Académique Documents

Professionnel Documents

Culture Documents

1 G Dual Axis Accelerometer: Ultra Low Noise, Offset Drift With Analog Outputs MXA2500E

Transféré par

estraj1954Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1 G Dual Axis Accelerometer: Ultra Low Noise, Offset Drift With Analog Outputs MXA2500E

Transféré par

estraj1954Droits d'auteur :

Formats disponibles

Ultra Low Noise, Offset Drift

±1 g Dual Axis Accelerometer

with Analog Outputs

MXA2500E

FEATURES

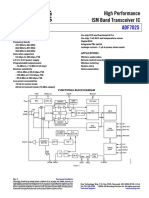

Sck Internal Temperature

Better than 1 mg resolution (optional) Oscillator Sensor

TOUT

Dual axis accelerometer fabricated on a monolithic CMOS IC

RoHS compliant Voltage

VREF

CLK Reference

On-chip mixed mode signal processing

No moving parts Continous

Heater

50,000 g shock survival rating Control

Self Test

17 Hz bandwidth expandable to >160 Hz

3V to 5.25V single supply continuous operation X axis

Low Pass

AOUTX

Filter

Small (5mm x 5mm x 2mm) surface mount package

Continuous self test

Factory Adjust

Custom programmable specifications Offset & Gain

Independent axis programmability (special order)

Low Pass

Y axis

Filter

AOUTY

APPLICATIONS 2-AXIS

SENSOR

Automotive – Vehicle Security/Active Suspension/ABS

VDD Gnd VDA

Headlight Angle Control/Tilt Sensing

Security – Gas Line/Elevator/Fatigue Sensing

Office Equipment – Computer Peripherals/PDA’s/ MXA2500E FUNCTIONAL BLOCK DIAGRAM

Cell Phones

Gaming – Joystick/RF Interface/Menu Selection/Tilt Sensing

White Goods – Spin/Vibration Control

GENERAL DESCRIPTION

The MXA2500E is an ultra low noise and low cost, dual The MXA2500E provides two absolute analog outputs.

axis accelerometer fabricated on a standard, submicron The typical noise floor is 0.2 mg/ Hz allowing signals

CMOS process. It is a complete sensing system with on- below 1 mg to be resolved at 1 Hz bandwidth. The 3dB

chip mixed mode signal processing. The MXA2500E rolloff of the device occurs at 17 Hz but is expandable to

measures acceleration with a full-scale range of ±1 g and a >160 Hz (ref. Application Note AN-00MX-003). The

MXA2500E is available in a LCC surface mount package

sensitivity of 500mV/g @5V at 25°C. It can measure both (5 mm x 5 mm x 2 mm). It is hermetically sealed and is

dynamic acceleration (e.g., vibration) and static operational over a -40°C to +105°C temperature range. It

acceleration (e.g., gravity). The MXA2500E design is also contains an on-chip temperature sensor and a bandgap

based on heat convection and requires no solid proof mass. voltage reference.

This eliminates stiction and particle problems associated

with competitive devices and provides shock survival of Due to the standard CMOS structure of the MXA2500E,

50,000 g, leading to significantly lower failure rates and additional circuitry can easily be incorporated into custom

lower loss due to handling during assembly. versions for high volume applications. Contact the factory

for more information.

Information furnished by MEMSIC is believed to be accurate and reliable.

MEMSIC, Inc.

However, no responsibility is assumed by MEMSIC for its use, nor for any

infringements of patents or other rights of third parties which may result from

One Technology Drive Suite 325,Andover MA01810,USA

its use. No license is granted by implication or otherwise under any patent or Tel: +1 978 738 0900 Fax: +1 978 738 0196

patent rights of MEMSIC. www.memsic.com

MEMSIC MXA2500E Rev G Page 1 of 9 2/26/2007

MXA2500E SPECIFICATIONS (Measurements @ 25°C, Acceleration = 0 g unless otherwise noted; VDD, VDA = 5.0V

unless otherwise specified)

MXA2500E

Parameter Conditions Min Typ Max Units

SENSOR INPUT Each Axis

Measurement Range1 ±1.0 g

Nonlinearity Best fit straight line 0.5 1.0 % of FS

Alignment Error2 ±1.0 degree

Transverse Sensitivity3 ±2.0 %

SENSITIVITY Each Axis

Sensitivity, Analog Outputs at pins

AOUTX and AOUTY6 475 500 525 mV/g

Change over Temperature (uncompensated)4 ∆ from 25°C, at –40°C +120 %

∆ from 25°C, at +105°C -55 %

Change over Temperature (compensated) 4 ∆ from 25°C, –40°C to +105°C <3.0 %

ZERO g BIAS LEVEL Each Axis

0 g Offset6 -0.1 0.00 +0.1 g

0 g Voltage6 1.20 1.25 1.30 V

0 g Offset over Temperature ∆ from 25°C ±0.4 mg/°C

∆ from 25°C, based on 500mV/g ±0.2 mV/°C

NOISE PERFORMANCE

Noise Density, rms Without frequency compensation 0.2 0.4 mg/ Hz

FREQUENCY RESPONSE

3dB Bandwidth - uncompensated 17 Hz

3dB Bandwidth - compensated5 >160 Hz

TEMPERATURE OUTPUT

Tout Voltage 1.15 1.25 1.35 V

Sensitivity 4.6 5.0 5.4 mV/°C

VOLTAGE REFERENCE OUTPUT

VRef output @3V-5.25V supply 2.4 2.5 2.65 V

Change over Temperature 0.1 mV/°C

Current Drive Capability Source 100 µA

SELF TEST

Continuous Voltage at AOUTX, AOUTY under @5.0V Supply, output rails to

Failure supply voltage 5.0 V

Continuous Voltage at AOUTX, AOUTY under @3.0V Supply, output rails to

Failure supply voltage 3.0 V

AOUTX and AOUTY OUTPUTS

Normal Output Range @5.0V Supply 0.1 4.9 V

@3.0V Supply 0.1 2.9 V

Current Source or sink, @ 3.0V-5.25V supply 100 µA

Turn-On Time7 @5.0V Supply 160 mS

@3.0V Supply 300 mS

POWER SUPPLY

Operating Voltage Range 3.0 5.25 V

Supply Current @ 5.0V 2.7 3.3 4.1 mA

Supply Current6 @ 3.0V 3.2 4.0 4.8 mA

TEMPERATURE RANGE

Operating Range -40 +105 °C

NOTES 6

1 The device operates over a 3.0V to 5.25V supply range. Please note that

Guaranteed by measurement of initial offset and sensitivity.

2 sensitivity and zero g bias level will be slightly different at 3.0V operation.

Alignment error is specified as the angle between the true and indicated

For devices to be operated at 3.0V in production, they can be trimmed at the

axis of sensitivity.

3 factory specifically for this lower supply voltage operation, in which case the

Transverse sensitivity is the algebraic sum of the alignment and the

inherent sensitivity errors. sensitivity and zero g bias level specifications on this page will be met.

4

The sensitivity change over temperature for thermal accelerometers is based Please contact the factory for specially trimmed devices for low supply

on variations in heat transfer that are governed by the laws of physics and it is voltage operation.

7

Output settled to within ±17mg.

highly consistent from device to device. Please refer to the section in this data

sheet titled “Compensation for the Change of Sensitivity over Temperature”

for more information.

5

External circuitry is required to extend the 3dB bandwidth. (ref.

Application Note: AN-00MX-003).

MEMSIC MXA2500E Rev G Page 2 of 8 2/26/2007

ABSOLUTE MAXIMUM RATINGS* 8

Supply Voltage (VDD, VDA) ………………...-0.5 to +7.0V

1 7

Storage Temperature ……….…………-65°C to +150°C

X +g

M EM SIC

Acceleration ……………………………………..50,000 g

2 6

*Stresses above those listed under Absolute Maximum Ratings may cause permanent

damage to the device. This is a stress rating only; the functional operation of the device 3 5

at these or any other conditions above those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for 4

extended periods may affect device reliability.

Y +g

Package Characteristics

Top View

Package θJA θJC Device Weight

LCC-8 110°C/W 22°C/W < 1 gram

Pin Description: LCC-8 Package

Pin Name Description I/O

1 TOUT Temperature (Analog Voltage) O

2 AOUTY Y-Axis Acceleration Signal O

3 Gnd Ground I

4 VDA Analog Supply Voltage I

5 AOUTX X-Axis Acceleration Signal O

6 Vref 2.5V Reference Output O

7 Sck Optional External Clock I

8 VDD Digital Supply Voltage I

Note: The MEMSIC logo’s arrow indicates the +X sensing

Ordering Guide direction of the device. The +Y sensing direction is rotated 90°

Model Package Style away from the +X direction following the right-hand rule.

MXA2500EL LCC8 RoHS compliant Small circle indicates pin one (1).

MXA2500EF LCC8, Pb-free RoHS compliant

*LCC parts are shipped in tape and reel packaging.

Caution

ESD (electrostatic discharge) sensitive device.

MEMSIC MXA2500E Rev G Page 3 of 8 2/26/2007

THEORY OF OPERATION to be the same as the sensitivity for the x-axis, the

The MEMSIC device is a complete dual-axis acceleration accelerometer can be programmed for non-equal

measurement system fabricated on a monolithic CMOS IC sensitivities on the x- and y-axes. Contact the factory for

process. The device operation is based on heat transfer by additional information on this feature.

natural convection and operates like other accelerometers

having a proof mass except it is a gas in the MEMSIC TOUT – This pin is the buffered output of the temperature

sensor. sensor. The analog voltage at TOUT is an indication of the

die temperature. This voltage is useful as a differential

A single heat source, centered in the silicon chip is measurement of temperature from ambient and not as an

suspended across a cavity. Equally spaced absolute measurement of temperature. After correlating

aluminum/polysilicon thermopiles (groups of the voltage at TOUT to 25°C ambient, the change in this

thermocouples) are located equidistantly on all four sides voltage due to changes in the ambient temperature can be

of the heat source (dual axis). Under zero acceleration, a used to compensate for the change over temperature of the

temperature gradient is symmetrical about the heat source, accelerometer offset and sensitivity. Please refer to the

so that the temperature is the same at all four thermopiles, section on Compensation for the Change in Sensitivity

causing them to output the same voltage. Over Temperature for more information.

Acceleration in any direction will disturb the temperature Sck – The standard product is delivered with an internal

profile, due to free convection heat transfer, causing it to be clock option (800kHz). This pin should be grounded

asymmetrical. The temperature, and hence voltage output when operating with the internal clock. An external

of the four thermopiles will then be different. The clock option can be special ordered from the factory

differential voltage at the thermopile outputs is directly allowing the user to input a clock signal between 400kHz

proportional to the acceleration. There are two identical and 1.6MHz.

acceleration signal paths on the accelerometer, one to

measure acceleration in the x-axis and one to measure Vref – This pin is the output of a reference voltage. It is set

acceleration in the y-axis. Please visit the MEMSIC at 2.50V typical and has 100µA of drive capability.

website at www.memsic.com for a picture/graphic

description of the free convection heat transfer principle. COMPENSATION FOR THE CHANGE IN

SENSITIVITY OVER TEMPERATURE

PIN DESCRIPTIONS All thermal accelerometers display the same sensitivity

VDD – This is the supply input for the digital circuits and change with temperature. The sensitivity change depends

the sensor heater in the accelerometer. The DC voltage on variations in heat transfer that are governed by the laws

should be between 3.0 volts and 5.25 volts. Refer to the of physics. Manufacturing variations do not influence the

section on PCB layout and fabrication suggestions for sensitivity change, so there are no unit-to-unit differences

guidance on external parts and connections recommended. in sensitivity change. The sensitivity change is governed

by the following equation (and shown in Figure 1 in °C):

VDA – This is the power supply input for the analog

amplifiers in the accelerometer. Refer to the section on Si x Ti2.90 = Sf x Tf2.90

PCB layout and fabrication suggestions for guidance on

external parts and connections recommended. where Si is the sensitivity at any initial temperature Ti, and

Sf is the sensitivity at any other final temperature Tf with

Gnd – This is the ground pin for the accelerometer. the temperature values in °K.

AOUTX – This pin is the output of the x-axis acceleration

sensor. The user should ensure the load impedance is 2.5

Sensitivity (normalized)

sufficiently high as to not source/sink >100µA. While the 2.0

sensitivity of this axis has been programmed at the factory

1.5

to be the same as the sensitivity for the y-axis, the

1.0

accelerometer can be programmed for non-equal

sensitivities on the x- and y-axes. Contact the factory for 0.5

additional information on this feature. 0.0

-40 -20 0 20 40 60 80 100

AOUTY – This pin is the output of the y-axis acceleration Temperature (C)

sensor. The user should ensure the load impedance is

sufficiently high as to not source/sink >100µA. While the Figure 1: Thermal Accelerometer Sensitivity

sensitivity of this axis has been programmed at the factory

MEMSIC MXA2500E Rev G Page 4 of 8 2/26/2007

In gaming applications where the game or controller is X

typically used in a constant temperature environment, +900

sensitivity might not need to be compensated in hardware

MEMS IC

gravity

or software. Any compensation for this effect could be

done instinctively by the game player. 00

For applications where sensitivity changes of a few percent Y

Top View

are acceptable, the above equation can be approximated

with a linear function. Using a linear approximation, an Figure 2: Accelerometer Position Relative to Gravity

external circuit that provides a gain adjustment of –

0.9%/°C would keep the sensitivity within 10% of its room

temperature value over a 0°C to +50°C range.

For applications that demand high performance, a low cost X-Axis Y-Axis

micro-controller can be used to implement the above X-Axis

equation. A reference design using a Microchip MCU (p/n Orientation Change Change

16F873/04-SO) and MEMSIC developed firmware is To Earth’s X per deg. Y per deg.

available by contacting the factory. With this reference Surface Output of tilt Output of tilt

design, the sensitivity variation over the full temperature (deg.) (g) (mg) (g) (mg)

90 1.000 0.15 0.000 17.45

range (-40°C to +105°C) can be kept below 3%. Please

85 0.996 1.37 0.087 17.37

visit the MEMSIC web site at www.memsic.com for 80 0.985 2.88 0.174 17.16

reference design information on circuits and programs 70 0.940 5.86 0.342 16.35

including look up tables for easily incorporating sensitivity 60 0.866 8.59 0.500 15.04

compensation. 45 0.707 12.23 0.707 12.23

30 0.500 15.04 0.866 8.59

DISCUSSION OF TILT APPLICATIONS AND 20 0.342 16.35 0.940 5.86

RESOLUTION 10 0.174 17.16 0.985 2.88

Tilt Applications: One of the most popular applications 5 0.087 17.37 0.996 1.37

0 0.000 17.45 1.000 0.15

of the MEMSIC accelerometer product line is in

Table 1: Changes in Tilt for X- and Y-Axes

tilt/inclination measurement. An accelerometer uses the

force of gravity as an input to determine the inclination

Resolution: The accelerometer resolution is limited by

angle of an object.

noise. The output noise will vary with the measurement

bandwidth. With the reduction of the bandwidth, by

A MEMSIC accelerometer is most sensitive to changes in

applying an external low pass filter, the output noise drops.

position, or tilt, when the accelerometer’s sensitive axis is

Reduction of bandwidth will improve the signal to noise

perpendicular to the force of gravity, or parallel to the

ratio and the resolution. The output noise scales directly

Earth’s surface. Similarly, when the accelerometer’s axis

with the square root of the measurement bandwidth. The

is parallel to the force of gravity (perpendicular to the

maximum amplitude of the noise, its peak- to- peak value,

Earth’s surface), it is least sensitive to changes in tilt.

approximately defines the worst case resolution of the

measurement. With a simple RC low pass filter, the rms

Table 1 and Figure 2 help illustrate the output changes in

noise is calculated as follows:

the X- and Y-axes as the unit is tilted from +90° to 0°.

Notice that when one axis has a small change in output per

degree of tilt (in mg), the second axis has a large change in Noise (mg rms) = Noise(mg/ Hz ) * ( Bandwidth( Hz ) *1.6)

output per degree of tilt. The complementary nature of

these two signals permits low cost accurate tilt sensing to The peak-to-peak noise is approximately equal to 6.6 times

be achieved with the MEMSIC device (reference the rms value (for an average uncertainty of 0.1%).

application note AN-00MX-007).

EXTERNAL FILTERS

AC Coupling: For applications where only dynamic

accelerations (vibration) are to be measured, it is

recommended to ac couple the accelerometer output as

shown in Figure 3. The advantage of ac coupling is that

variations from part to part of zero g offset and zero g

offset versus temperature can be eliminated. Figure 3 is a

HPF (high pass filter) with a –3dB breakpoint given by the

MEMSIC MXA2500E Rev G Page 5 of 8 2/26/2007

equation: f = 1 . In many applications it may be compensating circuit does not require adjustment for

2πRC individual units.

desirable to have the HPF –3dB point at a very low

frequency in order to detect very low frequency A simple compensating network comprising two

accelerations. Sometimes the implementation of this HPF operational amplifiers and a few resistors and capacitors

may result in unreasonably large capacitors, and the provides increasing gain with increasing frequency (see

designer must turn to digital implementations of HPFs Figure 5). The circuit shown is for an absolute output

where very low frequency –3dB breakpoints can be accelerometer operating at 5 V supply. It provides a DC

achieved. gain of X2, so the offset at the output is 2.5V and the

sensitivity is doubled. The 14.3 KΩ and the 5.9KΩ

resistors along with the non-polarized 0.82µF capacitors

C tune the gain of the network to compensate for the output

A O UT X A O UT X

Filtered attenuation at the higher frequencies. The resistors and the

O utput capacitors provide noise reduction and stability.

R

14.3K 5.9K

C 1.5uF 0.01uF

A O UT Y A O UTY

Filtered

R O utput

UA

Aout X or Y -

8.06K 160K

+

Figure 3: High Pass Filter

0.047uF 0.0022uF

Low Pass Filter: An external low pass filter is useful in

low frequency applications such as tilt or inclination. The

low pass filter limits the noise floor and improves the

resolution of the accelerometer. The low pass filter shown 14.3K 5.9K

in Figure 4 has a –3dB breakpoint given by the equation:

1.5uF 0.01uF

f =1 . For the 200 Hz ratiometric output device

2πRC

filter, C=0.1µF and R=8kΩ, ±5%, 1/8W.

UB

Freq. Comp. Output

- 8.06K

+

A O UT X R A O UTX 60

0.047uF

45

Filtered

30

C Output

Amplitude - dB

15

A O UTY R A O UT Y -15

Figure 5: Frequency Response Extension Circuit

Filtered -30

C Output -45

The accelerometer response (bottom trace), the network

-60

response10 (top trace) and the compensated

10 0 response (middle

10 00

F req ue ncy - H z

trace) are shown in Figure 6. The amplitude remains above

–3db beyond 100 Hz, and there is useable signal well

Figure 4: Low Pass Filter

after this frequency.

COMPENSATION FOR EXTENDING THE

FREQUENCY RESPONSE

The response of the thermal accelerometer is a function of

the internal gas physical properties, the natural convection

mechanism and the sensor electronics. Since the gas

properties of MEMSIC's mass produced accelerometer are

uniform, a simple circuit can be used to equally

compensate all sensors. For most applications, the

MEMSIC MXA2500E Rev G Page 6 of 8 2/26/2007

2

Change = a * Temperature + b * Temperature + c

where a,b,c are unique constants for each accelerometer.

Figure 6: Amplitude Frequency Response In normal operation the processor calculates the output:

Compensated Output = Acceleration – Change.

COMPENSATION FOR ZERO G OFFSET CHANGE

For a more detail discussion of temperature compensation

OVER TEMPERATURE

reference MEMSIC application note #AN-00MX-002.

In applications where a stable zero g offset is required, and

where the AC coupling external filter described earlier can

not be used, analog or digital temperature compensation

TEMPERATURE OUTPUT NOISE REDUCTION

can be applied. The compensation requires individual

It is recommended that a simple RC low pass filter is used

calibration because the magnitude of the zero g offset

when measuring the temperature output. Temperature

change over temperature is different for each unit. To

output is typically a very slow changing signal, so a very

compensate the change, a calibrated temperature

low frequency filter eliminates erroneous readings that may

dependent signal equal in magnitude but with opposite

result from the presence of higher frequency noise. A

polarity is added to the accelerometer output. The circuit

simple filter is shown in Figure 8.

in Figure 7 shows a circuit example applying an analog

linear compensation technique. In this circuit the

accelerometer temperature sensor output is added to or 8.2K

subtracted from the accelerometer output. The calibration TOUT Filtered TOUT

sequence is: start at room temperature with the 100K pot

set so that its wiper is at Vref. Next, soak the accelerometer MEMSIC 0.1uF

at the expected extreme temperature and observe the Accel.

direction of the change. Then set the switch to the non-

inverting input if the change is negative or vice versa.

Finally, adjust the 100K pot while monitoring the circuit

output, until the zero g offset change is removed. Figure 8: Temperature Output Noise Reduction

POWER SUPPLY NOISE REJECTION

Vref

Two capacitors and a resistor are recommended for best

10K 100K

+5V rejection of power supply noise (reference Figure 9 below).

10K

Aoutx or y The capacitors should be located as close as possible to the

SW SPDT 100K

+

zero g drift

compensated device supply pins (VDA, VDD). The capacitor lead length

100K -

should be as short as possible, and surface mount

Tout

100K capacitors are preferred. For typical applications,

10K

capacitors C1 and C2 can be ceramic 0.1 µF, and the

Aoutx or y

resistor R can be 10 Ω.

100K 100K

V SUPPLY

Figure 7: Zero g Offset Temperature Compensation Circuit

Various digital compensation techniques can be applied

using a similar concept. Digital techniques can provide C1 R C2

better compensation because they can compensate for non-

linear zero g offset vs. temperature. A micro-controller or

micro-processor would perform the compensation. The VDA VDD

acceleration signal and the temperature signal would be

digitized using an analog to digital converter. Like in the MEMSIC

Accelerometer

analog compensation, the first step is to test and

characterize the zero g change. The purpose of the

characterization is to create a look up table or to estimate a Figure 9: Power Supply Noise Rejection

mathematical representation of the change. For example,

the change could be characterized by an equation of the PCB LAYOUT AND FABRICATION SUGGESTIONS

form: 1. The Sck pin should be grounded to minimize noise.

MEMSIC MXA2500E Rev G Page 7 of 8 2/26/2007

2. Liberal use of ceramic bypass capacitors is 5. A metal ground plane should be added directly

recommended. beneath the MEMSIC device. The size of the ground

3. Robust low inductance ground wiring should be used. plane should be similar to the MEMSIC device’s

4. Care should be taken to ensure there is “thermal footprint and be as thick as possible.

symmetry” on the PCB immediately surrounding the 6. Vias can be added symmetrically around the ground

MEMSIC device and that there is no significant heat plane. Vias increase thermal isolation of the device

source nearby. from the rest of the PCB.

PACKAGE DRAWING

Fig 10: Hermetically Sealed Package Outline

MEMSIC MXA2500E Rev G Page 8 of 8 2/26/2007

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

MEMSIC:

MXA2500EL

Vous aimerez peut-être aussi

- MXD2020EDocument8 pagesMXD2020Eapi-3695729Pas encore d'évaluation

- Low Cost Accelerometer With Analog Output: 100 G Single AxisDocument5 pagesLow Cost Accelerometer With Analog Output: 100 G Single AxispejanssoPas encore d'évaluation

- Adxl103 203Document16 pagesAdxl103 203Eduardo Citti Truck CenterPas encore d'évaluation

- LA1136NDocument28 pagesLA1136NВячеслав ГлушакPas encore d'évaluation

- Low Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionDocument12 pagesLow Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionjosmelPas encore d'évaluation

- Small, Low Power, 3-Axis 3 G Accelerometer ADXL335: Features General DescriptionDocument16 pagesSmall, Low Power, 3-Axis 3 G Accelerometer ADXL335: Features General DescriptionRaman IyerPas encore d'évaluation

- ADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningDocument12 pagesADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningFargham SandhuPas encore d'évaluation

- ADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningDocument12 pagesADXRS150: 150°/s Single Chip Yaw Rate Gyro With Signal ConditioningFargham SandhuPas encore d'évaluation

- Low Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionDocument12 pagesLow Cost 1.2 G Dual Axis Accelerometer ADXL213: Features General DescriptionMarlon PerinPas encore d'évaluation

- 200Mhz Cursor Readout Analog Oscilloscope: FeaturesDocument2 pages200Mhz Cursor Readout Analog Oscilloscope: Featuresdani385arPas encore d'évaluation

- Adxl326 PDFDocument16 pagesAdxl326 PDFsumit kathuriaPas encore d'évaluation

- High Performance, ISM Band, FSK/ASK Transceiver IC: Data SheetDocument47 pagesHigh Performance, ISM Band, FSK/ASK Transceiver IC: Data SheetSsr ShaPas encore d'évaluation

- 50 V Ultra-Low Noise FOC Motor Controller: Features and Benefits DescriptionDocument26 pages50 V Ultra-Low Noise FOC Motor Controller: Features and Benefits Descriptionsanthosha rkPas encore d'évaluation

- ACS70310 11 DatasheetDocument30 pagesACS70310 11 DatasheetbillPas encore d'évaluation

- High Performance FSK/ASK Transceiver IC: Data SheetDocument45 pagesHigh Performance FSK/ASK Transceiver IC: Data Sheetআশিক পালোয়ানPas encore d'évaluation

- Low Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedDocument1 pageLow Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedmhasansharifiPas encore d'évaluation

- Low Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedDocument11 pagesLow Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedmhasansharifiPas encore d'évaluation

- ADF7021-NBCPZ ADF7021-NBCPZ. ADF7021-NBCPZ-RL7 Eval - ADF7021-NDB9Z Eval - ADF7021-NDBIZDocument69 pagesADF7021-NBCPZ ADF7021-NBCPZ. ADF7021-NBCPZ-RL7 Eval - ADF7021-NDB9Z Eval - ADF7021-NDBIZTuần Hào ĐỗPas encore d'évaluation

- Single/Dual Axis I Accelerometers ADXL150/ADXL250: 65 G To 650 G, Low Noise, Low PowerDocument15 pagesSingle/Dual Axis I Accelerometers ADXL150/ADXL250: 65 G To 650 G, Low Noise, Low PowerperezamorimPas encore d'évaluation

- Easygen - Exciter-10: Salient FeaturesDocument4 pagesEasygen - Exciter-10: Salient Featureszakie0690Pas encore d'évaluation

- TW28 Datasheet D4en PDFDocument80 pagesTW28 Datasheet D4en PDFiustinianPas encore d'évaluation

- DTS Tkda 08-2019 EngDocument2 pagesDTS Tkda 08-2019 EngErick PerezPas encore d'évaluation

- sc70 enDocument1 pagesc70 enRick ChenPas encore d'évaluation

- Camara Domo CNB LBM20SDocument1 pageCamara Domo CNB LBM20STecnoSmartPas encore d'évaluation

- ATS601LSG: Single-Element Tooth-Detecting Speed Sensor ICDocument14 pagesATS601LSG: Single-Element Tooth-Detecting Speed Sensor ICSakthivel PPas encore d'évaluation

- High Performance ISM Band Transceiver IC: Data SheetDocument41 pagesHigh Performance ISM Band Transceiver IC: Data SheetTuần Hào ĐỗPas encore d'évaluation

- Semiconductor Technical Data: Table 1: Hardware FeaturesDocument9 pagesSemiconductor Technical Data: Table 1: Hardware FeaturesspotPas encore d'évaluation

- High Performance, ISM Band, FSK/ASK Transceiver IC ADF7020: FeaturesDocument48 pagesHigh Performance, ISM Band, FSK/ASK Transceiver IC ADF7020: FeaturesDPas encore d'évaluation

- Product Brief QN8036: High Performance Digital FM Transceiver For Portable DevicesDocument3 pagesProduct Brief QN8036: High Performance Digital FM Transceiver For Portable Devicesdeena.karan5281Pas encore d'évaluation

- Akai 265dDocument2 pagesAkai 265dVagabundi GackenholzPas encore d'évaluation

- Service Manual: Argentine ModelDocument39 pagesService Manual: Argentine ModelDiego BandeiraPas encore d'évaluation

- Id210 SpecsDocument8 pagesId210 Specsrose HPas encore d'évaluation

- SPC1 Series SPC1 Series: Single-Phase, Power ControllerDocument6 pagesSPC1 Series SPC1 Series: Single-Phase, Power Controllerexcind loperaPas encore d'évaluation

- Vibration Motor Sensor Meme TypeDocument42 pagesVibration Motor Sensor Meme TypeBala KrishnanPas encore d'évaluation

- Low-Cost With Duty Cycle Output: 2 G Dual-Axis AccelerometerDocument12 pagesLow-Cost With Duty Cycle Output: 2 G Dual-Axis AccelerometerpraveensahPas encore d'évaluation

- ALM-012 Sid Guts Deluxe' - Operation ManualDocument14 pagesALM-012 Sid Guts Deluxe' - Operation Manualshawil71Pas encore d'évaluation

- Circuit Note: Fully Automatic High Performance Conductivity Measurement SystemDocument10 pagesCircuit Note: Fully Automatic High Performance Conductivity Measurement SystemSupolPas encore d'évaluation

- Easygen - Exciter-10: Salient FeaturesDocument4 pagesEasygen - Exciter-10: Salient FeaturesAbdallah AbdelrehimPas encore d'évaluation

- XTi2 DataSheet Lowres 121914 PDFDocument2 pagesXTi2 DataSheet Lowres 121914 PDFubaldo caraballoPas encore d'évaluation

- vb5 Portable Data Collector Datasheet - 111M6572Document6 pagesvb5 Portable Data Collector Datasheet - 111M6572Guillermo CardozoPas encore d'évaluation

- Features Descriptio: LTC1736 5-Bit Adjustable High Efficiency Synchronous Step-Down Switching RegulatorDocument28 pagesFeatures Descriptio: LTC1736 5-Bit Adjustable High Efficiency Synchronous Step-Down Switching RegulatorCarlos Henrique RibasPas encore d'évaluation

- GE Logiq-200-Pro - TrainingDocument39 pagesGE Logiq-200-Pro - Trainingsongtao yinPas encore d'évaluation

- Single Channel Strip Amplifiers: SeriesDocument2 pagesSingle Channel Strip Amplifiers: SeriesHanns JorgPas encore d'évaluation

- Integrated Dual-Axis Gyro IDG-1215: Features General DescriptionDocument8 pagesIntegrated Dual-Axis Gyro IDG-1215: Features General Descriptionsamsonit1Pas encore d'évaluation

- Epoch LT EN 201405 Web PDFDocument2 pagesEpoch LT EN 201405 Web PDFalexmontellPas encore d'évaluation

- GX GFDocument4 pagesGX GFMohamed AlaaPas encore d'évaluation

- Great Sound From Your Factory Radio: 2 Channel Active Line Output Converter With AccubassDocument2 pagesGreat Sound From Your Factory Radio: 2 Channel Active Line Output Converter With AccubassGaudencio Alberco vilcayauriPas encore d'évaluation

- SERIES Ver.2: Amplifier Built-In Extraordinarily Small and Slim SizeDocument14 pagesSERIES Ver.2: Amplifier Built-In Extraordinarily Small and Slim SizeaPas encore d'évaluation

- vb7 Datasheet 116m5255-1Document8 pagesvb7 Datasheet 116m5255-1ReginaldoVieiradaSilvaPas encore d'évaluation

- Material 78211438V44-2Document3 pagesMaterial 78211438V44-2Antonio MorenoPas encore d'évaluation

- I010-E1-03 3g3iv Users ManualDocument71 pagesI010-E1-03 3g3iv Users ManualHaresh vaghelaPas encore d'évaluation

- Installation and Operation Manual: Agile ModulatorDocument8 pagesInstallation and Operation Manual: Agile ModulatorRodrigo CarvajalPas encore d'évaluation

- True Zero-Speed, High Accuracy Gear Tooth Sensor IC: ATS667LSGDocument14 pagesTrue Zero-Speed, High Accuracy Gear Tooth Sensor IC: ATS667LSGAnonymous f6goFflg3TPas encore d'évaluation

- Amplifiers: Model 30S1G6Document6 pagesAmplifiers: Model 30S1G6raj1388Pas encore d'évaluation

- Sabre Genesis ENGDocument2 pagesSabre Genesis ENGanon_651906433Pas encore d'évaluation

- Sabre Genesis - BrochureDocument2 pagesSabre Genesis - BrochureSreejith SwaminathanPas encore d'évaluation

- Adcmxl 3021Document50 pagesAdcmxl 3021MatheusMatteiVavassoriPas encore d'évaluation

- SSH-G01: Hall-Effect Gear Tooth Speed and Direction SensorDocument3 pagesSSH-G01: Hall-Effect Gear Tooth Speed and Direction SensorVahn RaymundoPas encore d'évaluation

- Tiduby 4 ADocument47 pagesTiduby 4 ArichatPas encore d'évaluation

- Uart Spi I2cDocument17 pagesUart Spi I2cestraj1954100% (1)

- Chap. 8 Integrated-Circuit Logic Families: Chapter Outcomes (Objectives)Document62 pagesChap. 8 Integrated-Circuit Logic Families: Chapter Outcomes (Objectives)estraj1954Pas encore d'évaluation

- An10587 PDFDocument11 pagesAn10587 PDFestraj1954Pas encore d'évaluation

- DKD-R 8-1 Englisch NeuDocument32 pagesDKD-R 8-1 Englisch Neugsv988Pas encore d'évaluation

- Wems Electronics: EMI/EMC Filters: A Technical PresentationDocument55 pagesWems Electronics: EMI/EMC Filters: A Technical PresentationHilmi SanusiPas encore d'évaluation

- Parallel I/O Interface: Memory Actuator Output DeviceDocument14 pagesParallel I/O Interface: Memory Actuator Output Deviceestraj1954Pas encore d'évaluation

- DKD-R 8-1 Englisch NeuDocument32 pagesDKD-R 8-1 Englisch Neugsv988Pas encore d'évaluation

- ULN2803APG Datasheet en 20121126Document13 pagesULN2803APG Datasheet en 20121126Kang JadiJaya Otodidak100% (1)

- Devotional When God SpeaksDocument8 pagesDevotional When God Speaksestraj1954Pas encore d'évaluation

- Spi I2c UartDocument1 pageSpi I2c Uartestraj1954100% (1)

- I2c BusDocument41 pagesI2c BusSoethree Yono100% (2)

- Chapter 02Document92 pagesChapter 02estraj1954Pas encore d'évaluation

- An 10587Document11 pagesAn 10587estraj1954Pas encore d'évaluation

- P-Values Explained by Data Scientist For Data ScientistsDocument8 pagesP-Values Explained by Data Scientist For Data Scientistsestraj1954Pas encore d'évaluation

- Biological Sensors: Unit-IiiDocument64 pagesBiological Sensors: Unit-Iiiestraj1954Pas encore d'évaluation

- Deep Learning Tutorial: Release 0.1Document137 pagesDeep Learning Tutorial: Release 0.1estraj1954Pas encore d'évaluation

- Lecture Notes Methods of Mathematical Physics MATHDocument71 pagesLecture Notes Methods of Mathematical Physics MATHestraj1954Pas encore d'évaluation

- Clock Oscillators Surface Mount Type KC3225A-C3 Series: Features How To OrderDocument1 pageClock Oscillators Surface Mount Type KC3225A-C3 Series: Features How To Orderestraj1954Pas encore d'évaluation

- Development of A Perforated Diffusive Muffler For A Regenerative BlowerDocument8 pagesDevelopment of A Perforated Diffusive Muffler For A Regenerative Blowerestraj1954Pas encore d'évaluation

- Unit I Mathematical Tools 1.1 Basic Mathematics For Physics: I. Quadratic Equation and Its SolutionDocument16 pagesUnit I Mathematical Tools 1.1 Basic Mathematics For Physics: I. Quadratic Equation and Its SolutionJit AggPas encore d'évaluation

- Biomedical Engineering EducationDocument4 pagesBiomedical Engineering Educationestraj1954Pas encore d'évaluation

- Lecture Notes Methods of Mathematical Physics MATHDocument71 pagesLecture Notes Methods of Mathematical Physics MATHestraj1954Pas encore d'évaluation

- ADu CM350Document17 pagesADu CM350estraj1954Pas encore d'évaluation

- IDT SensingTechandSensorSolutions OVR 2018117Document16 pagesIDT SensingTechandSensorSolutions OVR 2018117estraj1954Pas encore d'évaluation

- Bidirectional Current Source-TIDocument9 pagesBidirectional Current Source-TIestraj1954100% (1)

- ADuCM350 PDFDocument40 pagesADuCM350 PDFestraj1954Pas encore d'évaluation

- Code:: Ckielstra SuggestionDocument37 pagesCode:: Ckielstra Suggestionestraj1954100% (1)

- Submersible Level TransmitterDocument1 pageSubmersible Level Transmitterestraj1954100% (1)

- Measurement Instrumentation PDFDocument10 pagesMeasurement Instrumentation PDFestraj1954Pas encore d'évaluation

- Measurement Systems IntroductionDocument46 pagesMeasurement Systems Introductionsonu thiglePas encore d'évaluation

- Everest EverestDocument24 pagesEverest Everestabhi24shekPas encore d'évaluation

- Sport GRTDocument56 pagesSport GRTCavok AvionicsPas encore d'évaluation

- 19 Ret 670 Ied PDFDocument45 pages19 Ret 670 Ied PDFbrahimPas encore d'évaluation

- Ca2 Power Amplifier: Product Description CA2 FeaturesDocument2 pagesCa2 Power Amplifier: Product Description CA2 FeaturessimonPas encore d'évaluation

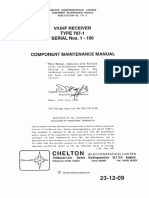

- + Chelton: V/Uhf Receiver TYPE 707-I SERIAL Nos. 1 - 100Document51 pages+ Chelton: V/Uhf Receiver TYPE 707-I SERIAL Nos. 1 - 100dadanPas encore d'évaluation

- Helac Series PowerTilt Service Manual HY34-1410Document60 pagesHelac Series PowerTilt Service Manual HY34-1410bkmin7Pas encore d'évaluation

- Method Statement FOR Laying of LV Cables: M & E ContractorDocument4 pagesMethod Statement FOR Laying of LV Cables: M & E ContractorJoe_AveragePas encore d'évaluation

- Brochure Extruder C2TXDocument4 pagesBrochure Extruder C2TXsarah ahmedPas encore d'évaluation

- PG Test-Instrument-PSWRDocument12 pagesPG Test-Instrument-PSWRyogesh pandeyPas encore d'évaluation

- SkillELECTRIC 2023 Core Competences 11.01.23Document1 pageSkillELECTRIC 2023 Core Competences 11.01.23ahmad yasinPas encore d'évaluation

- VSX-1015 RRV3113 PDFDocument140 pagesVSX-1015 RRV3113 PDFAlver TuizaPas encore d'évaluation

- Samsung Concealed Heat Pump Ceiling CassetesDocument3 pagesSamsung Concealed Heat Pump Ceiling Cassetese-ComfortUSAPas encore d'évaluation

- Installation Manual UB-5325 UB-5825: Electronic BoardDocument22 pagesInstallation Manual UB-5325 UB-5825: Electronic BoardIstimawan_BagusPas encore d'évaluation

- Oras Maišytuvai Kainynas 2021, UAB AnagaDocument35 pagesOras Maišytuvai Kainynas 2021, UAB AnagaMarius ImbrusPas encore d'évaluation

- Elevator Design ManualDocument14 pagesElevator Design ManualAbdulhamed FallahaPas encore d'évaluation

- Job Aid: Replacing The Field Replaceable Units (Frus) For The Avaya G450 Media GatewayDocument18 pagesJob Aid: Replacing The Field Replaceable Units (Frus) For The Avaya G450 Media Gatewayfaridfirdaus65Pas encore d'évaluation

- Parking Aid System: General InformationDocument20 pagesParking Aid System: General InformationPrvoslav DjordjevicPas encore d'évaluation

- Schlage P513-325 Rekeying ManualDocument32 pagesSchlage P513-325 Rekeying ManualBob CrosbyPas encore d'évaluation

- SuSD.1.F.008-Electrical Data SheetDocument6 pagesSuSD.1.F.008-Electrical Data SheetHonnie Mae PaduaPas encore d'évaluation

- Drawing or Document Control ListDocument22 pagesDrawing or Document Control ListRsp SrinivasPas encore d'évaluation

- Garage Inventory ChecklistDocument3 pagesGarage Inventory ChecklistBALJIT WARISPas encore d'évaluation

- BDP PDFDocument28 pagesBDP PDFjanolgo17Pas encore d'évaluation

- SILOS COMPONENTS MORE Kunststoffindustrie ENDocument15 pagesSILOS COMPONENTS MORE Kunststoffindustrie ENАлександр МихайловичPas encore d'évaluation

- SEBU6965-06 Before StartDocument6 pagesSEBU6965-06 Before StartLUIZ GUSTAVOPas encore d'évaluation

- Katalog PDFDocument20 pagesKatalog PDFIL Lo GarPas encore d'évaluation

- CV - Taruna Mandiri ElektrindoDocument2 pagesCV - Taruna Mandiri ElektrindoJD JayPas encore d'évaluation

- HX & HY Service Data SheetDocument16 pagesHX & HY Service Data Sheetmauricio olayaPas encore d'évaluation

- HRB Hydrostatic Regenerative Braking System TheDocument7 pagesHRB Hydrostatic Regenerative Braking System ThexxshPas encore d'évaluation

- Current Carrying Capacity BUSBARS - DNVDocument2 pagesCurrent Carrying Capacity BUSBARS - DNVStefanita0% (1)