Académique Documents

Professionnel Documents

Culture Documents

Type 526 PDF

Transféré par

Thiên KhánhTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Type 526 PDF

Transféré par

Thiên KhánhDroits d'auteur :

Formats disponibles

The-Safety-Valve.

com

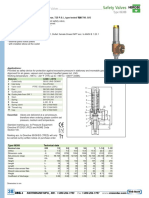

API , Type 526

API

Type 526

Safety valves from the API product group meet all the requirements

of API 526 such as standardized capacity, nominal diameter, and

center to face dimensions which offers 100% compatibility.

Because of their robust construction, they are especially suitable for

being constructed from special materials such as Duplex, Monel,

and Hastelloy.

Approvals

Industries

Oil and Gas Industry

Chemical Industry

Petrochemical Industry

Energy

Technical Gases

Further Links

API Catalog [DE]

Instructions [DE, EN, FR, ES, IT, RU, CN]

Stückliste Type 526 [DE]

Leistungstabellen Type 526 [DE]

© 2017 LESER GmbH & Co. KG Hamburg www.leser.com

The-Safety-Valve.com

API , Type 526

Datasheet

Product info Metric unit US unit

Key feature Fulfillment of API 526 Fulfillment of API 526

Nominal DN 25 - DN 200 1" - 8"

diameter inlet

Nominal

diameter

outlet

Orifice D -T D -T

Pressure

Actual orifice 14 - 161,5 mm 0,551 - 6,36 in

diameter d0

Actual orifice 154 - 20485 mm² 0,239 - 31,75 in²

area A0

Pressure 0,12 - 413,8 bar 2 - 6000 psig

Flange rating CL150 - CL2500 CL150 - CL2500

inlet

Temperature -270 to 550 °C -454 to 1022 °F

acc. to DIN

EN

Temperature -268 to 538 °C -450 to 1000 °F

acc. to ASME

Body material 1.0619, 1.4408, 1.7357 SA 216 WCB, SA 351 CF8M, SA 217 WC6, SA 352 LCB, SA 351 CF3M,

SA 995 Gr 4A CD3MN (Duplex), SA 494 M35-1 (Monel), SA 494 CX2MW

(Hastelloy), SA 494 CW-6MC (Inconel)

KUB-Materials

Valve Flange acc. to Flange acc. to

connection ASME B 16.5 ASME B 16.5

DIN EN 1092-1 DIN EN 1092-1

JIS 2220 JIS 2220

Bellows INCONEL® 625 INCONEL® 625

Type of Spring loaded Spring loaded

loading

Approvals ASME Sec. VIII Div. 1, DGRL/DIN ASME Sec. VIII Div. 1, DGRL/DIN EN ISO 4126-1, DGRL/AD

EN ISO 4126-1, DGRL/AD 2000-Merkblatt A2, AQSIQ, EAC

2000-Merkblatt A2, AQSIQ, EAC

Specials

© 2017 LESER GmbH & Co. KG Hamburg www.leser.com

The-Safety-Valve.com

API , Type 526

Options

Feature Option Code

Disc metal sealing, 1.4404 stellited J25

with soft sealing O-ring CR „K” J21

with soft sealing O-ring EPDM „D” J22

with soft sealing O-ring FKM „L” J23

with soft sealing O-ring FFKM „C” J20

with soft sealing plate SP „T” J49

with soft sealing plate PCTFE „G” J48

with soft sealing platePTFE „A” J44

Seat/nozzle Stellited seat / nozzle L62

Bellows Bellows: Inconel 625 / 2.4856 J82

Bellows: Inconel 625/ conn.Parts 316L J83

High temperature equipment (only for type J88

5267)

Balanced Piston K10

Caps and levers Screwed cap H2

Screwed plain lever H3

Screwed packed lever H4

Bolted cap H1 K01

Bolted lifting device H6 K06

Spring heat resistant X01

(Standard)

stainless steel 1.4310 X04

INCONEL X-750 X08

Test gag for cap H2 J70

for lifting device H4 J69

Bonnet closed

open

Heating jacket -

Lift indicator Lift indicator for lifting device H4 H4 (H6) J39J93

Lift stopper Lift stopper ring J51

Actuate screw H2 J52

Actuate screw H4 J50

Butt-weld connection Butt-weld connection S05

Free of oil and grease Free of oil and grease J85

Bug screen Bug screen M70

NACE material test certificate Sour gas resistance acc. to NACE MR0175; N78

Certificate acc. to DIN EN 10204-3.1

Sour gas resistance acc. to NACE MR0103; N77

Certificate acc. to DIN EN 10204-3.1

© 2017 LESER GmbH & Co. KG Hamburg www.leser.com

The-Safety-Valve.com

API , Type 526

High Alloy Concept 22Cr Duplex Body H1D

22Cr Duplex Level 1 (Nozzle and disc) K1AL43

22Cr Duplex Level 2 (Nozzle, disc, guide K1AL43K4DK3D

and spindlel)

Monel 400 Body H1B

Monel 400 Level 1 (Nozzle and disc) L66L40

Monel 400 Level 2 (Nozzle, disc, guide and L66L40K4AK3A

spindlel)

Hastelloy Body H1C

Hastelloy Level 1 (Nozzle and disc) L67L41

Hastelloy Level 2 (Nozzle, disc, guide and L67L41K4BK3B

spindlel)

Inconel Level 1 (Nozzle and disc) L69L42

Inconel Level 2 (Nozzle, disc, guide and L69L42K4CK3C

spindlel)

Further combinations of materials until the on request

complete valve

Balanced Piston Balanced Piston K10

© 2017 LESER GmbH & Co. KG Hamburg www.leser.com

Vous aimerez peut-être aussi

- 01 - Chapter 1 PDFDocument37 pages01 - Chapter 1 PDFThiên KhánhPas encore d'évaluation

- 02 - When & Why Stress Analysis MetricDocument1 page02 - When & Why Stress Analysis Metricsamprof4vwPas encore d'évaluation

- PSR E453 PDFDocument80 pagesPSR E453 PDFThiên KhánhPas encore d'évaluation

- Basket StrainersDocument15 pagesBasket StrainersYarlagadda Harsha VardhanPas encore d'évaluation

- Smartplant License Manager: Installation and User'S GuideDocument137 pagesSmartplant License Manager: Installation and User'S GuideRicardo A. Pol PérezPas encore d'évaluation

- PG800 Cryogenic Butterfly ValvesDocument16 pagesPG800 Cryogenic Butterfly ValvesThiên KhánhPas encore d'évaluation

- BS 4871-1 PDFDocument15 pagesBS 4871-1 PDFbich100% (1)

- Defining Navis ColorsDocument2 pagesDefining Navis ColorsKodali Naveen KumarPas encore d'évaluation

- Quy đổi đơn vịDocument6 pagesQuy đổi đơn vịThiên KhánhPas encore d'évaluation

- GT Bom Chuong123Document10 pagesGT Bom Chuong123Le Ngoc DungPas encore d'évaluation

- Cryogenic Service ValvesDocument84 pagesCryogenic Service ValvesThiên KhánhPas encore d'évaluation

- Compact Performance en 08 2016Document88 pagesCompact Performance en 08 2016Thiên KhánhPas encore d'évaluation

- PDFDocument8 pagesPDFThiên KhánhPas encore d'évaluation

- 38G-4 Safety Thermal Relief ValvesDocument1 page38G-4 Safety Thermal Relief ValvesThiên KhánhPas encore d'évaluation

- Cat VelanDocument28 pagesCat VelanRick FayPas encore d'évaluation

- Facts 526 Orifice P EN PDFDocument11 pagesFacts 526 Orifice P EN PDFThiên KhánhPas encore d'évaluation

- NORSOK Standard Piping Details L-CR-003Document41 pagesNORSOK Standard Piping Details L-CR-003Thiên KhánhPas encore d'évaluation

- Facts 459 enDocument14 pagesFacts 459 endanniloskyPas encore d'évaluation

- Flange Tables PDFDocument6 pagesFlange Tables PDFThiên KhánhPas encore d'évaluation

- 11 Dynamic Output ProcessingDocument19 pages11 Dynamic Output ProcessingThiên KhánhPas encore d'évaluation

- 9 Static Output ProcessorDocument53 pages9 Static Output ProcessorThiên KhánhPas encore d'évaluation

- Regulations For Color Code For Piping SystemsDocument15 pagesRegulations For Color Code For Piping SystemsThiên KhánhPas encore d'évaluation

- Process Plant Piping Maintenance RepairDocument73 pagesProcess Plant Piping Maintenance RepairMiguel Cárdenas JaramilloPas encore d'évaluation

- Regulations For Color Code For Piping SystemsDocument15 pagesRegulations For Color Code For Piping SystemsThiên KhánhPas encore d'évaluation

- 10 Dynamic AnalysisDocument113 pages10 Dynamic AnalysisThiên KhánhPas encore d'évaluation

- Caesar Ii: User's GuideDocument1 261 pagesCaesar Ii: User's GuideThiên KhánhPas encore d'évaluation

- Fabrication Erection and Installation Procedure For PipingDocument36 pagesFabrication Erection and Installation Procedure For PipingThiên Khánh67% (3)

- Bai Giang Cau ThepDocument65 pagesBai Giang Cau ThepThiên KhánhPas encore d'évaluation

- CADworx Structure Editor Users GuideDocument113 pagesCADworx Structure Editor Users GuideThiên Khánh100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Kajian Penerapan Soil NailingDocument5 pagesKajian Penerapan Soil Nailinghandry solimudinPas encore d'évaluation

- API RP505 Classfication SelectedDocument2 pagesAPI RP505 Classfication SelectedSing Yew LamPas encore d'évaluation

- Automatic ingot feeder streamlines aluminum productionDocument6 pagesAutomatic ingot feeder streamlines aluminum productionPooja BanPas encore d'évaluation

- Aqua Culture Brochure - Fusi TechDocument2 pagesAqua Culture Brochure - Fusi Techsaradhi sravan kumarPas encore d'évaluation

- Carbide ToolingDocument90 pagesCarbide ToolingHuron Industrial SupplyPas encore d'évaluation

- Schedule of Quantities: NIT No. 49/NIT/EE-I/CPWD/BBSR/2021-22Document11 pagesSchedule of Quantities: NIT No. 49/NIT/EE-I/CPWD/BBSR/2021-22Ajit JenaPas encore d'évaluation

- List of CompaniesDocument5 pagesList of Companiesdeep nikil60% (5)

- User Manual RCU Universal Rev01Document48 pagesUser Manual RCU Universal Rev01Anonymous FGY7goPas encore d'évaluation

- Evaluation of Mechanical and Thermal Properties of Al 6360 Alloy Reinforced With Sic ParticulatesDocument13 pagesEvaluation of Mechanical and Thermal Properties of Al 6360 Alloy Reinforced With Sic ParticulatesSripad APas encore d'évaluation

- AMS-2249-Chemical Check Analysis LimitsDocument6 pagesAMS-2249-Chemical Check Analysis LimitsSinan Yıldız100% (1)

- Canopy Glass Thickness PDFDocument1 pageCanopy Glass Thickness PDFRufus ChengPas encore d'évaluation

- First Part Lab ManualDocument6 pagesFirst Part Lab ManualInfo EsocketPas encore d'évaluation

- Toshiba 13A26 PDFDocument39 pagesToshiba 13A26 PDFJOMAREYPas encore d'évaluation

- Science Presence of God J2Document8 pagesScience Presence of God J2Kafui AugustinePas encore d'évaluation

- WWW - Osha.gov Pre Test Answer Key2Document3 pagesWWW - Osha.gov Pre Test Answer Key2raul_bsu100% (6)

- Zero Waste Europe Policy-Briefing Waste Prevention Framework enDocument12 pagesZero Waste Europe Policy-Briefing Waste Prevention Framework enFernanda BenedettiPas encore d'évaluation

- Pcw-Ts-Pcs Design Process 2017Document89 pagesPcw-Ts-Pcs Design Process 2017Marlon ReonicoPas encore d'évaluation

- Insulation system thermal classesDocument2 pagesInsulation system thermal classesVictor Hutahaean100% (1)

- Plastic ShredderDocument23 pagesPlastic ShredderJojimar JulianPas encore d'évaluation

- 1.1. Usb Legal PDFDocument60 pages1.1. Usb Legal PDFnadzrin_akatsuki94100% (1)

- Multi Zone Completion OptionsDocument6 pagesMulti Zone Completion OptionsTong ChaipanyakulPas encore d'évaluation

- Nuchprayoon 2018Document5 pagesNuchprayoon 2018chintan pandyaPas encore d'évaluation

- FULL CERAMIC BEARINGS TECHNICAL GUIDEDocument13 pagesFULL CERAMIC BEARINGS TECHNICAL GUIDEKatasterPas encore d'évaluation

- Moulding Effects & DefectsDocument91 pagesMoulding Effects & Defectsrijoy p pPas encore d'évaluation

- ACI Building Code Requirements for Thin Shells and Folded PlatesDocument84 pagesACI Building Code Requirements for Thin Shells and Folded PlateskrishnanunniPas encore d'évaluation

- Floor ReportDocument4 pagesFloor ReportStephen Gallagher0% (1)

- Samsung Refrigeretor - RS265TD Fast Track R2Document6 pagesSamsung Refrigeretor - RS265TD Fast Track R2Dan DrambareanuPas encore d'évaluation

- Progressive Failure Analysis of Fiber-Reinforced Laminated CompositesDocument17 pagesProgressive Failure Analysis of Fiber-Reinforced Laminated Compositesjunjie yiPas encore d'évaluation

- FS1 F.A.P. - FS1 F.A.P. - 3 - G000097241 PDFDocument4 pagesFS1 F.A.P. - FS1 F.A.P. - 3 - G000097241 PDFSaul SanchezPas encore d'évaluation