Académique Documents

Professionnel Documents

Culture Documents

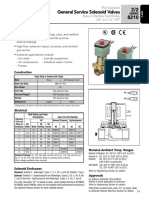

E l21s0 HP

Transféré par

rinthusTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

E l21s0 HP

Transféré par

rinthusDroits d'auteur :

Formats disponibles

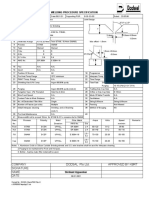

SDS M2012-04

BALANCED PRESSURE

THERMOSTATIC STEAM TRAP

MODEL L21S / L32S

BALANCED PRESSURE THERMOSTATIC TRAP WITH “FAIL-OPEN” DESIGN

Features

Forged steel thermostatic trap suitable for a

wide range of applications, including steam

mains, tracing, dryers and heaters.

1. “Fail open” feature will not hold back conden-

sate in the steam space.

2. Rugged, yet light construction, withstands

superheat and water hammer.

3. Cyclic operation with fixed subcooling through-

out the whole pressure range.

4. Outstanding air venting capability.

5. Compact, yet with high capacity.

6. Easy to clean and maintain.

7. Hardened stainless steel valve seat.

8. Built-in screen with large surface area.

9. Models L21SC/L32SC with built-in check valve

are available upon request.

Specifications

Model L21S L32S

250 240 °C

Temperature (°C)

Connection Screwed, Socket Welded, Flanged

Size (mm) 15, 20, 25 220 235 °C

200

Max. Operating Press. (MPaG) PMO 2.1 3.2

Min. Operating Press. (MPaG) 0.01 Saturated Steam Curve

150

Maximum Back Pressure 90% of Inlet Pressure

Max. Operating Temp. (°C) TMO see graph at right 100

Subcooling of X-element Fill (°C) up to 6 0 0.5 1.0 1.5 2.0 2.5 3.0

2.1 3.2

Type of X-element B Pressure (MPaG) 1 MPa = 10.197 kg/cm2

PRESSURE SHELL DESIGN CONDITIONS (NOT OPERATING CONDITIONS):

Maximum Allowable Pressure (MPaG) PMA: 3.2

Maximum Allowable Temperature (°C) TMA: 300

To avoid abnormal operation, accidents or serious injury, do not use

CAUTION this product outside of the specification range. Local regulations

may restrict the use of this product to below the conditions quoted.

No. Description Material JIS ASTM/AISI*

①RR Body Carbon Steel — A105

②RR Cover Carbon Steel — A105

③RR X-element Stainless Steel — —

④RR Screen inner/outer Stainless Steel SUS304/430 AISI304/430

⑤MR Screen Holder Gasket Soft Iron SUYP AISI1010

⑥RR Screen Holder Carbon Steel — A105

⑦RR Valve Seat Stainless Steel SUS420F AISI420F

⑧RR X-element Guide Stainless Steel SUS304 AISI304

⑨RR Spring Clip Stainless Steel SUS304 AISI304

⑩MR Cover Gasket Graphite/Stainl. Steel –/SUS316L –/AISI316L

⑪RR Cover Bolt Carbon Steel S45C AISI1045

⑫RR Nameplate Stainless Steel SUS304 AISI304

⑬RR Flange** Carbon/Cast Steel — A105/A216 Gr. WCB

⑭RR Check Valve Ball Stainless Steel SUS440C AISI440C

* Equivalent ** Shown on reverse, shape and material depend on flange specifications With optional Check Valve

Replacement kits available: (M) maintenance parts, (R) repair parts

Dimensions

¡L21S/L32S Screwed W L21S/L32S Screwed* (mm)

Size L H H1 W Weight (kg)

15

80 97 52 1.3

20 56

H

25 88 104 55 1.8

* Rc(PT), other standards available

H1

¡L21S/L32S Socket Welded W L21S/L32S Socket Welded (mm)

Size L H H1 W φD φC h Weight (kg)

15 30 22.2 12

80 97 52 1.3

20 56 36 27.7

14

D

C

25 88 104 55 44 34.5 1.8

H1

¡L21S/L32S Flanged L21S/L32S Flanged (mm)

L

Weight*

Size ASME Class H H1

(kg)

150RF 300RF 600RF

15 140 140 140 2.9

H

97 52

20 165 165 165 3.9

H1

25 210 210 210 104 55 4.7

Other standards available, but length and weight may vary

L * Weight is for Class 300 RF

The models L21SC and L32SC with internal check valves have

the same dimensions and weights as models L21S and L32S

Discharge Capacity

Differential Pressure (kg/cm2) 21

0.1 0.3 0.5 1 2 3 5 10 20 32

1000

L21S

700 L21SC

500

L32S

Discharge Capacity (kg/h)

L32SC

300

200

100

70

50

40

0.01 0.03 0.05 0.1 0.2 0.3 0.5 1 2.0 3.2

2.1

Differential Pressure (MPa)

1. Differential pressure is the difference between the inlet and outlet pressure of the trap.

2. Recommended safety factor: at least 2.

SDS M2012-04 Rev. 6/2014

Products for intended use only.

Specifications subject to change without notice.

Vous aimerez peut-être aussi

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyPas encore d'évaluation

- Free Float Steam Trap: Model Stainless SteelDocument2 pagesFree Float Steam Trap: Model Stainless SteelJustin GentryPas encore d'évaluation

- TLV Tc1 Self Acting Temperature Regulator FlangedDocument2 pagesTLV Tc1 Self Acting Temperature Regulator FlangedSDP02Pas encore d'évaluation

- E SVGMD HPDocument2 pagesE SVGMD HPSylvio Santiago LimaPas encore d'évaluation

- TLV SJ3FXDocument2 pagesTLV SJ3FXÁlvaro Martínez FernándezPas encore d'évaluation

- U dr20x HP PDFDocument2 pagesU dr20x HP PDFRicardo SanchezPas encore d'évaluation

- Pressure Reducing Valve For AirDocument2 pagesPressure Reducing Valve For AirSugeng SPas encore d'évaluation

- Free Float Free Float Steam Trap Steam Trap: ModelDocument2 pagesFree Float Free Float Steam Trap Steam Trap: ModelAnonymous cb9s3t0qPas encore d'évaluation

- Free Float Steam Trap: Model Ductile Cast Iron Cast IronDocument2 pagesFree Float Steam Trap: Model Ductile Cast Iron Cast IronSamerPas encore d'évaluation

- Steam Trap: P46SRN/P46SRM/P46SRWDocument2 pagesSteam Trap: P46SRN/P46SRM/P46SRWGina FelyaPas encore d'évaluation

- E j75x0 HP - UnlockedDocument2 pagesE j75x0 HP - Unlockedahmadsweiti11Pas encore d'évaluation

- (Steam Trap - Thermo) Yoshitake TD-10 NADocument2 pages(Steam Trap - Thermo) Yoshitake TD-10 NAAldeline SungahidPas encore d'évaluation

- Steam Trap Datasheet TLV Type P65SRNDocument2 pagesSteam Trap Datasheet TLV Type P65SRNAnonymous ThzA9zPas encore d'évaluation

- Trampa Tipo Balde JH7 TLVDocument2 pagesTrampa Tipo Balde JH7 TLVAriel InsaurraldePas encore d'évaluation

- V 020700905 B438 0003 GDocument11 pagesV 020700905 B438 0003 GHaroldCallanBacaPas encore d'évaluation

- Model GP-1000 Series Pressure Reducing Valve Installation & Operation ManualDocument14 pagesModel GP-1000 Series Pressure Reducing Valve Installation & Operation ManualJefanthony StevanoyaPas encore d'évaluation

- Air Pressure Reducing Valve: ACOS-10Document2 pagesAir Pressure Reducing Valve: ACOS-10guslohPas encore d'évaluation

- E t8n00 HP DesbloqueadoDocument2 pagesE t8n00 HP DesbloqueadoJaime RodriguezPas encore d'évaluation

- Arosta309H EngDocument1 pageArosta309H Engrusf123Pas encore d'évaluation

- Sensor Nivel Murphy LS200Document3 pagesSensor Nivel Murphy LS200Sergio PluchinskyPas encore d'évaluation

- 6 G Flow Series Catalogue - 50HzDocument18 pages6 G Flow Series Catalogue - 50HzIwan KurniawanPas encore d'évaluation

- 30SCC160 2pdeDocument30 pages30SCC160 2pdeمحمد مرسيPas encore d'évaluation

- Outershield 71M: Conformances Key FeaturesDocument3 pagesOutershield 71M: Conformances Key FeatureswilmercristianPas encore d'évaluation

- Functional Description: HA 5009 11/2010 Check ValvesDocument4 pagesFunctional Description: HA 5009 11/2010 Check ValvesSusmit patelPas encore d'évaluation

- TLV T8N Flow IndicatorDocument2 pagesTLV T8N Flow IndicatorDaniel ReyPas encore d'évaluation

- Model TB-20 20F: Steam Trap Installation & Operation ManualDocument12 pagesModel TB-20 20F: Steam Trap Installation & Operation ManualUcokPas encore d'évaluation

- Condensador SEER 13 NordenDocument2 pagesCondensador SEER 13 NordenJuan RobalinoPas encore d'évaluation

- General Service Solenoid Valves: FeaturesDocument6 pagesGeneral Service Solenoid Valves: FeaturesIgnacio FranPas encore d'évaluation

- Web Datasheet b4.1Document3 pagesWeb Datasheet b4.1Reza Khatibi NasabPas encore d'évaluation

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourPas encore d'évaluation

- Zero Loss Drain by QPPDocument2 pagesZero Loss Drain by QPPMod KaewdaengPas encore d'évaluation

- 8210R9 PDFDocument6 pages8210R9 PDFarturoncPas encore d'évaluation

- General Service Solenoid Valves: FeaturesDocument6 pagesGeneral Service Solenoid Valves: FeaturesMohamed RaafatPas encore d'évaluation

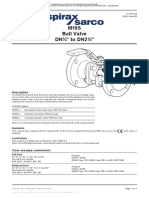

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalPas encore d'évaluation

- Liquid Level Switches: MLS SeriesDocument2 pagesLiquid Level Switches: MLS SeriesfharishputraPas encore d'évaluation

- Asco Flow Control Valves CatalogDocument4 pagesAsco Flow Control Valves CatalogCristian GutiérrezPas encore d'évaluation

- Air Trap RL1090 - RL1290Document2 pagesAir Trap RL1090 - RL1290satphoenixPas encore d'évaluation

- VB14 and 21 Vac BreakerDocument2 pagesVB14 and 21 Vac BreakercharlesanPas encore d'évaluation

- 11 MIG+MAG+TorchesDocument5 pages11 MIG+MAG+TorchesLLPas encore d'évaluation

- T4638 DatasheetDocument12 pagesT4638 DatasheetMUHAMMAD ABHAR AMZAR BIN ZAMZURIPas encore d'évaluation

- Fig - 33 TI S60 03 ENDocument5 pagesFig - 33 TI S60 03 ENAditomo PutrantoPas encore d'évaluation

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaPas encore d'évaluation

- Piston / Valve Design General Characteristics: Flow Switch 1.1. NovafixDocument2 pagesPiston / Valve Design General Characteristics: Flow Switch 1.1. NovafixJavier AffifPas encore d'évaluation

- CT312Document15 pagesCT312Kevin BlanerPas encore d'évaluation

- SE230701184 - Heater & Panel DatasheetsDocument18 pagesSE230701184 - Heater & Panel DatasheetsVivek SavaliyaPas encore d'évaluation

- Autrod 1264Document2 pagesAutrod 1264Anonymous yL7oldKPas encore d'évaluation

- Pilot Operated Relief Valves: Pressure ControlsDocument7 pagesPilot Operated Relief Valves: Pressure Controlssymantec37Pas encore d'évaluation

- Load Control ValvesDocument18 pagesLoad Control ValvesMusa ArysPas encore d'évaluation

- E ss1nh HPDocument2 pagesE ss1nh HPRigobertoMedinaPas encore d'évaluation

- MLS Series - Liquid Level Switches: Product Dimensions SpecificationsDocument2 pagesMLS Series - Liquid Level Switches: Product Dimensions SpecificationsSergio PluchinskyPas encore d'évaluation

- 38G-4 Safety Thermal Relief ValvesDocument1 page38G-4 Safety Thermal Relief ValvesThiên KhánhPas encore d'évaluation

- Castel Magn O8Document14 pagesCastel Magn O8Daniel Fancis Amabran BarrientosPas encore d'évaluation

- Series As1200 SDDocument4 pagesSeries As1200 SDSkay LopilPas encore d'évaluation

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoPas encore d'évaluation

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermePas encore d'évaluation

- Vaddl 12: Pressure Relief ValvesDocument2 pagesVaddl 12: Pressure Relief ValvesSachin RamadasanPas encore d'évaluation

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelagePas encore d'évaluation

- 1H050200 PDFDocument2 pages1H050200 PDFSachin RamadasanPas encore d'évaluation

- DBL 810388 04 RK16A enDocument2 pagesDBL 810388 04 RK16A enVignesh NadimuthuPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- 014-003 TBH enDocument1 page014-003 TBH enrinthusPas encore d'évaluation

- TB51 52 enDocument1 pageTB51 52 enrinthusPas encore d'évaluation

- TB5 CNDocument1 pageTB5 CNrinthusPas encore d'évaluation

- TB7N enDocument1 pageTB7N enrinthusPas encore d'évaluation

- TB3 CNDocument1 pageTB3 CNrinthusPas encore d'évaluation

- TB9N enDocument1 pageTB9N enrinthusPas encore d'évaluation

- Crown Tech Plus 10 819Document2 pagesCrown Tech Plus 10 819rinthusPas encore d'évaluation

- Specform SV ENDocument1 pageSpecform SV ENrinthusPas encore d'évaluation

- Energy and Economic Analysis of Heat Recovery From Boiler Exhaust Flue GasDocument7 pagesEnergy and Economic Analysis of Heat Recovery From Boiler Exhaust Flue GasrinthusPas encore d'évaluation

- Garispanduan 2007 FallDocument68 pagesGarispanduan 2007 FallFrancis WongPas encore d'évaluation

- Working at HeightDocument2 pagesWorking at HeightrinthusPas encore d'évaluation

- Welding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Document18 pagesWelding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Sreenivas GuduruPas encore d'évaluation

- Plateheatexchangers 161026111953Document28 pagesPlateheatexchangers 161026111953rinthusPas encore d'évaluation

- OSH (Work at Height) Regulations 2013Document14 pagesOSH (Work at Height) Regulations 2013SelmenPas encore d'évaluation

- Tools Starters PDFDocument1 pageTools Starters PDFrinthusPas encore d'évaluation

- 2018 01 17 Faktenpapier Palmkernoel Sept 2017 EnglDocument11 pages2018 01 17 Faktenpapier Palmkernoel Sept 2017 EnglrinthusPas encore d'évaluation

- OXY3690MPDocument6 pagesOXY3690MPrinthusPas encore d'évaluation

- Cassida Fluid HFDocument3 pagesCassida Fluid HFrinthusPas encore d'évaluation

- SSAS2.81 Magnetic PropertiesDocument2 pagesSSAS2.81 Magnetic Propertiesradule021Pas encore d'évaluation

- Welding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Document18 pagesWelding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Sreenivas GuduruPas encore d'évaluation

- Application - Three-Phase MotorsDocument4 pagesApplication - Three-Phase MotorsrinthusPas encore d'évaluation

- Surface Active Properties of Palm Oil With Respect To The Processing of Palm OilDocument10 pagesSurface Active Properties of Palm Oil With Respect To The Processing of Palm OilrinthusPas encore d'évaluation

- PFC A1Document10 pagesPFC A1rinthusPas encore d'évaluation

- S S ElectrodeDocument1 pageS S ElectrodeRajeev KhantwalPas encore d'évaluation

- Technical Bulletin #20Document1 pageTechnical Bulletin #20rinthusPas encore d'évaluation

- Air EliminationDocument4 pagesAir EliminationrinthusPas encore d'évaluation

- Tentang BoilerDocument5 pagesTentang BoileriyoznPas encore d'évaluation

- Weld Brite TDSDocument3 pagesWeld Brite TDSrinthusPas encore d'évaluation

- Ms 01 147 PDFDocument17 pagesMs 01 147 PDFrinthusPas encore d'évaluation

- Tensar Basetex Technical Info (April 2003)Document4 pagesTensar Basetex Technical Info (April 2003)sandycastlePas encore d'évaluation

- Bahrain O&g Facts and Figurs 2012 enDocument60 pagesBahrain O&g Facts and Figurs 2012 ennjava1978Pas encore d'évaluation

- Peeling MethodDocument7 pagesPeeling MethodFath BondPas encore d'évaluation

- Mini Mid-Scale LNG PDFDocument22 pagesMini Mid-Scale LNG PDFGeoffreyHunter100% (3)

- Material Safety Data Sheet: Acetylene DissolvedDocument3 pagesMaterial Safety Data Sheet: Acetylene Dissolvedandi permana100% (1)

- Radioactive Decay - WikipediaDocument22 pagesRadioactive Decay - WikipediaSaksham100% (1)

- Ketoconazole: SampleDocument7 pagesKetoconazole: SampleJuan PerezPas encore d'évaluation

- Extracting Bromine From Sea WaterDocument4 pagesExtracting Bromine From Sea WaterRaja Ji100% (2)

- Built-Up Backpressure at The Outlet Flange of A Pressure Relief ValveDocument8 pagesBuilt-Up Backpressure at The Outlet Flange of A Pressure Relief ValvemkapkPas encore d'évaluation

- Red BurnDocument224 pagesRed BurnigdecastejonPas encore d'évaluation

- Agriculture Current Affairs October PDFDocument48 pagesAgriculture Current Affairs October PDFHarisana ChandranPas encore d'évaluation

- Glossary of GroutingDocument9 pagesGlossary of Groutingdeepakverma33546Pas encore d'évaluation

- Determining Formaldehyde Concentration in Air From Wood Products Using A Small Scale ChamberDocument9 pagesDetermining Formaldehyde Concentration in Air From Wood Products Using A Small Scale ChamberRubén Eduardo Galindo CarmonaPas encore d'évaluation

- Forensic Chemistry - Laboratory Manual ANDREWS 2001 PDFDocument75 pagesForensic Chemistry - Laboratory Manual ANDREWS 2001 PDFjavier chavezPas encore d'évaluation

- Concrete DurabilityDocument3 pagesConcrete DurabilityShuvanjan Dahal100% (1)

- Extracting Chromium-Free Protein Hydrolysate From Leather Tanning WastesDocument6 pagesExtracting Chromium-Free Protein Hydrolysate From Leather Tanning WastesMamta AgarwalPas encore d'évaluation

- Nano-Particle Prepared From Sol-Gel Method: Titanium Tetra-Iso-Propoxide DiethanolamineDocument21 pagesNano-Particle Prepared From Sol-Gel Method: Titanium Tetra-Iso-Propoxide DiethanolamineMaggyBalcazarPas encore d'évaluation

- Colorcon Opadry Ambii 4pp WebDocument4 pagesColorcon Opadry Ambii 4pp WebLorentzPas encore d'évaluation

- Trisodium CitrateDocument2 pagesTrisodium CitrateAqmar Aqeem Bin AzharPas encore d'évaluation

- Draft SystemDocument5 pagesDraft Systemmkchy12Pas encore d'évaluation

- EDEXCEL A2 CHEMISTRY UNIT 4 January 2011Document24 pagesEDEXCEL A2 CHEMISTRY UNIT 4 January 2011Ghaleb W. MihyarPas encore d'évaluation

- Improving The Vase Life of Cut Gerbera Flower With Silver NanoparticlesDocument4 pagesImproving The Vase Life of Cut Gerbera Flower With Silver NanoparticlesThanhTung NguyenPas encore d'évaluation

- Evidence of Acceptability of Oral Paediatric Medicines: A ReviewDocument16 pagesEvidence of Acceptability of Oral Paediatric Medicines: A ReviewDenise Yanci DemiarPas encore d'évaluation

- Separator Sizing - PPTDocument21 pagesSeparator Sizing - PPTD K SPas encore d'évaluation

- Alfalaval Cip1800l and Cip2800l Pps00064enDocument2 pagesAlfalaval Cip1800l and Cip2800l Pps00064engmatweakPas encore d'évaluation

- BForbes RCCDocument6 pagesBForbes RCCLTE002Pas encore d'évaluation

- Pil 12636 EngDocument4 pagesPil 12636 EngDr. Bishundat YaneshPas encore d'évaluation

- Hot Tears in CastingDocument15 pagesHot Tears in CastingRafdi Abdul MajidPas encore d'évaluation

- 8.0 Series IBR 20/21/25/26 To 588 PSI, IBR 35/36 To 235 PSI: Fig.7.1: ITABAR IBR-25 For Pipe Size ID 5.76 InchesDocument7 pages8.0 Series IBR 20/21/25/26 To 588 PSI, IBR 35/36 To 235 PSI: Fig.7.1: ITABAR IBR-25 For Pipe Size ID 5.76 InchesarfanPas encore d'évaluation

- Transition Metals ColoursDocument24 pagesTransition Metals ColoursTomNaccaratoPas encore d'évaluation