Académique Documents

Professionnel Documents

Culture Documents

Wps Saldatura A T GTAW Aluminium

Transféré par

FedericoC0 évaluation0% ont trouvé ce document utile (0 vote)

145 vues3 pagesGTAW Aluminium wps

Titre original

Wps Saldatura a T GTAW Aluminium

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentGTAW Aluminium wps

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

145 vues3 pagesWps Saldatura A T GTAW Aluminium

Transféré par

FedericoCGTAW Aluminium wps

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

Lh

DET NORSKE VERITAS

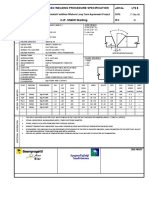

WELDER PERFORMANCE QUALIFICATION CERTIFICATE,

Qualification Cosee! Standards: EN ISO 9608.2

Conitiestion bay : ONY Cenfeation 8 V,

Designation: EN ISO 9606-2 141 P FW 23.3/23.1 § 16/8 PBI

Certificate Registration No.: ROT 2010.20328

Employer: Oversiulzen Thermal

Enginearing BV. Riddorkork

Weide Stas] Rage aunog

Waldng proceed [Fa Ta

Pa a Tab eT Preto

ree

aa aad FW AW

[Baonaalomnes [2a tema pzieaeezs

Fae

ent s S

Doigasoon | ERETEE (AMGS) | United

earners 678 =

Pips oasis me = Taare oT ot place

‘Samer fond

Waidng pean — [PA

Sighs — wa Weng Paes BRETT

=n

Singha [oT

wae ma oO

ides |S SO TATE il

c | nies ‘utemtena El

eee | Tainted

Pieces of wetting: Rsseraoa 111802010 xara A veri 0 69)

imo Felon Rae | RATS TOSSA R.

Mapectntent =

cared

Waar Fetomed capes | WPTRTAE TER OS Place: Barenarcht

awe 11-03-2010

Cr =

Desens Teteaared = ‘Quaticaton vad unt:

agra GAS NT ea = 14-05-2012

a -

o Pears wae | RAE Re OTE Fags VE

ra Tea =

Bad Rana =

ier Feannad amped | Rica WIE Repo OTAET papa ToTE

‘See reverse side for conitnatin statenent by ployer and protonation by DNV Cerifeaton 6.V. Adetonal information may ako be stated

tring column “Supplement remarks

=

Aiea

‘Advies,

real Welding ProcedureTest Record

we No.: LAB 1764 OSR.xx

ANERDUYN B.V. Testdate: 11-03-2010

Kerio 50 Customer: Oversluizen Thermal Enginesring Ridderkerk

28880 Newer Order Nas

none: +310T8S 401635 uta WeOR/ WO

Fax anoytesose1 —-PWRSNo LAB 1363

ax 310763 405616 ae

WEE SNONBS AOSSTE | Examiner: A. Verdin (WT 650)

seer Al taneumen) Certauth.: Det Norske Veritas Barendrecht

Website: wnlbverduynnt 2 DAV erm: RO DRI

XEN 180 1614-2

XEN 150 9606-2

8 mm (L-profile Sid UA 100x64x8mm)

Test plate I heat No

‘Test plate 2 heat No. RMRIG334.

[Alloy $754 22

Alloy 6082 T6.C

Ward

PB

Welding process: M1

Interpass temp.: ‘200°C

Preheat temp. min.: toc

PLWH. Ia

Welder / operators HLS. Mohamadsidik

121-02-1951 / Paramaribo

HIM /ID pass, ID5879828

Solid / FEW / SMA ‘solid

AWS. spec. / las. AWS AS 10: ERS356 (AIMS)

EN spec. class:

Brand Lincoln Electic

Type wit: LNT AIMes

Batch No: |srpao73202

Shietdinggas/ Flux: Argon 30% + Helium 70% (1 ace. ISO 14175)

Backinggas: es

Log current ime

a

oe Yep | Leo) pe |ierl oo | oo | aie Letine| “te | Sm [acs pe eam [cana | om)

a Se pe ies

ores

= (ayWPS ace, BN T30 13609. Daas welding onsale dentition ss OADTDT wares

WPOR: © (PS sc ENO 156041 Das! welding consume ml eines C2 NDTIDTtseprs

p Welding Procedure Specification

aig

‘Client; Atlas PIWPS NoalAB 1363

Project: Cooler Rev No._:00. IRSO

Inspec. by: 1 [Seas 22.3 ace: IS 15608 Dim, Pie

DNV Certification / MME R’kerk | Base | + | Tepe] Alloy 5784 H22 Dim. 6mm

‘Scope of work: material [> [Group] 23.1 acc. ISO 15608 Dim, Piste

‘Welding Procedure Qualification = | Tepe! Alloy 6082/16 /C = §mm

Welder Performance Qualification [Drawing No. na.

a Root: Filling pass: Back welding: Overlay weld:

‘elding process

na, 141 na. a.

Position: | PB ding, -Pavsesss Lit

es Tackwelding: [Min temp: > 10°¢

Pre-heating temp: Interpass.temp, Soaking temp: — °C

_ [zloec 200°C Soaking time: ~

Heat treatment: [pre-heating detalss na. Insulation: Dyes Eno

, Dyes

pwn: Ble

AWS AS 10: ERS3S6 (AIMES)

‘Argon Heo 7%

~~ (13 ace, ISO 14175)

2\ .

| Edge preparation/bead sequence

Cone acing

wraag | apie | “riter™ | nin, | Stein

sean Mate 1/008 | patsy | ampere | Voge

nin

Ta | air ERS [3S AC [60200 | Te1s | —TeIe |

KE

Prep weld edges: Mechanical cutting / degreasing. Featment of root na

[POR No. To be qualified Range POR: As per ENISO 156142 | WPQ ace:

Ace. EN ISO1S614-2 t Swil6mm a: 3wi6émm 1S0 9606-2

Dz > 150mm

Pos.: PA+PB -

NDT/DT | As per applicable code requirements

Prepared by: ‘Approved by Client

Date:

Lassner A

~ Bika Witkoe BV Keri 30 28800,

me Ta

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 2009 NC New Top InstallDocument21 pages2009 NC New Top InstallFedericoCPas encore d'évaluation

- EI 10168 Kapton Forming GuideDocument6 pagesEI 10168 Kapton Forming GuideFedericoCPas encore d'évaluation

- CNC 300Document2 pagesCNC 300FedericoCPas encore d'évaluation

- DRS Laser Users Guide 790309-0706Document145 pagesDRS Laser Users Guide 790309-0706FedericoCPas encore d'évaluation

- 6538Document2 pages6538FedericoCPas encore d'évaluation

- 790280-1009 Measure-X FastStart GuideDocument117 pages790280-1009 Measure-X FastStart GuideFedericoCPas encore d'évaluation

- Wps Saldatura A T GMAW SteelDocument4 pagesWps Saldatura A T GMAW SteelFedericoCPas encore d'évaluation

- Complete Manual PDFDocument189 pagesComplete Manual PDFAndyPas encore d'évaluation

- Seer For ManufacturingDocument5 pagesSeer For ManufacturingFjodor SergejevPas encore d'évaluation

- Review of CAD/CAM/CAEDocument30 pagesReview of CAD/CAM/CAEFedericoCPas encore d'évaluation

- DFMA TipsDocument81 pagesDFMA TipsFedericoCPas encore d'évaluation

- ENEA TurbogasDocument124 pagesENEA TurbogasSimone CastagnoPas encore d'évaluation

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- Datasheet3Document1 pageDatasheet3FedericoCPas encore d'évaluation

- Scan 001Document2 pagesScan 001FedericoCPas encore d'évaluation

- Forging CostDocument7 pagesForging CostFedericoCPas encore d'évaluation

- 1.1.1.1.1 Costo Del Materiale: Formule ForgiaturaDocument2 pages1.1.1.1.1 Costo Del Materiale: Formule ForgiaturaFedericoCPas encore d'évaluation

- WPS CSDocument2 pagesWPS CSFedericoCPas encore d'évaluation

- Eia Report Finland Memo Materials Memo 43s 20090201Document48 pagesEia Report Finland Memo Materials Memo 43s 20090201FedericoCPas encore d'évaluation

- Conceptual Cost EstimatingDocument17 pagesConceptual Cost Estimatingmarx0506Pas encore d'évaluation

- Recyclable Tooling Compositions and Methods of Their Manufacture and UseDocument9 pagesRecyclable Tooling Compositions and Methods of Their Manufacture and UseFedericoCPas encore d'évaluation

- Forging ClassificationDocument9 pagesForging ClassificationFedericoCPas encore d'évaluation