Académique Documents

Professionnel Documents

Culture Documents

Demco DM Iom PDF

Transféré par

Ashok SureshTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Demco DM Iom PDF

Transféré par

Ashok SureshDroits d'auteur :

Formats disponibles

Page 1 of 24

Installation, Operation, Maintenance and Repair Manual

DEMCO®

Model DM

Gate Valves

Classes : 400 1000

600 2000

900 3000

1500 5000

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 2 of 24

Publication TC1641 Published May 2002

© Cooper Cameron Corporation, Cooper Cameron Valves Division, 2002.

All rights reserved.

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 3 of 24

Table of Contents

Bill of Materials

Class 400-1500 (except 4" and 6x4" 1500) .. 4

Class 2000, 3000, 5000 2" & 2-1/2x2".......... 5

Class 2000-3000: 2-1/2" - 5x4"; 5000:

3" & 4x3"; Class 1500: 4"; 1000: 5" ......... 6

Class 5000: 4", 5x4", 6x4" .......................... 7

Class 3000-5000: 5", 6x5" ........................... 8

Nameplate Information .................................... 9

Scope .............................................................. 9

Storage.............................................................. 9

Installation ....................................................... 10

Operation......................................................... 11

Routine Maintenance ...................................... 11

Repair - General ............................................... 11

Repair

Class 400-1500 (except 4" and 6x4" 1500) . 12

Class 2000, 3000, 5000 2" & 2-1/2x2"......... 14

Class 2000-3000: 2-1/2" - 5x4"; 5000:

3" & 4x3"; Class 1500: 4"; 1000: 5" ........ 16

Class 5000: 4", 5x4", 6x4" ......................... 18

Class 3000-5000: 5", 6x5" .......................... 20

Trouble Shooting ............................................ 22

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 4 of 24

1

15

2 3

10

6

4

8 5

13 9

14

11

12 7

Figure 1 - Series DM Gate Valve Class 400-1500 (except 4" and 6x4" 1500)

ITEM QTY DESCRIPTION

1. 1 Handle

2. 1 Stem Pin

3. 1 Lube Fitting

4. 1 Back-up Ring

5. 1 Stem Seal

6. 1 Stem

7. 1 Bonnet

8. 4 Cap Screw or Stud

1 9. * Nut 1 Nut Qty=

10. 1 Bonnet Seal 0 for 1-1/2 through 3x2"

Class 400 and 600

11. 1 Body 4 for others

12. 1 Seat Assembly 2 Screw Seal Qty=

0 for Class 400 and 600

13. 1 Gate

1 for Class 900 and 1500

2 14. * Screw Seal Relief Fitting Qty=

3

3 15. * Relief Fitting 0 for Class 400 and 600

1 for Class 900 and 1500

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 5 of 24

22

1

19 4

6

21

BRONZE BUSHING 10 2

15

18

FLAT TOP FOLLOWER

11

FABRIC REINFORCED

SEAL RING 12

17 7

HOMOGENEOUS 16

RUBBER SEAL RING

20

FLAT BOTTOM 9 8

ADAPTER

13

Figure 2 - Series DM Gate Valve 2000, 3000, 5000 2" & 2-1/2x2"

ITEM QTY DESCRIPTION ITEM QTY DESCRIPTION

1. 1 Lube Fiting 13. 1 Lock Screw

2. 1 Handle 15. 1 Coupling

4. 1 Lock Handles 16. 1 Bonnet

6. 1 Stem Screw 17. 1 Index Pin

7. 1 Stem Screw Seal 18. 1 Bonnet Seal

8. 1 Screw Housing 19. 1 Gate

9. 1 Stem 20. 1 Body

10. 1 Secondary Seal 21. 1 Seat Assembly

11. 1 Retainer 22. 1 Pin-Lock Handle

12. 1 Stem Seal Assembly

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 6 of 24

19

BRONZE BUSHING 10

11 22

FLAT TOP FOLLOWER

4 1

FABRIC REINFORCED

SEAL RING 12

21

HOMOGENEOUS

RUBBER SEAL RING 23 2

18 FLAT BOTTOM

ADAPTER 26 7

25 16

24

20 6

9

Figure 3 - Series DM Gate Valve 2000-3000: 2-1/2" - 5x4"; 5000: 3" & 4x3"; Class 1500: 4"; 1000: 5"

ITEM QTY DESCRIPTION ITEM QTY DESCRIPTION

1. 1 Lube Fiting 16. 1 Bonnet

2. 1 Hub Assembly 18. 1 Bonnet Seal

4. 1 Lock Handle 19. 1 Gate

6. 1 Stem Screw 20. 1 Body

7. 1 Stem Screw Seal 21. 1 Seat Assembly

8. 1 Screw Housing 22. 1 Pin-Lock Handle

9. 1 Stem 23. 2 Bonnet Stud

10. 1 Secondary Seal 24. 2 Bonnet Stud Nut

11. 1 Retainer 25. 4 Body Stud

12. 1 Stem Seal Assembly 26. 4 Body Stud Nut

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 7 of 24

3

26

23

16 2

9 24

14

13

6

19 8

5

21

13

18 10

BRONZE BUSHING

25 11

FLAT TOP FOLLOWER

FABRIC REINFORCED

SEAL RING 12

HOMOGENEOUS

20 RUBBER SEAL RING

FLAT BOTTOM

ADAPTER

Figure 4 - Series DM Gate Valve 5000: 4", 5x4", 6x4"

ITEM QTY DESCRIPTION ITEM QTY DESCRIPTION

1. 1 Lube Fiting 13. 2 Bearing

2. 1 Handle 14. 1 Downstop Ring

3. 1 Tube 16. 1 Bonnet 1 Stud and

Nut Qty=

4. 1 Stem Cap 18. 1 Bonnet Seal 4 for valves

5. 1 Key 19. 1 Gate with Assembly

6. 1 Stem Screw Bast Part

20. 1 Body

Number

7. 1 Stem Screw Seal 21. 1 Seat Assembly J007420,

8. 1 Screw Housing 23. 2 Bnnet Stud J007421 and

9. 1 Stem J011928.

24. 2 Bonnet Stud Nut

10. 1 Secondary Seal 1 25. * Body Stud 12 studs

11. 1 Retainer 1 26. * Body Stud Nut and nuts for

12. 1 Stem Seal Assembly all other

assemblies.

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 8 of 24

24

23

9 1

14

6

22

26

25

4 19

THRUST WASHER NEEDLE AND CAGE

ASSEMBLY

13

18

12 THRUST WASHER NEEDLE AND CAGE

ASSEMBLY

10 BRONZE BUSHING

FLAT TOP FOLLOWER 21

8

20

FABRIC REINFORCED

SEAL RINGS

5

11

HOMOGENEOUS

RUBBER SEAL RING

FLAT BOTTOM

ADAPTER

Figure 5 - Series DM Gate Valve 3000-5000: 5", 6x5"

ITEM QTY DESCRIPTION ITEM QTY DESCRIPTION

1. 1 Handwheel 13. 1 Gate

2. 1 Screw, Handwheel 14. 1 Stem Screw Seal

3. 4 Screw, Retainer 18. 1 Stem Screw w/Bearings

4. 1 Downstop Ring 19. 1 Housing

5. 1 Stem Seal Assembly 20. 1 Secondary Seal

6. 1 Stem 21. 1 Retainer

7. 1 Bonnet 22. 4 Screw, Housing

8. 12 Body Stud 23. 1 Tube

9. 12 Body Stud Nut 24. 1 Stem Cap

10. 1 Bonnet Seal 25. 1 Lube Fitting

11. 1 Body 26. 1 Relief Fitting

12. 1 Seat Assembly

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 9 of 24

Scope Storage

This publication applies to the storage, installa- Demco model DM gate valves are shipped from

tion, operation, routine maintenance and trouble the factory fully open and with end protectors. It

shooting of the Demco model DM gate vales in is recommended that they remain in this condi-

pressure classes 400, 600, 900, 1500, 1000, 2000, tion until time for installation. They should be

3000 & 5000. Other information concerning these stored in a dry place, preferably indoors, away

valves (e.g. dimensional data, etc.) is to be found from extreme heat. These valves contain elasto-

in other publications. meric seals which deteriorate with heat and age.

Nameplate Information

The Demco model DM gate valve comes in several The valve serial number is a four to six digit

configurations, one of which is shown on the front number that is stamped on the nameplate and

cover of this publication. Each valve is completely body at the time of assembly. Serial numbers are

identified by the nameplate data which is shown kept on file at the factory and are traceable to the

below. valve assembly part number and date of assembly.

The serial number is stamped on or near one of

With the valve assembly part number and serial the end connections.

number a complete valve bill of material may be

obtained. The valve assembly part number will

appear on the purchase order and shipping ticket.

HYDROSTATIC TEST

PRESSURE, PSI

WORKING PRESSURE,

PSI

VALVE ASSEMBLY VALVE SERIAL

PART NUMBER NUMBER

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 10 of 24

Installation position. Apply a coating of grease to the body

seat bore and seat. Install the bonnet seal into the

Demco model DM gate valves are bi-directional body. Then, while holding the seat onto the

and may be installed with either end upstream. bonnet so that the gate is started into the slot in

the seat and the two pins on the seat are engag-

The valves should be installed as far as possible ing the holes in the bonnet, install the seat/

from sources of extreme heat, vibration and bonnet assembly as a unit into the body. This may

pulsation. The piping system should be equipped require two people on the larger valves. Never put

with a pulsation dampener if a reciprocating the seat into the body and then try to get the

pump is being used. Vibration and pulsation cause bonnet on. This will most likely result in a dam-

premature wear of the internal parts of the valve. aged seat. Draw the bonnet down uniformly until

it is flush with the body, then torque the nuts in a

star or cross pattern. Never draw one side of the

Note on weld end valves: Remove the bonnet, bonnet all the way down before tightening the

bonnet seal and seat prior to welding the valve nuts on the opposite side. This will most likely

into the line. Protect the seat bore from weld result in a damaged seat.

spatter. Be sure the weld procedure is qualified

for both pipe material and valve body material. If

the valve is going to be exposed to hydrogen

sulfide, the weld procedure must conform to the Before testing the system, the lines should be

requirements of NACE spec MR0175. The material flushed out to remove weld debris and other

grade of the valve body is cast or stamped on the foreign material. Test pressure should not exceed

valve body. If in doubt, contact the factory. After that shown on the valve nameplate with the valve

the valve body has been welded into the line and open and the pressure applied to a closed valve

has cooled down to below 200F, the bonnet seal, should not exceed the rated working pressure

seat and bonnet assembly may be reinstalled. shown on the nameplate.

Make sure the valve gate is in the fully open

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 11 of 24

Operation

A gate valve should be either fully open or fully 1) The handle moves down as the valve is

closed. Flow through a partially open valve may being closed. The valve is fully closed

erode the gate and seat. The Demco DM gate valve when the handle stops down on the

is designed to be opened or closed under full rated bonnet or housing. No further movement

pressure differential but it will last longer if it is is possible.

operated when there is little or no pressure in the

line. The valve is opened by turning the handle 2) The stem head engages a step in the inside

counterclockwise until a sharp increase in torque is of the bonnet when the valve is fully

felt. Further turning of the handle will damage closed. Further turning of the handle will

the stem. The valve is closed by turning the handle damage the stem. On these valves the top

clockwise. On all valves covered by this publica- of the stem will be flush with the top of

tion, either one of the following applies: the stem screw. This condition is visible

through the clear plastic stem protector

tube.

Number of handle turns required to fully open or close the valve:

ValveSize Rated working pressure as shown on the nameplate

990 1480 2220 3705 1000 2000 3000 5000

1-1/2, 2X1-1/2 3.4 3.4

2, 3x2 4.0 4.0 4.2 4.2 10.1 10.1 10.1

2-1/2 5.1 5.1 5.1 5.1 9.2 9.2

3, 4x3 5.9 5.9 6.0 6.0 10.6 10.6 10.6

4, 5x4, 6x4 7.6 7.6 7.6 11.6 11.6 11.6 23.0

5, 6x5 14.8 29.7 29.7

6, 8x6 11.1 11.1 11.1

Routine Maintenance

It is important to see that the valve is kept prop- are adequately lubricated. The valve should be

erly lubricated. Use a good #2 grade of water- lubricated at least once a year, depending on use.

resistant grease. Chevron Ultra-Duty #2 is used at

the factory. Grease is applied with an automotive Whenever the valve is exposed to frac sand,

type grease gun to the Alemite fitting either on drilling mud, cement or acidizing fluids it should

the handle hub or on the housing. On valves with be flushed out thoroughly at the first opportunity.

the fitting on top of the handle hub, the valve is

Sand, drilling mud, and cement can set up inside

best lubricated when it is closed. This prevents the

grease from escaping from the space between the

the valve and render it inoperable. Acidizing fluids

handle and stem screw before the housing threads can corrode the internal parts and result in leak-

age.

Repair - General

Repair as described in this manual is limited to

replacement of parts or minor cleaning and badly corroded or washed out bodies or bonnets

polishing of existing parts. For major repairs of please contact an authorized Cameron repair facility.

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 12 of 24

Repair – Series DM gate valve class 400-1500

(except 4” and 6x4” 1500)

1

15

2 3

10

6

4

8 5

13 9

14

11

12 7

Disassembly

Demco Class 400-1500 gate valves may be disas- 2. Stem seal (5) and back-up ring (4) may now be

sembled for inspection without removing from removed from the groove in the stem bore. Re-

the line. Simplicity of design and precision move seal (14) on Class 900-1500 valves.

workmanship assure ready replacement of parts

and satisfactory operation following field repairs. 3. Collapse the seat (12) by compressing the top pins

together and remove it from the valve body.

1. Fully open the gate valve. Remove nuts (9) (or Remove the bonnet seal ring (10) from its groove

cap screws on 1-1/2” and 2” valves) and lift the in the body.

bonnet (7) with stem and gate, from the body.

Using a hammer and pin punch, drive the stem

pin (2) out of the handle hub. Rotate the Inspection

handle counterclockwise, unscrewing it from Thoroughly clean all disassembled parts and

the bonnet. Withdraw the stem and gate from inspect them for wear and damage. Clean the

the bottom of the bonnet; rotate the gate (13) stem bore in the bonnet, including the seal ring

clockwise, unscrewing it from the stem (6). groove, and inspect for dirt or corrosion. It is

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 13 of 24

recommended that seals (4), (5), (10) and (14) be If the distance is incorrect, shorten or lengthen

replaced if worn or damaged. Inspect the straight by pulling the stem and turning the gate a half

section of the stem, which passes through the turn on the stem. (This changes the dimension

bonnet, for nicks or scratches and smooth with 1/4 inch.) When the distance is correct, replace

emery cloth if required. Before re-assembling the the punch or screwdriver by pin (2) and turn the

valve, apply a good grade of general purpose handle to full open position, retracting the gate

grease to all threads, seal rings (not the back-up into the bonnet.

ring), exterior of the seat and on the surfaces of

the bonnet and stem which contact seals. 1b. Other valves: Line up the holes in the hub and

stem and drive pin (2) through the hub. Screw

the gate on the stem counterclockwise until it

Reassembly touches the underside of the bonnet, then back

1. Install the stem seal (5) in the bonnet bore groove it off to align the gate with the bonnet cavity.

and insert the back-up ring (4) above it. This ring Turn the handle to full open position, retracting

prevents extrusion of the stem seal into the clear- the gate into the bonnet.

ance between stem and bonnet, so it must be

positioned on the low-pressure side of the stem 2. Replace the bonnet seal (10). Assemble seat (12)

seal. Replace seal (14) on Class 900-1500 valves. and bonnet to the valve body keeping the seat

Screw the handle on the bonnet to its limit of ports aligned with the body line bore, making

travel and slide the stem through the bonnet from sure the gate is in the slot in the seat and that

the underside. the top pins on the seat are in the drilled holes

in the bonnet while performing this operation.

1a. Class 400-600 valves 2” through 8”x6”: Replace nuts (9) (or cap screws on 1-1/2”, 2” and

Line up the holes in the hub and stem and insert 3x2” valves). Repack the handle threads with

a pin punch or screwdriver, of approximately general purpose grease through fitting(3).

pin hole size, through the hub. Screw the gate

on the stem counterclockwise until it touches

the underside of the bonnet, then back it off to

align the gate with the bonnet cavity. Remove

the punch or screwdriver. Pull the stem out of

the bonnet at least one-half inch, (do not permit

stem rotation) then rotate the gate on the stem

one more turn counterclockwise. Re-insert the

stem in the bonnet and the punch or screwdriver

through the holes in the stem and hub. Measure

the distance from the underside of the bonnet

to the farthest edge of the gate. This distance

must be within the following limits for each size

valve.

Valve Size Distance

2”, 3x2” 2-15/16” – 3-3/16”

2-1/2” 3-17/32” – 3-15/16”

3”, 4x3” 4-5/32” – 4-9/16”

4”, 6x4” 5-9/32” – 5-5/8”

6”, 8x6” 7-3/4” – 8-1/32”

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 14 of 24

Repair – Series DM gate valve 2000, 3000,

5000 2” & 2-1/2x2”

22

1

19 4

6

21

BRONZE BUSHING 10 2

15

18

FLAT TOP FOLLOWER

11

FABRIC REINFORCED

SEAL RING 12

17 7

HOMOGENEOUS 16

RUBBER SEAL RING

20

FLAT BOTTOM 9 8

ADAPTER

13

Disassembly

1. Fully open the gate valve. Unscrew coupling (15) reassembly instruction 3 after following the appli-

and withdraw the bonnet assembly from the body. cable maintenance instructions. If it is desired to

Collapse the seat (21) by compressing the top pins inspect other parts, the following instructions

together and remove it from the body. apply.

2. With the bonnet assembly on its side, remove pin 4. Turn the stem clockwise until it disengages from

(22) and lock handle (4) then lift off hub (2). stem screw (6) and withdraw it from the underside

Remove coupling (15). Turn stem screw (6) clock- of the bonnet. Unscrew the lock screw (13) and lift

wise to bottom, then withdraw gate (19) from stem screw housing (8) off the bonnet. Remove re-

(9) by rotating a quarter turn and sliding it off the tainer (11), o-ring seal (10) and stem seal assembly

tee-head of the stem. (12) from the bonnet. Turn stem screw (6) clock-

wise out of the screw housing. Remove screw seal

3. Seat or gate replacement may be made at this (7) from the screw housing and bonnet seal (18)

point. To reassemble the valve, proceed from from the valve body.

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 15 of 24

Inspection until the gate touches the underside of the bonnet

lugs. Align the gate with the opening between

Thoroughly clean all parts and inspect them for wear the lugs and retract it into the bonnet by turning

or damage. It is recommended that seals (7), (10), (18) the stem screw counterclockwise. Place the hub

and stem seal assembly (12) be replaced if they are on the stem screw, insert the lock handle and

worn or cut. All sealing surfaces should be clean and retain it with the cotter pin. Do not spread the pin

free of dirt, rust, nicks and scratches. These will since it may be removed later while adjusting the

include the areas inside the body adjacent to the line gate level.

bore where the seat fits, the area around the lower

part of the bonnet that lies against the bonnet o-ring 4. Install the seat on the bonnet and stand the

seal, the bonnet stuffing box and the surface of the assembly upright resting on the seat. Turn the

stem that passes through the packing. Clean these handle clockwise until the hub is stopped by the

surfaces well and polish with emery cloth if neces- top of the screw housing.

sary, paying particular attention to the valve stem.

Before reassembling, apply a good grade of general Make a pencil mark on one side of the gate even with

purpose grease to all threads, seal rings and exterior the bottom of the seat port. Raise the bottom of the

of the seat and on the surfaces of the bonnet, stem gate into the seat bore by rotating the handle and

and stem screw which are in contact with seals. measure the distance from the pencil mark to the

bottom of the gate. This distance must be be-

Reassembly tween 5/16" - 7/16". If the distance is correct,

proceed to assembly step 5. If not, remove the

1. Slide the threaded end of the stem through the

seat, lock handle and hub from the assembly.

bonnet bore from the underside and place the

Rotate the stem screw clockwise to bottom then

stem seal assembly over the stem. This assembly

back off one-eighth turn. Turn the gate and stem

consists of a flat bottomed adapter ring, homoge-

together while holding the stem screw: counter-

neous rubber seal ring, fabric reinforced seal ring,

clockwise to reduce the distance or clockwise to

a flat topped follower ring and a bushing, which

increase the distance as required. One-half turn of

are placed over the end of the stem, lips first, in

the gate and stem changes the distance 1/16".

that order. The lips on “V” rings point towards

Repeat step 4 until the closed gate position is

bottom of bonnet. Slide the retainer (11) with o-

correct.

ring seal (10) inside over the stem. Seat the stem

seal assembly into its counterbore in the bonnet.

5. Replace bonnet seal (18). Assemble seat (21) and

bonnet to the valve body keeping the seat ports

2. Engage the stem screw (6) in the screw housing (8)

aligned with the body line bore, making sure the

about half its total travel and place the screw

gate is in the slot in the seat and that the top pins

housing on the bonnet and stem. Replace lock

of the seat are in the drilled holes in the bonnet

screw (13). Place the coupling on the screw hous-

while performing this operation. Tighten the

ing.

coupling. Spread the cotter pin (22) in the lock

handle and repack the hub with general-purpose

3. Rotate the stem screw clockwise until it bottoms

grease through fitting (1). This is most effectively

on the retainer, then back it up approximately one-

done when the valve is closed.

eighth turn. Engage the gate on the tee-head of

the stem and turn them together counterclockwise

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 16 of 24

Repair – Series DM gate valve 2000-3000: 2-1/2” –

5X4”; 5000: 3” & 4x3”;Class 1500: 4”; 1000: 5”

19

BRONZE BUSHING 10

11 22

FLAT TOP FOLLOWER

4 1

FABRIC REINFORCED

SEAL RING 12

21

HOMOGENEOUS

RUBBER SEAL RING 23 2

18 FLAT BOTTOM

ADAPTER 26 7

25 16

24

20 6

9

Disassembly

1. Fully open the gate valve. Remove nuts (26) and 4. Turn the stem clockwise until it disengages from

withdraw the bonnet assembly from the body. stem screw (6) and withdraw it from the underside

Collapse the seat (21) by compressing the top pins of the bonnet. Unscrew the nuts (24) (cap screws on

together and remove it from the body. 5” and 6x5”) and lift screw housing (8) off the

bonnet. Remove retainer (11), o-ring seal (10) and

2. With the bonnet assembly on its side, remove pin stem seal assembly (12) from the bonnet. Turn

(22) and lock handle (4) then lift off hub (2). Turn stem screw (6) clockwise out of the screw housing.

stem screw (6) clockwise to bottom, then with- Remove screw seal (7) from the screw housing and

draw gate (19) from stem (9) by rotating a quarter bonnet seal (18) from the valve body.

turn and sliding it off the tee-head of the stem.

3. Seat or gate replacement may be made at this

Inspection

point. To reassemble the valve, proceed from Thoroughly clean all parts and inspect them for wear

reassembly instruction 3 after following the appli- or damage. It is recommended that seals (7), (10), (18)

cable maintenance instructions. If it is desired to and stem seal assembly (12) be replaced if they are

inspect other parts, the following instructions worn or cut. All sealing surfaces should be clean and

apply.

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 17 of 24

free of dirt, rust, nicks and scratches. These will 5” 1000:

include the areas inside the body adjacent to the line Place the hub on the stem screw, insert the lock

bore where the seat fits, the area around the lower handle and retain it with the cotter pin. Turn the

part of the bonnet that lies against the bonnet o-ring handle clockwise until the hub contacts the screw

seal, the bonnet stuffing box and the surface of the housing. Engage the gate on the tee-head of the

stem that passes through the packing. Clean these stem and turn them together counterclockwise

surfaces well and polish with emery cloth if neces- until the gate touches the underside of the bonnet

sary, paying particular attention to the valve stem. lugs. Align the gate with the opening between the

Before reassembling, apply a good grade of general lugs and retract it into the bonnet by turning the

purpose grease to all threads, seal rings and exterior handle counterclockwise.

of the seat and on the surfaces of the bonnet, stem

and stem screw which are in contact with seals. 4. Install the seat on the bonnet and stand the

assembly upright resting on the seat. Turn the

handle clockwise until the hub is stopped by the

Reassembly top of the screw housing. Make a pencil mark on

1. Slide the threaded end of the stem through the one side of the gate even with the bottom of the

bonnet bore from the underside and place the seat port. Raise the bottom of the gate into the

stem seal assembly over the stem. This assembly seat bore by rotating the handle and measure the

consists of a flat bottomed adapter ring, homoge- distance from the pencil mark to the bottom of the

neous rubber seal ring, fabric reinforced seal ring, gate. This distance must be within the following

a flat-topped follower ring and a bushing, which limits for each size valve: 2-1/2", 3" and 4x3” - 3/8"

are placed over the end of the stem, lips first, in to 1/2"; 4" and 5x4” - 7/16" to 9/16"; 5” and 6x5” –

that order. The lips on “V” rings point towards 1/2” to 5/8”.

bottom of bonnet. Slide the retainer (11) with o-

ring seal (10) inside over the stem. Seat the stem If the distance is correct, spread the cotter pin and

seal assembly into its counterbore in the bonnet. proceed to assembly step 5. If not, remove the seat,

lock handle and hub from the assembly. Rotate the

2. Engage the stem screw (6) in the screw housing (8) stem screw clockwise to bottom then back off one-

about half its total travel and place the screw eighth turn. Turn the gate and stem together while

housing on the bonnet and stem. Replace nuts (24) holding the stem screw: counterclockwise to reduce

(cap screws on 5” and 6x5”). the distance or clockwise to increase the distance as

required. One-half turn of the gate and stem changes

3. All except 5” 1000: the distance approximately 3/32". Repeat step 4 until

Rotate the stem screw clockwise until it bottoms the closed gate position is correct.

on the retainer, then back it up approximately one-

eighth turn. Engage the gate on the tee-head of 5. Replace bonnet seal (18). Assemble seat (21) and

the stem and turn them together counterclockwise bonnet to the valve body keeping the seat ports

until the gate touches the underside of the bonnet aligned with the body line bore, making sure the

lugs. Align the gate with the opening between the gate is in the slot in the seat and that the top pins

lugs and retract it into the bonnet by turning the of the seat are in the drilled holes in the bonnet

stem screw counterclockwise. Place the hub on the while performing this operation. Replace and

stem screw, insert the lock handle and retain it tighten nuts (26). Spread the cotter pin (22) in the

with the cotter pin. Do not spread the pin since it lock handle and repack the hub with general-

may be removed later while adjusting the gate purpose grease through fitting (1). This is most

level. effectively done when the valve is closed.

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 18 of 24

Repair – Series DM gate valves 5000: 4”, 5x4”

and 6x4” 4

3

26

23

16 2

7

9 24

14

13

6

19 8

5

21

13

18 10

BRONZE BUSHING

25 11

FLAT TOP FOLLOWER

FABRIC REINFORCED

SEAL RING 12

HOMOGENEOUS

20 RUBBER SEAL RING

FLAT BOTTOM

ADAPTER

Disassembly

1. Fully open the gate valve. Remove nuts (26) (this 3. Seat or gate replacement may be made at this

valve may have either 4 or 12 studs and nuts) and point. To reassemble the valve, proceed from

withdraw the bonnet assembly from the body. reassembly instruction 4 after following the appli-

Collapse the seat (21) by compressing the top pins cable maintenance instructions. If it is desired to

together and remove it from the body. inspect other parts, the following instructions

apply.

2. With the bonnet assembly on its side, turn the

handle (2) clockwise to move the gate (19) out of 4. Remove stem cap (4), tube (3), handle (2) and key

the bonnet. Withdraw the gate from the stem (9) (5). Remove nuts (24) and lift off the screw

by rotating a quarter turn and sliding it off the tee- housing (8). Rotate the stem screw (6) clockwise

head of the stem. off the stem and remove bearings (13) and retainer

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 19 of 24

(11). Lift the stem part way so that the down stop 2. Place the stem seal assembly (12) over the stem. This

ring (14) may be removed, then withdraw the assembly consists of a flat bottomed adapter ring,

stem from the underside of the bonnet. The stem homogeneous rubber seal ring, fabric reinforced

seal assembly (12), including the bushing, may seal ring, a flat topped follower ring and a bushing

now be removed. which are placed over the end of the stem in that

order. The lips on “V” rings point towards bottom

Inspection of bonnet. Work the seal and follower rings

carefully down over the stem thread, lips first, and

Thoroughly clean all parts and inspect them for into the stuffing box, being careful that the lips of

wear or damage. It is recommended that seals (7), the rings do not get curled back. After the bushing,

(10), (18) and stem seal assembly (12) be replaced if put the retainer (11), with o-ring inside, down over

they are worn or cut. All sealing surfaces should the stem with flat side up.

be clean and free of dirt, rust, nicks and scratches.

These will include the areas inside the body 3. Follow the retainer with a bearing (13) and the

adjacent to the line bore where the seat fits, the stem screw (6). The bearing must be concentric

area around the lower part of the bonnet that lies with the stem screw before further assembly. Place

against the bonnet o-ring seal, the bonnet stuffing another bearing down over the stem screw and

box and the surface of the stem that passes follow with the screw housing (8), with o-ring seal

through the packing. Clean these surfaces well (7) inside, and tighten nuts (24). Put the key (5) into

and polish with emery cloth if necessary, paying its slot in the stem screw and replace the handle (2),

particular attention to the valve stem. Also clean tube (3) and stem cap (4) in that order.

and polish the surfaces of the stem screw that run

against the bearings. Before reassembling, apply a 4. Slide the gate (19) into the stem, turn it a quarter

good grade of general purpose grease to all turn to line it up with the slot in the bonnet and

threads, bearings, seal rings and exterior of the draw it up all the way into the bonnet by turning

seat and on the surfaces of the bonnet, stem and the handle counterclockwise. Replace bonnet seal

stem screw which are in contact with seals. (18). Assemble seat (21) and bonnet to the valve

body

Reassembly keeping the seat ports aligned with the body line

bore, making sure the gate is in the slot in the seat

1. Slide the threaded end of the stem (9) through the

and that the top pins on the seat are in the drilled

bonnet bore from the underside and draw the stem

holes in the bonnet while performing this opera-

head part way up into the bonnet (16). Put the

tion. Tighten nuts (26) and repack the screw hous-

down stop ring (14) on over the bottom of the stem

ing (8) with general-purpose grease through fit-

head, lower the stem so that the down stop ring

ting (1).

shoulders on the inside of the bonnet.

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 20 of 24

Repair – Series DM gate valve 3000-5000: 5”, 6x5”

24

23

9 1

14

6

22

26

25

4 19

THRUST WASHER NEEDLE AND CAGE

ASSEMBLY

13

18

12 THRUST WASHER NEEDLE AND CAGE

ASSEMBLY

10 BRONZE BUSHING

FLAT TOP FOLLOWER 21

8

20

FABRIC REINFORCED

SEAL RINGS

5

11

HOMOGENEOUS

RUBBER SEAL RING

FLAT BOTTOM

ADAPTER

Disassembly

1. Fully open the gate valve. Remove nuts (9) and 3. Seat or gate replacement may be made at this

withdraw the bonnet assembly from the body. point. To reassemble the valve, proceed from

Collapse the seat (12) by compressing the insert reassembly instruction 4 after following the

pins together and remove it from the body. applicable maintenance instructions. If it is desired

to inspect other parts, the following instructions

2. With the bonnet assembly on its side, turn the apply.

handwheel (1) clockwise to move the gate (13) out

of the bonnet. Withdraw the gate from the stem 4. Remove stem cap (24), tube (23), screw (2) and

(6) by rotating a quarter turn and sliding it off the handwheel (1). Remove screws (22) and lift off the

tee-head of the stem. housing (19). Rotate the stem screw (18) off the

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

Page 21 of 24

stem (left hand Acme) and remove needle and cage 2. Place the stem seal assembly (5) over the stem. The

assemblies and thrust washers. Remove screws (3) order in which the rings are assembled must be

and lift off the retainer (21). Lift the stem part way exactly as shown with sealing lips down. While

so that the down stop ring (4) may be removed, installing the rings over the thread on the stem,

then withdraw the stem from the underside of the assure these lips are not damaged. Place bushing

bonnet. The stem seal assembly (5), including on top of the stem seal assembly.

bushing, may now be removed.

3. Put o-ring (20) into its groove in the bottom of

retainer (21) and work retainer with o-ring down

Maintenance over the stem. Bolt retainer to the bonnet with

four screws (3). Place two thrust washers with a

Thoroughly clean all parts and inspect them for wear

needle and cage assembly between them on top of

or damage. It is recommended that the seals (10),

the retainer then turn the stem screw (18)

(14), (20) and stem seal assembly (5) be replaced if they

counterclockwise on the stem so that it seats

are worn or cut. All sealing surfaces should be clean

against the thrust washer and lifts the stem off the

and free of dirt, scale, nicks and scratches. These will

down stop ring approximately one turn. Place the

include the areas inside the body adjacent to the line

other two thrust washers with needle and cage

bore where the seat fits, the area around the lower

assembly between them over the stem screw. Put

part of the bonnet that lies against the bonnet o-ring

o-ring (14) in its groove in housing (19) and bolt the

seal, the bonnet stuffing box and the surface of the

housing to the bonnet with screws (22). Attach

stem that passes through the packing. Clean these

handwheel (1) to the stem screw with screw (2) and

surfaces well and polish with 320 grit emery cloth if

replace tube (23) and stem cap (24).

necessary, paying particular attention to the valve

stem. Before reassembling, apply a good grade of

4. Slide the gate (13) onto the stem, turn it a quarter

general purpose grease to all threads, bearings, seal

turn to line it up with the slot in the bonnet and

rings and exterior of the seat and on the surfaces of

draw it up all the way into the bonnet by turning

the bonnet, stem and stem screw which are in contact

the handle counterclockwise. Replace the bonnet

with seals.

seal o-ring (10). Assemble the seat (12) and bonnet

to the valve body keeping the seat ports aligned

Reassembly with the body line bore, making sure the gate is in

1. Slide the threaded end of the stem (6) through the the slot in the seat and that the top pins on the seat

bonnet bore from the underside and draw the stem are in the drilled holes in the bonnet while

head part way up into the bonnet. Put the down performing this operation. Replace and tighten

stop ring (4) on over the bottom of the stem head, nuts (9). Repack housing (19) with a good grade of

lower the stem so that the down stop ring shoulders general-purpose grease through fitting (25).

on the inside of the bonnet.

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

Page 22 of 24

Troubleshooting

Trouble Pr obable Cause Remedy

Leakage through valve Valve not fully closed due to Open valve slightly and re-close.

obstruction in line. If this does not fix the problem,

remove bonnet for inspection.

Valve is not fully closed due to Disassemble valve and reassemble

improper assembly. according to proper instructions.

Valve gate may be jammed into Back off hand 1/4 turn.

bottom of seat. Never back off the handle under

normal conditions.

Seat or gate is damaged. Replace defective parts.

Seat material incompatible with Consult factory for proper materials.

operating media or temperature.

Body has eroded or corroded out of Replace or repair body.

tolerance.

Leakage around stem Stem seal material is incompatible Consult factory for proper materials.

with operating media or tempera-

ture.

Stem is bent or otherwise damaged. Replace

Leakage between Bonnet seal damaged. Replace

body and bonnet

Bonnet seal material is incompatible Consult factory for proper materials.

with operating media or tempera-

ture.

Porosity has developed in body or Replace valve.

bonnet.

Difficult or rough Valve needs lubrication. Lubricate per instructions under

operation "Routine Maintenance"

Threads or bearings are worn or

otherwise damaged. Replace defective parts.

Valve will not open or Valve is packed with solids. If ice or hydrates are suspected, the

close valve may be heated to 200°F max. If

the valve is packed with other solids,

it must be disassembled and cleaned

out.

Threaded parts are locked up. Damage may have resulted from

excessive operating forces.

See page 11 "Operation."

Valve was improperly assembled. Reassemble per proper instructions.

Additional information is also available on-line at http://www.c-a-m.com

Publication DEMCO® Model DM Gate Valve

TC1641 Installation, Operation , Maintenance & Repair Manual

~CAMERON Page 23 of 24

DEMCO® Model DM Gate Valve Publication

TC1641

Installation, Operation , Maintenance & Repair Manual

~CAMERON

Contact your Cameron's Valves & Measurement group representa~ve for a Repair Manual

DEMeo·

~CAMERON

32 50 Briarpa, k Driv •• Suit. 300

Ho..non, Tua< 77042

USA Toll f ,.... 800 123 9160

For 111. moot cu .... '" eontac:. ond Ioeatloft Inlorma'kIft go '0: www ......... comIv.I • •• and ...... u ..........

c c-nn'._ &" , eo . ,,,,' Groop

Ins tallation , Operation and Maintenance Manual IOM·DEM.GATE.oM

Vous aimerez peut-être aussi

- Demco Gate Valves BrochureDocument56 pagesDemco Gate Valves BrochureVictor100% (1)

- Stripper Packer DSV4 3.06 1 VentanaDocument12 pagesStripper Packer DSV4 3.06 1 VentanaValeria Sanchez100% (1)

- Annular Bop Packing Elements: Otu Se (Axs)Document2 pagesAnnular Bop Packing Elements: Otu Se (Axs)JoseManuelDominguezHuertaPas encore d'évaluation

- Annular Spherical Packing ElementsDocument21 pagesAnnular Spherical Packing Elementsjesus100% (1)

- Cameron EB 538 D Rev D2 - Shear Rams - Op & MaintDocument7 pagesCameron EB 538 D Rev D2 - Shear Rams - Op & MaintCanrig RamdePas encore d'évaluation

- Manual-0002 CDocument87 pagesManual-0002 CBoedi SyafiqPas encore d'évaluation

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 pagesStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaPas encore d'évaluation

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalhePas encore d'évaluation

- Malacates CatalogoDocument37 pagesMalacates Catalogohlarrottacamargo100% (1)

- Parker HTR ActuatorDocument22 pagesParker HTR ActuatorYorkistPas encore d'évaluation

- Cameron Type U BOPDocument3 pagesCameron Type U BOPPablo David SaabPas encore d'évaluation

- Tc1350 Drilling ChokeDocument26 pagesTc1350 Drilling ChokeazeazeazePas encore d'évaluation

- Shaffer Ram & Spherical Blowout Preventer PartsDocument5 pagesShaffer Ram & Spherical Blowout Preventer PartsJIN WANGPas encore d'évaluation

- Tc148-2 Manual GV O&mDocument20 pagesTc148-2 Manual GV O&mFam Escalante OnofrePas encore d'évaluation

- Hydril Shear Ram CapacityDocument7 pagesHydril Shear Ram CapacityLenny PuspitaPas encore d'évaluation

- Cameron - DL-Annular BopDocument1 pageCameron - DL-Annular BopAnonymous 48jYxR1CPas encore d'évaluation

- Preventores CameronRPC 2001Document60 pagesPreventores CameronRPC 2001VICTOR ALFONSO GARCIA LOPEZPas encore d'évaluation

- ADocument12 pagesAJulio ReisPas encore d'évaluation

- Parveen Well HeadDocument25 pagesParveen Well HeadGerman PinedaPas encore d'évaluation

- QBH Ram Bop'S: 4-1/16" 15,000 Psi WPDocument32 pagesQBH Ram Bop'S: 4-1/16" 15,000 Psi WPjuan olarte0% (1)

- M60eh44 Man 001Document40 pagesM60eh44 Man 001Riski KurniawanPas encore d'évaluation

- Parveen Well Head PDFDocument25 pagesParveen Well Head PDFRatnakar PatilPas encore d'évaluation

- Choke and Kill 4 Inch 10K 4 Inch 5K of NOVDocument2 pagesChoke and Kill 4 Inch 10K 4 Inch 5K of NOV刘 建Pas encore d'évaluation

- 1403E Under Over Stripper PDFDocument16 pages1403E Under Over Stripper PDFOvRrj AhmedPas encore d'évaluation

- TUT935 (TRUCK MOUNTED COILED TUBING UNIT) - 2010 Hydra Rig 10x8Document12 pagesTUT935 (TRUCK MOUNTED COILED TUBING UNIT) - 2010 Hydra Rig 10x8Alexander KlmPas encore d'évaluation

- Ram-Type BOPs U BOP at BULLET UII BOP UL PDFDocument24 pagesRam-Type BOPs U BOP at BULLET UII BOP UL PDFEnrique HortaPas encore d'évaluation

- MUD PUMP EXPENDABLES Emsco PDFDocument9 pagesMUD PUMP EXPENDABLES Emsco PDFleoPas encore d'évaluation

- 13.62 5K Model 7022 Manual PDFDocument30 pages13.62 5K Model 7022 Manual PDFPato GonzalezPas encore d'évaluation

- Woodco: Catalog For Inside Blowout PreventersDocument13 pagesWoodco: Catalog For Inside Blowout PreventersJairo PuentesPas encore d'évaluation

- 13.625 10K Double Cameron U BOP PDFDocument2 pages13.625 10K Double Cameron U BOP PDFAndung Suwarto100% (1)

- Regulator3 4 DSDocument4 pagesRegulator3 4 DSargaPas encore d'évaluation

- VR Lubricator ToolDocument2 pagesVR Lubricator ToolChrisPas encore d'évaluation

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 pagesOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezPas encore d'évaluation

- Maintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesDocument32 pagesMaintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesNeilton Junior100% (2)

- Cameron EB 555 D Rev U2 - VBR Engineering InfoDocument6 pagesCameron EB 555 D Rev U2 - VBR Engineering InfoCanrig Ramde100% (1)

- 3.06 10K EK Quad BOP PDFDocument25 pages3.06 10K EK Quad BOP PDFJose Leonardo Materano Perozo100% (1)

- General Catalog 2016Document64 pagesGeneral Catalog 2016Jamal100% (1)

- Tc148 FL & FLS Op and MaintDocument24 pagesTc148 FL & FLS Op and MaintAlejandro ParradoPas encore d'évaluation

- Catalog 2Document44 pagesCatalog 2Enrique HortaPas encore d'évaluation

- Uztel OrizontalDocument5 pagesUztel OrizontalDorin RaduPas encore d'évaluation

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocument24 pagesTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanPas encore d'évaluation

- WWW 018999Document39 pagesWWW 018999Andhie OsloPas encore d'évaluation

- Westco Product Catalog 2019Document16 pagesWestco Product Catalog 2019DiegoCaicedo1982100% (2)

- CadDocument21 pagesCadJuan Ulin100% (1)

- Engineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Document2 pagesEngineering Report Low Force Shear Ram Test Results AXON 18-3/4" 10M Type 50Bala KrishnanPas encore d'évaluation

- 719638-6A3-MAN - Rev 01 - 719638-6A3-MANDocument52 pages719638-6A3-MAN - Rev 01 - 719638-6A3-MANFam Escalante OnofrePas encore d'évaluation

- Varco BushingsDocument1 pageVarco BushingsVision100% (1)

- 7.6 SingleDocument226 pages7.6 Singlewuillian barretoPas encore d'évaluation

- Controll Cabin OEM PDFDocument47 pagesControll Cabin OEM PDFOvRrj AhmedPas encore d'évaluation

- Cameron Bop PartsDocument62 pagesCameron Bop PartsSurya Prakash DubeyPas encore d'évaluation

- Annular Bops D Bop DL Bop: To Contents PageDocument6 pagesAnnular Bops D Bop DL Bop: To Contents PageJohn Alexander Bonilla AngelPas encore d'évaluation

- Down Hole Assembly PDFDocument13 pagesDown Hole Assembly PDFOvRrj AhmedPas encore d'évaluation

- M60es54 Na549y QC Man 001Document29 pagesM60es54 Na549y QC Man 001Riski Kurniawan67% (3)

- MELCO General CatalogoDocument106 pagesMELCO General CatalogoDavid GonzalezPas encore d'évaluation

- DSQ4 10M SidedoorDocument15 pagesDSQ4 10M SidedoorДудла СтаніславPas encore d'évaluation

- COS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronDocument5 pagesCOS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronYudaPas encore d'évaluation

- Maintenance Schedule For Adapter Flange - 5131086 - 01Document7 pagesMaintenance Schedule For Adapter Flange - 5131086 - 01franko guddiPas encore d'évaluation

- SOP 829-009 Nipple Up BOPs.Document2 pagesSOP 829-009 Nipple Up BOPs.Anonymous XbmoAFtIPas encore d'évaluation

- Cameron Iom R DemcodmgatevalvesDocument24 pagesCameron Iom R DemcodmgatevalvesbenkaouhaPas encore d'évaluation

- 39 PRTPC1 IDocument2 pages39 PRTPC1 IKashif MasudPas encore d'évaluation

- Third Party Inspection ScopeDocument1 pageThird Party Inspection ScopeAshok SureshPas encore d'évaluation

- P16MBA3Document4 pagesP16MBA3Ashok SureshPas encore d'évaluation

- Small Engine Reassembly - GDLCDocument40 pagesSmall Engine Reassembly - GDLCAshok SureshPas encore d'évaluation

- P16MBA4Document2 pagesP16MBA4Ashok SureshPas encore d'évaluation

- NPS - Unit 102 ScopeDocument2 pagesNPS - Unit 102 ScopeAshok SureshPas encore d'évaluation

- Belzona 5111: Instructions For UseDocument2 pagesBelzona 5111: Instructions For UsePedro RuizPas encore d'évaluation

- Technical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarDocument2 pagesTechnical Information APP. 5 Field of Application:: 6 Bar/10 Bar /16 BarAshok SureshPas encore d'évaluation

- Demco DM Iom PDFDocument24 pagesDemco DM Iom PDFAshok SureshPas encore d'évaluation

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023Pas encore d'évaluation

- PVCMC 0501 Us PDFDocument40 pagesPVCMC 0501 Us PDFAshok SureshPas encore d'évaluation

- ShowdocwDocument7 pagesShowdocwFahad KhanPas encore d'évaluation

- Masts/Derricks/Substructures: Api RP 4GDocument12 pagesMasts/Derricks/Substructures: Api RP 4GegyinspectoryahooPas encore d'évaluation

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshPas encore d'évaluation

- BD-28 (B24) IomDocument39 pagesBD-28 (B24) Iomkrishan_raj_1Pas encore d'évaluation

- 4th 120316074120 Phpapp02Document27 pages4th 120316074120 Phpapp02Ahmed ghPas encore d'évaluation

- Kemper Catalog FlowControl Oct2013Document20 pagesKemper Catalog FlowControl Oct2013jesdcp7Pas encore d'évaluation

- Design Calculation: Part No: 16 FS 4950 CAL 001 Material: AISI 4130 Yield Strength, Sy 75,000 Psi. MinDocument1 pageDesign Calculation: Part No: 16 FS 4950 CAL 001 Material: AISI 4130 Yield Strength, Sy 75,000 Psi. MinAshok SureshPas encore d'évaluation

- BD-28 (B24) IomDocument39 pagesBD-28 (B24) Iomkrishan_raj_1Pas encore d'évaluation

- Ailgent Vs Pro - BrochureDocument6 pagesAilgent Vs Pro - BrochureTasha MorrisPas encore d'évaluation

- Adapter CouplingDocument48 pagesAdapter CouplingIan_SmythPas encore d'évaluation

- Cameron Part Numbering SystemDocument10 pagesCameron Part Numbering SystemAshok SureshPas encore d'évaluation

- Pressure Control EquipmentDocument169 pagesPressure Control EquipmentAshok SureshPas encore d'évaluation

- Cost Breakup For SGS Second PumpDocument1 pageCost Breakup For SGS Second PumpAshok SureshPas encore d'évaluation

- 12 Drilling PreventersDocument82 pages12 Drilling PreventersDavid Kusuma100% (1)

- Hercules Production Solutions Catalog PDFDocument28 pagesHercules Production Solutions Catalog PDFPedro Antonio Mejia SuarezPas encore d'évaluation

- Vciom 06204 enDocument19 pagesVciom 06204 enAshok SureshPas encore d'évaluation

- For Reference: Material: SS 304 3 MM ThickDocument2 pagesFor Reference: Material: SS 304 3 MM ThickAshok SureshPas encore d'évaluation

- Fastener HandoutDocument32 pagesFastener HandoutRaifan RaizerPas encore d'évaluation

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizPas encore d'évaluation

- MS2420 / MS2430: Installation and User's GuideDocument81 pagesMS2420 / MS2430: Installation and User's GuideMauricio MatutePas encore d'évaluation

- System Specification Information SheetDocument3 pagesSystem Specification Information SheetMaria Jane RubioPas encore d'évaluation

- Have You Ever Game: Canada Canada Canada CanadaDocument4 pagesHave You Ever Game: Canada Canada Canada CanadaAnami JumancaPas encore d'évaluation

- Catalog Hoap 2Document0 pageCatalog Hoap 2jiji1183Pas encore d'évaluation

- Preschool Cascade Training HandoutsDocument55 pagesPreschool Cascade Training Handoutsskbtblog100% (2)

- Ielts Writing Task 1 Maps Introductory SentencesDocument2 pagesIelts Writing Task 1 Maps Introductory SentencesPhùng ThúyPas encore d'évaluation

- Huawei Visco StencilsDocument98 pagesHuawei Visco StencilsJuan Camilo Galvis100% (1)

- PastriesDocument36 pagesPastriesNUR HANANI SHAFIKAH JAMALUDINPas encore d'évaluation

- Beatriz Milhazes Interview: There Is Nothing Simple About What I'm Doing'Document2 pagesBeatriz Milhazes Interview: There Is Nothing Simple About What I'm Doing'C_RigbyPas encore d'évaluation

- Piano TheoryDocument51 pagesPiano Theorychica liberato100% (2)

- Alchemy Gold Slot Demo RTP 96.78 Free PlayDocument1 pageAlchemy Gold Slot Demo RTP 96.78 Free Playbc287724Pas encore d'évaluation

- Numerology Worksheet PDFDocument1 pageNumerology Worksheet PDFgreenstar100% (8)

- Billiard DocumentationDocument6 pagesBilliard DocumentationFlash Game StudioPas encore d'évaluation

- World of Darkness FirearmsDocument23 pagesWorld of Darkness FirearmsPreston Halcomb67% (9)

- Mast Lift Cylinders, Models With Single Lift Cylinder MastDocument3 pagesMast Lift Cylinders, Models With Single Lift Cylinder MastJhonny Rodriguez100% (1)

- Drum Kit Diplomas Repertoire List PDFDocument11 pagesDrum Kit Diplomas Repertoire List PDFAshwin ShekharPas encore d'évaluation

- Catalogue Key BlanksDocument10 pagesCatalogue Key BlanksWiwitPas encore d'évaluation

- Web KameraDocument20 pagesWeb KameraDjerdj F. LazarPas encore d'évaluation

- Video ConferencingDocument2 pagesVideo ConferencingJeoPas encore d'évaluation

- Assignment Group Report PMKDocument16 pagesAssignment Group Report PMKMUSHI ABDULLAH BIN MUHAMAD JEHKA (KB)Pas encore d'évaluation

- K3V Series Parts DiagramsDocument6 pagesK3V Series Parts Diagramst5442071100% (3)

- Prepositions of MovementDocument4 pagesPrepositions of MovementLucia MeloPas encore d'évaluation

- PINK TryDocument3 pagesPINK Trym.prinettiPas encore d'évaluation

- Email MarketingDocument1 pageEmail MarketingRoss BeadmanPas encore d'évaluation

- Untitled 10Document2 pagesUntitled 10manas sankhlaPas encore d'évaluation

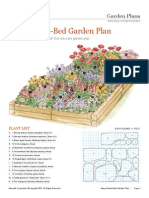

- Garden PlansDocument6 pagesGarden PlansRoberto LandaPas encore d'évaluation

- M5A99X EVO、M5A97 EVO、M5A97 PRO: DDR3 1067 Qualified Vendors List (QVL)Document12 pagesM5A99X EVO、M5A97 EVO、M5A97 PRO: DDR3 1067 Qualified Vendors List (QVL)Carlos Adrian Urcia PelaezPas encore d'évaluation

- Technological Advancements in SportsDocument24 pagesTechnological Advancements in SportsDishaNegiPas encore d'évaluation

- Jewell Hill ResumeDocument2 pagesJewell Hill ResumeJewell HillPas encore d'évaluation

- Datasheet of DS-2DF8236IX-AEL (W) - 20170911Document5 pagesDatasheet of DS-2DF8236IX-AEL (W) - 20170911gohilnarendraPas encore d'évaluation