Académique Documents

Professionnel Documents

Culture Documents

Concrete 14

Transféré par

Vicces P. EstradaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Concrete 14

Transféré par

Vicces P. EstradaDroits d'auteur :

Formats disponibles

energy expended upon the mix of at least 5000 joules per kilogram of the mix.

[57] A plasticizer or a

superplasticizer is then added to the activated mixture which can later be mixed with aggregates in a

conventional concrete mixer. In the HEM process, the intense mixing of cement and water with sand

provides dissipation of energy and increases shear stresses on the surface of cement particles. This

intense mixing serves to divide the cement particles into extremely fine nanometer scale sizes, which

provides for extremely thorough mixing. This results in the increased volume of water interacting with

cement and acceleration of Calcium Silicate Hydrate (C-S-H) colloid creation.

The initial natural process of cement hydration with formation of colloidal globules about 5 nm in

diameter[58] spreads into the entire volume of cement – water matrix as the energy expended upon the

mix approaches and exceeds 5000 joules per kilogram.

The liquid activated high-energy mixture can be used by itself for casting small architectural details and

decorative items, or foamed (expanded) for lightweight concrete. HEM Nanoconcrete hardens in low

and subzero temperature conditions and possesses an increased volume of gel, which reduces capillarity

in solid and porous materials.

Microbial[edit]

Bacteria such as Bacillus pasteurii, Bacillus pseudofirmus, Bacillus cohnii, Sporosarcina pasteuri, and

Arthrobacter crystallopoietes increase the compression strength of concrete through their biomass. Not

all bacteria increase the strength of concrete significantly with their biomass.[59]:143 Bacillus sp. CT-5.

can reduce corrosion of reinforcement in reinforced concrete by up to four times. Sporosarcina pasteurii

reduces water and chloride permeability. B. pasteurii increases resistance to acid.[59]:146 Bacillus

pasteurii and B. sphaericuscan induce calcium carbonate precipitation in the surface of cracks, adding

compression strength.[59]:147

Polymer[edit]

Main article: Polymer concrete

Polymer concretes are mixtures of aggregate and any of various polymers and may be reinforced. The

cement is more costly than lime-based cements, but polymer concretes nevertheless have advantages,

they have significant tensile strength even without reinforcement, and they are largely impervious to

water. They are frequently used for repair and construction of other applications such as drains.

Safety[edit]

Concrete, when ground, can result in the creation of hazardous dust. The National Institute for

Occupational Safety and Health in the United States recommends attaching local exhaust ventilation

shrouds to electric concrete grinders to control the spread of this dust.[60]

Properties[edit]

Main article: Properties of concrete

Concrete has relatively high compressive strength, but much lower tensile strength. For this reason it is

usually reinforced with materials that are strong in tension (often steel). The elasticity of concrete is

relatively constant at low stress levels but starts decreasing at higher stress levels as matrix cracking

develops. Concrete has a very low coefficient of thermal expansion and shrinks as it matures. All

Vous aimerez peut-être aussi

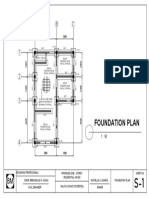

- Rubble Trench Foundation4Document2 pagesRubble Trench Foundation4Vicces P. EstradaPas encore d'évaluation

- Rubble Trench Foundation3Document6 pagesRubble Trench Foundation3Vicces P. EstradaPas encore d'évaluation

- Rubble Trench FoundationDocument2 pagesRubble Trench FoundationVicces P. EstradaPas encore d'évaluation

- Doors and WindowsDocument1 pageDoors and WindowsVicces P. EstradaPas encore d'évaluation

- Tension PilesDocument1 pageTension PilesVicces P. EstradaPas encore d'évaluation

- Painting WorksDocument1 pagePainting WorksVicces P. EstradaPas encore d'évaluation

- Strengthening Foundations with UnderpinningDocument2 pagesStrengthening Foundations with UnderpinningVicces P. EstradaPas encore d'évaluation

- Rubble Trench Foundation2Document4 pagesRubble Trench Foundation2Vicces P. EstradaPas encore d'évaluation

- Create The Project: Castro Valley Castro Valley Urban StudyDocument5 pagesCreate The Project: Castro Valley Castro Valley Urban StudyVicces P. EstradaPas encore d'évaluation

- Tile WorksDocument1 pageTile WorksVicces P. EstradaPas encore d'évaluation

- Methods of TunnellingDocument4 pagesMethods of TunnellingVicces P. EstradaPas encore d'évaluation

- Ground WorksDocument3 pagesGround WorksVicces P. EstradaPas encore d'évaluation

- CarpentryDocument1 pageCarpentryVicces P. EstradaPas encore d'évaluation

- Types of ExcavationDocument3 pagesTypes of ExcavationVicces P. EstradaPas encore d'évaluation

- Vibro ReplacementDocument2 pagesVibro ReplacementVicces P. EstradaPas encore d'évaluation

- Choosing the Right Excavator for Construction ProjectsDocument5 pagesChoosing the Right Excavator for Construction ProjectsVicces P. EstradaPas encore d'évaluation

- AlluviumDocument1 pageAlluviumVICCES ESTRADAPas encore d'évaluation

- Geothermal Pile FoundationsDocument9 pagesGeothermal Pile FoundationsVicces P. EstradaPas encore d'évaluation

- Bulk Filling MaterialsDocument1 pageBulk Filling MaterialsVicces P. EstradaPas encore d'évaluation

- A Watershed Is A Precipitation CollectorDocument3 pagesA Watershed Is A Precipitation CollectorVicces P. EstradaPas encore d'évaluation

- Hauling: v. Hauled, Haul Ing, Hauls V.TRDocument1 pageHauling: v. Hauled, Haul Ing, Hauls V.TRVicces P. EstradaPas encore d'évaluation

- Hauling Equipment5Document1 pageHauling Equipment5Vicces P. EstradaPas encore d'évaluation

- In Its Simplest FormcdeDocument1 pageIn Its Simplest FormcdeVicces P. EstradaPas encore d'évaluation

- Hauling: v. Hauled, Haul Ing, Hauls V.TRDocument1 pageHauling: v. Hauled, Haul Ing, Hauls V.TRVicces P. EstradaPas encore d'évaluation

- The Forms of ConcreteDocument1 pageThe Forms of ConcreteVicces P. EstradaPas encore d'évaluation

- In Its Simplest FormDocument1 pageIn Its Simplest FormVicces P. EstradaPas encore d'évaluation

- In Its Simplest FormcdDocument1 pageIn Its Simplest FormcdVicces P. EstradaPas encore d'évaluation

- In Its Simplest FormcDocument1 pageIn Its Simplest FormcVicces P. EstradaPas encore d'évaluation

- 2Document1 page2Vicces P. EstradaPas encore d'évaluation

- Cement & Concrete BasicsDocument1 pageCement & Concrete BasicsVicces P. EstradaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lecture 1 - RC Design To Eurocode 2 - 29.01.2024Document38 pagesLecture 1 - RC Design To Eurocode 2 - 29.01.2024Botsang GotshajwangPas encore d'évaluation

- Aci 352r - 02 PDFDocument37 pagesAci 352r - 02 PDFDYGA GramajoPas encore d'évaluation

- Standard Mnahours & Calculation of Duration of ActivtiesDocument9 pagesStandard Mnahours & Calculation of Duration of ActivtiesMubashirPas encore d'évaluation

- Astm D5340 03 PCI PDFDocument54 pagesAstm D5340 03 PCI PDFDavid Alonso Quintero HenaoPas encore d'évaluation

- Residential House Foundation PlanDocument1 pageResidential House Foundation PlanBrenndale SusasPas encore d'évaluation

- ACI 318 14 Benefits Rationale Availability RenoDocument29 pagesACI 318 14 Benefits Rationale Availability RenoMochammad SuryaPas encore d'évaluation

- Windpost & LintelsDocument32 pagesWindpost & LintelsNhuVan NguyenPas encore d'évaluation

- Comparative Study For Flexure Design Using IRC 112 2011 IRC 21 2000Document5 pagesComparative Study For Flexure Design Using IRC 112 2011 IRC 21 2000rammirisPas encore d'évaluation

- A Review On Seismic Behavior of Ultra-High Performance Concrete MembersDocument16 pagesA Review On Seismic Behavior of Ultra-High Performance Concrete Membersdragon HPas encore d'évaluation

- 03 Christoph MuellerDocument55 pages03 Christoph MuellerKaren LimPas encore d'évaluation

- SOR Civil Works Assam PWD Schedule 2013 14 PDFDocument176 pagesSOR Civil Works Assam PWD Schedule 2013 14 PDFwangdid khati64% (11)

- TSFDC Kothagudem WorkDocument42 pagesTSFDC Kothagudem WorkS UDAY KUMARPas encore d'évaluation

- Block 06 Bhatwari - SoR - MORTHDocument70 pagesBlock 06 Bhatwari - SoR - MORTHdaisyPas encore d'évaluation

- Strength and Ductility of Reinforced Concrete Moment Frame Connections Strengthened With Quasi-Isotropic LaminatesDocument6 pagesStrength and Ductility of Reinforced Concrete Moment Frame Connections Strengthened With Quasi-Isotropic LaminatesBadr AmmarPas encore d'évaluation

- Is 9459Document13 pagesIs 9459Anonymous mcHqIfbnV1Pas encore d'évaluation

- Nitocote EP410: Epoxy Resin Tank and Surface Lining MaterialDocument2 pagesNitocote EP410: Epoxy Resin Tank and Surface Lining MaterialVenkata Raju KalidindiPas encore d'évaluation

- 1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsDocument37 pages1021.000 Street and Road Closure Excavations Reinstatement and Traffic ControlsZubair Ahmed Khaskheli0% (1)

- Cement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementDocument4 pagesCement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementChalamaiah VMPas encore d'évaluation

- ACreferencias BibliográficasDocument3 pagesACreferencias BibliográficasSenialsell Lains GuillenPas encore d'évaluation

- Load Rating of Large Reaction Floor-Wall AssemblyDocument12 pagesLoad Rating of Large Reaction Floor-Wall Assemblyprashanth palaniPas encore d'évaluation

- Concrete Trial Mix Calculations of Grade M-25 RCC: National Highway Authority of India (Nhai)Document13 pagesConcrete Trial Mix Calculations of Grade M-25 RCC: National Highway Authority of India (Nhai)Ashok amlapurePas encore d'évaluation

- Is 2250 1981 PDFDocument36 pagesIs 2250 1981 PDFChockalingamPas encore d'évaluation

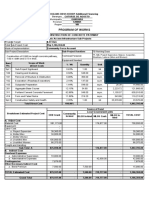

- Program of Works - PathwayDocument43 pagesProgram of Works - PathwayJonnel CatadmanPas encore d'évaluation

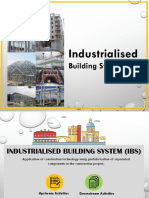

- Introduction of Industrial Building System in MalaysiaDocument14 pagesIntroduction of Industrial Building System in MalaysiaNurazwani AhmadPas encore d'évaluation

- CDPO RajupalemDocument161 pagesCDPO RajupalemCharan ReddyPas encore d'évaluation

- Bridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14Document10 pagesBridge Design For Prestressed Concrete Box Section Based On AASHTO 17th Edition & ACI 318-14jklo12Pas encore d'évaluation

- Astm C0317 - 1 (En)Document2 pagesAstm C0317 - 1 (En)svvasin2013Pas encore d'évaluation

- International Journal of Mechanical Engineering and Computer 2016 Applications, Vol. 4, No. 1, Jan- Feb ISSN - 2320-6349Document8 pagesInternational Journal of Mechanical Engineering and Computer 2016 Applications, Vol. 4, No. 1, Jan- Feb ISSN - 2320-6349Suresh GSPas encore d'évaluation

- Name: Dheeru Meher Batch: 74 Contact: 5 Roll No. 19 Subject: CSR Assign No: 01Document3 pagesName: Dheeru Meher Batch: 74 Contact: 5 Roll No. 19 Subject: CSR Assign No: 01Dhiru MeherPas encore d'évaluation

- Nitin Gokul Kolhe: +919284366246 at Post Vitave Tel - Chandwad Dist - Nashik Pin Code - 423101Document2 pagesNitin Gokul Kolhe: +919284366246 at Post Vitave Tel - Chandwad Dist - Nashik Pin Code - 423101Nitin kolhePas encore d'évaluation