Académique Documents

Professionnel Documents

Culture Documents

Flakiness Index Test

Transféré par

anasameranaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Flakiness Index Test

Transféré par

anasameranaDroits d'auteur :

Formats disponibles

FLAKINESS INDEX TEST

( IS: 2386 )

Location : RMC Plant - Date :

Source :

Size of Aggregate : 20 mm

Size of Aggregate Number of Particles Wt. Particles

Sl Pass Total In Each Passing Xi = e / d Total In Each Yi = Xi x Yi / 100

No. Thro Ret. on Fraction Thro Fraction g / Total %

mm mm Gauge

a b c d e f g h

1 63.0 50.0

2 50.0 40.0

3 40.0 31.5

4 31.5 25.0

5 25.0 20.0

6 20.0 16.0

7 16.0 12.5

8 12.5 10.0

9 10.0 6.3

Total = Total (%) =

FLAKINESS INDEX =

Size of Aggregate :12.5 mm / 10mm

Size of Aggregate Number of Particles Wt. Particles

Sl Pass Total In Each Passing Xi = e / d Total In Each Yi = Xi x Yi / 100

No. Thro Ret. on Fraction Thro Fraction g / Total

mm mm Gauge

a b c d e f g h

1 25.0 20.0

2 20.0 16.0

3 16.0 12.5

4 12.5 10.0

5 10.0 6.3

Total Total (%)

FLAKINESS INDEX =

Lab Technician QC Incharge

ELONGATION INDEX TEST

( IS: 2386 )

Location : RMC Plant Date :

Source :

Size of Aggregate : 20mm

Sl. Size of Aggregate Weight of particles, g

No. Pass Thro . Ret . on Total In Each Ret.Each

mm mm Fraction Fraction

1 40.0 25.0

2 25.0 20.0

3 20.0 16.0

4 16.0 12.5

5 12.5 10.0

6 10.0 6.3

Total Sample Total Sample

(Yi) = (Xi) =

ELONGATION INDEX = ( Xi / Yi) x 100

Size of Aggregate : 12.5mm / 10mm

Sl. Size of Aggregate Weight of particles, g

No. Pass Thro . Ret . on Total In Each Ret.Each

mm mm Fraction Fraction

1 25.0 20.0

2 20.0 16.0

3 16.0 12.5

4 12.5 10.0

5 10.0 6.3

Total Sample Total Sample

(Yi) = (Xi) =

ELONGATION INDEX = ( Xi / Yi) x 100

Lab Technician QC Incharge

CLIENT NAME :

SL No GRADE SLUMP DATE DATE AGE AT WEIGHT LOAD COMPRESSIVE AVERAGE

OF LOCATION OF IN OF OF TEST OF IN STRENGTH STRENGTH REMARKS

RMC CONCRETE mm CASTING TESTING DAYS CUBE,Kg KN N/mm 2

N/mm2

Lab Technician QC Incharge

SIEVE ANALYSIS OF FINE AGGREGATE

( IS: 383 / 2386)

Location : RMC Plant Date

Source :

Size of Aggregate : (River Sand / Crushed Stone Sand)

IS Weight retained % Cum % Cum %

Remarks

Sieve,mm gms Retained Retained Passing

10.000

4.750

2.360

1.180

0.600

0.300

0.150

pan

Total =

Grading Zone =

Test accepted / rejected under clause. 4.1 ( Table - 2 ) of IS: 383 - 1970.

Remarks.

Lab Technician QC Incharge

SIEVE ANALYSIS OF COARSE AGGREGATE

( IS: 2386 / IS: 383 )

Location : RMC Plant Date :

Source :

Size of Aggregate : 20mm

IS Weight retained % Cum % Cum %

Remarks

Sieve,mm gms Retained Retained Passing

40.00

20.00

10.00

4.75

pan

Total =

Size of Aggregate : 12.5/10mm

IS Weight retained % Cum % Cum %

Remarks

Sieve,mm gms Retained Retained Passing

16.00

12.50

10.00

4.75

2.36

pan

Total =

Test accepted / rejected under clause. 4.1 ( Table - 2 ) of IS: 383 - 1970.

Remarks.

Lab Technician QC Incharge

ALL IN AGGREGATE

Location : RMC Plant Date :

Source :

CUM % PASSING IN MATERIAL CUM % PASSING IN MATERIAL CUM% IS 383

% % % % % % % % PASSING LIMITS

IS SIEVE

100 100 100 100 ALL IN AGG ALL IN AGG

20mm 10mm R.SAND C.S.SAND 20mm 10mm R.SAND C.S.SAND

40.00 100

20.00 95 -100

4.75 30 - 50

0.60 10 - 35

0.15 0-6

BLENDED FOR PUMPABLE MIX

120

100

80

% PASSING

60

Column M

Column O

40

20

0

0.15 0.6 4.75 20 40

IS SIEVE (mm)

Lab Technician QC Incharge

WET SIEVE ANALYSIS OF FINE AGG & COARSE AGG SILT & CLAY TEST

(IS: 2386 / IS 383)

Location : RMC Plant - Date :

Source :

SL No DETERMINATION 1 2

1 Weight of Rep. sample

2 Weight of Sample after oven drying

3 Oven dried weight of sample retained on 75 micron

sieve after washing

4 Percentage of silt / clay (3-4) / (3) x 100

Test accepted / rejected under clause Table - 1, Sl.No.(iii) of IS : 383 - 1970.

Remarks ______________________

Lab Technician QC Incharge

DETERMINATION OF IMPACT VALUE

( IS: 2386 /PART 4 )

Location : RMC Plant - Date :

Source :

Size of Aggregate : PASSING 12.5 mm

RETAINED ON 10 mm

DETERMINATION No. 1 2

Weight of Dry Aggregate (W1) gms.

Weight of Aggregate retained on 2.36 mm

Weight of Aggregate passing through

2.36 mm sieve (W2) gms.

Impact Value = W2/W1X100 %

Average Impact value %

Lab Technician QC Incharge

DETERMINATION OF SPECIFIC GRAVITY

( IS: 2386 /PART 4 )

Location : RMC Plant - Date :

Source :

Size of Aggregate :

DETERMINATION 1 2

Weight of Empty Pyconometer (W1) gms

Wt. of PYC + Sample (W2) gms

Wt. of PYC + Sample + Water (W3) gms

Wt. of PYC + Water (W4) gms

Specific gravity= (W2-W1)/(W4-W1)-(W3-W2)

Specific gravity Average

Lab Technician QC Incharge

DRY LOOSE BULK DENSITY - COARSE & FINE AGGREGATE

( IS: 2386 )

Location : RMC Plant - Date

Source :

Size of Aggregate :

SL No DETERMINATION 1 2

1 CYLINDER + SAMPLE Wt (g)

2 Wt of CYLINDER (g)

3 Wt of SAMPLE (g)

4 CYLINDER VOLUME

5 DLBD kg/m3

6 AVERAGE DLBD kg/m3

Lab Technician QC Incharge

Coarse & Fine Aggregates – TIP No:7 / IRC-36

Location : RMC Plant -

Source : Date

Weight of Wet. Weight dry sample, g Weight of water , g Water Content, % Average water

Sl. No.

Sample , g B C B-C B-C/C content, %

20mm Agg

10mm Agg

Fine Agg

Tests accepted / rejected under clause Tip No:7 / IRC-36

Remarks _______________

Lab Technician QC Incharge

DIRECT / INTRA Date :-

SL Clients Grade of Receipe Batch Correction Batch Mix For

No Name Concrete No Ingradiants Qty ( 1 m3 ) Factor Operator

Lab Technician QC Incharge

EFFECT ON STRENGTH, SETTING TIME & SLUMP RETENTION

Date :

TRIAL MIX DOSAGE OF FREE CEMENT SLUMP ( mm ) AVERAGE COMPRESSIVE

REFERENCE TEST ADMIXTURE W/C CONTENT 5 30 60 90 120 150 STRENGTH N/mm2

No BY Wt OF RATIO IN Kg/m3 min min min min min min 3 Days 7 Days 28 Days

CEMENT

NOTE :-

1) CEMENT BATCH No :

2) ADMIXTURE BATCH No :

3) TOTAL DOSAGES :

4) CONCRETE INITIAL SETTING TIME :

Lab Technician QC Incharge

DETERMINATION OF WATER ABSORPTION

( IS: 2386 /PART 4 )

Location : RMC Plant -

Source :

Size of Aggregate : Date :

DETERMINATION No 1 2

Wt of SSD Agg in Air (W1) g

Wt of Dry Agg in Air (W2) g

Water Absorption,% (W1-W2)/W2x100

Average %

Lab Technician QC Inchargge

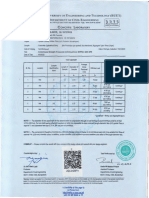

BATCHING PLANT CALIBRATION

Date : 24/2/2006

AGGREGATES

PLANT NO. :- 8 ( ORU )

LOADING DIAL ERROR % UN LOADING DIAL ERROR %

SL STD GAUGE IN OF STD GAUGE IN OF

NO WEIGHT READING Kgs ERROR WEIGHT READING Kgs ERROR

IN Kgs IN Kgs

1 0 0 0 0 1800 1795 -5 -0.28

2 50 50 0 0 1750 1745 -5 -0.29

3 100 100 0 0 1700 1695 -5 -0.29

4 150 150 0 0 1650 1645 -5 -0.30

5 200 200 0 0 1600 1596 -4 -0.25

6 250 250 0 0 1550 1546 -4 -0.26

7 300 300 0 0 1500 1496 -4 -0.27

8 350 350 0 0 1450 1447 -3 -0.21

9 400 400 0 0 1400 1397 -3 -0.21

10 450 450 0 0 1350 1347 -3 -0.22

11 500 500 0 0 1300 1297 -3 -0.23

12 550 550 0 0 1250 1247 -3 -0.24

13 600 600 0 0 1200 1197 -3 -0.25

14 650 650 0 0 1150 1148 -2 -0.17

15 700 700 0 0 1100 1098 -2 -0.18

16 750 750 0 0 1050 1048 -2 -0.19

17 800 800 0 0 1000 998 -2 -0.20

18 850 848 -2 -0.24 950 948 -2 -0.21

19 900 898 -2 -0.22 900 898 -2 -0.22

20 950 948 -2 -0.21 850 848 -2 -0.24

21 1000 998 -2 -0.20 800 800 0 0.00

22 1050 1048 -2 -0.19 750 750 0 0.00

23 1100 1097 -3 -0.27 700 700 0 0.00

24 1150 1147 -3 -0.26 650 650 0 0.00

25 1200 1197 -3 -0.25 600 600 0 0.00

26 1250 1247 -3 -0.24 550 550 0 0.00

27 1300 1297 -3 -0.23 500 500 0 0.00

28 1350 1347 -3 -0.22 450 450 0 0.00

29 1400 1397 -3 -0.21 400 400 0 0.00

30 1450 1447 -3 -0.21 350 350 0 0.00

31 1500 1496 -4 -0.27 300 300 0 0.00

32 1550 1546 -4 -0.26 250 250 0 0.00

33 1600 1596 -4 -0.25 200 200 0 0.00

34 1650 1646 -4 -0.24 150 150 0 0.00

35 1700 1695 -5 -0.29 100 100 0 0.00

36 1750 1745 -5 -0.29 50 50 0 0.00

37 1800 1795 -5 -0.28 0 0 0 0.00

Batching tolerence :- As per IS Specification ± 3%

QC Incharge P&M Incharge

BATCHING PLANT CALIBRATION

Date : 24/2/2006

WATER

PLANT NO. :- 8 ( ORU )

LOADING DIAL ERROR % UN LOADING DIAL ERROR %

SL STD GAUGE IN OF STD GAUGE IN OF

NO WEIGHT READING Kgs ERROR WEIGHT READING Kgs ERROR

IN Kgs IN Kgs

1 0 0 0.0 0 200 199 -1 -0.5

2 20 20 0.0 0.0 180 179 -1 -0.6

3 40 40 0.0 0.0 160 159 -1 -0.6

4 60 60.5 0.5 0.8 140 140.5 0.5 0.4

5 80 80.5 0.5 0.6 120 120.5 0.5 0.4

6 100 100.5 0.5 0.5 100 100.5 0.5 0.5

7 120 120.5 0.5 0.4 80 80.5 0.5 0.6

8 140 140.5 0.5 0.4 60 60.5 0.5 0.8

9 160 159 -1.0 -0.6 40 40 0 0.0

10 180 179 -1.0 -0.6 20 20 0 0.0

11 200 199 -1.0 -0.5 0 0 0 0.0

Batching tolerence :-

QC Incharge P&M Incharge

TEST CERTIFICATE FOR FLYASH

SAMPLE FROM : JOB ID NO

REF LETTER NO: TEST REF. No.

SOURCE : DATE OF TEST

DATE OF REPORT

Sl. No. NAME OF TEST RESULTS OBTAINED

1 Specific gravity

2 Passing through 45 micron, %

3 Surface area by Blaines, m2 /kg

REMARKS: ACCEPTED / REJECTED AS PER IS 3812 part 1 - 2003 PHYSICAL REQUIREMENTS

Tested by Incharge ZTC(S)

CHEMICAL ADMIXTURE TEST REPORT ( IS : 9103 )

SAMPLE FROM JOB ID NO

REF LETTER NO TEST REF NO

MANUFACTURER DATE

ADMIXTURE

BATCH NO

SOLIDS CONTENT

Trial No.

Sl. No. Details

1 2

1 Weight of empty dish, g.

2 Weight of dish. + Admixture sample, g.

3 Weight of dish. + admixture sample after oven dry

at a Temperature of 100oC

4 Percentage of Solids content = (3 - 1) / (2 - 1) x 100

Average (%).

SPECIFIC GRAVITY

1 Specific gravity of admixture determined by

Hydrometer at 28oC.

Remarks.

Tested By Incharge ZTC(S)

BATCHING PLANT CALIBRATION

Date: 24/2/2006

ADMIXTURE

PLANT NO. :- 8 ( ORU )

Disply Out put Error %

SL NO Reading Reading in of Remarkes

(kg) (lit) (kg) Error

1 2

1 1.5 1.48 -0.02 -1.33

2 2.5 2.48 -0.02 -0.80

3 3.5 3.47 -0.03 -0.86

4 4.5 4.47 -0.03 -0.67

5 5.5 5.44 -0.06 -1.09

QC Incharge P&M Incharge

Sl.

No. STD No. Year Description

Specification for 33 Grade ordinary portland cement

1 IS 269 1989( Reaffirmed 1998)

( P No : 7)

Specification for coarse and fine aggregate from natural

2 IS 383 1970( Reaffirmed 1997)

source for concrete ( P No : 19 )

3 IS 455 1989( Reaffirmed 1995) Specification for portland slag cement ( P No : 7 )

Plain and reinforced concrete code of practice

4 IS 456 2000

( P No : 100 )

Plain and reinforced concrete code of practice

5 IS 456 2001

( P No : 5 )

6 IS 516 1959( Reaffirmed 1999) Methods of tests for strength of concrete ( P No : 24 )

Specification for standard sand for testig of cement.

7 IS 650 1991 ( Reaffirmed 1999)

( P No : 4 )

Methods of sampling and analysis of concrete ( P No :

8 IS 1199 1959( Reaffirmed '1999')

44 )

9 IS 1343 1980( Reaffirmed 1999) Code of practice for prestressed concrete (P No : 62 )

IS 1489 Portland pozzolana cement - specification

10 1991

( Part - II ) Part - II ( P No : 16 )

Method of test aggregate of concrete - Particle size and

11 IS 2386 P-I 1963( Reaffirmed 1997)

shape ( P No : 17 )

Method of test aggregate of concrete - Estimation of

12 IS 2386 P-II 1963( Reaffirmed 1990) deleterious materials and arganic impurities.

( P No : 15 )

Method of test aggregate of concrete - Specific gravity,

13 IS 2386 P-III 1963( Reaffirmed 1997)

density, voids, absorption and bulking.( P No : 17 )

Method of test aggregate of concrete - Determination

14 IS 2386 P-IV 1963( Reaffirmed 1997) Crushing value, Impact value & Abrasion value ( P No :

28 )

Method for sampling of aggregate for concrete.

15 IS 2430 1986( Reaffirmed 1995)

( P No : 12 )

16 IS 3535 1986( Reaffirmed 1999) Method of sampling hydralic cement ( P No : 13 )

Specification for fly ash for use as pozzolama and

17 IS 3812 1981( Reaffirmed 1999)

admixture ( First Revision ) ( P No : - 9 )

IS 4031

18 1996( Reaffirmed 2000) Determination of fineness by dry sieving ( P No : 4 )

( Part I )

Method of Physical tests for hydraulic cement-

19 IS 4031 P-IV 1988( Reaffirmed 1995) Determination of considency of standard cement paste

( P No : 2 )

Method of Physical tests for hydraulic cement-

20 IS 4031 P-V 1988( Reaffirmed 1995) Determination of initial and final setting time ( P.No :2)

IS 4031 Determination of compressive strength of hydraulic

21 ( Part 1988 cement other than masonry cement ( P.No : 3)

VI )

Recommendations on stacking and storage of

22 IS 4082 1996

constrction materials at site ( P No : 11 )

Specification for concrete batching and mixing plant

23 IS 4925 1968( Reaffirmed 1996)

( P No : 14 )

Specification for ready mixed concrete

24 IS 4926 1976( Reaffirmed 1999)

( P No : 12 )

Code of practice for extreme weather concreting

25 IS 7861 P-I 1975( Reaffirmed 1997) recommended practice for hot weather concreting

( P No : 20 )

Specification for 43 grade ordinary portland cement

26 IS 8112 1989

( P No : 7 )

Methods of tests for determining setting time of concrete

27 IS 8142 1976( Reaffirmed 1997)

by penetration resistance ( P No : 8 )

Methods of making curing and determining compressive

28 IS 9013 1978( Reaffirmed 1999) strength of accelerated concrete cured test specimens.

( P No : 12 )

29 IS 9103 1999 Specification for admixture for concrete ( P No : 14 )

Recommended guideliness for concrete mix design

30 IS 10262 1982( Reaffirmed 1999)

( P No : 21 )

Specification for 53 grade ordinary portland cement

31 IS 12269 1987( Reaffirmed 1999)

( P No :- 5 )

Prepared By :

Rev No : 00 .

Vous aimerez peut-être aussi

- Sysmex Xs-800i1000i Instructions For Use User's ManualDocument210 pagesSysmex Xs-800i1000i Instructions For Use User's ManualSean Chen67% (6)

- Postgraduate Notes in OrthodonticsDocument257 pagesPostgraduate Notes in OrthodonticsSabrina Nitulescu100% (4)

- TOGAF 9 Foundation Part 1 Exam Preparation GuideDocument114 pagesTOGAF 9 Foundation Part 1 Exam Preparation GuideRodrigo Maia100% (3)

- FLAKINESS AND ELONGATION INDEXDocument3 pagesFLAKINESS AND ELONGATION INDEXRAJESHPas encore d'évaluation

- Combine Flakiness & Elongation TestDocument1 pageCombine Flakiness & Elongation TestFariha AzadPas encore d'évaluation

- Vicat ApparatusDocument1 pageVicat ApparatusBIPL REPORTPas encore d'évaluation

- GONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Document6 pagesGONDA SUB-STATION (400/220/132kV) : Flakiness & Elongation Index (Is 2386, Part 1)Aamir Anwar100% (1)

- WMM material test results for Mundan Construction Company projectDocument2 pagesWMM material test results for Mundan Construction Company projectbrajesh kumar100% (1)

- Ultratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Document24 pagesUltratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Mamata BhangalePas encore d'évaluation

- Mix Design - m40 - Modified 28 Days CcsDocument23 pagesMix Design - m40 - Modified 28 Days CcsKuldeep Chakerwarti100% (2)

- Mix Design and Pie Chart RepresentationDocument40 pagesMix Design and Pie Chart RepresentationKuldeep ChakerwartiPas encore d'évaluation

- Concrete Mix Design For - M5: (As Per IS 10262-2019)Document8 pagesConcrete Mix Design For - M5: (As Per IS 10262-2019)mahesh naikPas encore d'évaluation

- CompressiveStrength (ASTM-C39) Test ReportDocument21 pagesCompressiveStrength (ASTM-C39) Test ReportNadira PervinPas encore d'évaluation

- Civil works quality plan for sewage treatment projectsDocument24 pagesCivil works quality plan for sewage treatment projectsShesha ShayanPas encore d'évaluation

- EPC Contractor Rep. Authority/Authority's EngineerDocument6 pagesEPC Contractor Rep. Authority/Authority's Engineersunil kuldeepPas encore d'évaluation

- M30 Concrete Mix DesignDocument4 pagesM30 Concrete Mix DesignrajupetalokeshPas encore d'évaluation

- Quality Control Format For MPR Ex Dsc-2Document7 pagesQuality Control Format For MPR Ex Dsc-2Rahmat mulyadiPas encore d'évaluation

- South India Textile Research Association standards guideDocument4 pagesSouth India Textile Research Association standards guidePower AgePas encore d'évaluation

- Date: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreDocument2 pagesDate: 19.02.2020 CC Kerb Stone (Core) Test Report The Executive Engineer, Project Central 10, BBMP BangaloreVithun PoojaryPas encore d'évaluation

- Concrete dispatch slip quality planDocument1 pageConcrete dispatch slip quality planShesha ShayanPas encore d'évaluation

- ACI Method of Proportioning Concrete MixesDocument6 pagesACI Method of Proportioning Concrete MixesEulogio JameroPas encore d'évaluation

- AAC Blcok Test ReportDocument1 pageAAC Blcok Test ReportEyutt HghghPas encore d'évaluation

- Half-Cell Potential Method for Measuring Reinforcing Bar Corrosion RiskDocument3 pagesHalf-Cell Potential Method for Measuring Reinforcing Bar Corrosion RiskBIPL REPORTPas encore d'évaluation

- M-25 Design MixDocument7 pagesM-25 Design MixAbhishek GoundPas encore d'évaluation

- 1195 Specification For Bitumen Mastic For FlooringDocument14 pages1195 Specification For Bitumen Mastic For FlooringRakesh RanjanPas encore d'évaluation

- Quality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteDocument9 pagesQuality Control Check List For Documentation SL - No Description Testing Method YES NO N/A Remarks 1 Concreting For All Grades of ConcreteRadhakrishna KPPas encore d'évaluation

- Risk Register: Test Scope: Aggregate Crushing ValueDocument2 pagesRisk Register: Test Scope: Aggregate Crushing ValuechinhonPas encore d'évaluation

- Splash Works Water Parks Core Test Report PDFDocument1 pageSplash Works Water Parks Core Test Report PDFJahid HasanPas encore d'évaluation

- Nitobond SBR Latex - 635641Document1 pageNitobond SBR Latex - 635641Civil DiaryPas encore d'évaluation

- FT004 - FLAKINESS & ELONGATION INDICESdDocument23 pagesFT004 - FLAKINESS & ELONGATION INDICESdjjksite voyantsPas encore d'évaluation

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocument9 pagesDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedPas encore d'évaluation

- M-20 Mix Designs as per IS-10262-2009Document25 pagesM-20 Mix Designs as per IS-10262-2009Prasad MsrkPas encore d'évaluation

- WMM Calibration 05.01.2016Document8 pagesWMM Calibration 05.01.2016SRR QAQCPas encore d'évaluation

- Is 16720 Product Manual Fuel AshDocument7 pagesIs 16720 Product Manual Fuel AshKolkata PIUPas encore d'évaluation

- Manzini to Mbadlane Highway Project Soil Testing ReportDocument12 pagesManzini to Mbadlane Highway Project Soil Testing ReportSoundar PachiappanPas encore d'évaluation

- Calibration of Blain Air Permeability ApparatusDocument1 pageCalibration of Blain Air Permeability ApparatusBIPL REPORT0% (1)

- 4031 - 4 Part 4 Determination of Consistency of Standard Cement PasteDocument3 pages4031 - 4 Part 4 Determination of Consistency of Standard Cement Pastevelmurug_balaPas encore d'évaluation

- Mandatory testing of crystalline durabilityDocument1 pageMandatory testing of crystalline durabilitySean HarshaPas encore d'évaluation

- Sand Replacement TestDocument8 pagesSand Replacement Testkrishna buildconPas encore d'évaluation

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeDocument3 pagesM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanPas encore d'évaluation

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignBuditama ChandranegaraPas encore d'évaluation

- Design Concrete Mix Using IS CodeDocument27 pagesDesign Concrete Mix Using IS CodevassihayPas encore d'évaluation

- Aropol in 5334Document2 pagesAropol in 5334GautamPas encore d'évaluation

- Ultratech Cement Opc 53 PDFDocument1 pageUltratech Cement Opc 53 PDFAquib khanPas encore d'évaluation

- Aggregate Elongation Index ValueDocument7 pagesAggregate Elongation Index ValuemlakkissPas encore d'évaluation

- Calibration Sand Pouring Cylinder of 100mm DiaDocument15 pagesCalibration Sand Pouring Cylinder of 100mm DiaSamrat Ashok vishwakarma0% (1)

- Report on Concrete Mix DesignDocument7 pagesReport on Concrete Mix DesignSnehashish BasuPas encore d'évaluation

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuPas encore d'évaluation

- Mix Design PosterDocument1 pageMix Design PosterAbhilash KumarPas encore d'évaluation

- Bitumen Extraction Test Observation SheetDocument2 pagesBitumen Extraction Test Observation SheetramPas encore d'évaluation

- Is Code 13311 Part 1 (NDT)Document11 pagesIs Code 13311 Part 1 (NDT)Arun EthirajPas encore d'évaluation

- 3812 1 PDFDocument14 pages3812 1 PDFइंजि कौस्तुभ पवारPas encore d'évaluation

- Physical PropertiesDocument16 pagesPhysical PropertiesRahul GoyalPas encore d'évaluation

- NUVOCO VISTAS CORP. LTD. FLAKINESS & ELONGATION TEST REPORT FOR RMX - POONAMALLEEDocument1 pageNUVOCO VISTAS CORP. LTD. FLAKINESS & ELONGATION TEST REPORT FOR RMX - POONAMALLEEvenkata krishna reddy MorthlaPas encore d'évaluation

- Flakiness IndexDocument4 pagesFlakiness IndexTewodros TadessePas encore d'évaluation

- Elongation Index For Coarse Aggregate22mmDocument2 pagesElongation Index For Coarse Aggregate22mmMarwa AlasheebiPas encore d'évaluation

- Shear Test FormatsDocument2 pagesShear Test FormatspiteshPas encore d'évaluation

- Determination of Particle Shape - Flakiness Index of Coarse AggregatesDocument1 pageDetermination of Particle Shape - Flakiness Index of Coarse AggregatesAdrian FrantescuPas encore d'évaluation

- 06 - Sieve Analysis of Coarse Aggregate (19-5mm) (Astm c136) (Rswtp-01-Hcg-qc-g00-Tp-0006)Document1 page06 - Sieve Analysis of Coarse Aggregate (19-5mm) (Astm c136) (Rswtp-01-Hcg-qc-g00-Tp-0006)Mahmudul MasumPas encore d'évaluation

- ASTM C88 Soundness of AggregateDocument3 pagesASTM C88 Soundness of AggregateShaher Abo Meazer100% (1)

- Form Uji Esktraksi 2Document2 pagesForm Uji Esktraksi 2yobifranamarpaPas encore d'évaluation

- Prime / Tack Coat Test: Make/BrandDocument11 pagesPrime / Tack Coat Test: Make/BrandQuality JamPas encore d'évaluation

- 07 - Sieve Analysis of Coarse Aggregate (19-10mm) (Astm c136) (Rswtp-01-Hcg-qc-g00-Tp-0007)Document1 page07 - Sieve Analysis of Coarse Aggregate (19-10mm) (Astm c136) (Rswtp-01-Hcg-qc-g00-Tp-0007)Mahmudul MasumPas encore d'évaluation

- Legal Support For Construction ClaimDocument1 pageLegal Support For Construction ClaimSamer MichealPas encore d'évaluation

- FIFA World Cup South Africa 2010 - Excel File .Document6 pagesFIFA World Cup South Africa 2010 - Excel File .U. Milakovic100% (1)

- Cost ResponsibilitiesDocument1 pageCost ResponsibilitiesanasameranaPas encore d'évaluation

- Flakiness Index TestDocument20 pagesFlakiness Index TestanasameranaPas encore d'évaluation

- Cost ManagementDocument36 pagesCost ManagementAmer Y KPas encore d'évaluation

- 16 Cost EstimatingDocument5 pages16 Cost EstimatinganasameranaPas encore d'évaluation

- Effect of The Quality Costing SystemDocument8 pagesEffect of The Quality Costing SystemanasameranaPas encore d'évaluation

- Oracle Learning ManagementDocument168 pagesOracle Learning ManagementAbhishek Singh TomarPas encore d'évaluation

- Numerical Methods Chapter 10 SummaryDocument8 pagesNumerical Methods Chapter 10 SummarynedumpillilPas encore d'évaluation

- Why Genentech Is 1Document7 pagesWhy Genentech Is 1panmongolsPas encore d'évaluation

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainPas encore d'évaluation

- Ensayo Bim - Jaime Alejandro Martinez Uribe PDFDocument3 pagesEnsayo Bim - Jaime Alejandro Martinez Uribe PDFAlejandro MartinezPas encore d'évaluation

- If V2 would/wouldn't V1Document2 pagesIf V2 would/wouldn't V1Honey ThinPas encore d'évaluation

- Orc & Goblins VII - 2000pts - New ABDocument1 pageOrc & Goblins VII - 2000pts - New ABDave KnattPas encore d'évaluation

- Towards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningDocument21 pagesTowards A Human Resource Development Ontology Combining Competence Management and Technology-Enhanced Workplace LearningTommy SiddiqPas encore d'évaluation

- Progressive Myoclonic Epilepsies - Practical Neurology 2015. MalekDocument8 pagesProgressive Myoclonic Epilepsies - Practical Neurology 2015. MalekchintanPas encore d'évaluation

- Reader's Digest (November 2021)Document172 pagesReader's Digest (November 2021)Sha MohebPas encore d'évaluation

- Unit 3 Computer ScienceDocument3 pagesUnit 3 Computer ScienceradPas encore d'évaluation

- ServiceDocument47 pagesServiceMarko KoširPas encore d'évaluation

- August 03 2017 Recalls Mls (Ascpi)Document6 pagesAugust 03 2017 Recalls Mls (Ascpi)Joanna Carel Lopez100% (3)

- Budgetary ControlsDocument2 pagesBudgetary Controlssiva_lordPas encore d'évaluation

- Obstetrical Hemorrhage: Reynold John D. ValenciaDocument82 pagesObstetrical Hemorrhage: Reynold John D. ValenciaReynold John ValenciaPas encore d'évaluation

- Mercedes BenzDocument56 pagesMercedes BenzRoland Joldis100% (1)

- Analytical Approach To Estimate Feeder AccommodatiDocument16 pagesAnalytical Approach To Estimate Feeder AccommodatiCleberton ReizPas encore d'évaluation

- Sarvali On DigbalaDocument14 pagesSarvali On DigbalapiyushPas encore d'évaluation

- Inorganica Chimica Acta: Research PaperDocument14 pagesInorganica Chimica Acta: Research PaperRuan ReisPas encore d'évaluation

- Contact and Profile of Anam ShahidDocument1 pageContact and Profile of Anam ShahidSchengen Travel & TourismPas encore d'évaluation

- Assignment 2 - Weather DerivativeDocument8 pagesAssignment 2 - Weather DerivativeBrow SimonPas encore d'évaluation

- Liebert PSP: Quick-Start Guide - 500VA/650VA, 230VDocument2 pagesLiebert PSP: Quick-Start Guide - 500VA/650VA, 230VsinoPas encore d'évaluation

- Ir35 For Freelancers by YunojunoDocument17 pagesIr35 For Freelancers by YunojunoOlaf RazzoliPas encore d'évaluation

- India Today 11-02-2019 PDFDocument85 pagesIndia Today 11-02-2019 PDFGPas encore d'évaluation

- FS2004 - The Aircraft - CFG FileDocument5 pagesFS2004 - The Aircraft - CFG FiletumbPas encore d'évaluation

- UNIT FOUR: Fundamentals of Marketing Mix: - Learning ObjectivesDocument49 pagesUNIT FOUR: Fundamentals of Marketing Mix: - Learning ObjectivesShaji ViswambharanPas encore d'évaluation

- Good Ethics Is Good BusinessDocument9 pagesGood Ethics Is Good BusinesssumeetpatnaikPas encore d'évaluation