Académique Documents

Professionnel Documents

Culture Documents

Avvl O&m Valves

Transféré par

Bantoo RajamandiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Avvl O&m Valves

Transféré par

Bantoo RajamandiDroits d'auteur :

Formats disponibles

Gate / Globe & Check Valve

Phone : (91 – 562) – 2281202, 2281203, 2281204

A.V. VALVES LIMITED Fax : (91 – 562) – 2281201

16, Industrial Estate, Nunhai

E-mail : avvalves@sancharnet.in , avengg@dataone.in

Agra – 282 006 ( INDIA)

Estd.-1969 Web-site : http://www.avvalves.com

1

INTRODUCTION

Valve need regular inspection during operation and prompt attention when trouble

arises. As a general rule, they should be subject to scheduled maintenance in the

manner normal to all running machinery. Whenever the operating conditions of a

system are altered, check the valves to ensure that they are suitable for the new

working conditions. Isolation and emergency valves only worked occasionally but

when they are needed, they are needed urgently; so they should be tested regularly.

Inspection should be carried out thoroughly every six months.

OPERATION AND INSTALLATION :-

(i) Check the tightness of bolts / nuts as they are liable to loosed due to

vibration of long journey upto destination.

(ii) Before a valve is tested / put in the service, it must be flushed throughly to

remove all dirt from inside the valve, it might have accumulated during its

storage.

(iii) If the valve has been tested by water, it should be cleaned and water

removed completely before keeping the valve aside.

(iv) When screwed end valves are installed, care should be taken to see that the

compound is applied on the pipe only and not on the valve lest the

compound would get on the valve seat and damage it.

(v) Close the gate in the case of Gate Valves while installing to avoid the

twisting of the gate.

(vi) When the valves are welded on to the pipe-line, care should be taken to see

that the weld splatters does not damage the wedge / plug or seating.

(vii) While installing the check valves care should be taken to install it in the

direction of the flow marked on the valve body by an arrow.

(viii) If a Valve leaks slightly when shut off, open it a little to flush particles that

may be hindering seating. Trying force it shut with a crow bar is likely to ruin

the seat.

(ix) The valve seatings are made for clean fluid operation. Therefore, it must be

ensured that service fluid should be free from foreign particles.

(x) During installation, the centre line of valve should be properly aligned with

centre line of the pipe. It is essentially important in the case of swing check

valve. As far as possible the valve must be kept in upright position.

(xi) In case of By-pass valves (as the by-pass assembly is packed separately)

same number is given on main valve and its by-pass valve. Care should be

taken to fit the same number of by-pass valves with the corresponding

number of the main valve.

Phone : (91 – 562) – 2281202, 2281203, 2281204

A.V. VALVES LIMITED Fax : (91 – 562) – 2281201

16, Industrial Estate, Nunhai

E-mail : avvalves@sancharnet.in , avengg@dataone.in

Agra – 282 006 ( INDIA)

Estd.-1969 Web-site : http://www.avvalves.com

2

MAINTENANCE AND ASSEMBLIES

EXERCISING

Valves that are not operated frequently and which may remain open or closed for long

period, should be worked even partially, about once a month.

LUBRICATION :

Where provision is specifically made on the valve, a regular check up is essential to

see that the lubricant in sufficient quantity is regularly fed. Greasing of spindle,

gearing and other working components as appropriate, should be Performed every

six months. In case of a unit that has not been operated for a long time all moving parts

should be lubricated before operation.

GLAND PACKING :

Do not allow the valve packing to leak. This reduces the efficiency of the packing and

may make a new valve stem necessary. The leaking also wastes material. The fact

that gland packing tends to harden and make movement of the valve element more

difficult if a unit is left inactive for a long period should not be overlooked. When using

split rings the ring splits should be staggered so that they are not all on the same side

of the stem, thus forming a potential source of leakage. The gland nuts should be

tightened uniformly.

GASKETS :

When faulty gasket is the cause of leak, care should be taken to ensure that the

replacement is of the correct material and size.

VIBRATION :

After a long period of operation, connecting bolts should be checked for tightness.

This should be done more often if vibration is experienced in the pipeline.

Maintenance of the valve is reduced to the minimum if the choice of the type and

material is proper.

REPLACEMENT OF COMPONENTS :

In the event of damage or break-down which warrants the replacement of damaged

components genuine spares from us ( the original manufacturer ) should only be

used.

To ensure that right spares for right valve are used, proper reference has to be given

to us (the manufacturer). When valve serial number is punched on the valve body and

bonnet, apart from name plate, this number should also be communicated.

Phone : (91 – 562) – 2281202, 2281203, 2281204

A.V. VALVES LIMITED Fax : (91 – 562) – 2281201

16, Industrial Estate, Nunhai

E-mail : avvalves@sancharnet.in , avengg@dataone.in

Agra – 282 006 ( INDIA)

Estd.-1969 Web-site : http://www.avvalves.com

3

Vous aimerez peut-être aussi

- ARV ComparisonDocument5 pagesARV ComparisonBantoo RajamandiPas encore d'évaluation

- TDC Tech Spec For PlateDocument3 pagesTDC Tech Spec For PlateBantoo RajamandiPas encore d'évaluation

- CV Values BFVDocument2 pagesCV Values BFVBantoo RajamandiPas encore d'évaluation

- DBRAU Scheme 2016 Main ExamDocument10 pagesDBRAU Scheme 2016 Main ExamBantoo RajamandiPas encore d'évaluation

- Insp Call-PO# E2Q1440Document1 pageInsp Call-PO# E2Q1440Bantoo RajamandiPas encore d'évaluation

- Attachment-2 LP Valves Legend SheetDocument1 pageAttachment-2 LP Valves Legend SheetBantoo RajamandiPas encore d'évaluation

- Destructive TestingDocument16 pagesDestructive TestingBantoo RajamandiPas encore d'évaluation

- Tanzania - Zimbabwe - Country Paper NSBDocument7 pagesTanzania - Zimbabwe - Country Paper NSBBantoo RajamandiPas encore d'évaluation

- Stores Scrap AuctionDocument4 pagesStores Scrap AuctionBantoo RajamandiPas encore d'évaluation

- MSS and ASME valve standards guideDocument2 pagesMSS and ASME valve standards guideNilesh MistryPas encore d'évaluation

- Vel BF WebDocument19 pagesVel BF WebrampyaripatelPas encore d'évaluation

- MTC MissiDocument2 pagesMTC MissiBantoo RajamandiPas encore d'évaluation

- Paint Procedure ACE 3254Document1 pagePaint Procedure ACE 3254Bantoo RajamandiPas encore d'évaluation

- Top stainless steel grades comparison chartDocument1 pageTop stainless steel grades comparison chartRajput PratiksinghPas encore d'évaluation

- Insp Call CI NRV P200Document1 pageInsp Call CI NRV P200Bantoo RajamandiPas encore d'évaluation

- ADMIT CARD: 2015-2016: Dayalbagh Educational Institute, Dayalbagh, AgraDocument1 pageADMIT CARD: 2015-2016: Dayalbagh Educational Institute, Dayalbagh, AgraBantoo RajamandiPas encore d'évaluation

- AAP Manifesto 2013Document50 pagesAAP Manifesto 2013RealityviewsPas encore d'évaluation

- Jash Engineering Limited's Well Equipped Facilities in IndoreDocument14 pagesJash Engineering Limited's Well Equipped Facilities in IndoreBantoo RajamandiPas encore d'évaluation

- AAP Manifesto 2013Document50 pagesAAP Manifesto 2013RealityviewsPas encore d'évaluation

- AAP Manifesto 2013Document50 pagesAAP Manifesto 2013RealityviewsPas encore d'évaluation

- JEE Advanced 2014 Solution Paper IDocument28 pagesJEE Advanced 2014 Solution Paper IanandPas encore d'évaluation

- Worlds DisasterDocument1 pageWorlds DisasterBantoo RajamandiPas encore d'évaluation

- Nepal EarthquackDocument1 pageNepal EarthquackBantoo RajamandiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Erp Software Internship Report of Union GroupDocument66 pagesErp Software Internship Report of Union GroupMOHAMMAD MOHSINPas encore d'évaluation

- NDA Template Non Disclosure Non Circumvent No Company NameDocument9 pagesNDA Template Non Disclosure Non Circumvent No Company NamepvorsterPas encore d'évaluation

- The Greco-Turkish War of 1920-1922: Greece Seeks Territory in Asia MinorDocument14 pagesThe Greco-Turkish War of 1920-1922: Greece Seeks Territory in Asia MinorFauzan Rasip100% (1)

- Apple Inc.: Managing Global Supply Chain: Case AnalysisDocument9 pagesApple Inc.: Managing Global Supply Chain: Case AnalysisPrateek GuptaPas encore d'évaluation

- Sky Education: Organisation of Commerce and ManagementDocument12 pagesSky Education: Organisation of Commerce and ManagementKiyaara RathorePas encore d'évaluation

- General First Aid QuizDocument3 pagesGeneral First Aid QuizLucy KiturPas encore d'évaluation

- APP Eciation: Joven Deloma Btte - Fms B1 Sir. Decederio GaganteDocument5 pagesAPP Eciation: Joven Deloma Btte - Fms B1 Sir. Decederio GaganteJanjan ToscanoPas encore d'évaluation

- Inferences Worksheet 6Document2 pagesInferences Worksheet 6Alyssa L0% (1)

- Successfull Weight Loss: Beginner'S Guide ToDocument12 pagesSuccessfull Weight Loss: Beginner'S Guide ToDenise V. FongPas encore d'évaluation

- USP 11 ArgumentArraysDocument52 pagesUSP 11 ArgumentArraysKanha NayakPas encore d'évaluation

- Indian Medicinal PlantsDocument121 pagesIndian Medicinal PlantsN S Arun KumarPas encore d'évaluation

- Edpb 506 Intergrated Unit Project RubricDocument1 pageEdpb 506 Intergrated Unit Project Rubricapi-487414247Pas encore d'évaluation

- Surah Al A'araf (7:74) - People of ThamudDocument2 pagesSurah Al A'araf (7:74) - People of ThamudMuhammad Awais TahirPas encore d'évaluation

- Review 6em 2022Document16 pagesReview 6em 2022ChaoukiPas encore d'évaluation

- Donut FenderDocument5 pagesDonut FenderMaria Angelin NaiborhuPas encore d'évaluation

- Cambridge IGCSE: 0500/12 First Language EnglishDocument16 pagesCambridge IGCSE: 0500/12 First Language EnglishJonathan ChuPas encore d'évaluation

- International BankingDocument3 pagesInternational BankingSharina Mhyca SamontePas encore d'évaluation

- Case Digest in Special ProceedingsDocument42 pagesCase Digest in Special ProceedingsGuiller MagsumbolPas encore d'évaluation

- Sewing Threads From Polyester Staple FibreDocument13 pagesSewing Threads From Polyester Staple FibreganeshaniitdPas encore d'évaluation

- Shilajit The Panacea For CancerDocument48 pagesShilajit The Panacea For Cancerliving63100% (1)

- Bo de On Thi Hoc Ki 1 Lop 3 Mon Tieng AnhDocument66 pagesBo de On Thi Hoc Ki 1 Lop 3 Mon Tieng AnhHằng DiệuPas encore d'évaluation

- Piramal Annual ReportDocument390 pagesPiramal Annual ReportTotmolPas encore d'évaluation

- 4TH Quarter English 10 Assessment TestDocument6 pages4TH Quarter English 10 Assessment TestafbnjkcdPas encore d'évaluation

- Math 8 1 - 31Document29 pagesMath 8 1 - 31Emvie Loyd Pagunsan-ItablePas encore d'évaluation

- Waiver: FEU/A-NSTP-QSF.03 Rev. No.: 00 Effectivity Date: Aug. 10, 2017Document1 pageWaiver: FEU/A-NSTP-QSF.03 Rev. No.: 00 Effectivity Date: Aug. 10, 2017terencePas encore d'évaluation

- Under the Angels Restaurant Transports Guests to Old CracowDocument2 pagesUnder the Angels Restaurant Transports Guests to Old CracowBence KlusóczkiPas encore d'évaluation

- Unit 6 Lesson 3 Congruent Vs SimilarDocument7 pagesUnit 6 Lesson 3 Congruent Vs Similar012 Ni Putu Devi AgustinaPas encore d'évaluation

- Final Literature CircleDocument10 pagesFinal Literature Circleapi-280793165Pas encore d'évaluation

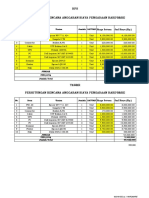

- HPS Perhitungan Rencana Anggaran Biaya Pengadaan Hardware: No. Item Uraian Jumlah SATUANDocument2 pagesHPS Perhitungan Rencana Anggaran Biaya Pengadaan Hardware: No. Item Uraian Jumlah SATUANYanto AstriPas encore d'évaluation

- 2020052336Document4 pages2020052336Kapil GurunathPas encore d'évaluation