Académique Documents

Professionnel Documents

Culture Documents

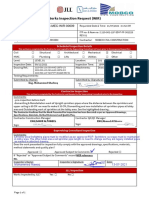

M & E QC Plan - 0063b REV. 0

Transféré par

Anonymous 3eHGEDbxTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

M & E QC Plan - 0063b REV. 0

Transféré par

Anonymous 3eHGEDbxDroits d'auteur :

Formats disponibles

XYZ Page 1 of 4

QC~PLAN.

Project No. & Name:

Name of Client/ Consultant: Doc. No. M & E QC~P

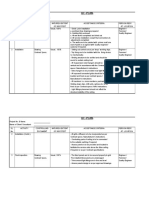

SL ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE CRITERIA PERSON RESP.

No. DOCUMENT OF INSP./TEST AT LOCATION

1 Installation Drawing Visual, 100% - Establish position of pipe inlets with respect Engineer/

Contract Specs. to fixtures Foremen/

Mfr.'s instructions - Pipe supports provided as per the horizontal Quality Engineer

BS 8000 Part 13 & vertical spacing requirement / drawing

- Pipes laid to uniform / specified gradient

- Clean outs provided at change of direction of

flow

- Access cover provided in walls, ducts &

ceilings where access caps are fixed

- Fire couplers provided where pipe passes

from ceilings and walls from plant room

- Pipe end covered while unattended

2 Bending (for metal Drawing Visual, 100% - Rippling, throating & reduction in bore Engineer/

pipes) Contract Specs. diameter avoided while bending Foremen/

BS 8000 Part 13 Quality Engineer

3 Pipe supports Drawing Visual, 100% - Fixed not greater than as follows: Engineer/

Contract Specs. Pipe dia Vertically Horizontally Foremen/

Mfr.'s instructions 35 mm 1.2 m 0.5 m Quality Engineer

BS 8000 Part 13 40 mm 1.2 m 0.5 m

55 mm 1.2 m 0.9 m

110 mm 1.8 m 0.9 m

- Pipe gradient

Pipe Dia Gradient

35 mm

40 mm 1 : 40

55 mm

75 mm 1 : 60

110 mm 1 : 100

388038828.xls Date: January 26, 2001

XYZ Page 2 of 4

QC~PLAN.

Project No. & Name:

Name of Client/ Consultant: Doc. No. M & E QC~P

SL ACTIVITY CONTROLLING NATURE & EXTENT ACCEPTANCE CRITERIA PERSON RESP.

No. DOCUMENT OF INSP./TEST AT LOCATION

4 Suspended floor drains Drawing Visual, 100% - Additional pipe supports provided Engineer/

Contract Specs. - Pipes dropping from plant rooms fire coupler Foremen/

Mfr.'s instructions provided Quality Engineer

BS 8000 Part 13 - Clean out provision provided

5 Pipe Jointing Drawing Visual, 100% Type Jointing Engineer/

Contract Specs. Cast iron pipes Cold / lead caulking Foremen/

Galvanized

BS 8000 Part 13 pipes Bolted flanges / gaskets Quality Engineer

Copper pipe

Capillary soldering

- UPVC Compression fittings using

ring seals & solvent cement

Polyethylene & Compression fittings using

Polypropylene ring seals by fusion welding

- Pipe ends straight cut square, chamfered, burr

removed before jointing using rubber seal rings

- Spigot end & socket end cleaned while using

solvent (for UPVC Pipes)

- Follow pipe manufacturer's instructions & use

recommended lubricants / solvents

6 Pipe sleeves Drawing Visual, 100% - Pipes crossing through beams / walls / floors Engineer/

Contract Specs. shall be provided sleeves of same material Foremen/

BS 8000 Part 13 Quality Engineer

7 Inspection & Testing Drawing Leak Test , 100% - Water testing done for ordinary pipe work. Engineer/

Contract Specs. Static head not to exceed 2 m & without loss Foremen/

BS 8000 Part 13 for 15 minutes Quality Engineer

Work Location: Quality Engineer: Engineer / Foremen:

Remarks: Date: Date:

388038828.xls Date: January 26, 2001

XYZ Page 3 of 4

QC~PLAN.

Above Ground Drainage

Doc. No. M & E QC~Plan- 063b/ REV. 0

RECORD

Above Ground Drainage

M & E QC~Plan-

063b-01/ REV. 0

Above Ground Drainage

M & E QC~Plan-

063b-01/ REV. 0

Above Ground Drainage

M & E QC~Plan-

063b-01/ REV. 0

388038828.xls Date: January 26, 2001

XYZ Page 4 of 4

QC~PLAN.

Above Ground Drainage

Doc. No. M & E QC~Plan- 063b/ REV. 0

RECORD

Above Ground Drainage

M & E QC~Plan-

063b-01/ REV. 0

Above Ground Drainage

M & E QC~Plan-

063b-01/ REV. 0

Above Ground Drainage

M & E QC~Plan-

063b-01/ REV. 0

Above Ground Drainage

M & E QC~Plan-

063b-01/ REV. 0

388038828.xls Date: January 26, 2001

Vous aimerez peut-être aussi

- Vinyl Flooring InstallationDocument51 pagesVinyl Flooring InstallationAnonymous 3eHGEDbx100% (1)

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument5 pages5 - Tank Itp - Inspection & Test Plan For TanksmandiPas encore d'évaluation

- BOQ-Mechanical - Option 2 (G+1+2)Document9 pagesBOQ-Mechanical - Option 2 (G+1+2)psn_kylmPas encore d'évaluation

- M & e MST - 038 Rev. 0Document3 pagesM & e MST - 038 Rev. 0Anonymous 3eHGEDbxPas encore d'évaluation

- Cable Pulling and Laying Inspection Checklist: P0022-CS-E-004Document1 pageCable Pulling and Laying Inspection Checklist: P0022-CS-E-004nayumPas encore d'évaluation

- Acoustical AssembliesDocument40 pagesAcoustical AssembliesBrent SmithPas encore d'évaluation

- Optial Fiber Cable Inst and Splicing ProcedureDocument8 pagesOptial Fiber Cable Inst and Splicing ProcedureTalha AltafPas encore d'évaluation

- 5.piping SeminarDocument85 pages5.piping Seminarvg100% (2)

- DCE Alumni BookDocument242 pagesDCE Alumni BookYaman AroraPas encore d'évaluation

- Sample - Pipe Manufacturer Data SheetDocument22 pagesSample - Pipe Manufacturer Data SheetAmal KaPas encore d'évaluation

- Pressure Vessel Fabrication & Inspection: Poyyara ConsultantsDocument137 pagesPressure Vessel Fabrication & Inspection: Poyyara ConsultantsPratik VashiPas encore d'évaluation

- Cable Tray Inspection ListDocument1 pageCable Tray Inspection ListTreesa Archnana100% (1)

- Inspection Test PlanDocument36 pagesInspection Test PlanShahid IqbalPas encore d'évaluation

- ELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Document2 pagesELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Muhammad Irfan100% (1)

- Column BasesDocument29 pagesColumn BasesNavi Rengarajan100% (4)

- Design Optimization of GFRP Pole Structures Using Finite Element Analysis PDFDocument8 pagesDesign Optimization of GFRP Pole Structures Using Finite Element Analysis PDFAhmed TahaPas encore d'évaluation

- ADDC Electricity Wiring Regulations - Mar.2014Document276 pagesADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHPas encore d'évaluation

- 200mm 250mm 300 MM: Project Name Location Bill No. - 00 (Rev. 0) Consultant Contractor Buildiong Name DATEDocument2 pages200mm 250mm 300 MM: Project Name Location Bill No. - 00 (Rev. 0) Consultant Contractor Buildiong Name DATEganesh gundPas encore d'évaluation

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesD'EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesÉvaluation : 4 sur 5 étoiles4/5 (1)

- NQA ISO 45001 Implementation GuideDocument36 pagesNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- Shires BrochureDocument52 pagesShires BrochureAnonymous 3eHGEDbxPas encore d'évaluation

- The Controversy of Icu and IcsDocument2 pagesThe Controversy of Icu and IcsUsama AhmedPas encore d'évaluation

- SACEP - RTCC - Delivery #0971291-01Document9 pagesSACEP - RTCC - Delivery #0971291-01Ryan condePas encore d'évaluation

- M & E QC Plan - 01a REV. 0Document4 pagesM & E QC Plan - 01a REV. 0Anonymous 3eHGEDbxPas encore d'évaluation

- M & E QC Plan - 0062 REV. 0Document4 pagesM & E QC Plan - 0062 REV. 0Anonymous 3eHGEDbxPas encore d'évaluation

- 051 GlazingDocument2 pages051 GlazingAnonymous 3eHGEDbxPas encore d'évaluation

- FF Boq R1Document3 pagesFF Boq R1Mahmoud A. HafeezPas encore d'évaluation

- Method Statement For Fire Rated Coating WorksDocument21 pagesMethod Statement For Fire Rated Coating WorksSudhiv civilPas encore d'évaluation

- Works Inspection Request (WIR) : KAFD-A1-501-MCC-MEC-WIR-00609Document8 pagesWorks Inspection Request (WIR) : KAFD-A1-501-MCC-MEC-WIR-00609Hazem AbdelmonemPas encore d'évaluation

- BAUER Response - AGL351. OPS. RFA-441 - SS Railings Shop Drawing AR. 2022 11 25Document25 pagesBAUER Response - AGL351. OPS. RFA-441 - SS Railings Shop Drawing AR. 2022 11 25MarielPas encore d'évaluation

- ESACPC-3K661-AB (Tie Rod Boot Spec)Document14 pagesESACPC-3K661-AB (Tie Rod Boot Spec)Francesco VignaliPas encore d'évaluation

- 018 Insitu FlooringDocument4 pages018 Insitu FlooringAnonymous 3eHGEDbxPas encore d'évaluation

- Goa LHDocument6 pagesGoa LHtnd tbecPas encore d'évaluation

- 0183-Itp-04 R1Document2 pages0183-Itp-04 R1Belal hassanPas encore d'évaluation

- TFP620 05 2014Document8 pagesTFP620 05 2014Furkan KadıPas encore d'évaluation

- 4024.SBI LHO. Check List For HVAC Works.22.11.21Document24 pages4024.SBI LHO. Check List For HVAC Works.22.11.21Bhavik GajjarPas encore d'évaluation

- PVC vs. Polypropylene (PP) Sewer Pipe: Proven Performance Makes PVC The Right ChoiceDocument2 pagesPVC vs. Polypropylene (PP) Sewer Pipe: Proven Performance Makes PVC The Right ChoiceRaul ArmendarizPas encore d'évaluation

- Inspection 4 Industry LLC: GeneralDocument31 pagesInspection 4 Industry LLC: GeneralKaliya PerumalPas encore d'évaluation

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadPas encore d'évaluation

- Dacon Corrossion Under Support PresentationDocument22 pagesDacon Corrossion Under Support PresentationMohammed Ilyas MohiuddinPas encore d'évaluation

- Sub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionDocument3 pagesSub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionJosue FishPas encore d'évaluation

- Work Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of InspectionDocument10 pagesWork Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of Inspectionamith_kmPas encore d'évaluation

- NS2 DH01 P0ZEN 740017 ITP For PulverizerDocument100 pagesNS2 DH01 P0ZEN 740017 ITP For PulverizerBui van DiepPas encore d'évaluation

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderPas encore d'évaluation

- Electrical Installation ManualDocument142 pagesElectrical Installation ManualEi Ei PhyoPas encore d'évaluation

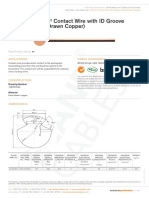

- 107mm2 Contact Wire Id Groove Hard Drawn CopperDocument1 page107mm2 Contact Wire Id Groove Hard Drawn CopperandreflsoaresPas encore d'évaluation

- QC - 16 Guided Bend Test.Document3 pagesQC - 16 Guided Bend Test.mahendra100% (1)

- Resubmit Re-Lgm-011 Tds of Street Light Pole - ApprovedDocument3 pagesResubmit Re-Lgm-011 Tds of Street Light Pole - Approvedsujit naikwadiPas encore d'évaluation

- MS - Kaveri IDEMI PDFDocument16 pagesMS - Kaveri IDEMI PDFAnjum AttarPas encore d'évaluation

- Neom Nwa Dat 2021 021 Air ValveDocument5 pagesNeom Nwa Dat 2021 021 Air ValveES RAAPas encore d'évaluation

- MS - RacewaysDocument3 pagesMS - Racewaysthamizharasan11Pas encore d'évaluation

- Product CAT BLMT - DatasheetDocument8 pagesProduct CAT BLMT - DatasheetiamlpPas encore d'évaluation

- Jay Mata Di CHSLDocument6 pagesJay Mata Di CHSLrohitbhosle5971203Pas encore d'évaluation

- NS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CDocument8 pagesNS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CAnh VàngPas encore d'évaluation

- NEW PLUMBING package 03.03 - Rev.02 - 20200423 - 对分包商Document4 pagesNEW PLUMBING package 03.03 - Rev.02 - 20200423 - 对分包商Ahmed AtefPas encore d'évaluation

- Solar QutationDocument1 pageSolar Qutationarpit patelPas encore d'évaluation

- TAPPI TIP-0402-21 Ultrasonic Performance Technician ..Document8 pagesTAPPI TIP-0402-21 Ultrasonic Performance Technician ..a_parrat100% (1)

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOEPas encore d'évaluation

- 021-Suspended CeilingDocument4 pages021-Suspended CeilingAnonymous 3eHGEDbxPas encore d'évaluation

- Column Laping at Level + 6000mm: School NameDocument5 pagesColumn Laping at Level + 6000mm: School NameSujit RasailyPas encore d'évaluation

- D 2729 - 96 - Rdi3mjktukve PDFDocument6 pagesD 2729 - 96 - Rdi3mjktukve PDFAndre CasteloPas encore d'évaluation

- General Notes: Rebar Details For Girl's Bed Room SlabDocument1 pageGeneral Notes: Rebar Details For Girl's Bed Room SlabMukhtar Case2022Pas encore d'évaluation

- PlugDocument2 pagesPlugJalal AlbadriPas encore d'évaluation

- ITP For BLOCKWORKDocument4 pagesITP For BLOCKWORKimkashifsaleemPas encore d'évaluation

- M & E QC Plan - 037 REV. 0Document2 pagesM & E QC Plan - 037 REV. 0Anonymous 3eHGEDbxPas encore d'évaluation

- ITP Service PL 001 RWPDocument1 pageITP Service PL 001 RWPDedi KartiwaPas encore d'évaluation

- Mill Certificate - Neltex SWG SDR 34Document2 pagesMill Certificate - Neltex SWG SDR 34Jose Fermin SantiagoPas encore d'évaluation

- Aisc s340 Metric Properties of StructuralDocument49 pagesAisc s340 Metric Properties of StructuraltgrimleyPas encore d'évaluation

- Abu Dhabi Transmission and Despatch CompanyDocument113 pagesAbu Dhabi Transmission and Despatch CompanyranasherdilPas encore d'évaluation

- Abu Dhabi Transmission and Despatch CompanyDocument113 pagesAbu Dhabi Transmission and Despatch CompanyranasherdilPas encore d'évaluation

- Allowable Stress Design-Simple Shear ConnectionsDocument64 pagesAllowable Stress Design-Simple Shear ConnectionsAnonymous 3eHGEDbxPas encore d'évaluation

- Historical Record Dimensions and PropertiesDocument145 pagesHistorical Record Dimensions and PropertiesAnonymous 3eHGEDbxPas encore d'évaluation

- Elec Wiring Regs 2007 Rev 01Document240 pagesElec Wiring Regs 2007 Rev 01Anonymous 3eHGEDbxPas encore d'évaluation

- HScode ENDocument384 pagesHScode ENAbid KasanaPas encore d'évaluation

- MOUNT - Fixing PlatesDocument8 pagesMOUNT - Fixing PlatesAnonymous 3eHGEDbxPas encore d'évaluation

- National Gypsum Steel StudPartitionsDocument9 pagesNational Gypsum Steel StudPartitionsAnonymous 3eHGEDbxPas encore d'évaluation

- HScode ENDocument384 pagesHScode ENAbid KasanaPas encore d'évaluation

- Pub 100427Document5 pagesPub 100427Engr Nabeel AhmadPas encore d'évaluation

- M & e MST - 037 Rev. 0Document2 pagesM & e MST - 037 Rev. 0Anonymous 3eHGEDbxPas encore d'évaluation

- 13 Occupational Safety and HealthDocument45 pages13 Occupational Safety and HealthVi VekPas encore d'évaluation

- Acoustic Brochure PDFDocument6 pagesAcoustic Brochure PDFAnonymous 3eHGEDbxPas encore d'évaluation

- Purpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingDocument4 pagesPurpose: Method Statement M & E No.: M & E Mst-004/ Rev 0 Page 1 of 4 Title: LV Switchgear Installation and TestingAnonymous 3eHGEDbxPas encore d'évaluation

- Steel Window Service: Scale Drawn CheckedDocument1 pageSteel Window Service: Scale Drawn CheckedAnonymous 3eHGEDbxPas encore d'évaluation

- M & e MST - 036 Rev. 0Document3 pagesM & e MST - 036 Rev. 0Anonymous 3eHGEDbxPas encore d'évaluation

- M & e MST - 039 Rev. 0Document3 pagesM & e MST - 039 Rev. 0Anonymous 3eHGEDbxPas encore d'évaluation

- M & E-Mst-0007Document5 pagesM & E-Mst-0007Anonymous 3eHGEDbxPas encore d'évaluation

- Xyz Company: PurposeDocument3 pagesXyz Company: PurposeAnonymous 3eHGEDbxPas encore d'évaluation

- M & E-Mst-0006Document7 pagesM & E-Mst-0006Anonymous 3eHGEDbxPas encore d'évaluation

- Xyz Company: PurposeDocument3 pagesXyz Company: PurposeAnonymous 3eHGEDbxPas encore d'évaluation

- M & E-Mst-008Document5 pagesM & E-Mst-008Anonymous 3eHGEDbxPas encore d'évaluation

- Xyz Company: PurposeDocument5 pagesXyz Company: PurposeAnonymous 3eHGEDbxPas encore d'évaluation

- Lesson 1 - Basic Concept of DesignDocument32 pagesLesson 1 - Basic Concept of DesignSithara BandaraPas encore d'évaluation

- ZHA - Arum Instillation and Exhibition Venice Architecture BiennaleDocument2 pagesZHA - Arum Instillation and Exhibition Venice Architecture BiennaleGiuseppe PerriPas encore d'évaluation

- The City of Winnipeg - Water & Waste Department - Electrical Design Guide (2013) PDFDocument158 pagesThe City of Winnipeg - Water & Waste Department - Electrical Design Guide (2013) PDFadd8742Pas encore d'évaluation

- Et ZC413Document3 pagesEt ZC413Chirag BhanvadiaPas encore d'évaluation

- AcronymsDocument3 pagesAcronymsNestor CzerwackiPas encore d'évaluation

- Static Analysis and Size Optimization For The BedDocument7 pagesStatic Analysis and Size Optimization For The Bedalaalao2000Pas encore d'évaluation

- Engineering ManagementDocument21 pagesEngineering ManagementRYAN MAGBANUAPas encore d'évaluation

- Annex 10a Wet Heating Systems - Domestic - Updated 4sept11Document20 pagesAnnex 10a Wet Heating Systems - Domestic - Updated 4sept11starykltPas encore d'évaluation

- 1 - Harish Kumar B Dept. of Mechanical Engineering, CETDocument19 pages1 - Harish Kumar B Dept. of Mechanical Engineering, CETKowsik Nandagopan DPas encore d'évaluation

- BitucellDocument2 pagesBitucellzultrsb689Pas encore d'évaluation

- Fatigue IDocument22 pagesFatigue IamdevaPas encore d'évaluation

- Holibajoli ARMAC Quotation VidyutDocument3 pagesHolibajoli ARMAC Quotation VidyutLalit SharmaPas encore d'évaluation

- R&D Division BrochureDocument4 pagesR&D Division BrochureShai WeissPas encore d'évaluation

- TRDC ProfileDocument6 pagesTRDC ProfilePrespective innovationPas encore d'évaluation

- A MATLAB-Based Application For Modeling and Simulation of Solar Slurry Photocatalytic Reactors For Environmental ApplicationsDocument17 pagesA MATLAB-Based Application For Modeling and Simulation of Solar Slurry Photocatalytic Reactors For Environmental ApplicationsMiume MewPas encore d'évaluation

- Cameron Kashani CVDocument2 pagesCameron Kashani CVCameron KashaniPas encore d'évaluation

- 1 Hyundai Elevator ProfileDocument10 pages1 Hyundai Elevator ProfileAndi Muhammad Nur PutraPas encore d'évaluation

- T. K. M. College of Engineering KOLLAM, KERALA - 691 005: Preparatory Classes For Electrical Supervisor LicenseDocument2 pagesT. K. M. College of Engineering KOLLAM, KERALA - 691 005: Preparatory Classes For Electrical Supervisor LicenseAkhil SurendranPas encore d'évaluation

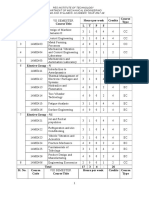

- Btech 4th Year Me Pesit Batch 2014-18Document25 pagesBtech 4th Year Me Pesit Batch 2014-18api-294538209Pas encore d'évaluation

- Tech-2: Technical Proposal For General Consultant For Chennai Metro Rail Phase-2 Project - Corridor 4Document4 pagesTech-2: Technical Proposal For General Consultant For Chennai Metro Rail Phase-2 Project - Corridor 4Samridh GuptaPas encore d'évaluation

- ASD Perforated Shear Wall PDFDocument5 pagesASD Perforated Shear Wall PDFsyedabdulhannanPas encore d'évaluation

- Johns Hopkins (Chemical Engineering) Personal StatementDocument3 pagesJohns Hopkins (Chemical Engineering) Personal StatementVictor AceroPas encore d'évaluation

- Computer Applications in TextilesDocument2 pagesComputer Applications in Textilesnatarajan1234Pas encore d'évaluation

- History and Evolution of MechatronicsDocument6 pagesHistory and Evolution of MechatronicsZaheer AhamedPas encore d'évaluation

- 2020 - 21 Session Full SyllabusDocument167 pages2020 - 21 Session Full Syllabuskec.abhishek463Pas encore d'évaluation

- Ramesh ResumeDocument3 pagesRamesh ResumeKrishnaswamy GnanasekaranPas encore d'évaluation