Académique Documents

Professionnel Documents

Culture Documents

GEO Fabrics HPS Group Data Sheet

Transféré par

SergejjjCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

GEO Fabrics HPS Group Data Sheet

Transféré par

SergejjjDroits d'auteur :

Formats disponibles

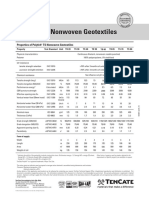

HPS (High Performance Square) non-woven needlepunched geotextiles - 08/08/12

Optimised for maximum mechanical performance - not weight. Sufficient mass of fibre will be included to achieve these performance values.

All GEOfabrics' HPS products are tested, in an independently-audited, ISO 17025, UKAS-acredited laboratory, for all mechanical-performance properties at a minimum of one set every 6000m 2

Test HPS2 HPS2.5 HPS3 HPS4 HPS5 HPS6 HPS7 HPS8 HPS9 HPS11 HPS12 HPS14 HPS17 HPS19 HPS22 HPS25 HPS30 HPS35 HPS40

Polymer Prime-quality, virgin polypropylene containing 1% carbon black UV inhibitor.

Fibre type A blend of high-tenacity, staple fibres with diameters selected for optimum performance.

Static puncture strength [CBR] (kN) 2 2.5 3 4 5 6 7 8 9 11 12 14 17 19 22 25 30 35 40

BS EN ISO 12236

Push-through displacement (mm) 75 75 65 65 65 65 65 65 65 65 65 65 65 65 65 65 65 65 65

md 10 15 20 25 30 35 40 45 50 60 65 75 90 100 115 130 160 180 210

Tensile strength (kN/m) BS EN ISO 10319

cmd 10 15 20 25 30 35 40 45 50 60 65 75 90 100 115 130 160 180 210

md 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80

Tensile elongation % BS EN ISO 10319

cmd 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80 80

Cone drop (mm) BS EN 13433 13 10 6 5 5 4 3 2 2 1 1 0 0 0 0 0 0 0 0

Thickness @ 2kPa (mm) BS EN ISO 9863-1 3.5 3.5 3.9 4.4 4.9 5.2 5.5 5.8 6 6.7 7 7.8 8.8 9.5 10.5 14 15 16.5 17

Apparent pore size 90% finer (mm) EN ISO 12956 150 150 130 100 80 80 80 70 70 <69 <69 <69 <69 <69 <69 <69 <69 <69 <69

2

Waterflow (l/s/m ) 100 100 85 75 65 55 50 45 40 35 30 25 15 10 9 8 8 5 5

BS EN ISO 11058

Coefficient of permeability (m/s) x10

-3

7.0 7.0 6.6 6.6 6.4 5.7 5.5 5.2 4.8 4.7 4.2 3.9 2.6 1.9 1.9 2.2 2.4 1.7 1.7

Protector Efficiency (kN/m )

2

EN ISO 13719 x 10 3

N/A N/A N/A N/A 14 20 25 30 33 39 42 48 56 60 100 139 175 210

2

Resistance to weathering (UV) @ 50MJ/m

radiant exposure (1-4 months depending on EN12224 Retained strength = >90%

location/season)

Resistance to oxidation (150 years) EN13438 Retained strength after 84 days = >90%

Microbiological resistance EN12225 Retained strength = 100%

Resistance to liquids (pH 1.5 to 12.1) EN14030 Retained strength = >90%

Needle detection The full width of each product is electronically inspected during the production process

Standard roll length (m) 200 200 175 150 150 150 125 125 100 75 75 75 50 50 50 50 50 50 50

Standard roll width (m) # 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 5.9 5.9 5.9 5.9

Approximate roll weight (kg) * 298 372 378 396 460 532 513 610 570 496 537 627 525 584 690 850 973 1120 1298

# Roll widths of 5.9m are supplied for container shipments. * Roll weight for handling guidance only.

Values are Typical , with the exception of Thickness, which is Nominal . Typical indicates the mean value derived from the samples taken for any one test as defined in the BS EN ISO standard - usually the mean of five samples. Nominal is a guide value.

Geofabrics Limited, Skelton Grange Rd, Stourton

Leeds LS10 1RZ, United Kingdom.

Tel: +44 (0)113 202 5678 Fax +44 (0)113 202 5655

www.geofabrics.com e-mail: info@geofabrics.com

No warranty is given or implied for the use of this information for design and installation as these are beyond our control. Geofabrics Limited reserves the right to change specifications without notice.

Vous aimerez peut-être aussi

- British Commercial Computer Digest: Pergamon Computer Data SeriesD'EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesPas encore d'évaluation

- Multitrack SNW RangeDocument2 pagesMultitrack SNW RangeSergejjjPas encore d'évaluation

- TenCate Polyfelt TS Nonwoven GeotextilesDocument6 pagesTenCate Polyfelt TS Nonwoven GeotextilesChee Soon LeePas encore d'évaluation

- TDS PH MacTexMXL May2014Document1 pageTDS PH MacTexMXL May2014Catherine MagnayePas encore d'évaluation

- Fibertex Geotextiles: Product Data SheetDocument2 pagesFibertex Geotextiles: Product Data Sheetmanuel agostinhoPas encore d'évaluation

- Property of Polyfelt TS Nonwoven GeotextilesDocument1 pageProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Armacell - PET GR SeriesDocument4 pagesArmacell - PET GR SeriesJose Leandro AlvesPas encore d'évaluation

- Armacell ArmaPET StructDocument4 pagesArmacell ArmaPET StructPeter Pumpkin EaterPas encore d'évaluation

- Teslin TableDocument1 pageTeslin TableEzequiel FernandezPas encore d'évaluation

- Declaration of Performance-145mmDocument3 pagesDeclaration of Performance-145mmProdaja YumCommercePas encore d'évaluation

- Jain PVC Ball ValveDocument2 pagesJain PVC Ball ValveKarthickPas encore d'évaluation

- GeotextleDocument2 pagesGeotextleShashwati DobaiPas encore d'évaluation

- TDS-MY-MacTex MXC, Feb2020Document1 pageTDS-MY-MacTex MXC, Feb2020CHEONG WEI HAOPas encore d'évaluation

- Erc 500-1000 - GBDocument2 pagesErc 500-1000 - GBtram 11100% (1)

- Geotextiles DatasheetDocument1 pageGeotextiles DatasheetMohammad TalalPas encore d'évaluation

- Geotextile White PET 02Document2 pagesGeotextile White PET 02lingatong110372Pas encore d'évaluation

- Nonwoven Geotextile - MHL2Document2 pagesNonwoven Geotextile - MHL2lailatin latinPas encore d'évaluation

- 1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveDocument4 pages1000 WOG, Economical Type 2-PC Body, Full Port Thread Ends Ball ValveabrahamPas encore d'évaluation

- Desch KB 16 GB Lutex LKBDocument6 pagesDesch KB 16 GB Lutex LKBchodgemPas encore d'évaluation

- Screenshot 2022-07-14 at 12.30.24Document44 pagesScreenshot 2022-07-14 at 12.30.24zakkPas encore d'évaluation

- Eddyfi Technologies Tubing ProbesDocument34 pagesEddyfi Technologies Tubing ProbesJesus E ContrerasPas encore d'évaluation

- Cat 6A S FTP Installation Cable 600MHZ V1901Document2 pagesCat 6A S FTP Installation Cable 600MHZ V1901Trunghieu LePas encore d'évaluation

- Pipe Wrap Tape BrochureDocument8 pagesPipe Wrap Tape BrochureRamadon BernalPas encore d'évaluation

- Coarse: Aggregate Test ResultsDocument24 pagesCoarse: Aggregate Test ResultsMahendar ErramPas encore d'évaluation

- Extruder Brochure - Old SeriesDocument4 pagesExtruder Brochure - Old SeriesAmirmasoudPas encore d'évaluation

- Bontec Non-Woven Geotextiles - TDSDocument11 pagesBontec Non-Woven Geotextiles - TDSAnang BagusPas encore d'évaluation

- Drincable 800 CableDocument3 pagesDrincable 800 Cableheri fauziPas encore d'évaluation

- Prestressing Thread Steel BarDocument3 pagesPrestressing Thread Steel BarIsmantoTaufikPas encore d'évaluation

- Bondstrand PDFDocument8 pagesBondstrand PDFkrisPas encore d'évaluation

- Brosur EPS ISULATION SPECIFICATIONDocument2 pagesBrosur EPS ISULATION SPECIFICATIONtitaPas encore d'évaluation

- Double ISA B-B Equal AngleDocument18 pagesDouble ISA B-B Equal AngleKasiPas encore d'évaluation

- WSTSB April 2013Document2 pagesWSTSB April 2013Anas OUDADDAPas encore d'évaluation

- Property Unit G 12P G 15P G20P G25P G30P G40P G50P G60P G70P G100P Test StandardDocument1 pageProperty Unit G 12P G 15P G20P G25P G30P G40P G50P G60P G70P G100P Test StandardAnonymous MAQrYFQDzVPas encore d'évaluation

- m1tr SS Anchor BoltDocument1 pagem1tr SS Anchor BoltLeo SerasinghePas encore d'évaluation

- FLSV2-200 FotometriaDocument10 pagesFLSV2-200 FotometriaGomez Ponte MiguelPas encore d'évaluation

- Structures - Suplimentory Data - EnC CheckDocument78 pagesStructures - Suplimentory Data - EnC Checkdinesh kumarPas encore d'évaluation

- Tyre Coupling With Spacer UNEFLEX SD SeriesDocument3 pagesTyre Coupling With Spacer UNEFLEX SD SeriesGabriel MoreiraPas encore d'évaluation

- TCS-Geotechnics-Terram-T Series-Standard Nonwoven Geotextile-Data SheetDocument1 pageTCS-Geotechnics-Terram-T Series-Standard Nonwoven Geotextile-Data SheetBerat DalyabrakPas encore d'évaluation

- Compacted Graphite Iron Material Data Sheet PDFDocument2 pagesCompacted Graphite Iron Material Data Sheet PDFDewang KambrePas encore d'évaluation

- Luminaire PropertyDocument7 pagesLuminaire PropertyLucas NunesPas encore d'évaluation

- P. Mains (Waterline) PDocument2 pagesP. Mains (Waterline) PJim Paul MendozaPas encore d'évaluation

- 33kV MV Cables BS6622 BS7835 3 Core XLPE SWA Stranded Copper ConductorsDocument2 pages33kV MV Cables BS6622 BS7835 3 Core XLPE SWA Stranded Copper ConductorsRonit KayasthaPas encore d'évaluation

- 2009 Catalogue: Conveyor BeltingDocument25 pages2009 Catalogue: Conveyor BeltingSaswita SaktiPas encore d'évaluation

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezPas encore d'évaluation

- BS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsDocument2 pagesBS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsRafly ZelristraPas encore d'évaluation

- En Iso Mattex Geomatt TB - I-25!08!2013Document1 pageEn Iso Mattex Geomatt TB - I-25!08!2013FarhatPas encore d'évaluation

- P I CABS 2 10TN MOD v2 ENDocument5 pagesP I CABS 2 10TN MOD v2 ENDiana AlexandraPas encore d'évaluation

- Steel Cord Conveyor Belts PDFDocument2 pagesSteel Cord Conveyor Belts PDFnicolasPas encore d'évaluation

- 33Kv Cables MV Cable SpecificationDocument3 pages33Kv Cables MV Cable SpecificationelsayedPas encore d'évaluation

- Danoil 3Gg: Oil Suction and Discharge Composite Hose Inner Hose From 25 To 102 MMDocument1 pageDanoil 3Gg: Oil Suction and Discharge Composite Hose Inner Hose From 25 To 102 MMpo truongPas encore d'évaluation

- Grade 100 Alloy ChainDocument1 pageGrade 100 Alloy ChainPanthPas encore d'évaluation

- Aerial Bundle Conductor Abc CableDocument1 pageAerial Bundle Conductor Abc CableBrianPas encore d'évaluation

- En 10241 FittingsDocument6 pagesEn 10241 FittingsDhavalPas encore d'évaluation

- Fibromat MTS series-PET - 240227 - 113902Document1 pageFibromat MTS series-PET - 240227 - 113902fendi brsbPas encore d'évaluation

- Eddyfi Technologies Tubing Probes 01Document36 pagesEddyfi Technologies Tubing Probes 01abdPas encore d'évaluation

- Canada Culvert Non Woven Geotextile Spec Sheet 1Document1 pageCanada Culvert Non Woven Geotextile Spec Sheet 1VindirePas encore d'évaluation

- Super Cable PDFDocument3 pagesSuper Cable PDFSaeedAhmedKhanPas encore d'évaluation

- OF Effective: Pitch Diameter (MM) Diameter + (2Document1 pageOF Effective: Pitch Diameter (MM) Diameter + (2srinivas murthyPas encore d'évaluation

- 170M 6809Document2 pages170M 6809bernaPas encore d'évaluation

- Excavator Attachments: Demolition, Recycling and Earth-Moving. Experience Our Hydraulic Attachment ToolsDocument8 pagesExcavator Attachments: Demolition, Recycling and Earth-Moving. Experience Our Hydraulic Attachment ToolsSilvio CeolPas encore d'évaluation

- LinkStud, Design Manual To EC2Document35 pagesLinkStud, Design Manual To EC2SergejjjPas encore d'évaluation

- Design Manual To EC2Document39 pagesDesign Manual To EC2Tomas MerkeviciusPas encore d'évaluation

- Bulletin 27 - Final Report of The International Commission For The Study of Environmental Effects of Dredging and Disposal of Dredged MaterialsDocument100 pagesBulletin 27 - Final Report of The International Commission For The Study of Environmental Effects of Dredging and Disposal of Dredged MaterialsSergejjjPas encore d'évaluation

- Corrosion Manual 43 To 45 Contact CorrosionDocument3 pagesCorrosion Manual 43 To 45 Contact CorrosionSergejjjPas encore d'évaluation

- Heavy Duty PavementsDocument89 pagesHeavy Duty Pavementsgoyotech100% (1)

- PIANC WG17 - Inspection, Mtce & Repair of Maritime Structures PDFDocument55 pagesPIANC WG17 - Inspection, Mtce & Repair of Maritime Structures PDFSergejjj100% (1)

- Title: SubtitleDocument2 pagesTitle: SubtitleSergejjjPas encore d'évaluation

- TTT (VK20 1)Document9 pagesTTT (VK20 1)SergejjjPas encore d'évaluation

- Design of Anchorage To Concrete Using ACI 318 08 & CSA A23.3 04 CodeDocument155 pagesDesign of Anchorage To Concrete Using ACI 318 08 & CSA A23.3 04 CodeTawfik Omar0% (1)

- TTT (VK20 1)Document9 pagesTTT (VK20 1)SergejjjPas encore d'évaluation

- APT 2 ReportDocument188 pagesAPT 2 ReportSergejjjPas encore d'évaluation

- Wedding PoemsDocument8 pagesWedding PoemsSergejjjPas encore d'évaluation

- ICE 6 Ed Part 1 PDFDocument53 pagesICE 6 Ed Part 1 PDFSergejjjPas encore d'évaluation

- Payum Vossoughi PresentationDocument27 pagesPayum Vossoughi PresentationGregorius FilipusPas encore d'évaluation

- Keller F - Brochure Dec2010Document20 pagesKeller F - Brochure Dec2010SergejjjPas encore d'évaluation

- Puwer 2014Document84 pagesPuwer 2014Krishnakumar Aravindakshan NairPas encore d'évaluation

- Unsteady Bernoulli Equation: Advanced Fluid M Ech AnicsDocument13 pagesUnsteady Bernoulli Equation: Advanced Fluid M Ech AnicsThomas SantosaPas encore d'évaluation

- SCI P394 SecureDocument120 pagesSCI P394 SecureIulian Valentin CimbruPas encore d'évaluation

- Bollard GuideDocument23 pagesBollard GuideSergejjjPas encore d'évaluation

- 06 ER Stimac PDFDocument10 pages06 ER Stimac PDFBahtir HamidovićPas encore d'évaluation

- Staad Pro V8i Getting StartedDocument338 pagesStaad Pro V8i Getting StartedNathaniel Miranda Dagsa Jr93% (14)

- Corus SHS Welding GuideDocument42 pagesCorus SHS Welding GuidesanggythaPas encore d'évaluation

- Coastal Eng StudentDocument72 pagesCoastal Eng Studentapi-3700706Pas encore d'évaluation

- CH 17Document12 pagesCH 17SergejjjPas encore d'évaluation

- Coastal GroinsDocument91 pagesCoastal GroinsEGS_falconer100% (1)

- LKIF in Line Strainers Product LeafletDocument3 pagesLKIF in Line Strainers Product LeafletGisela ViskaPas encore d'évaluation

- Range of Flocculants and Caogulants For Water and Wastewater TreatmentDocument6 pagesRange of Flocculants and Caogulants For Water and Wastewater Treatmentginga716Pas encore d'évaluation

- KAAP Technology Description and BenfitsDocument4 pagesKAAP Technology Description and BenfitsTalha Jamil100% (1)

- Elements of Mechanical EngineeringDocument5 pagesElements of Mechanical EngineeringnavitgmPas encore d'évaluation

- Emergency Override SwitchesDocument4 pagesEmergency Override SwitchesBlutch0Pas encore d'évaluation

- Mine 480 Assignment 1 Phase Relations and Filter Design-1Document3 pagesMine 480 Assignment 1 Phase Relations and Filter Design-1sh y0% (1)

- Technicalinfo 6066670Document2 pagesTechnicalinfo 6066670petriPas encore d'évaluation

- Eco Task Force: Integrated Waste Management Subcommittee Annual ReportDocument9 pagesEco Task Force: Integrated Waste Management Subcommittee Annual ReportsustainableunhPas encore d'évaluation

- Trusses II Queenpost TrussesDocument11 pagesTrusses II Queenpost TrussesCristian Morar-BolbaPas encore d'évaluation

- Aws - The Practical Welding Engineer PDFDocument154 pagesAws - The Practical Welding Engineer PDFSEGO4EVER100% (5)

- DEVISE - Industrial HIGH-RATE - Brochure - r1Document2 pagesDEVISE - Industrial HIGH-RATE - Brochure - r1mesratiPas encore d'évaluation

- Manesty DistillationDocument15 pagesManesty DistillationGaurav Sharma0% (1)

- Simplified Cost Models For Prefeasibility Mineral Evaluations 2005Document4 pagesSimplified Cost Models For Prefeasibility Mineral Evaluations 2005Juan Pablo Henríquez Valencia50% (2)

- Scientific American Supplement, No. 455, September 20, 1884 by VariousDocument83 pagesScientific American Supplement, No. 455, September 20, 1884 by VariousGutenberg.orgPas encore d'évaluation

- TDS - 4S Service ManualDocument271 pagesTDS - 4S Service ManualLeonardo Alvarez100% (4)

- TALAT Lecture 3501: Alloys and PropertiesDocument8 pagesTALAT Lecture 3501: Alloys and PropertiesCORE MaterialsPas encore d'évaluation

- Biomass Technology OverviewDocument28 pagesBiomass Technology Overviewbdeol267% (3)

- Dedicated Outdoor Air SystemsDocument5 pagesDedicated Outdoor Air SystemseduardofemecPas encore d'évaluation

- Separator 01dyDocument44 pagesSeparator 01dyFadhil KhalidPas encore d'évaluation

- Cantilever PriceDocument3 pagesCantilever Pricelangit biruPas encore d'évaluation

- Science Fair - ECOBRICKSDocument17 pagesScience Fair - ECOBRICKSBrian Voyd RebitoPas encore d'évaluation

- ACI 506.1 (1998) Committee Report On Fiber Reinforced ShotcreteDocument11 pagesACI 506.1 (1998) Committee Report On Fiber Reinforced ShotcretephilipyapPas encore d'évaluation

- Textile Colors: For A Colorful WorldDocument12 pagesTextile Colors: For A Colorful WorldSamuel VanoostenPas encore d'évaluation

- 1 - Catalogo Deionizador Qw-48Document92 pages1 - Catalogo Deionizador Qw-48Edgar Muñoz100% (1)

- Accelerating Admixtures For ShotcreteDocument7 pagesAccelerating Admixtures For Shotcreteneen61Pas encore d'évaluation

- Solved SAILMT Exam Paper For Mechanical EngineerDocument12 pagesSolved SAILMT Exam Paper For Mechanical EngineerSudeesh BabuPas encore d'évaluation

- Degree o FreedomDocument27 pagesDegree o FreedomHassan BhinderPas encore d'évaluation

- BdeM Taller No. 2Document2 pagesBdeM Taller No. 2Luisfer PricePas encore d'évaluation

- ABS Disposable Formworks For Lightweight FillingsDocument32 pagesABS Disposable Formworks For Lightweight FillingsABS YAPIPas encore d'évaluation

- Kathy Longaberger Goodyear Tire & Rubber Company SLA Los Angeles 2002Document17 pagesKathy Longaberger Goodyear Tire & Rubber Company SLA Los Angeles 2002Rubber TeamPas encore d'évaluation