Académique Documents

Professionnel Documents

Culture Documents

QB

Transféré par

Sebastian RajeshTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

QB

Transféré par

Sebastian RajeshDroits d'auteur :

Formats disponibles

No.

20 to 112 micron

50 psi

Yes.

Yes SAES-H-001 minimum nozzle pressure is 90 psig (Normally 90 to 100 psi is recommended)

No. Venturi Nozzle is more efficient

No. commercial blast cleaning SSPC SP 6

No. Volume solid is the term which indicates the proportion

of the solid containing in the paint on a volume basis.

No. Pot life means the length of time a paint material is useful after

its original package is opened, or after catalysts or other ingredients

are added.

Linear Polymerization. Branched

Polymerization and Cross Linked

Polymerization are correct

Flow viscometer to measure viscosity

Atmospheric Condition, type of material, Temp. Refer data sheet for approximate time

frame

QC Daily check list

SSPC PA2 No.

No. All coating materials for each coating system shall be supplied by the same

Manufacturer unless otherwise approved by the Consulting Services Department.

10 degree celsius or 3 degree above dew point which is greater (at any

case substrate temperature must be above 3 degree to dew point)

APCS-19C or APCS-113A

125mm.

Yes. as per SAES-H-002 5.4.2 It is allowed.

False, Dust respirator, Face Shield, Gloves and Goggle are required

PPE Yes.

Yes.

No. Anode, Cathode, Electrolyte

Yes, as per SAES-H-001 7.3 A and metallic pathway

85%

APCS-22 offshore APCS-26 onshore

APCS-12 for non-skid surface

No. White metal Blast Cleaning.

Yes. Correct

Yes. More than 5L need power stirrer for mixing

Adequate washing facilities shall be readily available.

No. only manufacturer can supply approved materials

all new materials need approval prior to supply

Correct

No. APCS-2B is allowed

without magnification

and to choose appropriate surface

preparation method

Solvents and paints shall not be applied surfaces warmer

than 80 degree celsius if practical alternatives exist

Solvents shall not be used for personnel cleaning and washing

3 degree Celsius more than dew point

The amount of moisture in the air compared to saturation

level and is expressed as percentage.

10000cfm

Respirator chemical cartridge, face shield and rubber gloves

distilled water

relative

humidity

also

SAES-H-100 Rust grade C is steel surface

completely cover with rust

little or no pitting visible.

False, Blast cleaning can begin if surface temperature 3 degree above dew point

27 degree

15 degree

Yes, If dew point temperature below 9 degree

Celsius

For coating system APCS-17A

No. SSPC SP 5 means white metal blast cleaning

No. Can't start

Yes, Can

based on psychrometer wet bulb dry bulb temperature use dew point

calculator to get dew point and relative humidity (Psychrometer is used

to for measure ambient air temperature)

anodic area

zinc

Zinc is more active and platinum is more

passive

correct

dry abrasive blast cleaning to sa 3

correct

correct

moisturised atmosphere

Dry abrasive blasting / Dry grit blasting / Air Blasting (Air

compressor, air dryer, blast pot, blast hose and nozzle)

Steel grit, Steel Shot, Angular chilled Iron

Blotter Test

to check Venturi type nozzle ID

safety wired at each coupling using proper safety pins

cross section of a blasted area

Litmus paper test compressors to check air quality (Air shall be free from

water, oil or any other foreign matters)

Rust Grade A

Power tool cleaning SP3,

Commercial grade power tool

cleaning SP15, Power tool cleaning

685.8

to bare metal SP 11

will affect viscosity and difficult apply

improve adhesion with substrate

Quality control daily check list (I

am not sure)

403.2 WFT

378.78 WFT

Correct

Spray Gun good distance is 25 to 35 cm

Correct, paint pot considered as pump like 30:1 etc...

Fine coating finish

Dry spray, Over Spray and thin coating (if to

short alligator skin finish and result too much

coating on surface)

Spray Gun Tip

Correct

correct

Logical Pattern

to ensure the coating ability of

withstanding against chemical attack

SAES-H-100

Qualitative test (to ensure the

coating ability of withstanding

against chemical attack)

25mm

1x, 2x, 10x

nonmagnetic shims of known thickness over the bare, prepared substrate

average of 5 readings

No peeling or .removal

contaminations on substrate after cleaning.

False, Grounding is required.

acceptable if fails after the required value attained.

DFT 180microns

DFT 261microns

DFT 28microns

wind disturbance or too much distance between spray nozzle to substrate

0 to 75microns

Pull off magnetic Gauges eg. Banana Gauge

yes

universal microscope with reticle

24.8mils

300mm / second.

500microns

acceptable if fails after the required value attained.

APCS-2A - Phenolic Epoxy APCS-2E - Solvent Free Phenolic Epoxy

APCS-2F - Glass Flake Polyester APCS-2G - Glass Flake Vinyl Ester

APCS-2H - Glass Flake Epoxy APCS-2I - Ceramic/Inorganic Filled Epoxy-Phenolic/Novolac

Correct. Aviation fuel APCS-2D - Epoxy

6 cuts at 2mm apart made in each direction

Fish eye

Target Zone

Called as crazing

No.

Yes.

SSPC VIS2

Yes. (Rust grade numbered 0 to 10 (11 Grades) Pictures

9x3=27 Grade 0 & 10 don't have picture)

Compatible to existing Coating

No Picture

Correct

Chalking

Feathering

No.

ASTM D714 Standard Test Method for Evaluating

Degree of Blistering of Paints

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Your Vodafone Bill: Amount DueDocument13 pagesYour Vodafone Bill: Amount DueSebastian RajeshPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Travel BudgetDocument4 pagesTravel BudgetErik TrujilloPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- PlanDocument1 pagePlanSebastian RajeshPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Brochure Title: SubtitleDocument2 pagesBrochure Title: SubtitlePaolo PerandosPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Your Vodafone Bill: Amount DueDocument13 pagesYour Vodafone Bill: Amount DueSebastian RajeshPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- VF Bill 38133410-20180801Document1 pageVF Bill 38133410-20180801Sebastian RajeshPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Ultrasonic Testing of Welds Report: Wisconsin Department of Transportation DT2104 2004 (Replaces EM771)Document2 pagesUltrasonic Testing of Welds Report: Wisconsin Department of Transportation DT2104 2004 (Replaces EM771)Abdul GhafoorPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Coating Inspector ResponsibilityDocument1 pageCoating Inspector ResponsibilitySebastian RajeshPas encore d'évaluation

- Customer Care NumbersDocument1 pageCustomer Care NumbersSebastian RajeshPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- QBDocument4 pagesQBSebastian Rajesh100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Personal or Telephone Interview Tips For Mechanical InspectorDocument12 pagesPersonal or Telephone Interview Tips For Mechanical InspectorSakthi PkPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- 4aa6 4775eepDocument2 pages4aa6 4775eepSebastian RajeshPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- SQAE Velosi Interview PreparationDocument10 pagesSQAE Velosi Interview PreparationSebastian RajeshPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- ITP For Process PipingDocument4 pagesITP For Process PipingSebastian RajeshPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Aramco Interview QuestionsDocument19 pagesAramco Interview QuestionsSebastian Rajesh100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- JD QAQC Engineer Mech 2016Document2 pagesJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- QA Engineer QuestionsDocument3 pagesQA Engineer QuestionsSebastian RajeshPas encore d'évaluation

- JD QAQC Engineer Mech 2016Document2 pagesJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- ALJV Manpower Selection ScheduleDocument2 pagesALJV Manpower Selection ScheduleSebastian RajeshPas encore d'évaluation

- Trinity Institute of NDT Technology: Plot No. V-22 (A), 2nd Stage, Peenya Industrial Estate, Bangalore - 560 058, INDIADocument2 pagesTrinity Institute of NDT Technology: Plot No. V-22 (A), 2nd Stage, Peenya Industrial Estate, Bangalore - 560 058, INDIASebastian RajeshPas encore d'évaluation

- JD QAQC Engineer Mech 2016Document2 pagesJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- QC ManualDocument35 pagesQC ManualSebastian RajeshPas encore d'évaluation

- Asme P NumberDocument1 pageAsme P NumberSebastian RajeshPas encore d'évaluation

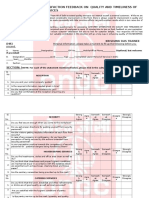

- Customer Satisfaction Feedback On Quality and Timeliness of Administration ServicesDocument4 pagesCustomer Satisfaction Feedback On Quality and Timeliness of Administration ServicesSebastian RajeshPas encore d'évaluation

- Technical Brochure Gre Site Activities: 44 Years ExperienceDocument30 pagesTechnical Brochure Gre Site Activities: 44 Years ExperienceSebastian RajeshPas encore d'évaluation

- ElectricDocument42 pagesElectricAbd ZouhierPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Transisi Iso 2001 TH 2008 Ke 2015 PDFDocument32 pagesTransisi Iso 2001 TH 2008 Ke 2015 PDFsellen34Pas encore d'évaluation

- Heat Treatement 3.2 PDFDocument11 pagesHeat Treatement 3.2 PDFSebastian RajeshPas encore d'évaluation

- Bajaj CNSDocument3 pagesBajaj CNSAbhijit PaikarayPas encore d'évaluation

- Karthik ResumeDocument2 pagesKarthik ResumeArun Raj APas encore d'évaluation

- Holiday AssignmentDocument18 pagesHoliday AssignmentAadhitya PranavPas encore d'évaluation

- Feds Subpoena W-B Area Info: He Imes EaderDocument42 pagesFeds Subpoena W-B Area Info: He Imes EaderThe Times LeaderPas encore d'évaluation

- Buildingawinningsalesforce WP DdiDocument14 pagesBuildingawinningsalesforce WP DdiMawaheb ContractingPas encore d'évaluation

- Report On Marketing Strategy of Nestle MILKPAKDocument13 pagesReport On Marketing Strategy of Nestle MILKPAKAzeem Ahmad100% (1)

- Getting Returning Vets Back On Their Feet: Ggoopp EennddggaammeeDocument28 pagesGetting Returning Vets Back On Their Feet: Ggoopp EennddggaammeeSan Mateo Daily JournalPas encore d'évaluation

- WinCC Control CenterDocument300 pagesWinCC Control Centerwww.otomasyonegitimi.comPas encore d'évaluation

- Unit 4Document15 pagesUnit 4David Lopez LaraPas encore d'évaluation

- Bushcraft Knife AnatomyDocument2 pagesBushcraft Knife AnatomyCristian BotozisPas encore d'évaluation

- PDS (OTO360) Form PDFDocument2 pagesPDS (OTO360) Form PDFcikgutiPas encore d'évaluation

- Life in The Ancient WorldDocument48 pagesLife in The Ancient Worldjmagil6092100% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Christena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Document293 pagesChristena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Emiliano CalabazaPas encore d'évaluation

- Building For The Environment 1Document3 pagesBuilding For The Environment 1api-133774200Pas encore d'évaluation

- Terminal Blocks: Assembled Terminal Block and SeriesDocument2 pagesTerminal Blocks: Assembled Terminal Block and SeriesQuan Nguyen ThePas encore d'évaluation

- En 50124 1 2001Document62 pagesEn 50124 1 2001Vivek Kumar BhandariPas encore d'évaluation

- Toxemias of PregnancyDocument3 pagesToxemias of PregnancyJennelyn LumbrePas encore d'évaluation

- P. E. and Health ReportDocument20 pagesP. E. and Health ReportLESSLY ABRENCILLOPas encore d'évaluation

- ISO - 21.060.10 - Bolts, Screws, Studs (List of Codes)Document9 pagesISO - 21.060.10 - Bolts, Screws, Studs (List of Codes)duraisingh.me6602Pas encore d'évaluation

- Dialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Document1 pageDialog+ SW9xx - SM - Chapter 7 - 2-2013 - EN - Rinsing Bridge Version 5Al ImranPas encore d'évaluation

- Fair & LovelyDocument10 pagesFair & LovelyAymanCheema100% (3)

- Using The Monopoly Board GameDocument6 pagesUsing The Monopoly Board Gamefrieda20093835Pas encore d'évaluation

- TMPRO CASABE 1318 Ecopetrol Full ReportDocument55 pagesTMPRO CASABE 1318 Ecopetrol Full ReportDiego CastilloPas encore d'évaluation

- Hindi ShivpuranDocument40 pagesHindi ShivpuranAbrar MojeebPas encore d'évaluation

- JP Selecta IncubatorDocument5 pagesJP Selecta IncubatorAhmed AlkabodyPas encore d'évaluation

- Understanding The Marshall AttackDocument6 pagesUnderstanding The Marshall Attacks.for.saad8176Pas encore d'évaluation

- A SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Document15 pagesA SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Batuhan ElçinPas encore d'évaluation

- Hetal Patel: Team Leader - SalesDocument2 pagesHetal Patel: Team Leader - SalesPrashant kumarPas encore d'évaluation

- AcousticsDocument122 pagesAcousticsEclipse YuPas encore d'évaluation

- Unit 1 and 2Document4 pagesUnit 1 and 2Aim Rubia100% (1)

- The Fabric of Civilization: How Textiles Made the WorldD'EverandThe Fabric of Civilization: How Textiles Made the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (58)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaD'EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaPas encore d'évaluation

- The End of Craving: Recovering the Lost Wisdom of Eating WellD'EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellÉvaluation : 4.5 sur 5 étoiles4.5/5 (82)

- Sully: The Untold Story Behind the Miracle on the HudsonD'EverandSully: The Untold Story Behind the Miracle on the HudsonÉvaluation : 4 sur 5 étoiles4/5 (103)

- Hero Found: The Greatest POW Escape of the Vietnam WarD'EverandHero Found: The Greatest POW Escape of the Vietnam WarÉvaluation : 4 sur 5 étoiles4/5 (19)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureD'EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureÉvaluation : 5 sur 5 étoiles5/5 (125)