKKKNovita RPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 1.1 Original ResearchDocument8 pages1.1 Original ResearchNovita RPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- JJHVBBDocument3 pagesJJHVBBNovita RPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- 1.1 Original ResearchDocument8 pages1.1 Original ResearchNovita RPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 1.1 Original ResearchDocument8 pages1.1 Original ResearchNovita RPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Design of A Removable Partial Denture: by Taseef Hasan Farook, BDS (Final Year, University of Dhaka)Document70 pagesDesign of A Removable Partial Denture: by Taseef Hasan Farook, BDS (Final Year, University of Dhaka)Novita RPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- 96 130 1 SM PDFDocument6 pages96 130 1 SM PDFNovita RPas encore d'évaluation

- Aceh 2 PDFDocument1 pageAceh 2 PDFNovita RPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Podj 38Document4 pagesPodj 38Mohamed AliPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Biomechanics of Oral Mucosa: ReviewDocument20 pagesBiomechanics of Oral Mucosa: ReviewNovita RPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 1.1 Original ResearchDocument8 pages1.1 Original ResearchNovita RPas encore d'évaluation

- HKGFDDocument4 pagesHKGFDNovita RPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Removable Prosthodontics: Complete Denture Fabrication MethodsDocument1 pageRemovable Prosthodontics: Complete Denture Fabrication MethodsNovita RPas encore d'évaluation

- OgfdgDocument4 pagesOgfdgNovita RPas encore d'évaluation

- Case Report: A Technique For Removing Implant-Retained Denture: Direct Relining ComplicationDocument4 pagesCase Report: A Technique For Removing Implant-Retained Denture: Direct Relining ComplicationNovita RPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- KkakakaDocument5 pagesKkakakaNovita RPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- KKJKKKDocument10 pagesKKJKKKNovita RPas encore d'évaluation

- VITA 1511GB A Guide To Complete Denture Prosthetics PS EN V00 PDFDocument150 pagesVITA 1511GB A Guide To Complete Denture Prosthetics PS EN V00 PDFLaizaEuniceT.Monte0% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Fabrication of Combined Prosthesis With 6d86091e - 2 PDFDocument7 pagesFabrication of Combined Prosthesis With 6d86091e - 2 PDFNovita RPas encore d'évaluation

- V8I9A4Document5 pagesV8I9A4Novita RPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Analysis of Variability in The Manufacture of Cr-Co Fixed Partial Dentures by Geometric ComparisonDocument8 pagesAnalysis of Variability in The Manufacture of Cr-Co Fixed Partial Dentures by Geometric ComparisonNovita RPas encore d'évaluation

- Zaleske NC MC Article - 2Document2 pagesZaleske NC MC Article - 2Novita RPas encore d'évaluation

- 1 s2.0 S0022391314003606 MainDocument4 pages1 s2.0 S0022391314003606 MainNovita RPas encore d'évaluation

- Simplified Fabrication of An Implant-Supported Framework With Luted Abutment CylindersDocument5 pagesSimplified Fabrication of An Implant-Supported Framework With Luted Abutment CylindersNovita RPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Simplified Fabrication of An Implant-Supported Framework With Luted Abutment CylindersDocument5 pagesSimplified Fabrication of An Implant-Supported Framework With Luted Abutment CylindersNovita RPas encore d'évaluation

- Bgcse Physics Paper 1 2017Document17 pagesBgcse Physics Paper 1 2017Katlego LebekwePas encore d'évaluation

- Improvement of Soil Properties by Using Waste PlasticDocument6 pagesImprovement of Soil Properties by Using Waste PlasticnehamyaPas encore d'évaluation

- ECE 6123 Advanced Signal Processing: 1 FiltersDocument9 pagesECE 6123 Advanced Signal Processing: 1 FiltersJanaki KPas encore d'évaluation

- WLP Creative WritingDocument12 pagesWLP Creative Writingsheena balaisPas encore d'évaluation

- Conduction A Long Simple BarDocument5 pagesConduction A Long Simple Bardiaa ibrahimPas encore d'évaluation

- GasCalc Module enDocument2 pagesGasCalc Module ensppramPas encore d'évaluation

- MALVINO & BATES Chapter 08Document29 pagesMALVINO & BATES Chapter 08Reece RevosaPas encore d'évaluation

- Supercritical PlantDocument71 pagesSupercritical PlantNitish KumarPas encore d'évaluation

- H Beam Weight-TWC PDFDocument1 pageH Beam Weight-TWC PDFSankar CdmPas encore d'évaluation

- IPT2020 Problem01 - CumulativeCannon MIPTDocument31 pagesIPT2020 Problem01 - CumulativeCannon MIPT林凱文Pas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Acara 4 GranulometriDocument63 pagesAcara 4 GranulometriHana Riwu KahoPas encore d'évaluation

- Bp8-Tension: User Defined Applied Forces at Interface Basic DimensionsDocument4 pagesBp8-Tension: User Defined Applied Forces at Interface Basic DimensionsMallesh NenkatPas encore d'évaluation

- List of Least Learned Competencies With Interventions ConductedDocument2 pagesList of Least Learned Competencies With Interventions ConductedGerry Chel-Nunez Awa-Laurente Aga100% (1)

- Life Cycle of Star LabDocument19 pagesLife Cycle of Star LabanicitoaPas encore d'évaluation

- Guide Du Soudage Des Aciers InoxydablesDocument92 pagesGuide Du Soudage Des Aciers InoxydablesFares Hayder100% (1)

- FMP-401 2021-Ag-8243Document4 pagesFMP-401 2021-Ag-8243ABdullah ButtPas encore d'évaluation

- PEX250í 1200 Instruction ManualDocument10 pagesPEX250í 1200 Instruction ManualSebastian Aguila RaipanPas encore d'évaluation

- MathsDocument2 pagesMathsAditya Singh PatelPas encore d'évaluation

- AC O& M City Mall Version 1.0Document12 pagesAC O& M City Mall Version 1.0yewminyun6098Pas encore d'évaluation

- Vib PDFDocument2 pagesVib PDFprasanna1990Pas encore d'évaluation

- NEXAFS Tutorial Review ArticleDocument12 pagesNEXAFS Tutorial Review ArticleAngelique LusuanPas encore d'évaluation

- Dry Gas Seal Systems - Part 2Document3 pagesDry Gas Seal Systems - Part 2Jai-Hong ChungPas encore d'évaluation

- JL Torero - Buoyancy Effects On Smoldering of Polyurethane FoamDocument229 pagesJL Torero - Buoyancy Effects On Smoldering of Polyurethane FoamIsraelPas encore d'évaluation

- UNU - Geothermal Well TestingDocument30 pagesUNU - Geothermal Well TestingZakariyaPas encore d'évaluation

- Earth and Life Science Copy (Repaired)Document39 pagesEarth and Life Science Copy (Repaired)Aaron Manuel MunarPas encore d'évaluation

- Leaded Receptacle Switch BrochureDocument18 pagesLeaded Receptacle Switch BrochureArturo De Asis SplushPas encore d'évaluation

- Report 3 Schlieren Visualisation of Over-Expanded NozzleDocument6 pagesReport 3 Schlieren Visualisation of Over-Expanded NozzleAbhishek DhaknePas encore d'évaluation

- Wopho 13 Prob7-Final PDFDocument3 pagesWopho 13 Prob7-Final PDFPeter JonesPas encore d'évaluation

- Method To Make Yttrium-Barium-Copper Oxide Superconductor (YBCO)Document2 pagesMethod To Make Yttrium-Barium-Copper Oxide Superconductor (YBCO)RUBYPas encore d'évaluation

- Performance Evaluation On Low-Crest Breakwater at North Coast of Java IslandDocument12 pagesPerformance Evaluation On Low-Crest Breakwater at North Coast of Java IslandSobariMuchlisPas encore d'évaluation

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideD'Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- The Laws of Thermodynamics: A Very Short IntroductionD'EverandThe Laws of Thermodynamics: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionD'EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- Aerodynamics for Engineering StudentsD'EverandAerodynamics for Engineering StudentsÉvaluation : 5 sur 5 étoiles5/5 (5)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseD'EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseÉvaluation : 4.5 sur 5 étoiles4.5/5 (51)