Académique Documents

Professionnel Documents

Culture Documents

307320-1 Grounding Systems For Electric Fences

Transféré par

sajjad ramezanzadehTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

307320-1 Grounding Systems For Electric Fences

Transféré par

sajjad ramezanzadehDroits d'auteur :

Formats disponibles

Fencing

Order No. 307.320-1

Revised December 2015

GROUNDING SYSTEMS FOR ELECTRIC FENCES

The majority of electric fence problems relate to grounding concerns. This factsheet looks at the

two methods of system grounding commonly used and how to test a grounding system.

THE EFFECT OF SOIL CONDITIONS receive 24 inches or less annual precipitation (or

where the precipitation is poorly distributed

Electric fences are designed so the animal will

throughout the year), a “wire return” system should be

complete the electrical circuit upon touching the fence

used.

wire. This forms the closed circuit required for

electrons to flow. For simplicity, the standard electric

fence uses the earth as the “return” leg of the circuit.

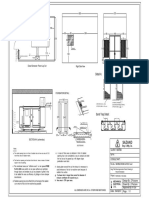

This is only effective if the conductivity is good, as in GROUNDING IN MOIST EARTH

moist soil. CONDITIONS ( Earth Return )

This is the standard grounding situation as shown in

If the soil is dry, frozen or snow covered the Figure 1. The moisture in the earth is sufficient to

conductivity is reduced which reduces the allow a flow of electrical current that will ensure a

effectiveness of the electric fence. For areas that shock occurs. The critical component is the soil

Figure 1 Grounding in Moist Earth ( earth return )

Factsheet 307.320-1 Page 1 of 4

contact of the grounding rods. They connect the earth • Brass or copper clamps, and

return current flow to the controller and must have

• #6 bare copper wire from rods to controller.

good soil contact to ensure this flow is not restricted.

This requires:

Although a smaller wire size may be adequate, a #6

wire may be directly buried which is a good method to

• For safety reasons, a location for the grounding protect the system from damage. The grounding rods

system that is at least 7 feet from any other can be driven 6 or 8 inches below the earth surface, say

electrical or telephone grounding system and from into a small dug depression. The wire can be laid into a

any building foundation (especially a dairy barn) or shallow trench, clamped to the rods, then buried. The

underground water piping wire may be buried all the way to the fence controller.

• A location where the wiring cannot be easily

damaged or disconnected by livestock or Note that where this controller ground is near a

building with an electrical service, the wire from the

machinery (see below regarding burial)

ground rods to the controller should be insulated to

• A minimum of 3 galvanized steel earthing rods, avoid ‘cross grounding’.

driven into moist earth; (these need not be located

right at the fence controller but must be at a moist In addition to this main grounding of the fence

earth location) controller, secondary grounding of the nonelectrified

fence wire(s) may be done as explained for the “wire

• A separation space between the rods of 6 feet return” systems.

• A continuous length of wire for connection

between the rods and the controller

• A standard electrical grounding clamp GROUNDING IN DRY EARTH

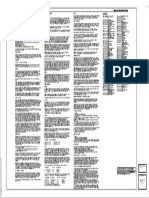

(noncorrosive) for each rod/wire connection. CONDITIONS ( Wire Return )

In dry, frozen or snow covered conditions the earth

A grounding system that will meet the Electrical Code return system is not sufficient to ensure current flow

for grounding uses the following standard electrical that will produce a shock. In these conditions, one or

components: more fence wires are used for the return circuit to the

fence controller (in addition to the earth return

• Galvanized steel ground rods, 6 feet x 5/8 inch grounding of the fence controller) as shown in Figure 2.

diameter,

Figure 2 Grounding in Dry Earth ( wire return )

Factsheet 307.320-1 Page 2 of 4

This method ensures a circuit when the animal touches Auger or dig 3 holes for the ground rods that are at

both an energized wire and a grounded wire (in semi- least 3 inches diameter by 4 feet deep, spaced 35

wet conditions, some current may also flow via the feet apart

earth return). A shock then occurs even in these poor

• Fill each hole with a wet slurry of 2 parts Bentonite

earth return conditions (i.e. dry, frozen or snow

(a clay material sometimes called “driller’s mud”)

covered).

and 1 part coarse salt

The nonelectrified fence wire(s) are connected to the • Place a 4 foot by ½ or ¾ inch diameter stainless

main fence controller grounding system as well as to steel tube down the center of the hole (stainless

single groundrods located approximately every 1/2 because of the corrosive nature of salt)

mile along the fence line (more frequently in very dry

• Cover the area with an inch or two of sand to

conditions). These ground rods are the same as the

reduce evaporation.

main grounding rods. To ensure the animal can easily

contact a “hot” wire and a grounded wire and thereby

The ground wire is clamped to these tubes as before.

receive a shock, alternating fence wires may be

To ensure continued low resistance, these salt core

electrified and grounded. However, while being more

ground rods can be watered during drought conditions.

effective, it may cause maintenance problems as any

debris that may contact the fence wires will more

easily short out the circuit then if contacting a “hot”

wire and the earth.

TESTING THE GROUND SYSTEM

The earth return system of grounding a fence controller

SALT CORE GROUND RODS relies on the soil moisture conditions for current flow

and these conditions change throughout the year. To

For very dry sites the main ground rods may have high

ensure continued fence performance, a yearly

resistance to current flow. This can be greatly reduced

grounding check should be made, preferably at the

by using the following technique (which adds salt

driest season the fence is being used. The following

around the ground rods to increase the soil

procedure should be followed (see Figure 3):

conductivity and a clay material to hold moisture):

Figure 3 Testing a Fence Grounding System

Factsheet 307.320-1 Page 3 of 4

• About 300 feet from the controller connection to • A higher meter reading will indicate the grounding

the fence, use 3 or 4 steel fence posts (or similar system cannot handle the flow and more ground

steel material) to create a dead short from an rods are required

energized wire to the earth

• Add another ground rod and repeat the test.

• This will reduce the fence line voltage to less than

1000 volts and put the grounding system under load

with a high flow of electrons trying to get through

the soil back to the energizer (An optional method is to skip the meter and simply

grasp a ground rod with one hand and touch the

• Using a volt meter (suitable for electric fences),

earth with the other hand. A poor ground is

measure the voltage between the ground wire to the

indicated with a shock, the severity of which will

controller and the earth at least 3 feet from any

depend upon the condition of the grounding

ground rod

system. This is not recommended except for the

• If the grounding system is adequate the flow will all foolhardy.)

be handled by the ground rods and the meter

reading will be very low (200 volts or so)

FOR FURTHER INFORMATION CONTACT MINISTRY OF AGRICULTURE

Phone: 604.556.3001 1767 Angus Campbell Road

Toll Free: 1.888.221.7141 Abbotsford, B.C. V3G 2M3

Factsheet 307.320-1 Page 4 of 4

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Nsa EngDocument4 pagesNsa Engsajjad ramezanzadehPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- 1 Gl312 ArevaDocument14 pages1 Gl312 Arevasajjad ramezanzadehPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- High Voltage Centre Break Disconnectors 72 5 KV Up To 245 KVDocument8 pagesHigh Voltage Centre Break Disconnectors 72 5 KV Up To 245 KVsajjad ramezanzadehPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Karta TEC+TEB-angDocument2 pagesKarta TEC+TEB-angsajjad ramezanzadehPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Roomlayout REV2 PDFDocument1 pageRoomlayout REV2 PDFsajjad ramezanzadehPas encore d'évaluation

- NAVODILA KNJIZ SQ0204 GB Ver 2.01Document36 pagesNAVODILA KNJIZ SQ0204 GB Ver 2.01sajjad ramezanzadehPas encore d'évaluation

- Distance Protection SchemeDocument8 pagesDistance Protection Schemesajjad ramezanzadehPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- SSSPL Security Electric FencingDocument21 pagesSSSPL Security Electric Fencingsajjad ramezanzadehPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Electric Fencing Cat 2010Document12 pagesElectric Fencing Cat 2010sajjad ramezanzadehPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- DuoDocument4 pagesDuosajjad ramezanzadehPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Gas Insulated Switchgear: Primary PlusDocument24 pagesGas Insulated Switchgear: Primary Plussajjad ramezanzadehPas encore d'évaluation

- Iskra (Sq0204)Document14 pagesIskra (Sq0204)sajjad ramezanzadehPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Sip5 Apn 030Document48 pagesSip5 Apn 030sajjad ramezanzadehPas encore d'évaluation

- Metrik Instruments I3g21eDocument26 pagesMetrik Instruments I3g21esajjad ramezanzadehPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- BHEL BHOPAL Vocational Training Report - 1301Document31 pagesBHEL BHOPAL Vocational Training Report - 1301Shubham yadav100% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- NI Circuit Design Suite: Getting Started GuideDocument72 pagesNI Circuit Design Suite: Getting Started GuideAlberto Manuel CarrilloPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Activity ProposalSeminarDocument6 pagesActivity ProposalSeminarWil AlgonesPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Muthiga Septic Tank Details1Document1 pageMuthiga Septic Tank Details1Daniel OkerePas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Bajaj Pulsar Vs Hero Honda HunkDocument5 pagesBajaj Pulsar Vs Hero Honda HunkDavid John Leo100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- A Project Report On: " Manufacturing of Concrete Pipes "Document8 pagesA Project Report On: " Manufacturing of Concrete Pipes "Adnan SyedPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- (Abstract) Automatic Railway Gate ControllingDocument4 pages(Abstract) Automatic Railway Gate ControllingNikhith ReddyPas encore d'évaluation

- CL-E131 Stator Earth Fault Protection 90%: Commissioning Check List EDocument2 pagesCL-E131 Stator Earth Fault Protection 90%: Commissioning Check List Emirage1977Pas encore d'évaluation

- DataBase2 1Document45 pagesDataBase2 1Abhijith RajPas encore d'évaluation

- REPORT (2014-2017) Department of Electrical & Electronics EngineeringDocument145 pagesREPORT (2014-2017) Department of Electrical & Electronics EngineeringEzikeoha BuchiPas encore d'évaluation

- AgisDocument20 pagesAgisFabian Andres Blanco GPas encore d'évaluation

- ARCH THESIS (Chapter 1)Document10 pagesARCH THESIS (Chapter 1)Clifford Jan Tabada AtigPas encore d'évaluation

- Empanelment of Architects, ConsultantsDocument21 pagesEmpanelment of Architects, ConsultantsbethalasPas encore d'évaluation

- Factors Affecting Selection of FoundationDocument4 pagesFactors Affecting Selection of FoundationRoy JariPas encore d'évaluation

- Shell Corena S4 R - TDSDocument3 pagesShell Corena S4 R - TDSAnonymous oAbjbl4HPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Muestra EstructuralDocument1 pageMuestra Estructuralsua749Pas encore d'évaluation

- Aftercooler - Test PDFDocument6 pagesAftercooler - Test PDFDaniel Castillo Peña100% (1)

- Apex Conveyor Handbook 2002Document92 pagesApex Conveyor Handbook 2002linmar7071Pas encore d'évaluation

- D1586D1586M 40725Document26 pagesD1586D1586M 40725Denisse Landaverde Ramírez100% (1)

- Limit State of ServiceabilityDocument20 pagesLimit State of ServiceabilityNavi RengarajanPas encore d'évaluation

- GS 715 U-1Document1 pageGS 715 U-1Bhoomaiah SunkenapalliPas encore d'évaluation

- EN Manual SC8108 A PDFDocument17 pagesEN Manual SC8108 A PDFDuong Thuy NgacPas encore d'évaluation

- Analysis of Shoe Manufacturing Factory by SimulatiDocument9 pagesAnalysis of Shoe Manufacturing Factory by SimulatiJosé Lorenzo ArtigasPas encore d'évaluation

- Technical Guide On Internal Audit of Automobile Industry: ISBN: 978-81-8441-853-8Document205 pagesTechnical Guide On Internal Audit of Automobile Industry: ISBN: 978-81-8441-853-8Dev JainPas encore d'évaluation

- 62-02460 - Rev - C - Manual de Peças, Compressor 05KDocument19 pages62-02460 - Rev - C - Manual de Peças, Compressor 05KBianca PinudoPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Premium Lumber, Limited: Comm3501 - Production and Operations ManagementDocument20 pagesPremium Lumber, Limited: Comm3501 - Production and Operations ManagementRegan HinesPas encore d'évaluation

- Overview of API 682 and ISO 21049Document7 pagesOverview of API 682 and ISO 21049pedpixPas encore d'évaluation

- Xylene SolubaleDocument4 pagesXylene Solubale6850079Pas encore d'évaluation

- P2-FYP2-Conformity of Thesis FormatDocument2 pagesP2-FYP2-Conformity of Thesis FormatMuhd Ashraf AzmiPas encore d'évaluation

- Auc Asme ProgramDocument2 pagesAuc Asme ProgramyasserosmanPas encore d'évaluation

- Crazy for the Storm: A Memoir of SurvivalD'EverandCrazy for the Storm: A Memoir of SurvivalÉvaluation : 3.5 sur 5 étoiles3.5/5 (217)