Académique Documents

Professionnel Documents

Culture Documents

Frequently Asked Questions: General

Transféré par

Rahul MoottolikandyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Frequently Asked Questions: General

Transféré par

Rahul MoottolikandyDroits d'auteur :

Formats disponibles

Frequently Asked Questions

General

What is the difference between a strainer and a filter?

Strainers and filters are both products that filer solids from fluids. However, when the solid to be filtered is visible to

the naked eye (greater than 40 μm) then the term “strainer” is used and when filtration is smaller than or equal to 40

μm, the term “filter” is used.

What is the difference between a filter and a separator?

Filters are products that are generally used for separation of suspended solids from fluids i.e. liquids or gases. An

example of a filter would be a product that separates minute metal shavings of hydraulic pistons in a hydraulic oil

power pack. Separators are products that are generally used for separation of phases of emulsified fluids i.e. liquids

from gases and/or liquids from liquids. An example of a separator would be a product that separates emulsified liquid

water particles in a compressed gas pipeline.

Why should I use a strainer?

There are two reasons to use a strainer or filter:

o Safety requirement

A strainer is to be used before any expensive capital equipment like pump, valve, heat exchanger, flow meters,

compressors, etc to protect them damage from foreign particles like dirt, scales, seeds, salt, un-dissolved resins,

lumps of pulp, pigments, etc. This guarantees a long service life for the expensive equipment and reduced

operational costs in the long run.

o Process requirement

If the process requires that the fluid be free from particles above a certain size, then a strainer (or filter) can be used

to meet that requirement. For example if an ethylene glycol process line requires that it be free from particles above

25 μm for further processing, then a strainer with a 25 μm opening filter media can be used to eliminate particles

above that size.

What is flash steam recovery?

Flash steam recovery or blowdown steam recovery is the process of recovering the steam that is formed when high

pressure and high temperature condensate is transmitted to a low pressure vessel. Flash steam is low pressure

steam which may be used in other areas where applicable thereby reducing the need/amount (cost) of low pressure

steam generation. Our FR-V Series Flash Vessels are designed for efficient recovery of this flash steam.

What is the difference between strainer screen, filter element, inner element, or basket?

They are all one and the same. It refers to the filter element inside the strainer body.

Selection of Filtration & Separation Products

What type of strainer should I use?

Please refer our Comparative Study of Strainer Types, which provides a general understanding of the different types

of strainer and their different applications.

What are the different fluids that can be filtered?

Sungov strainers are designed to be used for practically any fluid be it liquid or gas. Most of our standard offerings

would suit common applications like water, fuel/furnace oil, liquor, diesel, steam, air, nitrogen and the like. In case our

standard product does not suit your requirements, we can custom design a strainer for you.

What are the major factors in the selection of strainer?

There are two aspects to strainer design:

o Material selection

This is done based on the fluid and service conditions (atm. pressure/temperature/humidity). Based on chemical

resistance charts we decide the recommended material for strainer. Cast steel is the most common material used.

Stainless steel or other alloy materials are used where corrosion is a concern.

o Strainer sizing

This is done based on fluid characteristics. We optimally design the strainer for you based on your flow data utilizing

our extensive filtration know-how.

What are the basic features to look for in a good strainer?

Some key features to look for in a good strainer are:

o Adequate filtration area

o Low rated pressure drop

o Machined seating for NIL bypass

o Adequate mechanical strength of body & screen

What are micron filters? How are they selected?

Micron filters are manufactured using depth filter media. These filter media are called so because of their ability to

hold particles in their depth i.e. cross section which have various layers of micro fibers held together in a “Brownian

Movement” type pattern. This zig zag pattern helps in greatly improving filter efficiency as both volumetric and linear

particles are held in the depth. This is unlike surface filter media (woven wire mesh) which can retain particles only on

the surface and are susceptible to let through linear impurities, but have relatively very low pressure drop.

A good micron filter has the following features:

o Good dust holding capacity

o Low rated pressure drop

o High terminal pressure drop

Please see our micron filters range PFS Series.

Maintenance

What are the maintenance requirements of strainers?

Depending on the type of the strainers, the maintenance requirements of strainers vary. Generally basket strainers

are the easiest to maintain as the cleaning is from the top and they are designed to hold the dirt in a closed basket

design. The easiest of all strainers to maintain are the quick open strainers, which do not require much effort to clean.

Please refer our QF Series strainers for more information. Strainers need to be cleaned periodically (at a frequency

dependant on volume of impurities).

Can I clean the strainers without shutting down the operations?

Certainly yes! if your operation requires continuous running, we can offer the DBX Series strainers which allows for

the use of two individual strainer vessels. When one strainer is being serviced, the other is in use and vice versa. This

way the operation is online all the time.

What happens if I don’t clean the strainer screens regularly?

Strainers need to be cleaned regularly failing which, dire consequences (flow will stop) will occur running in to millions

in restoration/repurchasing of expensive capital equipment. They need to be cleaned before clogging to ensure

smooth operation. Hence, we recommend that you always have one spare screen on hand to reduce downtime to

minimum.

How do I know it is time to clean the strainer screen?

The simple way to know when to clean a strainer screen is to install a differential pressure indicator (between inlet

and outlet). When the differential pressure reaches a threshold point, it can be ascertained that it is time for cleaning.

These differential pressure indicators can even have electronic control equipment fitted to them to enable remote

access. Alternatively, one can also use independent inlet and outlet pressure gauges to denote inlet and outlet

pressure. The difference between the two would give the differential pressure. Any of these can be provided with our

strainers as optional accessories. Please indicate your requirements in your enquiry.

How do I know when to change out a micron filter element?

The indication that it is time to change out a micron filter element is provided by either a visual or electrical differential

pressure indicator mounted on the filter. Micron filters are strongly recommended to be fitted with differential pressure

indicators. Our PFS and PFF Series come with a visual indicator as standard. The pressure differential at which the

indicator informs you to change out the filter is called terminal pressure drop – a key parameter in filter design.

Functionality

How do I know if the strainer is fitted correctly?

It is essential that the strainer be fitted in the right direction of flow to ensure its functionality. To facilitate this, the

direction of flow is marked on every one of our strainers. Please click here to view a pictorial representation of correct

fitment of strainers.

My fluid has 50% impurities by volume. Can I use a strainer for this application?

As a thumb rule, strainers are best effective when impurities are, at most, less than 0.5% by volume. If the impurities

are more than this, specially designed strainers are to be used mostly in a multi-stage set up. Alternatively, once can

also use other methods of filtration. Kindly contact us for a thorough discussion of your requirements.

Vous aimerez peut-être aussi

- Filter Types, LocationsDocument5 pagesFilter Types, LocationsRevathy AarthyPas encore d'évaluation

- Cartridge Filter Application NotesDocument5 pagesCartridge Filter Application NotesSamik MukherjeePas encore d'évaluation

- FiltrationDocument46 pagesFiltrationSharmimi RazakPas encore d'évaluation

- Design & Selection Criteria For StrainersDocument4 pagesDesign & Selection Criteria For StrainersKamal ChokshiPas encore d'évaluation

- AFP Brochure08Document4 pagesAFP Brochure08YongoloooPas encore d'évaluation

- The Basics of Hydraulic FiltrationDocument3 pagesThe Basics of Hydraulic Filtrationbee1406763181Pas encore d'évaluation

- Shanghai Test Results - Filtersafe White PaperDocument21 pagesShanghai Test Results - Filtersafe White PaperBlack PantherPas encore d'évaluation

- Return FilterDocument1 pageReturn FilterALEXANDER MUGABEPas encore d'évaluation

- Filtro de Vapor SPIRAX SARCODocument4 pagesFiltro de Vapor SPIRAX SARCOmaurozuriPas encore d'évaluation

- FLSmidthAFP Filter Press BrochureDocument4 pagesFLSmidthAFP Filter Press BrochureLENINROMEROH4168Pas encore d'évaluation

- StrainerDocument5 pagesStrainerMohit BauskarPas encore d'évaluation

- CIP Nozzle DesignDocument20 pagesCIP Nozzle DesigngeorgemmscribdPas encore d'évaluation

- Carotek Filtration Strainers Selection Guide 06042020Document3 pagesCarotek Filtration Strainers Selection Guide 06042020SaidFerdjallahPas encore d'évaluation

- FiltarationDocument22 pagesFiltarationAvinash GarikapatiPas encore d'évaluation

- Cartridge FiltersDocument7 pagesCartridge FiltersMohamed TallyPas encore d'évaluation

- Centrifugal Separator Working Principle, Benefits and ApplicationDocument5 pagesCentrifugal Separator Working Principle, Benefits and ApplicationBrian MasauliPas encore d'évaluation

- What Is Filter, Types, Cleaning and Maintenance at Ship: Posted by Categories DateDocument8 pagesWhat Is Filter, Types, Cleaning and Maintenance at Ship: Posted by Categories DateKurupath SidharthanPas encore d'évaluation

- Guidelines For The Preparation of Strainer SpecificationDocument10 pagesGuidelines For The Preparation of Strainer Specificationssmith2007Pas encore d'évaluation

- FRI Internal Design Vol4Document55 pagesFRI Internal Design Vol4syamsudin2006Pas encore d'évaluation

- Specialty Items - PipingDocument12 pagesSpecialty Items - PipingSanjeev KumarPas encore d'évaluation

- Guidelines For Selection of Strainers August 2006 EditionDocument10 pagesGuidelines For Selection of Strainers August 2006 EditionEver Briceño100% (1)

- Intake Screens For Cooling and Heating Coils: DurhamDocument8 pagesIntake Screens For Cooling and Heating Coils: DurhamDony RamdhaniPas encore d'évaluation

- TEFSA - High Yield Filter PressesDocument8 pagesTEFSA - High Yield Filter PressesianphilanderPas encore d'évaluation

- Compressors and Silent Root Causes For FailureDocument7 pagesCompressors and Silent Root Causes For Failurenaveenbaskaran1989Pas encore d'évaluation

- Andritz Se Pusher Centrifuge SZ enDocument12 pagesAndritz Se Pusher Centrifuge SZ enMehmet ErenPas encore d'évaluation

- Wa0002.Document25 pagesWa0002.Hardik ShahPas encore d'évaluation

- Unit IX: Purifier and Oil TreatmentDocument79 pagesUnit IX: Purifier and Oil TreatmentRojel SolisPas encore d'évaluation

- 52 Filtrex BrochureDocument6 pages52 Filtrex BrochureCvitaCvitićPas encore d'évaluation

- Jet Venturi Fume ScrubbersDocument7 pagesJet Venturi Fume ScrubbersihllhmPas encore d'évaluation

- Basket Type StrainerDocument12 pagesBasket Type Strainerprateek_bhoir100% (1)

- Cooling Tower Side Stream FiltrationDocument6 pagesCooling Tower Side Stream FiltrationVenkat DoraPas encore d'évaluation

- The Illustration Is That of A "Power Unit" Which Includes The ReservoirDocument30 pagesThe Illustration Is That of A "Power Unit" Which Includes The ReservoirTarunPatraPas encore d'évaluation

- 064640Document314 pages064640venalum90Pas encore d'évaluation

- Basic Techniques For Polishing MoldsDocument32 pagesBasic Techniques For Polishing Moldskailashparmar150% (6)

- Compressors and Silent Root Causes For FailureDocument10 pagesCompressors and Silent Root Causes For FailureluttermanPas encore d'évaluation

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009Pas encore d'évaluation

- How To Select Strainer: Scholenberg Global VnieursatatisDocument6 pagesHow To Select Strainer: Scholenberg Global VnieursatatisCaner KibarPas encore d'évaluation

- Filters Technical InformationDocument13 pagesFilters Technical InformationcartarPas encore d'évaluation

- LT32599 10Document38 pagesLT32599 10Angela BaileyPas encore d'évaluation

- Eaton - Internormen Fluid Purifier SystemsDocument4 pagesEaton - Internormen Fluid Purifier SystemsEaton FiltrationPas encore d'évaluation

- Basic Filtration ConceptsDocument3 pagesBasic Filtration ConceptsAFLAC ............Pas encore d'évaluation

- Bollfilter Automatic Filter 6.64Document7 pagesBollfilter Automatic Filter 6.64recutuPas encore d'évaluation

- Drippers Cataloge 2014Document156 pagesDrippers Cataloge 2014Carlos Rovello GandoPas encore d'évaluation

- 30-36 Filter ManualDocument10 pages30-36 Filter ManualDavid RodriguezPas encore d'évaluation

- Design and MaintenanceDocument2 pagesDesign and MaintenanceNjugi DeusPas encore d'évaluation

- Hydraulic Reservoirs and FiltersDocument22 pagesHydraulic Reservoirs and FiltersMohamed ZahranPas encore d'évaluation

- Filters For Compressed Air: Product InformationDocument16 pagesFilters For Compressed Air: Product InformationAnthony JamesPas encore d'évaluation

- Filtration in Brief: How The Contamination Is MeasuredDocument7 pagesFiltration in Brief: How The Contamination Is MeasuredArhant PathardePas encore d'évaluation

- FILTERS and Strainers Calculate Pressure DropDocument7 pagesFILTERS and Strainers Calculate Pressure Dropbakhtyar21Pas encore d'évaluation

- WPP FabricspressDocument18 pagesWPP FabricspressAkhil SinghPas encore d'évaluation

- Compressed Air Filters Sample FiltersDocument46 pagesCompressed Air Filters Sample FiltersMohsinShaikhPas encore d'évaluation

- Eaton Tubular Backwashing AFC AFR & F-Series FiltersDocument14 pagesEaton Tubular Backwashing AFC AFR & F-Series FiltersJuan CarvajalPas encore d'évaluation

- Sparkler Filter BrochureDocument4 pagesSparkler Filter BrochurekiranPas encore d'évaluation

- Decanter SiebtechnikDocument14 pagesDecanter Siebtechnikzeppilli23Pas encore d'évaluation

- Hydraulic Filters: Prof. Salvador Vargas Díaz Semestre 2020-IDocument15 pagesHydraulic Filters: Prof. Salvador Vargas Díaz Semestre 2020-ISalvador Vargas-DiazPas encore d'évaluation

- Netafim Greywater Drip Irrigation Design ManualDocument16 pagesNetafim Greywater Drip Irrigation Design ManualwengruelPas encore d'évaluation

- PTG Facet Industrial Catalog 1Document78 pagesPTG Facet Industrial Catalog 1suraj pandeyPas encore d'évaluation

- GLV - Drum Filter (PGS) LR PDFDocument8 pagesGLV - Drum Filter (PGS) LR PDFSamuel MushakaPas encore d'évaluation

- GJ 2278 MasterflexApplicationsDocument48 pagesGJ 2278 MasterflexApplicationsMarcello Aires RomãoPas encore d'évaluation

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Paint GlossaryDocument18 pagesPaint Glossaryramaraj_37Pas encore d'évaluation

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Document1 pageWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyPas encore d'évaluation

- Need of Surface TreatmentDocument6 pagesNeed of Surface TreatmentRahul MoottolikandyPas encore d'évaluation

- OrganicDocument11 pagesOrganicRahul MoottolikandyPas encore d'évaluation

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocument7 pagesMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyPas encore d'évaluation

- Report #19aDocument2 pagesReport #19aRahul MoottolikandyPas encore d'évaluation

- 1Document17 pages1Rahul MoottolikandyPas encore d'évaluation

- Guide To Fillet WeldingDocument7 pagesGuide To Fillet WeldingPeter KyawPas encore d'évaluation

- Pipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Document3 pagesPipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Rahul MoottolikandyPas encore d'évaluation

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDocument6 pagesPresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyPas encore d'évaluation

- Report #16ADocument2 pagesReport #16ARahul MoottolikandyPas encore d'évaluation

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyPas encore d'évaluation

- Stainless 20Document45 pagesStainless 20k_sivakumar16Pas encore d'évaluation

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyPas encore d'évaluation

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyPas encore d'évaluation

- Intresting To KnowDocument1 pageIntresting To KnowRahul MoottolikandyPas encore d'évaluation

- Inspection NotesDocument1 pageInspection NotesRahul MoottolikandyPas encore d'évaluation

- HYDocument6 pagesHYRahul MoottolikandyPas encore d'évaluation

- Safety Relief ValveDocument1 pageSafety Relief ValveRahulPas encore d'évaluation

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyPas encore d'évaluation

- Hydro Test Key PointsDocument16 pagesHydro Test Key PointsRahulPas encore d'évaluation

- Safety Relief ValveDocument1 pageSafety Relief ValveRahulPas encore d'évaluation

- Mass Earth's Atmosphere: DensityDocument23 pagesMass Earth's Atmosphere: DensityRahul MoottolikandyPas encore d'évaluation

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyPas encore d'évaluation

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocument7 pagesMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyPas encore d'évaluation

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDocument1 pageDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyPas encore d'évaluation

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyPas encore d'évaluation

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 pagesMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyPas encore d'évaluation

- Report #01Document4 pagesReport #01Rahul MoottolikandyPas encore d'évaluation

- Gate Pass Request Form: Requested Date: Reference NoDocument1 pageGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyPas encore d'évaluation

- Chapter 3Document16 pagesChapter 3Anthony Leire MontealtoPas encore d'évaluation

- Chow - Open Channel HydraulicsDocument350 pagesChow - Open Channel HydraulicsAnish Prasad91% (11)

- GP 03 19 01Document12 pagesGP 03 19 01Anonymous fvO1W3100% (2)

- Week 6 Science 7Document21 pagesWeek 6 Science 7Abigail Serquiña LagguiPas encore d'évaluation

- Data Sheets PDFDocument58 pagesData Sheets PDFRamy MahmoudPas encore d'évaluation

- Solution TEST 1 INDUSTRIAL INSTRUMENTATION AND APPLICATIONSDocument4 pagesSolution TEST 1 INDUSTRIAL INSTRUMENTATION AND APPLICATIONSSaumik HeronPas encore d'évaluation

- Esp Tec All PDFDocument188 pagesEsp Tec All PDFIgnacio VivarPas encore d'évaluation

- Heat Exchanger DesignDocument2 pagesHeat Exchanger DesignAmit Sharma ParasharPas encore d'évaluation

- Wellhead and Valves DataDocument14 pagesWellhead and Valves Datajairaso2950Pas encore d'évaluation

- WRE-412 Design of Hydraulic Structure: Md. Raiful Islam Lecturer, DWRE, BUET Contact: Room 730, 6 Cell: +8801520103477Document34 pagesWRE-412 Design of Hydraulic Structure: Md. Raiful Islam Lecturer, DWRE, BUET Contact: Room 730, 6 Cell: +8801520103477Azwad AbeerPas encore d'évaluation

- Buckley Leverett SimulationDocument10 pagesBuckley Leverett SimulationMod Hah GhasdcPas encore d'évaluation

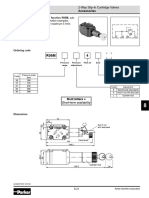

- Parker-SVLA1006P07 Cartridge ValveDocument12 pagesParker-SVLA1006P07 Cartridge Valvemhmd.bilal1Pas encore d'évaluation

- Cooling Curve For Pure Solvent: DiscussionDocument3 pagesCooling Curve For Pure Solvent: DiscussionKeith Steven Brinces ApuliPas encore d'évaluation

- Lesson 4-ECE 2405 - Water Management and InfiltrationDocument19 pagesLesson 4-ECE 2405 - Water Management and Infiltrationray spinzPas encore d'évaluation

- 05.process DescriptionDocument48 pages05.process DescriptionHarish MOORTHIPas encore d'évaluation

- Maxseal Solenoid Operated Valves: Ico3S 1/4" 3/2 TPMRDocument4 pagesMaxseal Solenoid Operated Valves: Ico3S 1/4" 3/2 TPMR4122acaPas encore d'évaluation

- There Are Two Types of Rising MainDocument2 pagesThere Are Two Types of Rising MainMariah IbrahimPas encore d'évaluation

- Effect of Fat Content and Preheat Treatment On The Apparent Viscosity of Coconut Milk After HomogenizationDocument6 pagesEffect of Fat Content and Preheat Treatment On The Apparent Viscosity of Coconut Milk After HomogenizationAn TrầnPas encore d'évaluation

- Determination of Total Solids, Dissolved Solids (TSD)Document7 pagesDetermination of Total Solids, Dissolved Solids (TSD)hayder alali100% (1)

- Kernel StationDocument163 pagesKernel StationArifal100% (1)

- AlfaNova U - TurnDocument2 pagesAlfaNova U - Turnevrimk100% (1)

- CDL/CDLF Vertical Multistage PumpDocument12 pagesCDL/CDLF Vertical Multistage PumpSams AnderPas encore d'évaluation

- Estimation of Sodium Bicarbonate Crystals SizeDocument10 pagesEstimation of Sodium Bicarbonate Crystals SizeBasar ÖnolPas encore d'évaluation

- 01 ExxonMobil Surface Equipment Policy & Procedures - 1Document11 pages01 ExxonMobil Surface Equipment Policy & Procedures - 1sitemaster60Pas encore d'évaluation

- Assignment 2Document3 pagesAssignment 2Pranaw PariharPas encore d'évaluation

- DS1 2023 Vapour Power Cycle Part 1Document27 pagesDS1 2023 Vapour Power Cycle Part 1Tommba TommyPas encore d'évaluation

- Waterflood Optimization Using StreamlineDocument155 pagesWaterflood Optimization Using StreamlinechirazPas encore d'évaluation

- TutorialDocument5 pagesTutorialAbdul Razak RahmatPas encore d'évaluation

- Wrokover ManualDocument14 pagesWrokover ManualCARLOSELSOARESPas encore d'évaluation