Académique Documents

Professionnel Documents

Culture Documents

Intrinsically Safe-An Intro

Transféré par

soumyakantCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Intrinsically Safe-An Intro

Transféré par

soumyakantDroits d'auteur :

Formats disponibles

AUTOMATION &

C O N T R O L S

T he definition of intrinsic safety used in the relevant IEC apparatus standard IEC 60079-11

is a 'type of protection based on the restriction of electrical energy within apparatus and of

interconnecting wiring exposed to the potentially explosive atmosphere to a level below that which

can cause ignition by either sparking or heating effects'.

An introduction to intrinsic safety

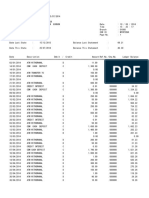

Fig.1 illustrates a typical intrinsically safe Information from Extech Safety Systems

(IS) system where the safe performance

of each piece of apparatus is dependent

on the integrity of all the equipment in

the system. For example, the safety of

the temperature transmitter (Tx) depends

on the amount of energy supplied by the

IS interface.

In most process control applications,

each piece of apparatus in a system is

individually certified. A document that

confirms the safety of the whole system

is then produced using the information

from the individual apparatus certificates,

in accordance with the system standard

IEC 60079-25. This system document

also includes details of cable types and

simple apparatus used in the system. Fig. 1: Typical IS system.

It is important to recognise that where

pieces of intrinsically safe apparatus Level 'ib' Typical Gas group Ignition

are interconnected, it is the safety of 'ib' apparatus, which is adequately safe gas energy

the system that must be established. with one fault and a factor of safety of ethane IIA I 0µ

There are however some examples of 1,5 is considered safe for use in less Ethylene IIB 80µ

apparatus which stand alone, such frequently hazardous areas (Zone 1). Hydrogen IIC 20µ

as mobile radios and portable gas Level 'ic' Table 1: Typical gases, their classification

detectors, where the system approach 'ic' apparatus which is assessed in and ignition energies.

is not relevant. 'normal operation' with a unity factor

Levels of protection of safety is generally acceptable in Faults

Intrinsic safety utilises three levels infrequently hazardous areas (Zone 2).

The 'ic' concept is relatively new (2005) If a fault can adversely affect the safety

of protection, 'ia', 'ib' and 'ic' which of the equipment it is called a 'countable'

attempt to balance the probability of and will replace the 'energy-limited' (nL)

of the type 'n' standard IEC 60079-15 fault. The situation is further complicated

an explosive atmosphere being present because the apparatus standard permits

and possibly the 'non-incendive' concept

against the probability of an ignition some specially designed components

of North American standards.

capable situation occurring. to be regarded as infallible and some

It is usual for a system to be allocated inadequately designed features to be

Level 'ia'

a level of protection as a whole,

This offers the highest level of protection failed in normal operation. Consequently

depending on the level of protection of

and is generally considered as being there are faults that are not considered

the apparatus in the system. However it

adequately safe for use in the most to happen, faults, which are counted,

is possible for different parts of a system

hazardous locations (Zone 0) because to have different levels of protection and faults, which are imposed but not

the possibility of two 'faults' (see below) where suitable segregation exists. This counted.

and a factor of safety of 1,5 is considered must be made clear in the system One of the major advantages of intrinsic

in the assessment of safety. documentation. safety is that 'live maintenance' on

September 2008 - Vector - Page 62

1 2 6 which additional faults have to be need to be temperature classified but

450oC 300oC 200oC 135oC 100oC 80oC considered. must be used within its specified ambient

temperature range.

Table 2: The 'T' classes. Gas classification

The amount of energy required to ignite Categories and equipment

equipment is permitted without the a particular gas/air mixture varies for safety levels

necessity of obtaining 'gas clearance' each gas. Industrial gases capable of When the European Directive (ATEX) for

certificates. A consequence of this is that being ignited are divided, in the UK, into apparatus for use in hazardous areas

during the safety analysis the possibility three classes, IIA, IIB and IIC. (94/9/EC) was created, it introduced the

of open circuiting and short-circuiting concept of categories, which was intended

Table 1 shows a representative gas for to clarify the Zone(s) in which apparatus

any field wiring is regarded as normal each group and the minimum energy

operation. could safely be used. Unfortunately, and

required to ignite it. IIC is clearly the for nothing more than pedantic reasons, it

Fortunately understanding the apparatus most sensitive. was decided that a category 0 would not

standard and faults is only necessary Apparatus can be designed to be be used and the result was the confusing

for apparatus designers and certifying acceptably safe in any of these groups. situation illustrated in Table. 1, where the

authorities. The apparatus certificates Usually apparatus is designed to be category and Zone numbers differ.

remove the necessity to consider faults, safe in IIC, because it can then be used More recently (2004) the IEC took up

except for field wiring faults, in system in any gas atmosphere. Sometimes a the concept of identifying the level of

design. IIB classification is used as this permits protection offered by a piece of apparatus

Simple apparatus slightly higher powers to be available. and also paid a little more attention to

Only very rarely however is apparatus risk analysis as a method of determining

In general, intrinsically safe apparatus

designed for the IIA classification the acceptable use of equipment. The

is certified; usually by an independent

because this restricts its use to this group result was the creation of equipment

body such as an Accredited Certification

alone. protection levels (EPLs), which are similar

Body (ACB) under the IEC Ex scheme.

Apparatus is usually assessed using to ATEX categories but have numbers that

Self-certification by the manufacturer of

'ic' equipment is also quite commonly the curves and tables included in align with their normal Zones of use. In

accepted. the apparatus standard which lists practice both categories and EPLs align

acceptable levels of current and voltage. with the levels of protection 'ia', 'ib' and

The exception to the rule is 'simple 'ic' as indicated in Table 1 and, as far

apparatus', which is considered not to More complex circuits are checked

with 'spark test' apparatus; normally the as intrinsic safety is concerned, they

appreciably affect the intrinsic safety of can largely be ignored, as the level

the system. This apparatus is exempted preserve of certifying authorities.

of protection is already defined as 'ia',

from the requirement for certification. Temperature classification 'ib' or 'ic'. They do however appear on

The simple requirements are clearly apparatus marking and certificates and

The second method of causing an explosion

specified in the apparatus standard. consequently need to be explained.

is normally considered to be ignition by a

'Simple apparatus' should always be hot surface. When a gas is heated above its

readily demonstrable to be adequately Summary

ignition temperature it may spontaneously

safe. The usual examples are switches, ignite. The ignition temperature varies with Intrinsic safety offers an acceptable level

thermocouples, RTDs and junction the gas and is not correlated to ignition of safety in all hazardous locations.

boxes. energy. Consequently, when selecting Arguably it is safer and less prone to

Cables apparatus, both properties of the explosive accidental errors than other methods

gas have to be considered. Apparatus of protection. This combined with its

Because cables have inductance and

is classified into temperature ('T') classes flexible use of available apparatus and

capacitance, and hence energy storage

depending on its maximum permitted the ability to do 'live working' means that

capabilities, they can affect system

surface temperature. The standard enables it is the natural choice for instrumentation

safety. Consequently the system design

almost all apparatus, dissipating not more systems in hazardous areas. For example

imposes restrictions on the amount of

than 1,3 W, to be allocated a temperature it is the only technique which is readily

each of these parameters. A great deal

classification of T4 (135°C). Almost all applicable to Zone 0 locations. The

has been written on this subject but only

intrinsically safe field mounted apparatus introduction of the 'ic' concept completes

rarely is there a serious limitation placed

meets the requirements of T4 temperature the picture.

on the available cable.

classification, which permits its use in The essential requirements of an

As cable faults are taken into account all industrial gas atmospheres except in

during the system analysis, the type of intrinsically safe system are:

those comprising carbon disulfide (CS2) l The system must work

cable in individual installations is not and air. These require a T6 classification,

closely specified in the system standard. which is difficult to achieve at high l The apparatus in the system must be

The choice is therefore determined by ambient temperatures. There are also 'certified' or 'simple'.

the need for reliable system operation. toxicity problems associated with carbon l The compatibility of the apparatus

Where intrinsically safe systems are disulfide. must be established.

combined in a multi-core, then there are The other temperature that needs to be l The level of protection of the system

special requirements. These determine considered for each piece of apparatus established.

is its ambient temperature rating, which l The temperature classification and

tt ut u ts A tg s does directly affect the safety of the ambient temperature rating of each

apparatus in several ways. Apparatus piece of apparatus established.

2 1 0 0

normally mounted in the safe area but l The requirements of the cable

1 2 1 1

which affects the safety of the intrinsically established.

0 3 2 2 safe system (such as the intrinsically safe Contact Gary Friend, Extech Safety

Table 3: Relationships between different interface in Fig. 1) is called 'associated Systems, Tel 011 791-6000,

methods of assessing safety levels. apparatus'. Such apparatus does not garyf@tempcon.co.za D

September 2008 - Vector - Page 64

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Sony SL HF-900 Owners ManualDocument53 pagesSony SL HF-900 Owners ManualThomas Christoph100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Capsule Research ProposalDocument4 pagesCapsule Research ProposalAilyn Ursal80% (5)

- Project Report - Mouth FreshnerDocument20 pagesProject Report - Mouth FreshnersoumyakantPas encore d'évaluation

- From The Seas To The HimalayasDocument242 pagesFrom The Seas To The HimalayassoumyakantPas encore d'évaluation

- Palm Reading: Lines & Signs On PalmDocument6 pagesPalm Reading: Lines & Signs On PalmsoumyakantPas encore d'évaluation

- Edelweiss Tokio Life - Income Builder: An Individual, Non-Linked, Non-Par, Savings, Life Insurance ProductDocument16 pagesEdelweiss Tokio Life - Income Builder: An Individual, Non-Linked, Non-Par, Savings, Life Insurance ProductsoumyakantPas encore d'évaluation

- Mo Bidyut ApplicationDocument1 pageMo Bidyut ApplicationsoumyakantPas encore d'évaluation

- Truck Mounted Cranes: Hazard & Risk Assessment - Plant OperationDocument3 pagesTruck Mounted Cranes: Hazard & Risk Assessment - Plant OperationsoumyakantPas encore d'évaluation

- Robot SafetyDocument80 pagesRobot SafetysoumyakantPas encore d'évaluation

- Career Guide: To The Safety ProfessionDocument63 pagesCareer Guide: To The Safety ProfessionsoumyakantPas encore d'évaluation

- Osht 2309Document5 pagesOsht 2309soumyakantPas encore d'évaluation

- Idip Revision QAns RRC 2010-13Document64 pagesIdip Revision QAns RRC 2010-13soumyakant100% (1)

- Qatar New Labour Law PDFDocument84 pagesQatar New Labour Law PDFsoumyakant40% (5)

- News PDFDocument8 pagesNews PDFsoumyakantPas encore d'évaluation

- Labour Law Upcoming Changes October 26 2016 1Document84 pagesLabour Law Upcoming Changes October 26 2016 1zeeshan ansariPas encore d'évaluation

- NARM Related DocsDocument11 pagesNARM Related DocssoumyakantPas encore d'évaluation

- LMI CraneDocument32 pagesLMI CranesoumyakantPas encore d'évaluation

- Epson Manu - PL TX 110dfDocument2 pagesEpson Manu - PL TX 110dfsoumyakantPas encore d'évaluation

- PlsqldocDocument21 pagesPlsqldocAbhishekPas encore d'évaluation

- Final Project Report GMS BtechDocument68 pagesFinal Project Report GMS Btech02Musaib Ul FayazPas encore d'évaluation

- SettingsDocument3 pagesSettingsrusil.vershPas encore d'évaluation

- A Survey On Multicarrier Communications Prototype PDFDocument28 pagesA Survey On Multicarrier Communications Prototype PDFDrAbdallah NasserPas encore d'évaluation

- Exoskeleton ArmDocument5 pagesExoskeleton Armc214ocPas encore d'évaluation

- Ms Microsoft Office - WordDocument3 pagesMs Microsoft Office - WordFarisha NasirPas encore d'évaluation

- Amel Forms & Logging SheetsDocument4 pagesAmel Forms & Logging SheetsisaacPas encore d'évaluation

- Rs 422Document1 pageRs 422rezakaihaniPas encore d'évaluation

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDocument10 pagesA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungPas encore d'évaluation

- Awais Inspector-PaintingDocument6 pagesAwais Inspector-PaintingMohammed GaniPas encore d'évaluation

- Dreamweaver Lure v. Heyne - ComplaintDocument27 pagesDreamweaver Lure v. Heyne - ComplaintSarah BursteinPas encore d'évaluation

- White Button Mushroom Cultivation ManualDocument8 pagesWhite Button Mushroom Cultivation ManualKhurram Ismail100% (4)

- Milestone 9 For WebsiteDocument17 pagesMilestone 9 For Websiteapi-238992918Pas encore d'évaluation

- Ethercombing Independent Security EvaluatorsDocument12 pagesEthercombing Independent Security EvaluatorsangelPas encore d'évaluation

- Health, Safety & Environment: Refer NumberDocument2 pagesHealth, Safety & Environment: Refer NumbergilPas encore d'évaluation

- Bank Statement SampleDocument6 pagesBank Statement SampleRovern Keith Oro CuencaPas encore d'évaluation

- Bill Swad's Wealth Building Strategies - SwadDocument87 pagesBill Swad's Wealth Building Strategies - Swadjovetzky50% (2)

- WHO Partograph Study Lancet 1994Document6 pagesWHO Partograph Study Lancet 1994Dewi PradnyaPas encore d'évaluation

- MLT Torque Ring Field Make-Up HandbookDocument44 pagesMLT Torque Ring Field Make-Up HandbookKolawole Adisa100% (2)

- The Finley ReportDocument46 pagesThe Finley ReportToronto StarPas encore d'évaluation

- Kayako Support Suite User Manual PDFDocument517 pagesKayako Support Suite User Manual PDFallQoo SEO BaiduPas encore d'évaluation

- Ficha Tecnica 320D3 GCDocument12 pagesFicha Tecnica 320D3 GCanahdezj88Pas encore d'évaluation

- In Comparison With Oracle 8i, 9i Is Have Lot Many New Features. Important IsDocument241 pagesIn Comparison With Oracle 8i, 9i Is Have Lot Many New Features. Important IsBalaji ShindePas encore d'évaluation

- Design & Construction of New River Bridge On Mula RiverDocument133 pagesDesign & Construction of New River Bridge On Mula RiverJalal TamboliPas encore d'évaluation

- Presentation - Prof. Yuan-Shing PerngDocument92 pagesPresentation - Prof. Yuan-Shing PerngPhuongLoanPas encore d'évaluation

- ABB Price Book 524Document1 pageABB Price Book 524EliasPas encore d'évaluation

- Product Guide TrioDocument32 pagesProduct Guide Triomarcosandia1974Pas encore d'évaluation

- KV Tripple Eccentric Butterfly Valve-LinDocument12 pagesKV Tripple Eccentric Butterfly Valve-LinWelma JohnsonPas encore d'évaluation