Académique Documents

Professionnel Documents

Culture Documents

ACS150 Brosura

Transféré par

KatarinaKostovTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ACS150 Brosura

Transféré par

KatarinaKostovDroits d'auteur :

Formats disponibles

Low voltage AC drives

ABB component drives

ACS150

0.5 to 5 hp / 0.37 to 4 kW

Catalog

ABB component drives

ABB component drives Highlights

ABB component drives are designed to be incorporated into − Worldwide availability through logistical distributors

a wide variety of machines such as mixers, conveyors, fans or − User-friendly LCD control panel and integrated

pumps or anywhere where a fixed speed motor needs to go potentiometer

variable speed motor. − Flexible mounting alternatives

− PID control

The ABB component drives meet the requirements of OEMs, − Integrated EMC filter

machinery builders and panel builders. These drives are − Built-in brake chopper

widely available through the ABB distribution network. The − FlashDrop tool for fast drive commissioning

drives are easy to select and provide a range of built-in

features as standard including PID control, brake chopper,

fixed keypad and speed control potentiometer.

Feature Advantage Benefit

Worldwide availability and service Drives are available worldwide and permanently stocked in four Fast and reliable delivery with dedicated

regions. support to any country in the world.

Dedicated global service and support network that is one of the

largest in the industry.

User-friendly LCD control panel and Clear alphanumeric display. Easy set-up and use. Time savings

integrated potentiometer

Flexible mounting alternatives Screw or DIN rail mounting, sideways or side-by-side One drive type can be used in various

designs, saving installation costs and time

Integrated EMC filter High electromagnetic compatibility Low EMC emissions in selected environments

Built-in brake chopper as standard No need for an external brake chopper Space savings, reduced installation cost

FlashDrop tool Faster and easier drive set up and commissioning for volume Fast, safe and trouble-free parameter setting

manufacturing and maintenance. The FlashDrop tool enables without the need to power-up the drive.

both downloading and uploading drive parameters. Patented.

PID control Varies the drive’s performance according to the need of the Enhances production output, stability and

application. accuracy.

Coated boards Board coating protects the electronics from hazards including Reduces maintenance due to good protection

static discharge and airborne contaminates, including moisture. of electronics components.

2 ABB component drives ACS150 | Catalog

Typical applications

ABB component drives bring speed control benefits to a wide A heat pump system consists of an indoor unit with fan and

variety of applications. an outdoor unit with a compressor and a blower. The heat

pump cools indoor environment by gathering heat from air,

In mixing applications the drive provides high starting torque and transferring the heat to air outside. The outdoor unit uses

which benefits the start of the mixing operation. The silent the compressor and the blower to dissipate the heat. The

operation mode adjusts the switching frequency of the drive cooled air is blown indoors by fans located in the indoor unit.

to a higher level after the high-torque start, resulting in lower Drive allows the user to variably control the cooling power

audible noise. The FlashDrop tool provides a quick and safe based on customer request. AC drives optimizes systems’

way to configure multiple drives for identical mixer applications. energy efficiency and smoothens system operation.

In conveyors the belt speed can be controlled using a drive Fans are used for process cooling and ventilation in industrial,

and a motor. Production lines often have multiple stages, commercial and domestic environments. Using a drive

including conveyors, which need to be efficiently linked with to control air flow enables energy savings compared to

each other to provide high production output. A drive provides mechanical flow control methods. An ABB drive has integrated

smooth start and stop of the conveyor, thereby reducing PID control which provides optimal air flow by adjusting the fan

mechanical stress and lowering maintenance costs. speed based on a given reference value. Compact size and

various mounting methods enable flexible system design.

Catalog | ABB component drives ACS150 3

Ratings, types and dimensions

Type designation Ratings Type designation Frame

In column 4 on the right is the unique reference number that PN PN I2N size

clearly indentifies your drive by power rating and frame size. hp kW A

Once you have selected the type designation, the frame size 1-phase supply voltage 200 to 240 V units

(column 5) can be used to determine the drives dimensions, 0.5 0.37 2.4 ACS150-01U-02A4-2 R0

shown below. 1 0.75 4.7 ACS150-01U-04A7-2 R1

1.5 1.1 6.7 ACS150-01U-06A7-2 R1

2 1.5 7.5 ACS150-01U-07A5-2 R2

Voltages

3 2.2 9.8 ACS150-01U-09A8-2 R2

ACS150 is available in two voltage ranges:

3-phase supply voltage 200 to 240 V units

0.5 0.37 2.4 ACS150-03U-02A4-2 R0

2 = 200 to 240 V 0.75 0.55 3.5 ACS150-03U-03A5-2 R0

4 = 380 to 480 V 1 0.75 4.7 ACS150-03U-04A7-2 R1

1.5 1.1 6.7 ACS150-03U-06A7-2 R1

Insert either “2” or “4”, depending on your chosen voltage, 2 1.5 7.5 ACS150-03U-07A5-2 R1

into the type designation shown on the right. 3 2.2 9.8 ACS150-03U-09A8-2 R2

3-phase supply voltage 380 to 480 V units

Construction 0.5 0.37 1.2 ACS150-03U-01A2-4 R0

0.75 0.55 1.9 ACS150-03U-01A9-4 R0

“01U” and “03U” within the type designation varies depending

1 0.75 2.4 ACS150-03U-02A4-4 R1

on the drive phase. Choose below the one you need.

1.5 1.1 3.3 ACS150-03U-03A3-4 R1

2 1.5 4.1 ACS150-03U-04A1-4 R1

01 = 1-phase 3 2.2 5.6 ACS150-03U-05A6-4 R1

03 = 3-phase 5 4 8.8 ACS150-03U-08A8-4 R1

U = EMC filter disconnected, 60 Hz frequency

(In case the filter is required it can easily be connected.)

X within the type code stands for E or U.

Cabinet-mounted drives (UL open)

Frame IP20 UL open

size H1 H2 H3 W D Weight

in in in in in lb

R0 6.65 7.95 9.41 2.76 5.59 2.5

H1 H2 H3

R1 6.65 7.95 9.41 2.76 5.59 2.9

R2 6.65 7.95 9.41 4.13 5.59 3.3

H1 = Height without fastenings and clamping plate.

H2 = Height with fastenings but without clamping plate.

H3 = Height with fastenings and clamping plate. D

W = Width W

D = Depth

Wall-mounted drives (NEMA 1)

Frame NEMA 1

size H4 H5 W D Weight

in in in in lb

R0 10.12 11.02 2.76 5.59 3.3

H4 H5

R1 10.12 11.02 2.76 5.59 3.75

R2 10.12 11.1 4.13 5.59 4.2

H4 = Height with fastenings and NEMA 1 connection box.

H5 = Height with fastenings, NEMA 1 connection box and hood.

W = Width

D

D = Depth

W

4 ABB component drives ACS150 | Catalog

Technical data

Mains connection Programmable control connections

Voltage and power range 1-phase, 200 to 240 V ± 10% One analog input

0.5 to 3 hp (0.37 to 2.2 kW) Voltage signal 0 (2) to 10 V, Rin > 312 kΩ

3-phase, 200 to 240 V ± 10% Current signal 0 (4) to 20 mA, R in = 100 Ω

0.5 to 3 hp (0.37 to 2.2 kW) Potentiometer reference value 10 V ± 1% max. 10 mA, R < 10 kΩ

3-phase, 380 to 480 V ± 10% Resolution 0.1%

0.5 to 5 hp (0.37 to 4 kW) Accuracy ± 2%

Frequency 48 to 63 Hz Auxiliary voltage 24 V DC ± 10%, max. 200 mA

Motor connection Five digital inputs 12 to 24 V DC with internal or external

Voltage supply, PNP and NPN, pulse train

3-phase, from 0 to Usupply

0 to 16 kHz

Frequency 0 to 500 Hz

Input impedance 2.4 kΩ

Continuous loading Rated output current I2N

capability One relay output

(constant torque at a max. Type NO + NC

ambient temperature 40 ºC) Maximum switching voltage 250 V AC/30 V DC

Maximum switching current 0.5 A/30 V DC; 5 A/230 V AC

Overload capability At heavy duty use 1.5 x I 2N for 1 minute

Maximum continuous current 2 A rms

(at a max. ambient every 10 minutes

temperature of 40 ºC) At start 1.8 x I2N for 2 s Product compliance

Switching frequency Low voltage Directive 2006/95/EC with supplements

Default 4 kHz Machinery Directive 2006/42/EC

Selectable 4 to 16 kHz with 4 kHz steps EMC Directive 2004/108/EC with supplements

Acceleration time 0.1 to 1800 s Quality assurance system ISO 9001

Deceleration time 0.1 to 1800 s Environmental system ISO 14001

UL, cUL, CE, C-Tick and GOST R approvals

Braking Built-in brake chopper as standard

RoHS compliant

Motor control method Scalar U/f

Environmental limits

Ambient temperature 14 to 104 ºF (-10 to 40 ºC), no frost

allowed, 122 ºF (50 ºC) with 10%

derating

Altitude

Output current Rated current available at 0 to 3281 ft

(0 to 1000 m) reduced by 1% per

328 ft (100 m) over 3281 to 6562 ft

(1000 to 2000 m)

Relative humidity Lower than 95% (without condensation)

Degree of protection IP20 / Optional NEMA 1 enclosure

Enclosure colour NCS 1502-Y, RAL 9002, PMS 420 C

Contamination levels IEC 721-3-3

No conductive dust allowed

Transportation Class 1C2 (chemical gases)

Class 1S2 (solid particles)

Storage Class 2C2 (chemical gases)

Class 2S2 (solid particles)

Operation Class 3C2 (chemical gases)

Class 3S2 (solid particles)

Catalog | ABB component drives ACS150 5

Control connections and interfaces

Application macros

Application macros are preprogrammed parameter sets.

When starting up the drive, the user typically selects one of

Removable clip for

the macros that is best suited for the application. The diagram brand labeling

below gives an overview of ACS150 control connections

and shows the default I/O connections for the ABB standard

Integrated interface

macro.

ABB component drives have six standard macros:

FlashDrop

EMC filter connection

− ABB standard macro grounding

− 3-wire macro screw (EMC)

− Alternate macro Integrated

Varistor potentiometer

− Motor potentiometer macro grounding

screw (VAR)

− Hand/auto macro

Input, brake I/O connections

− PID control macro resistor

and motor

connections Analog input signal

In addition to the standard macros the user can create three selector (U/I)

user macros. The user macro allows the user to save the

parameter settings for later use.

Typical I/O connections

ACS150 I

SCR

0 - 20 mA AI

Potentiometer U

Ground the cable GND

Screen SCR screen on the

SI +10 V

Analog input AI sourcing end +24 V +24 V

I

0 to 10 V start/

GND U GND

AI stop

Reference voltage DCOM

+10 V const. fwd/ DI1

+10 V DC, max. 10 mA speed rev

COM DI2

Aux. voltage output +24 V 1

NC Relay output DI3

+24 V DC, max. 200 mA GND

NO 250 V AC / 30 V DC / 6 A DI4

COM DI5

DI1 0V

ROCOM

PROGRAMMABLE DI2 DI configuration PNP

RONC

DIGITAL INPUTS connected (source)

DI3 RONO

with external power

DI4 EMC EMC filter grounding screw supply

DI5 can also be used

as a frequency input DI5 VAR Varistor grounding screw

ACS150 I

6

FlashDrop SCR

R < 10 kΩ

AI U

GND

+10 V

PE PE +24 V

L1 U1 U2 GND

V2 M start/

L2 V1 DCOM

3~ ramp const. fwd/ stop

L3 W1 W2 DI1

Brake pair speed rev

DI2

3-phase Input EMC chopper Output AC motor sel. 1

DI3

power choke filter BRK+ BRK- choke

DI4

supply,

DI5

200 to

480 V AC DI configuration

NPN connected (sink) ROCOM

t° Brake resistor RONC

RONO

6 ABB component drives ACS150 | Catalog

Cooling and fuses

Cooling Fuses

ACS150 is fitted with cooling fans as standard. The cooling Standard fuses can be used with ABB component drives.

air must be free from corrosive substances and must not be For input fuse connections see table below.

above the maximum ambient temperature of 104 °F (122 °F

with derating). For more specific limits see the Technical data

- Environmental limits in this catalog.

Cooling air flow Selection table

Type designation Frame Heat dissipation Air flow Type designation Frame IEC Fuses UL fuses

size size Fuse Fuse

3 3 ) )

[W] BTU/hr ft /min m /h [A] type * [A] type *

1-phase supply voltage 200 to 240 V units 1-phase supply voltage 200 to 240 V units

) )

ACS150-01U-02A4-2 R0 25 85 -* -* ACS150-01U-02A4-2 R0 10 gG 10 UL class T

ACS150-01U-04A7-2 R1 46 157 14 24 ACS150-01U-04A7-2 R1 16 gG 20 UL class T

ACS150-01U-06A7-2 R1 71 242 14 24 ACS150-01U-06A7-2 R1 20 gG 25 UL class T

ACS150-01U-07A5-2 R2 73 249 12 21 ACS150-01U-07A5-2 R2 25 gG 30 UL class T

ACS150-01U-09A8-2 R2 96 328 12 21 ACS150-01U-09A8-2 R2 35 gG 35 UL class T

3-phase supply voltage 200 to 240 V units 3-phase supply voltage 200 to 240 V units

) )

ACS150-03U-02A4-2 R0 19 65 -* -* ACS150-03U-02A4-2 R0 10 gG 10 UL class T

) )

ACS150-03U-03A5-2 R0 31 106 -* -* ACS150-03U-03A5-2 R0 10 gG 10 UL class T

ACS150-03U-04A7-2 R1 38 130 14 24 ACS150-03U-04A7-2 R1 10 gG 15 UL class T

ACS150-03U-06A7-2 R1 60 205 14 24 ACS150-03U-06A7-2 R1 16 gG 15 UL class T

ACS150-03U-07A5-2 R1 62 212 12 21 ACS150-03U-07A5-2 R1 16 gG 15 UL class T

ACS150-03U-09A8-2 R2 83 283 12 21 ACS150-03U-09A8-2 R2 16 gG 20 UL class T

3-phase supply voltage 380 to 480 V units 3-phase supply voltage 380 to 480 V units

) )

ACS150-03U-01A2-4 R0 11 38 -* -* ACS150-03U-01A2-4 R0 10 gG 10 UL class T

) )

ACS150-03U-01A9-4 R0 16 55 -* -* ACS150-03U-01A9-4 R0 10 gG 10 UL class T

ACS150-03U-02A4-4 R1 21 72 8 13 ACS150-03U-02A4-4 R1 10 gG 10 UL class T

ACS150-03U-03A3-4 R1 31 106 8 13 ACS150-03U-03A3-4 R1 10 gG 10 UL class T

ACS150-03U-04A1-4 R1 40 137 8 13 ACS150-03U-04A1-4 R1 16 gG 15 UL class T

ACS150-03U-05A6-4 R1 61 208 11 19 ACS150-03U-05A6-4 R1 16 gG 15 UL class T

ACS150-03U-08A8-4 R1 94 321 14 24 ACS150-03U-08A8-4 R1 20 gG 25 UL class T

*) Frame size R0 with free convection cooling.

* ) According to IEC-60269 standard.

Free space requirements

Enclosure type Space above Space below Space on left/right

in in in

All frame sizes 2.95 2.95 0

Catalog | ABB component drives ACS150 7

Options

FlashDrop tool Protection class NEMA 1

FlashDrop is a powerful palm sized tool for fast and easy The NEMA 1 kit includes a connection box for finger

parameter selecting and setting. It gives the possibility to protection, conduit tube installation, and a hood for protection

hide selected parameters to protect the machine. Only the against dirt and dust.

parameters needed in the application are shown. The tool can

copy parameters between two drives or between a PC and a Brake resistors

drive. All the above can be done without a power connection All ACS150 drives are configured with a built-in brake chopper

to the drive – in fact, it is not even necessary to unpack the capable of 100% braking. By connecting an external resistor,

drive. you can enable the dynamic braking function. The minimum

and maximum resistance and the required power is show in

DrivePM the table. Ensure the resistor purchased does not exceed

DrivePM (Drive parameter manager) is a tool to create, edit the maximum resistance nor is smaller than the minimum

and copy parameter sets for FlashDrop. For each parameter/ resistance. For more information about the selection of brake

group the user has a possibility to hide it, which means that resistors, see the ACS150 User’s Manual ( 3AFE68576032)

the drive user does not see the parameter/group at all. and PowerOhm Resistor Inc Price List (LVD-PNPL02U-EN).

DrivePM requirements

− Windows 2000/XP/Vista/Windows 7

− Free serial port from a PC

FlashDrop package includes

− FlashDrop tool

− DrivePM software on a CD-rom

− User’s manual in pdf-format on the previous CD-rom

− Cable for connection between the PC and FlashDrop

− Battery charger

8 ABB component drives ACS150 | Catalog

Notes

Catalog | ABB component drives ACS150 9

Contact us

3AUA0000085631 REV E US 4.3.2011 ACS150-PHTC01U-EN

www.abb.us/drives © Copyright 2011 ABB. All rights reserved.

Specifications subject to change without notice.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lecture 4, 5, 6, 7, 9Document37 pagesLecture 4, 5, 6, 7, 9Madeeha DanishPas encore d'évaluation

- G. David Garson-Correspondence Analysis-Statistical Associates Publishing (2012)Document37 pagesG. David Garson-Correspondence Analysis-Statistical Associates Publishing (2012)andresPas encore d'évaluation

- JOT Cue SheetsDocument53 pagesJOT Cue SheetsMukund KrishnaPas encore d'évaluation

- Lecturer Notes of Unit - 3Document59 pagesLecturer Notes of Unit - 3Graba Cada50% (2)

- Pricelist2014 PDFDocument7 pagesPricelist2014 PDFjay rickPas encore d'évaluation

- Solar Powered Room Cleaning MachineDocument39 pagesSolar Powered Room Cleaning MachineDebashishParidaPas encore d'évaluation

- RPTDocument6 pagesRPTparagkulkarni11Pas encore d'évaluation

- Vibration Safety - Toolbox Meeting PDFDocument1 pageVibration Safety - Toolbox Meeting PDFProsun SarkarPas encore d'évaluation

- Class 9-WS-sci-II Chapter. 18Document3 pagesClass 9-WS-sci-II Chapter. 18ddddPas encore d'évaluation

- 1.food Choices and Human HealthDocument56 pages1.food Choices and Human HealthGabi hilaniPas encore d'évaluation

- Fundamentals of Physics Extended 10e CH 3 SolutionsDocument6 pagesFundamentals of Physics Extended 10e CH 3 Solutionssin8310% (1)

- Ch10 LectureDocument53 pagesCh10 LectureaikatPas encore d'évaluation

- FS19 Hof Bergmann ChangelogDocument6 pagesFS19 Hof Bergmann ChangelogErik0% (1)

- Fundamentals of Systems Biology Ba8f PDFDocument356 pagesFundamentals of Systems Biology Ba8f PDFRodrigo Celis LopezPas encore d'évaluation

- Architects Choise Design Number 3 DollhouseDocument10 pagesArchitects Choise Design Number 3 Dollhouseminutemen_us100% (2)

- Crew Management in Indian Railways: A Case of Delhi DivisionDocument9 pagesCrew Management in Indian Railways: A Case of Delhi Divisionishikadhamija2411Pas encore d'évaluation

- Atswa QaDocument400 pagesAtswa QaMelody OkunugaPas encore d'évaluation

- Cellular AberrationsDocument94 pagesCellular AberrationsKatherineCentenoIlaganRNPas encore d'évaluation

- Oliver Heaviside Physical MathematicianDocument7 pagesOliver Heaviside Physical MathematicianAKHI9Pas encore d'évaluation

- UPSX Series 1-3kVA CatalogueDocument2 pagesUPSX Series 1-3kVA CatalogueTech KnowPas encore d'évaluation

- NSTM 079 v2 r3 (DC - Practical DC Dec 08)Document334 pagesNSTM 079 v2 r3 (DC - Practical DC Dec 08)Luciano SalazarPas encore d'évaluation

- The Mexican Gray WolfDocument3 pagesThe Mexican Gray Wolfanyei nicol curasiPas encore d'évaluation

- Ornithofauna from Archaeological Sites in VojvodinaDocument8 pagesOrnithofauna from Archaeological Sites in VojvodinaDanaGrujićPas encore d'évaluation

- Principles of Acct - Chapter-5Document54 pagesPrinciples of Acct - Chapter-5Yonas N IsayasPas encore d'évaluation

- Astm D3418-15Document7 pagesAstm D3418-15sebastian ramirezPas encore d'évaluation

- PSYC2512 - Evolution and Human BehaviourDocument44 pagesPSYC2512 - Evolution and Human BehaviourLauren NewmanPas encore d'évaluation

- Epidemiology of Human African TrypanosomiasisDocument19 pagesEpidemiology of Human African Trypanosomiasisrifa iPas encore d'évaluation

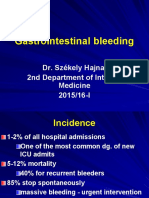

- Gastrointestinal Bleeding: Dr. Székely Hajnal 2nd Department of Internal Medicine 2015/16-IDocument74 pagesGastrointestinal Bleeding: Dr. Székely Hajnal 2nd Department of Internal Medicine 2015/16-ISutisna NisaPas encore d'évaluation

- High School Physics Rutherford Atom Lesson 27Document4 pagesHigh School Physics Rutherford Atom Lesson 27John JohnsonPas encore d'évaluation

- Datasheet SHT3x-DIS: Humidity and Temperature SensorDocument20 pagesDatasheet SHT3x-DIS: Humidity and Temperature SensorjulioclavijoPas encore d'évaluation