Académique Documents

Professionnel Documents

Culture Documents

Welding Solutions: Selecting The Proper Positioner

Transféré par

Anonymous iztPUhIiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Welding Solutions: Selecting The Proper Positioner

Transféré par

Anonymous iztPUhIiDroits d'auteur :

Formats disponibles

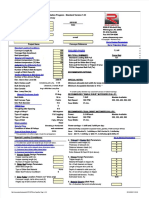

Pipe Weight Per Linear Foot

WELD PLUS

Nominal Pipe Size Thickness Schedule 40 Standard Pipe Weight

½ 0.109 .851

¾ 0.113 1.131

® 1 0.133 1.679

WELDING SOLUTIONS 1¼ 0.140 2.273

1½ 0.145 2.718

2 0.154 3.653

2½ 0.203 5.794

800-288-9414

3 0.216 7.580

3½ 0.226 9.110

4 0.237 10.790

5 0.258 14.620

6 0.280 18.980

www.weldplus.com

8 0.322 28.560

10 0.365 40.500

12 0.406 49.600

14 0.438 54.600

16 0.500 62.600

Selecting The Proper Positioner 18 0.562 70.600

20 0.594 78.600

POSITIONER ROTATING CAPACITY POSITIONER TILT CAPACITY 24 0.688 94.600

30 0.688 118.700

A B

WE KNOW WELDING!

Load x Distance = Rotational Torque Rating Load x (Distance + INH OH) = Tilt Torque Rating

(Lbs.) (Inches) (Lbs. - Inches) (Lbs.) (Inches) (Lbs. - Inches)

1. Determine the total weight you will be positioning, including fixtures.

2. Calculate the center of gravity of the work.

A. Distance from rotational center.

B. Distance from face of table.

3. Using the distance found in step 2-A, calculate the rotational torque required.

(Illustration A)

4. Using the distance found in step 2-B, calculate the tilt torque required.

(Illustration B)

5. Compare the required rotational and tilt torque with the chart. Select a

Positioner with a load capacity equal to or greater than your requirements.

Positioner Cost Analysis

Deposition rates for welding a ¾” single 45º bevel, single-pass fillet weld in two 1 inch thick carbon steel plates.

Average deposition rates in lb/hr are for one-hour period. Average depostion rates for eight-hour shift will be

lower. Average rates for manual welding will be significantly lower over an eight-hour shift due to operator

fatigue.

Positioned for automated Positioned for manual

downhand (flat) welding downhand (flat) welding Manual vertical Manual overhead

Stick Instantaneous - 12 lb/hr (5.4 kg/hr) 3 lb/hr (1.4 kg/hr) 1.5 lb/hr (0.68 kg/hr)

electrodes Actual arc-hrs. - 6 lb/hr (2.7 kg/hr) 1.5 lb/hr (0.68 kg/hr) 0.75 lb/hr (0.34 kg/hr)

Instantaneous 20 lb/hr (9 kg/hr) 12 lb/hr (5.4 kg/hr) 3 lb/hr (1.4 kg/hr) 1.5 lb/hr (0.68 kg/hr)

MIG-Argon

Actual arc-hrs. 20 lb/hr (9 kg/hr) 10 lb/hr (4.5 kg/hr) 2.5 lb/hr (1.1 kg/hr) 1.3 lb/hr (0.59 kg/hr)

Flux-cored, Instantaneous 20 lb/hr (9 kg/hr) 20 lb/hr (9 kg/hr) 5 lb/hr (2.3 kg/hr) 2.5 lb/hr (1.1 kg/hr)

CO shielded Actual arc-hrs. 20 lb/hr (9 kg/hr) 10 lb/hr (4.5 kg/hr) 2.5 lb/hr (1.1 kg/hr) 1.2 lb/hr (0.54 kg/hr)

²

Submerged Instantaneous 55 lb/hr (25 kg/hr) 55 lb/hr (25 kg/hr) - -

arc Actual arc-hrs. 55 lb/hr (25 kg/hr) 27 lb/hr (12 kg/hr) - -

Vous aimerez peut-être aussi

- ISF MainPrint 22122021 1020Document2 pagesISF MainPrint 22122021 1020Maintenance PlannerPas encore d'évaluation

- Types of WinesDocument91 pagesTypes of Winesrajanrld19880% (1)

- LINEAR INDUCTION MOTOR 6981660.ppsxDocument56 pagesLINEAR INDUCTION MOTOR 6981660.ppsxFalley FasterPas encore d'évaluation

- QP MICROWAVE Bias TeesDocument2 pagesQP MICROWAVE Bias TeesTribu Vaquero JimenezPas encore d'évaluation

- Chemical Process DebottleneckingDocument46 pagesChemical Process DebottleneckingAhmed Ansari100% (2)

- BS 3100 1991Document20 pagesBS 3100 1991Anonymous iztPUhIi100% (1)

- DEAD STARS by Paz Marquez BenitezDocument17 pagesDEAD STARS by Paz Marquez BenitezArmiethazen Khea Page PalarcaPas encore d'évaluation

- Penetration Test & Softening PointDocument7 pagesPenetration Test & Softening PointAli M. Chehadeh100% (4)

- ISO 1940-2-1997 Mechanical VibDocument20 pagesISO 1940-2-1997 Mechanical VibJavad Monfared100% (3)

- ISO 1940-2-1997 Mechanical VibDocument20 pagesISO 1940-2-1997 Mechanical VibJavad Monfared100% (3)

- Head N Neck-MCQsDocument57 pagesHead N Neck-MCQsbhargavi pasagadaPas encore d'évaluation

- Elkem 10 Tundish Cover Ladle Nodularization PDFDocument2 pagesElkem 10 Tundish Cover Ladle Nodularization PDFAnonymous iztPUhIiPas encore d'évaluation

- Induction Furnace Vs Electric Arc FurnaceDocument1 pageInduction Furnace Vs Electric Arc FurnaceAnonymous iztPUhIi100% (1)

- Third Quarter Pre-Test Mathematics 7 Directions: RDocument4 pagesThird Quarter Pre-Test Mathematics 7 Directions: RAhron RivasPas encore d'évaluation

- Sew 520Document8 pagesSew 520Anonymous iztPUhIiPas encore d'évaluation

- Design of CEB BuildingDocument20 pagesDesign of CEB BuildingVishalya Nipuni Lankeshi100% (1)

- SWG - Standard Wire GaugeDocument3 pagesSWG - Standard Wire GaugeSachin PrajapatiPas encore d'évaluation

- SWG - Standard Wire GaugeDocument3 pagesSWG - Standard Wire GaugeSachin PrajapatiPas encore d'évaluation

- SWG - Standard Wire GaugeDocument3 pagesSWG - Standard Wire GaugeSachin PrajapatiPas encore d'évaluation

- ZnO PDFDocument2 pagesZnO PDFLab Fisika Eksperimental (LabFis2022)Pas encore d'évaluation

- Spears - PIPE SCH80Document1 pageSpears - PIPE SCH80F. AhmadPas encore d'évaluation

- Schedule 80 Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 Pipe Dimensions & Pressure RatingsDGWPas encore d'évaluation

- BWG - Birmingham Wire GaugeDocument8 pagesBWG - Birmingham Wire GaugepurnawanPas encore d'évaluation

- Calculation of Leveling: Bacaan Rambu Ukur Elevation From (MSL) Stand I Stand Ii BT BTDocument26 pagesCalculation of Leveling: Bacaan Rambu Ukur Elevation From (MSL) Stand I Stand Ii BT BTheriPas encore d'évaluation

- Pka Grupo 12Document6 pagesPka Grupo 12Patricia Mora NicolásPas encore d'évaluation

- Asme B18 2.1 y 2.2 B18.5Document34 pagesAsme B18 2.1 y 2.2 B18.5JJGM120Pas encore d'évaluation

- Missing DimensionsDocument2 pagesMissing Dimensionssherwin perezPas encore d'évaluation

- Cross Section Aa - 111805Document1 pageCross Section Aa - 111805Santi NgoranPas encore d'évaluation

- UBC97 Earthquak Lateral Forces Edit Protected 09-06-2012Document21 pagesUBC97 Earthquak Lateral Forces Edit Protected 09-06-2012Jaycee Bareng PagadorPas encore d'évaluation

- BJT-CB Output CharacteristicsDocument1 pageBJT-CB Output CharacteristicsChandanPas encore d'évaluation

- Metodo Hardy Cross: Ejercicio Tipico: Calcular Los Diagramas de Momento Flector y Diagrama de Fuera CortanteDocument7 pagesMetodo Hardy Cross: Ejercicio Tipico: Calcular Los Diagramas de Momento Flector y Diagrama de Fuera CortanteMiguel Angel Tocto AyalaPas encore d'évaluation

- ManggisDocument1 pageManggisLab Fisika Eksperimental (LabFis2022)Pas encore d'évaluation

- Mill Test CertificateDocument2 pagesMill Test CertificateAbdullah MughalPas encore d'évaluation

- Astable Con IC 555Document4 pagesAstable Con IC 555Sergio Ancizar Wilches PeñaPas encore d'évaluation

- 20230208-Sharing Session 5G Depoyment - TelkomDocument30 pages20230208-Sharing Session 5G Depoyment - Telkomyoga purna tamaPas encore d'évaluation

- (TABLES K and L) Critical Values For The Wilcoxon Signed-Ranked Test The Rank Correlation CoefficientDocument1 page(TABLES K and L) Critical Values For The Wilcoxon Signed-Ranked Test The Rank Correlation CoefficientDanial ShahPas encore d'évaluation

- 19-23 MZ EX+Document1 page19-23 MZ EX+Wilkenn TuazonPas encore d'évaluation

- Schedule 80 PVC Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 PVC Pipe Dimensions & Pressure RatingsprathapPas encore d'évaluation

- Henderson-Hasselbach vs. PH: PH PH Real A1 Ap A2 Log10Document8 pagesHenderson-Hasselbach vs. PH: PH PH Real A1 Ap A2 Log10Wilmer Nevardo Rivera MateusPas encore d'évaluation

- Raisfall Naraya Nassar RamadhanDocument1 pageRaisfall Naraya Nassar RamadhanraisfallnarayaPas encore d'évaluation

- B C D E: SRM Stadium Bar Bending ScheduleDocument4 pagesB C D E: SRM Stadium Bar Bending ScheduleStephen RajPas encore d'évaluation

- BJT-CE Input Characteristics NewDocument1 pageBJT-CE Input Characteristics NewPRATEEK KUMARPas encore d'évaluation

- POT. MELINTANG Ruas 1Document64 pagesPOT. MELINTANG Ruas 1heriPas encore d'évaluation

- Part Section1Document1 pagePart Section1حساب تجاريPas encore d'évaluation

- Rsa Report 08-06-2020 PDFDocument85 pagesRsa Report 08-06-2020 PDFRutik PatelPas encore d'évaluation

- Bifasica Barra1Document1 pageBifasica Barra1Deyvis CadillopPas encore d'évaluation

- (7)Document1 page(7)Алексей ЗавгороднийPas encore d'évaluation

- Standard Groove SpecificationsDocument5 pagesStandard Groove SpecificationsDavid SalgueroPas encore d'évaluation

- Standard Groove Specifications PDFDocument5 pagesStandard Groove Specifications PDFDavid Salguero OlveaPas encore d'évaluation

- Wind LoadsDocument1 pageWind LoadsAli Al-BashaPas encore d'évaluation

- Dow Engineering InformationDocument29 pagesDow Engineering InformationbenakiaPas encore d'évaluation

- NASM21314Document1 pageNASM21314Bogdan RusuPas encore d'évaluation

- Schedule 40 PVC Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 40 PVC Pipe Dimensions & Pressure RatingspicottPas encore d'évaluation

- Schedule 40 PVC Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 40 PVC Pipe Dimensions & Pressure RatingsprathapPas encore d'évaluation

- RollerChain - Chain Length Technical SheetDocument2 pagesRollerChain - Chain Length Technical SheetOscar Orellana CruzPas encore d'évaluation

- 4th Floor Inside and Ceilling Plaster CheckedDocument89 pages4th Floor Inside and Ceilling Plaster CheckedRajat KoleyPas encore d'évaluation

- Alcohol StandardDocument2 pagesAlcohol StandardMaricel CayananPas encore d'évaluation

- PVC Common Design Details: Short Circuit Rating For PVC Insulated CablesDocument2 pagesPVC Common Design Details: Short Circuit Rating For PVC Insulated Cablessouvikbesu89Pas encore d'évaluation

- Datasheet 1x19 Stainless Steel Strand Wire RopeDocument1 pageDatasheet 1x19 Stainless Steel Strand Wire RopePrattyPas encore d'évaluation

- Rate Analysis of Box CulvertDocument3 pagesRate Analysis of Box CulvertA M100% (1)

- Ports July 2021Document37 pagesPorts July 2021Siddhartha ShekharPas encore d'évaluation

- Cord Conn Selec ChartDocument3 pagesCord Conn Selec ChartP Vikram MoudgalPas encore d'évaluation

- DiameterDocument1 pageDiameterRajesh RoyPas encore d'évaluation

- PVC Schedule 80 Conduit Spec Sheet Allied Tube and ConduitDocument1 pagePVC Schedule 80 Conduit Spec Sheet Allied Tube and ConduitJhaero Esteban PerezPas encore d'évaluation

- Mesh Sizing Chart For StrainersDocument3 pagesMesh Sizing Chart For StrainersMalik DaniyalPas encore d'évaluation

- Siti Reni ApriyaniDocument1 pageSiti Reni ApriyaniSupianto SupiPas encore d'évaluation

- Rumus Falidity and ReabilityDocument9 pagesRumus Falidity and ReabilitylindariPas encore d'évaluation

- Velocity (M/S) : F Upstream C UpstreamDocument3 pagesVelocity (M/S) : F Upstream C Upstreamkhairi_mohammadPas encore d'évaluation

- 8950P229 SampleDocument5 pages8950P229 SamplecarlosPas encore d'évaluation

- Appendix H Resistance of Copper Wire, Ohms Per Mile, 25 C (77 F) Size, Cir - Mils or AWG Number of Wires Outside Diameter, Mils Ohm Per Mile StrandedDocument2 pagesAppendix H Resistance of Copper Wire, Ohms Per Mile, 25 C (77 F) Size, Cir - Mils or AWG Number of Wires Outside Diameter, Mils Ohm Per Mile Strandedariel mentawanPas encore d'évaluation

- PVT & Eos Modelling: Using Pvtsim SoftwareDocument65 pagesPVT & Eos Modelling: Using Pvtsim SoftwareMario HuasasquichePas encore d'évaluation

- Pile Driving Test Pier 2Document11 pagesPile Driving Test Pier 2Emmanuel CristobalPas encore d'évaluation

- ANSI-ASME B16.5 Blind Flange 600lbDocument1 pageANSI-ASME B16.5 Blind Flange 600lbVishal MistryPas encore d'évaluation

- PDF Design ImperialDocument9 pagesPDF Design ImperialAnonymous iztPUhIiPas encore d'évaluation

- Astm A 297Document3 pagesAstm A 297friasdelacruz50% (2)

- Spheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeDocument5 pagesSpheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeAnonymous iztPUhIiPas encore d'évaluation

- Chance in BballDocument12 pagesChance in BballAnonymous iztPUhIiPas encore d'évaluation

- Steel Castings in Architecture and Engineering: Hans SchoberDocument5 pagesSteel Castings in Architecture and Engineering: Hans SchoberAnonymous iztPUhIiPas encore d'évaluation

- Working With The Cold Box ProcessDocument21 pagesWorking With The Cold Box ProcessAnonymous iztPUhIiPas encore d'évaluation

- Process Knowledge in FoundriesDocument23 pagesProcess Knowledge in FoundriesAnonymous iztPUhIiPas encore d'évaluation

- Solovastru Ioan L1Document7 pagesSolovastru Ioan L1Anonymous iztPUhIiPas encore d'évaluation

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesDocument60 pagesPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65Pas encore d'évaluation

- Instructor: DR - Ashok Kaushal: Orthogonal ViewsDocument49 pagesInstructor: DR - Ashok Kaushal: Orthogonal ViewsKristi GjokaPas encore d'évaluation

- Hydraulics Course FileDocument81 pagesHydraulics Course FileSwarna LathaPas encore d'évaluation

- CM Bu9000 Eng Bushings 3Document36 pagesCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- Lec22 Mod 5-1 Copper New TechniquesDocument24 pagesLec22 Mod 5-1 Copper New TechniquesAaila AkhterPas encore d'évaluation

- Ah 1000Document1 pageAh 1000Zafir SihabuddinPas encore d'évaluation

- 4th Semester Electrical Engg.Document19 pages4th Semester Electrical Engg.Bhojpuri entertainmentPas encore d'évaluation

- DSR Codes - 1Document108 pagesDSR Codes - 1lakkireddy seshireddyPas encore d'évaluation

- English 3 Avicenna Graded Test 1Document11 pagesEnglish 3 Avicenna Graded Test 1Mohd FarisPas encore d'évaluation

- Motor Starting: Why Do The Calculation?Document13 pagesMotor Starting: Why Do The Calculation?carlos_eqnPas encore d'évaluation

- The Latent Phase of LaborDocument8 pagesThe Latent Phase of LaborLoisana Meztli Figueroa PreciadoPas encore d'évaluation

- NDT Matrix 12-99-90-1710 - Rev.2 PDFDocument2 pagesNDT Matrix 12-99-90-1710 - Rev.2 PDFEPC NCCPas encore d'évaluation

- PositioningDocument2 pagesPositioningKishan AndurePas encore d'évaluation

- Annie Ovenden Exibition 2017Document19 pagesAnnie Ovenden Exibition 2017Vitaliy ChuenkoPas encore d'évaluation

- List ToolingDocument10 pagesList Toolingyohanes adi saputroPas encore d'évaluation

- Bsi MD Ivdr Conformity Assessment Routes Booklet Uk enDocument15 pagesBsi MD Ivdr Conformity Assessment Routes Booklet Uk enGuillaumePas encore d'évaluation

- 6.003 Homework #12 Solutions: ProblemsDocument9 pages6.003 Homework #12 Solutions: ProblemsSamu PacurucuPas encore d'évaluation

- Nitofloor NDocument3 pagesNitofloor Nkiranmisale7Pas encore d'évaluation

- Camouflage Lesson PlanDocument4 pagesCamouflage Lesson Planapi-344569443Pas encore d'évaluation

- Chapter 01Document16 pagesChapter 01deepak_baidPas encore d'évaluation

- Ora Laboratory Manual: Section 1 Section 1Document36 pagesOra Laboratory Manual: Section 1 Section 1Ahmed IsmailPas encore d'évaluation

- Assignment 1 - Statistics ProbabilityDocument3 pagesAssignment 1 - Statistics ProbabilityAzel Fume100% (1)