Académique Documents

Professionnel Documents

Culture Documents

4

Transféré par

Jai DeepTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

4

Transféré par

Jai DeepDroits d'auteur :

Formats disponibles

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

** ON A/C 016-022, 024-100, 103-109, 111-150, 201-201, 203-206, 208-209, 211-211, 215-216, 219-222, 227-

250, 350-350

TASK 72-00-00-100-808-A

EcoPower Engine Gas Path Clean for Performance Improvement (Water Only)

WARNING: YOU MUST FIND AND OBEY THE MANUFACTURER'S HEALTH AND SAFETY DATA FOR THE

MATERIAL (MSDS). YOU MUST ALSO REFER TO LOCAL REGULATIONS TO MAKE SURE

THAT THE PROCEDURES ARE DONE SAFELY. IF YOU DO NOT DO THIS, AN INJURY OR EN-

VIRONMENTAL DAMAGE CAN OCCUR.

CAUTION: DO NOT USE WATER TO WASH ENGINES WITH GAS PATHS THAT HAVE BEEN EXPOSED

TO DRY POWDER FIRE EXTINGUISHING AGENTS. THESE AGENTS ARE NOT WATER SOL-

UBLE. IF YOU CLEAN WITH WATER, THESE MATERIALS WILL BOND TO ENGINE PARTS.

CAUTION: TO PREVENT THE FORMATION OF ICE, MIX V01-007 OR V01-124 ALCOHOL WITH THE WA-

TER YOU USE TO DILUTE THE CLEANER IF THE AMBIENT TEMPERATURE IS BELOW 40

DEG.F (4.4 DEG.C) TO 25 DEG.F (3.9 DEG.C). DO NOT WASH BELOW TEMPERATURES OF

25 DEG.F (3.9 DEG.C).

CAUTION: THE ENGINE EGT MUST BE BELOW 150 DEG.F (65.6 DEG.C) TO PREVENT ENGINE DAM-

AGE.

CAUTION: IF POSSIBLE, DO NOT DO THIS PROCEDURE ON MORE THAN ONE ENGINE ON AN AIR-

CRAFT DURING THE SAME MAINTENANCE VISIT.

IF YOU MUST DO MAINTENANCE ON MORE THAN ONE ENGINE AT THE SAME TIME, IT IS

RECOMMENDED THAT DIFFERENT TEAMS DO THE SERVICING OF EACH ENGINE. THIS

MAINTENANCE ACTION MUST OBEY THE CURRENTLY APPROVED CONTINUOUS AIRWOR-

THINESS MAINTENANCE PROGRAM OF THE OWNER OPERATOR.

THIS IS TO PREVENT DUAL ENGINE DAMAGE OR FAILURE IF THE CLEANING PROCESS IS

INCORRECT.

FIN : 1000EM1 , 1000EM2

1. Reason for the Job

To clean the engine gas path for performance improvement or to remove debris because of birdstrike. It is

recommended to use pure water only for the engine gas path cleaning.

NOTE: This task can contribute to fuel savings and take off Exhaust Gas Temperature (EGT) margin recovery.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific 1 AIR SOURCE 5 BAR (72.5 PSI)

No specific 1 BOTTLE - SAMPLE

No specific 1 NITROGEN COMPRESSED SOURCE 5 BAR (75.5 PSI) - (DRY)

No specific AR PLUG - BLANKING

No specific AR SAFETY CLIP - CIRCUIT BREAKER

No specific AR WARNING NOTICE(S)

No specific AR WATER - DEMINERALISED

Print Date: May 27, 2018 Page 1 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

REFERENCE QTY DESIGNATION

No specific Torque wrench: range to between 142 and 150 lbf.in

(1.60 and 1.70 m.daN)

No specific Torque wrench: range to between 182 and 199 lbf.in

(2.06 and 2.25 m.daN)

No specific Torque wrench: range to between 283 and 310 lbf.in

(3.20 and 3.50 m.daN)

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. V01-007) ethyl alcohol

(Material No. V01-124) Isopropyl Alcohol, Technical grade

(Material No. V01-201) distilled de-ionized demineralized water

(Material No. V02-274) safety cable

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

FOR 1000EM1 (ENGINE-1)

437AL, 438AR,

451AL, 452AR

FOR 1000EM2 (ENGINE-2)

447AL, 448AR,

461AL, 462AR

D. Referenced Information

REFERENCE DESIGNATION

(Ref. 12-13-79-610-010-A). Drain the Engine Oil System

(Ref. 12-13-79-610-011-A). Check Oil Level and Replenish

(Ref. 70-23-11-911-013-A). General Torque Tightening Techniques

(Ref. 70-40-11-911-016-A). General Instructions for Uses of Safety Cable

(Ref. 71-00-00-700-013-A). Procedure to Dry Out the High Pressure Turbine After Oil Contamina-

tion

(Ref. 71-00-00-710-013-C). Test No.11 : High Power Assurance Test

(Ref. 71-00-00-710-018-A). Discontinued Start, Restart and Shutdown Procedures

(Ref. 71-00-00-710-043-A). Normal Engine Automatic Start Procedure

(Ref. 71-00-00-710-045-A). Test No.1 : Dry Motor Leak Check

(Ref. 71-00-00-710-047-A). Normal Engine Manual Start Procedure

(Ref. 71-13-00-010-010-A). Opening of the Fan Cowls 437AL(447AL),438AR(448AR)

(Ref. 71-13-00-410-010-A). Closing of the Fan Cowls 437AL(447AL),438AR(448AR)

(Ref. 73-22-49-220-040-A). Purge the Burner Pressure Sensor Tube

(Ref. 75-32-41-000-010-A). Removal of the Variable Stator Vane (VSV) Actuator

(Ref. 75-32-41-000-010-A-01). Removal of the Variable Stator Vane (VSV) Actuator (SBE 72-0564)

(Ref. 75-32-41-400-010-A). Installation of the Variable Stator Vane (VSV) Actuator

(Ref. 75-32-41-400-010-A-01). Installation of the Variable Stator Vane (VSV) Actuator (SBE 72-0564)

and SBE 75-0122)

(Ref. 77-21-43-350-801-A). EGT Harness and Junction Box Dry-Out Procedure

Print Date: May 27, 2018 Page 2 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

REFERENCE DESIGNATION

(Ref. 78-30-00-040-012-A). Deactivation of the Thrust Reverser Hydraulic Control Unit (HCU) for

Ground Maintenance

(Ref. 78-30-00-440-012-A). Re-activation of the Thrust Reverser Hydraulic Control Unit (HCU) after

Ground Maintenance

(Ref. 78-32-00-010-010-A). Opening of the Thrust Reverser Halves

(Ref. 78-32-00-410-010-A). Closing of the Thrust Reverser Halves

Stage 12 (P3) Air Tube SHEET 1

Electronic Engine Control SHEET 1

Alcohol and Water Mixture Ratio SHEET 1

EcoPower lnlet Manifold

Print Date: May 27, 2018 Page 3 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

STAGE 12 (P3)

AIR TUBE

CONNECTOR ASSEMBLY

bmi0005027

N_MM_720000_7_XQR0_01_01

Figure 72(IAE)-00-00-991-28300-13-A / SHEET 1/1 - Stage 12 (P3) Air Tube

** ON A/C 016-022, 024-100, 103-109, 111-150, 201-201, 203-

206, 208-209, 211-211, 215-216, 219-222, 227-250, 350-350

Print Date: May 27, 2018 Page 4 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

UNION 1

HOSE 2

3 HOSE 4 UNION

bmi0005028

N_MM_720000_7_XQM0_01_00

Figure 72(IAE)-00-00-991-52900-13-A / SHEET 1/1 - Electronic Engine Control

** ON A/C 016-022, 024-100, 103-109, 111-150, 201-201, 203-

206, 208-209, 211-211, 215-216, 219-222, 227-250, 350-350

Print Date: May 27, 2018 Page 5 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

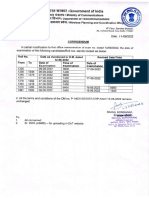

OUTSIDE AIR PERCENT ALCOHOL

TEMPERATURE BY VOLUME

40 deg F (4.4 deg C) 3

38 deg F (3.3 deg C) 6

36 deg F (2.2 deg C) 9

33 deg F (0.6 deg C) 14

31 deg F (-0.6 deg C) 17

28 deg F (-2.2 deg C) 20

26 deg F (-3.3 deg C) 22

25 deg F (-3.9 deg C) 23

ALCOHOL MIXTURE

bmi0005024

N_MM_720000_7_YAB0_01_00

Figure 72(IAE)-00-00-991-66600-13-A / SHEET 1/1 - Alcohol and Water Mixture Ratio

** ON A/C 016-022, 024-100, 103-109, 111-150, 201-201, 203-

206, 208-209, 211-211, 215-216, 219-222, 227-250, 350-350

Print Date: May 27, 2018 Page 6 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

A

A

B

STRAP / HOOK

ECOPOWER R INLET

WASH MANIFOLD

1 LOCATION

ECOPOWER R INLET

WASH MANIFOLD

1 LOCATION

pwzxxa0076

PWV

N_MM_720000_7_YAA0_01_00

Figure 72(IAE)-00-00-991-66700-13-A / SHEET 1/2 - EcoPower lnlet Manifold

** ON A/C 016-022, 024-100, 103-109, 111-150, 201-201, 203-

206, 208-209, 211-211, 215-216, 219-222, 227-250, 350-350

Print Date: May 27, 2018 Page 7 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

SECTION

A-A

ECOPOWER REAR MOUNTED C

J-HOOK, FAN (FORWARD SPRAYING)

(RMJF) MANIFOLD

1 LOCATION

ECOPOWER REAR MOUNTED

J-HOOK, FAN (FORWARD SPRAYING)

(RMJF) MANIFOLD

1 LOCATION

RETENTION

CLAMP

pwzxxa0077

PWV

N_MM_720000_7_YAA0_02_00

Figure 72(IAE)-00-00-991-66700-13-A / SHEET 2/2 - EcoPower lnlet Manifold

** ON A/C 016-022, 024-100, 103-109, 111-150, 201-201, 203-

206, 208-209, 211-211, 215-216, 219-222, 227-250, 350-350

Print Date: May 27, 2018 Page 8 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

3. Job Set-up

Subtask 72-00-00-941-261-A

A. Safety Precautions

(1) On the center pedestal, on the ENG panel 115VU:

(a) Put a WARNING NOTICE(S) to tell persons not to start the engine.

(2) Make sure that the engine 1(2) shutdown occurred not less than 5 minutes before you do this

procedure.

(3) On the overhead maintenance panel 50VU:

(a) Make sure that the ON legend of the ENG/FADEC GND PWR/1(2) pushbutton switch is off.

(b) Put a WARNING NOTICE(S) to tell persons not to energize the FADEC 1(2).

Subtask 72-00-00-010-361-A

B. Open the fan cowls (Ref. AMM TASK 71-13-00-010-010) :

(1) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(2) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

Subtask 72-00-00-040-172-A

C. Deactivate the thrust reverser Hydraulic Control Unit (HCU) (Ref. AMM TASK 78-30-00-040-012) .

Subtask 72-00-00-010-362-A

D. Open the thrust reverser halves (Ref. AMM TASK 78-32-00-010-010) :

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

4. Procedure

(Ref. Fig. Stage 12 (P3) Air Tube SHEET 1) (Ref. Fig. Electronic Engine Control SHEET 1) (Ref. Fig. Alcohol

and Water Mixture Ratio SHEET 1) (Ref. Fig. EcoPower lnlet Manifold)

Subtask 72-00-00-010-363-A

A. Set the cabin services bleed valves to the closed position.

(1) On the AIR COND panel 30VU, release the ENG 1(2) BLEED pushbutton switch.

(2) The OFF legend of this pushbutton switch comes on.

Subtask 72-00-00-020-113-A

B. Disconnection of the Sense Line Hoses and if Necessary, the Variable Stator Vane (VSV) Actuator

(1) Disconnect the P4.9 (P5) hose from the adapter and the union on the bottom of the Electronic Engine

Control (EEC).

(Ref. Fig. Electronic Engine Control SHEET 1)

(a) Removal of the lockwire

WARNING: USE PROTECTIVE GOGGLES AND GLOVES WHEN YOU REMOVE OR IN-

STALL LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND DIS-

CARD IT IMMEDIATELY. LOOSE LOCKWIRE CAN CUT YOU OR MAKE YOU

BLIND, AND/OR CAN CAUSE DAMAGE.

Print Date: May 27, 2018 Page 9 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

1 Remove the lockwire that safeties the nut of the hose (2) and the union (1)

(b) Disconnect the nut of the hose (2) from the union.

(2) Disconnect the PS3 (PB) hose from the adapter and the union on the bottom of the EEC. See the

figure:

(Ref. Fig. Electronic Engine Control SHEET 1)

(a) Remove the wire that safeties the nut of the hose (3) and the union (4).

(b) Disconnect the nut of the hose (3) from the union (4).

PRE SBE 75-0081

(3) Disconnect stage 12 (P3) air tube at its connection with the off-take tube located at the six o'clock

position below the diffuser case (the off-take tube supplies pneumatic pressure to the group of

solenoids at three o'clock on the fan case.

(Ref. Fig. Stage 12 (P3) Air Tube SHEET 1)

(4) Put PLUG - BLANKING on the disconnected line ends.

END OF PRE SBE 75-0081

NOTE: The disconnection of the Variable Stator Vane (VSV) actuator and the manual opening of the

stator vanes is optional. An additional core wash cycle can be done to compensate the core

wash efficiency reduction due to a closed VSV during the core wash. Disconnecting and re-

connecting the VSV actuator requires a high-power assurance run.

(5) Optional

WARNING: BE CAREFUL NOT TO PUT FOD (FOREIGN OBJECT DEBRIS) INTO THE ENGINE

INLET. FOREIGN OBJECT DEBRIS CAN CAUSE INJURY TO PERSONS AND FAIL-

URE OF THE ENGINE.

CAUTION: WHEN YOU USE TOOLS OR SHARP OBJECTS, BE CAREFUL NOT TO CAUSE

DAMAGE TO THE DYNAROHR MATERIAL IN THE INLET. DO NOT COMPLETE AD-

JUSTMENTS IN THE INLET AND DO NOT PUT OTHER TOOLS THAN THE MANI-

FOLD IN THE INLET. IF YOU DO, YOU CAN CAUSE DAMAGE TO THE ENGINE.

(a) Disconnect the VSV actuator from the actuator control rod and manually move the stator vanes

to fully open (Ref. AMM TASK 75-32-41-000-010) .

NOTE: Refer to the applicable equipment operations manual and procedure for the correct

equipment steps.

Subtask 72-00-00-410-313-A

C. Close the thrust reverser halves (Ref. AMM TASK 78-32-00-410-010) :

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

Subtask 72-00-00-410-314-A

D. When using the EcoPower inlet mounted or rear-mounted J-hook, fan (forward spraying) (RMJF) manifold

systems, the thrust reverser doors must be closed to capture effluent during the wash. See the sheet 1

and 2 of the figure:

(Ref. Fig. EcoPower lnlet Manifold)

Print Date: May 27, 2018 Page 10 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

NOTE: Inspect inlet and fan blades for damage before installing the wash manifold assembly.

Subtask 72-00-00-820-055-A

E. Calibrate and install the EcoPower manifold system (inlet-mounted or rear-mounted J-hook, fan (forward

spraying)(RMJF)) into the engine in preparation for the wash.

Subtask 72-00-00-869-093-A

F. Check the engine oil level

(1) Check the engine oil level. If necessary, add oil to the engine oil tank (Ref. AMM TASK 12-13-79-

610-011) .

Subtask 72-00-00-865-061-A

G. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU ENGINE/1 AND 2/IGN/SYS A 1JH A03

FOR FIN 1000EM1 (ENGINE-1)

121VU ENGINE/IGN/ENG1/SYS B 3JH1 P41

121VU ENGINE/IGN/ENG1/SYS A BAT 2JH1 P39

FOR FIN 1000EM2 (ENGINE-2)

121VU ENGINE/IGN/ENG2/SYS B 3JH2 P42

121VU ENGINE/IGN/ENG2/SYS A BAT 2JH2 P40

Subtask 72-00-00-110-101-A

H. Cleaning of the Compressor Gas Path

(Ref. Fig. Alcohol and Water Mixture Ratio SHEET 1)

CAUTION: IF THE AMBIENT TEMPERATURE IS BETWEEN 40 DEG.F (4.4 DEG.C) AND 25 DEG.F

(-3.9 DEG.C), MIX V01-007 OR V01-124 ALCOHOL WITH THE WATER THAT YOU USE

TO DILUTE THE CLEANER. THIS WILL PREVENT ICE FORMATION. ICE CAN CAUSE

DAMAGE TO THE ENGINE.

(1) The EcoPower wash unit will be filled with the appropriate amount of water to perform the wash. The

water will be heated to between 149 deg.F (65.00 deg.C) and 158 deg.F (70.00 deg.C). Use WATER

- DEMINERALISED or WATER - DEMINERALISED mixed with ethyl alcohol (Material No. V01-007)

or Isopropyl Alcohol, Technical grade (Material No. V01-124).

(Ref. Fig. Alcohol and Water Mixture Ratio SHEET 1)

NOTE: If you have the correct water specification, it is permitted to use potable water. It is not neces-

sary to test before each wash. If the water does not have the correct water specification, use

distilled de-ionized demineralized water (Material No. V01-201).

Table 701 - Potable or Demineralized Water Specification

Constituent Na*K Ca*Mg Total Halides S04 P04 TDS pH

PPM Max 50 100 100 100 50 500 6.6 - 8.5

Use WATER - DEMINERALISED or WATER - DEMINERALISED mixed with ethyl

alcohol (Material No. V01-007) or Isopropyl Alcohol, Technical grade (Material No. V01-124).

(Ref. Fig. Alcohol and Water Mixture Ratio SHEET 1)

(2) Operate the starter

Print Date: May 27, 2018 Page 11 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

WARNING: DURING THE MOTORING OF THE ENGINE:

- DO NOT GO IN THE INLET OR EXHAUST HAZARD AREAS

- STAY A MINIMUM OF 15 FEET AWAY FROM THE INLET

AFTER THE MOTORING, WAIT UNTIL THE FAN NO LONGER TURNS OR TURNS

ONLY BECAUSE OF THE WIND BEFORE YOU GO IN THE INLET HAZARD AREA.

IF YOU DO NOT OBEY THESE INSTRUCTIONS, INJURY TO PERSONS CAN OC-

CUR.

WARNING: WEAR EAR PROTECTION DURING AIRCRAFT ENGINE MOTORING. THE NOISE

OF THE ENGINE CAN CAUSE INJURY TO YOUR EARS.

CAUTION: DO NOT MOTOR THE ENGINE MORE THAN THE LIMIT OR YOU CAN CAUSE DAM-

AGE TO THE STARTER (NOT CONTROLLED BY THE EEC).

(a) Make sure that you do not operate the starter more than its operating limit

1 Three cycles: Two of two-minutes and one of one-minute duration maximum.

2 Do not operate for 15 seconds between cycles to allow for starter rotor lubrication.

3 After three cycles, let the starter cool for 30 minutes before you try a new start or motoring.

4 Do not engage the starter again with the engine motoring above ten percent N2.

(b) First wash cycle:

1 Motor the engine with the starter until a minimum of 14 percent N2 is reached (approximately

ten seconds after start air is activated), push the pump ON button to start spraying water

(Ref. AMM TASK 71-00-00-710-045) .

2 Add water for the remaining time up to two minutes maximum from start air on (water

application lime approximately 1 min and 45 seconds).

a Push the pump OFF button to stop the flow.

b Stop motoring and let the engine soak for ten minutes.

(c) Second wash cycle:

1 Do Para. 4.H.(2).(b) again.

(d) Third wash cycle:

1 Motor the engine with the starter until a minimum of 14 percent N2 is reached

(Ref. AMM TASK 71-00-00-710-045) .

a Once the engine has reached 14 percent N2 (approximately ten seconds) push the

pump ON button and spray demineralized water for a total of one minute since the start

of motoring.

b Stop motoring after one minute and let the engine drain prior to removing the collection

system.

2 EcoPower personnel will remove all wash equipment from the engine, remove manifold from

engine, being cautious of the Dynarohr material and remove the collection system. Check

inlet for Foreign Object Damage (FOD).

NOTE: If effluent flow from the tail pipe is dirty following the third wash cycle, additional be-

nefit may be gained by additional wash cycles. The operator may elect to repeat the

wash procedure at their discretion. ln this case, ensure that the time between suc-

cessive motoring cycles complies with the starter duty-cycle requirements. EcoPower

recommends that you do not exceed six wash cycles.

Print Date: May 27, 2018 Page 12 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

Subtask 72-00-00-010-364-A

J. Open the thrust reverser halves (Ref. AMM TASK 78-32-00-010-010) :

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

Subtask 72-00-00-870-050-A

K. Purge PS3 (PB), P4.9 (PS) pressure sensor lines and reconnect the tubes

CAUTION: DO NOT BLOW COMPRESSED AIR OR NITROGEN THROUGH THE LINES TO THE

EEC. IF YOU DO, DAMAGE TO THE PRESSURE SENSORS CAN OCCUR.

CAUTION: DO NOT USE LUBRICANTS ON THE EEC SENSING TUBES, ADAPTERS OR PACK-

INGS. IF YOU DO, CONTAMINATION OF THESE COMPONENTS CAN OCCUR.

CAUTION: MAKE SURE THAT:

- THERE IS NO WATER IN ALL THE DISCONNECTED ENGINE EEC LINES

- YOU REMOVE THE PROTECTION COVERS FROM THEIR ENDS

- YOU RECONNECT THEM CORRECTLY.

IF THE OPENINGS OF THE LINES ARE BLOCKED OR IF THE LINES ARE INCOR-

RECTLY INSTALLED, DAMAGE TO THE ENGINE CAN OCCUR. THIS CAN HAVE AN

UNWANTED EFFECT ON THE OPERATION OF THE AIRCRAFT.

(1) Remove the PLUG - BLANKING from the disconnected line ends.

(2) Purge the burner pressure PS3 (PB) sensor tube (Ref. AMM TASK 73-22-49-220-040) .

(Ref. Fig. Electronic Engine Control SHEET 1)

(3) Purge P4.9 (P5) sensor tube.

(Ref. Fig. Electronic Engine Control SHEET 1)

(a) Blow out all contamination from the P4.9 pressure sensor line from the EEC into the engine with

NITROGEN COMPRESSED SOURCE 5 BAR (75.5 PSI) - (DRY) or AIR SOURCE 5 BAR (72.5

PSI) for three minutes.

Subtask 72-00-00-420-104-A

L. Connection of the the stage 12 (P3) air tube

PRE SBE 75-0081

(1) Connect the stage 12 (P3) air tube to the off-take tube on the EEC.

(2) TORQUE the tube connector to between 283 and 310 lbf.in (3.20 and 3.50 m.daN)

(Ref. AMM TASK 70-23-11-911-013) .

(3) Safety the tube connector

WARNING: USE PROTECTIVE GOGGLES AND GLOVES WHEN YOU REMOVE OR INSTALL

LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND DISCARD IT IMME-

DIATELY. LOOSE LOCKWIRE CAN CUT YOU OR MAKE YOU BLIND, AND/OR CAN

CAUSE DAMAGE.

(a) Safety the tube connector with safety cable (Material No. V02-274) (Ref. AMM TASK 70-40-11-

911-016) .

END OF PRE SBE 75-0081

Subtask 72-00-00-420-105-A

Print Date: May 27, 2018 Page 13 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

M. Connection of the P4.9 tube

(1) Connect the P4.9 tube to P5 connection on the bottom of the EEC.

(2) Connect the nut of the hose (2) to the union (1).

(3) TORQUE the nut of the hose (2) to between 182 and 199 lbf.in (2.06 and 2.25 m.daN)

(Ref. AMM TASK 70-23-11-911-013) .

(4) Safety the union of the hose (2).

WARNING: USE PROTECTIVE GOGGLES AND GLOVES WHEN YOU REMOVE OR INSTALL

LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND DISCARD IT IMME-

DIATELY. LOOSE LOCKWIRE CAN CUT YOU OR MAKE YOU BLIND, AND/OR CAN

CAUSE DAMAGE.

(a) Safety the nut of the hose (2) with safety cable (Material No. V02-274) (Ref. AMM TASK 70-40-

11-911-016) .

Subtask 72-00-00-420-106-A

N. Connect the Pb tube to the Pb connection on the bottom of the EEC

(1) Connect the nut of the hose (3) to the union (4).

(2) TORQUE the nut of the hose (3) to between 142 and 150 lbf.in (1.60 and 1.70 m.daN)

(Ref. AMM TASK 70-23-11-911-013) .

(3) Safety the nut of the hose (3)

WARNING: USE PROTECTIVE GOGGLES AND GLOVES WHEN YOU REMOVE OR INSTALL

LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND DISCARD IT IMME-

DIATELY. LOOSE LOCKWIRE CAN CUT YOU OR MAKE YOU BLIND, AND/OR CAN

CAUSE DAMAGE.

(a) Safety the nut of the hose (3) with safety cable (Material No. V02-274) (Ref. AMM TASK 70-40-

11-911-016) .

Subtask 72-00-00-420-107-A

P. Reconnection of the VSV

(1) If disconnected, reconnect the VSV actuator from the actuator control rod and manually move the

stator vanes to fully open (Ref. AMM TASK 75-32-41-400-010) .

NOTE: Disconnecting and reconnecting the VSV actuator requires a high-power assurance run.

Subtask 72-00-00-865-062-A

Q. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU ENGINE/1 AND 2/IGN/SYS A 1JH A03

FOR FIN 1000EM1 (ENGINE-1)

121VU ENGINE/IGN/ENG1/SYS B 3JH1 P41

121VU ENGINE/IGN/ENG1/SYS A BAT 2JH1 P39

FOR FIN 1000EM2 (ENGINE-2)

121VU ENGINE/IGN/ENG2/SYS B 3JH2 P42

121VU ENGINE/IGN/ENG2/SYS A BAT 2JH2 P40

Subtask 72-00-00-350-055-A

Print Date: May 27, 2018 Page 14 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

R. Remove the moisture from the Exhaust Gas Temperature (EGT) harness and junction box

(Ref. AMM TASK 77-21-43-350-801) .

5. Close-up

Subtask 72-00-00-410-315-A

A. Close the thrust reverser halves (Ref. AMM TASK 78-32-00-410-010) :

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

Subtask 72-00-00-440-162-A

B. Activate the thrust reverser Hydraulic Control Unit (HCU) (Ref. AMM TASK 78-30-00-440-012) .

Subtask 72-00-00-710-075-A

C. Post Wash Engine Oil Contamination Check

(1) Do a visual check of the engine oil tank sight glass for contamination.

(a) Look at oil through the oil tank sight glass. If the oil is emulsified (has a white color) drain the

engine oil system and fill the system with new oil immediately (Ref. AMM TASK 12-13-79-610-

010) and (Ref. AMM TASK 12-13-79-610-011) .

(b) If the visual check was satisfactory, continue with the steps that follow.

Subtask 72-00-00-410-316-A

D. Close Access

(1) Close the fan cowls (Ref. AMM TASK 71-13-00-410-010) :

(a) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(b) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

(2) Remove the warning notice(s).

Subtask 72-00-00-700-052-A

E. Dry Out the High Pressure Turbine

(1) Do the dry out procedure for the HPT (Ref. AMM TASK 71-00-00-700-013) .

NOTE: If the VSV actuator was disconnected and reconnected, a high-power assurance run is re-

quired (Ref. AMM TASK 71-00-00-710-013) .

Subtask 72-00-00-710-076-A

F. Post High Pressure (HP) Compressor Wash and Oil Sampling

NOTE: EcoPower recommends running the engine as soon as possible post water wash. However, it is

possible for the engine to sit up to 24 hours before the engine idle run. ln freezing conditions ( 40

deg.F (4.44 deg.C) and below), it is recommended the engine dry-out run is completed within 30

minutes after the wash.

(1) If the engine is sent back to revenue service in less than 12 hours, no more action is required.

(2) If a high-power assurance run is done within 12 hours, no further action is necessary

(Ref. AMM TASK 71-00-00-710-013) .

Print Date: May 27, 2018 Page 15 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

(3) If criteria at Para. 5.F.(1) or Para. 5.F.(2) above are not fulfilled, do the steps that follow:

(a) If necessary, open the fan cowls (Ref. AMM TASK 71-13-00-010-010) :

1 FOR 1000EM1 (ENGINE-1)

437AL, 438AR

2 FOR 1000EM2 (ENGINE-2)

447AL, 448AR

(b) Check engine oil for water contamination

CAUTION: MAKE SURE THERE IS NO CONTAMINATION FROM AN EXTERNAL WATER

SOURCE. ONE DROP OF WATER WILL CAUSE THE SAMPLE TO READ OVER

THE LIMITS.

1 Use a new clear BOTTLE - SAMPLE to collect approximately 0.0159 USgal (0.06 l) sample

of oil for the thin film capacitive polymer oil water content tester test. It is permissible to insert

the thin film capacitive polymer oil water content tester directly into the main oil tank fill.

2 Reinstall the main oil tank tiller cap and ensure it is properly locked in position.

3 For the thin film capacitive polymer oil water content tester, perform the following:

a Set thin film capacitive polymer oil water content tester to MIL-L-23699 oil.

4 Stir the probe in the oil until the unit has reached the steady state level of water

concentration for 20 seconds. This normally takes at least two minutes of stirring to

complete.

(c) Engine water on content limit(s):

1 If the water content is below 1000 parts per million by weight or by volume, the engine can

sit no more than a maximum of 24 hours before the next engine run-up.

2 If the water content is above 1000 parts per million by weight or by volume, remove the

water content from the oil. Do the steps that follow:

(4) Perform the following idle dry-out run

WARNING: COMPLETE AMM TASK 71-00-00-710-043 OR TASK 71-00-00-710-047 TO OPER-

ATE THE POWER PLANT. IF YOU DO NOT USE ONE OF THESE PROCEDURES,

INJURY TO PERSONS AND/OR DAMAGE TO EQUIPMENT CAN OCCUR.

CAUTION: YOU MUST START THE ENGINE AND OPERATE IT AT IDLE DURING 10 MINUTES

BEFORE YOU OPERATE THE ENGINE BLEEDS. IF YOU DO NOT OBEY THIS IN-

STRUCTION, THE AIR-CONDITIONING SYSTEM CAN BECOME CONTAMINATED.

(a) Use the power plant operation (normal) procedure to start the engine (Ref. AMM TASK 71-00-

00-710-043) or (Ref. AMM TASK 71-00-00-710-047) .

CAUTION: DO NOT OPERATE THE ENGINE ABOVE IDLE DURING THIS PROCEDURE. IF YOU

DO, THE OIL THAT IS IN THE HIGH PRESSURE TURBINE CAN IGNITE. THIS CAN

CAUSE ENGINE COMPONENT DAMAGE.

(b) Operate the engine at minimum idle for a minimum of ten minutes.

NOTE: The engine bleeds need to be cycled during the engine run to ensure no odors or fumes

in the cabin prior to returning aircraft back to revenue service. Odor or fumes in the cabin

is not expected if only WATER - DEMINERALISED was used for the wash.

Print Date: May 27, 2018 Page 16 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : IGO Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 016-016

Rev. Date : May 01, 2018

72-00-00-100-808-A - EcoPower Engine Gas Path

Clean for Performance Improvement (Water Only)

(c) Operate the cabin bleeds and anti-ice system (IAW applicable AMM task) to purge any water

trapped in the system.

(d) Use the power plant operation (normal) procedure to do the engine shutdown

(Ref. AMM TASK 71-00-00-710-018) .

(5) Check engine oil for water contamination:

CAUTION: MAKE SURE THERE IS NO CONTAMINATION FROM AN EXTERNAL WATER

SOURCE. ONE DROP OF WATER WILL CAUSE THE SAMPLE TO READ OVER THE

LIMITS.

(a) Use a new clear BOTTLE - SAMPLE to collect approximately 0.0159 USgal (0.06 l) sample of oil

for the thin film capacitive polymer oil water content tester test. It is permissible to insert the thin

film capacitive polymer oil water content tester directly into the main oil tank fill.

(b) Reinstall the main oil tank filler cap and ensure it is properly locked in position.

(6) For the film capacitive polymer oil water content tester, perform the following:

(a) Set film capacitive polymer oil water content tester to MIL-L-23699 oil.

(b) Stir the probe in the oil until the unit has reached the steady state level of water concentration for

20 seconds. This normally takes at least two minutes of stirring to complete.

(c) Engine water oil content limit(s):

1 If the water content is below 1000 parts per million by weight or by volume, the engine can

sit up to a maximum of 24 hours before the next engine run.

2 If the water content is above 1000 parts per million by weight or by volume, remove the

water content by repeating the idle dry-out run again.

3 If the water content of 1000 parts per million by weight or by volume or less cannot be

obtained by additional idle runs, dratn the engine oil system and fill the system with new oil

(Ref. AMM TASK 12-13-79-610-010) and (Ref. AMM TASK 12-13-79-610-011) .

End of document

Print Date: May 27, 2018 Page 17 of 17

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Vous aimerez peut-être aussi

- Helicopter MaintenanceDocument347 pagesHelicopter MaintenanceJai Deep88% (24)

- Aviation Insurance Re Insurance - 16122008Document33 pagesAviation Insurance Re Insurance - 16122008kaushikkopallePas encore d'évaluation

- AIRCRAFT PROPELLERS AND CONTROLS - by Fank DelpDocument159 pagesAIRCRAFT PROPELLERS AND CONTROLS - by Fank DelpT/ROX100% (38)

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsD'EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsPas encore d'évaluation

- PT6A ICS Best Maintenance Practices PDFDocument87 pagesPT6A ICS Best Maintenance Practices PDFirfan1076Pas encore d'évaluation

- Ramp Safety PracticesDocument76 pagesRamp Safety PracticesSEBI P RAJA BABUPas encore d'évaluation

- Snap OnDocument146 pagesSnap OnMilad Mohammadi100% (1)

- Airbus A330 ATA 46 INFORMATION SYSTEMS B2 PrintDocument29 pagesAirbus A330 ATA 46 INFORMATION SYSTEMS B2 PrintMeysam530100% (1)

- Ground Run Procedure ManualDocument17 pagesGround Run Procedure ManualAhmad Dayan Ma'shumPas encore d'évaluation

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireD'EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WirePas encore d'évaluation

- Hydraulic SystemDocument59 pagesHydraulic SystemMerselinne FeriaPas encore d'évaluation

- Failure Modes-US Navy UnclassifiedDocument85 pagesFailure Modes-US Navy UnclassifiedBaluDasPas encore d'évaluation

- Aircraft Gas Turbine Tecnology by IRWINE TREAGER PDFDocument684 pagesAircraft Gas Turbine Tecnology by IRWINE TREAGER PDFJai Deep87% (67)

- HYDRO A320 - Equipment CatalogueDocument90 pagesHYDRO A320 - Equipment CatalogueDũng NguyễnPas encore d'évaluation

- A320 Aircraft CharacteristicsDocument387 pagesA320 Aircraft CharacteristicsEder LucianoPas encore d'évaluation

- Fom Parta 27112012Document487 pagesFom Parta 27112012Eliim Rehman100% (3)

- Airfield Drivers Training Powepoint SlidesDocument69 pagesAirfield Drivers Training Powepoint SlideslenPas encore d'évaluation

- Sop I2r5Document406 pagesSop I2r5Hung PhanPas encore d'évaluation

- A320 ATA 24 Electrical PowerDocument474 pagesA320 ATA 24 Electrical PowerDavid MF CocPas encore d'évaluation

- FOD PREVENTION AREASDocument27 pagesFOD PREVENTION AREASyatheendravarmaPas encore d'évaluation

- Offwing Alide InstallDocument16 pagesOffwing Alide InstallAndreea MăgureanuPas encore d'évaluation

- Job Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..Document10 pagesJob Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..billyPas encore d'évaluation

- 23 CommunicationsDocument238 pages23 CommunicationsMaher Abu-ElolaPas encore d'évaluation

- Combined Reset Tables Mod6Document275 pagesCombined Reset Tables Mod6Sallak IdrisPas encore d'évaluation

- Ata25 AirbusDocument308 pagesAta25 AirbusOliver BarrientosPas encore d'évaluation

- 71-00-00-710-004-B - Engine Manual StartDocument9 pages71-00-00-710-004-B - Engine Manual StartEder LucianoPas encore d'évaluation

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanPas encore d'évaluation

- LEAP-1A - Oil Stains On The Fan Cowls: Purpose of This ArticleDocument3 pagesLEAP-1A - Oil Stains On The Fan Cowls: Purpose of This Articlejivomir100% (1)

- AR2016 StratechDocument116 pagesAR2016 StratechZX LeePas encore d'évaluation

- A320 Family ReferenceDocument1 pageA320 Family Referencejoshua corpuzPas encore d'évaluation

- Exterior Inspection B737-800Document14 pagesExterior Inspection B737-800Me KeenPas encore d'évaluation

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) GeneralDocument8 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) Generalripan thakurPas encore d'évaluation

- Airbus FAST Magazine 44 p8 p16Document9 pagesAirbus FAST Magazine 44 p8 p16Subha SahaPas encore d'évaluation

- FAST52Document21 pagesFAST52Vahid AlimoradiPas encore d'évaluation

- Airport Pavement Construction Safety GuidanceDocument62 pagesAirport Pavement Construction Safety GuidanceDinesh PoudelPas encore d'évaluation

- EfcsDocument4 pagesEfcsJai DeepPas encore d'évaluation

- EASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Document9 pagesEASA TCDS E.007 (IM) General Electric CF6 80E1 Series Engines 02 25102011Graham WaterfieldPas encore d'évaluation

- A320fam Iae Ata79 Oil PDFDocument42 pagesA320fam Iae Ata79 Oil PDFshabbirjama103Pas encore d'évaluation

- Removal v2500Document32 pagesRemoval v2500Magureanu ValeriuPas encore d'évaluation

- Engine Out TaxiDocument30 pagesEngine Out TaxiEddy Jhet100% (1)

- Airnavx Standalone User GuideDocument34 pagesAirnavx Standalone User GuideUtku OzdoganPas encore d'évaluation

- 74Document43 pages74Jai DeepPas encore d'évaluation

- Bird Strike - A ReviewDocument20 pagesBird Strike - A ReviewApolloPas encore d'évaluation

- A320 Cockpit Lights Training ManualDocument40 pagesA320 Cockpit Lights Training ManualAhmad ZakwanPas encore d'évaluation

- 01 Avionics Level 1Document342 pages01 Avionics Level 1teminaniPas encore d'évaluation

- 777F Air Conditioning Smoke or Fumes Odor v5Document4 pages777F Air Conditioning Smoke or Fumes Odor v5arizonaflyer1_732976Pas encore d'évaluation

- Auditor Qualification CriteriaDocument10 pagesAuditor Qualification CriteriaMani Rathinam RajamaniPas encore d'évaluation

- Technical Ground School Study Guide: AIRBUS A319/320/321 2009 - 2010Document15 pagesTechnical Ground School Study Guide: AIRBUS A319/320/321 2009 - 2010Ravi Vikram SinghPas encore d'évaluation

- A330 Easa Tcds A.004 - Issue 50Document64 pagesA330 Easa Tcds A.004 - Issue 50Pablo CarmonaPas encore d'évaluation

- ON A/C 051-100: Zone/Access Zone DescriptionDocument7 pagesON A/C 051-100: Zone/Access Zone DescriptionEder LucianoPas encore d'évaluation

- Push Back Head Set CommunicationsDocument6 pagesPush Back Head Set CommunicationsJai DeepPas encore d'évaluation

- Airside SafetyDocument94 pagesAirside SafetyMelvin Mateo100% (1)

- Ata 36 PneumaticDocument30 pagesAta 36 PneumaticSohaib Aslam ChaudharyPas encore d'évaluation

- Isi-45.00.00039 01dec2017.p6Document40 pagesIsi-45.00.00039 01dec2017.p6sithuPas encore d'évaluation

- On A/C All: Reference Qty DesignationDocument7 pagesOn A/C All: Reference Qty DesignationRicardoBillEdwinPas encore d'évaluation

- Ata 30Document11 pagesAta 30jontis jasoliyaPas encore d'évaluation

- CH 31Document4 pagesCH 31Ahmed Abdoul ZaherPas encore d'évaluation

- A318/A319/A320/A321 Aircraft Pressure Refuel ProcedureDocument7 pagesA318/A319/A320/A321 Aircraft Pressure Refuel Procedureraiday84Pas encore d'évaluation

- A320 LG ServicingDocument59 pagesA320 LG ServicingSergej RepenkovPas encore d'évaluation

- Brake InspectionDocument5 pagesBrake InspectionbillyPas encore d'évaluation

- HAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)Document2 pagesHAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)tenhero92Pas encore d'évaluation

- Check Engine Oil LevelDocument6 pagesCheck Engine Oil LevelSatishReddyPas encore d'évaluation

- Product Overview: Naples, May 25th 2011Document39 pagesProduct Overview: Naples, May 25th 2011Mohd Shahril Abd LatiffPas encore d'évaluation

- Bro ATR42MP 2012 PDFDocument16 pagesBro ATR42MP 2012 PDFfranz_zero2Pas encore d'évaluation

- Square Gasket PDFDocument2 pagesSquare Gasket PDFGoutam SahaPas encore d'évaluation

- Single Aisle Aircraft Communications ManualDocument102 pagesSingle Aisle Aircraft Communications ManualCassiano CapellassiPas encore d'évaluation

- Dornier 328jet - Fuel: Fuel Control Panel (Sheet 1 of 2)Document27 pagesDornier 328jet - Fuel: Fuel Control Panel (Sheet 1 of 2)brunner_marak100% (1)

- B737-800 Anti IceDocument5 pagesB737-800 Anti IceReynaldoPas encore d'évaluation

- JCP TitleDocument14 pagesJCP Titlebilly100% (1)

- 14WN Test 2Document7 pages14WN Test 2Ahsan AvioniquePas encore d'évaluation

- 24 Electrical PowerDocument164 pages24 Electrical PowermarkPas encore d'évaluation

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) CommunicationsDocument42 pagesSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) CommunicationsjuanPas encore d'évaluation

- Cas 67A Tcas Ii System Installation ManualDocument6 pagesCas 67A Tcas Ii System Installation ManualАлександр КорякинPas encore d'évaluation

- Ata 36Document11 pagesAta 36jontis jasoliyaPas encore d'évaluation

- DCAM PART 66 CAT B1.1 MODULE 4 ELECTRONIC FUNDAMENTALS SEMICONDUCTORSDocument114 pagesDCAM PART 66 CAT B1.1 MODULE 4 ELECTRONIC FUNDAMENTALS SEMICONDUCTORSwmfadzli7265100% (2)

- Fuel System - Wing and Center Tank 1Document1 pageFuel System - Wing and Center Tank 1chinna_jetPas encore d'évaluation

- ATA 30 - Ice & Rain 09-04-18 PDFDocument143 pagesATA 30 - Ice & Rain 09-04-18 PDFDavid OwenPas encore d'évaluation

- A320 Fam Air Wing Leaks Spurious WRNDocument8 pagesA320 Fam Air Wing Leaks Spurious WRNMCC GoairPas encore d'évaluation

- Service Bulletin Atr72: Transmittal Sheet Revision No. 12Document16 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 12Pradeep K sPas encore d'évaluation

- Aircraft Anti-Icing SystemDocument3 pagesAircraft Anti-Icing SystemVejay RamPas encore d'évaluation

- A320 Notes PDFDocument4 pagesA320 Notes PDFPrajwal Patidar100% (1)

- RTR A Delhi Exam Candidates Revised ListDocument1 pageRTR A Delhi Exam Candidates Revised ListJai DeepPas encore d'évaluation

- 9Document21 pages9Jai DeepPas encore d'évaluation

- Master of Science in MACHINE LEARNING & ARTIFICIAL INTELLIGENCEDocument20 pagesMaster of Science in MACHINE LEARNING & ARTIFICIAL INTELLIGENCEJai DeepPas encore d'évaluation

- 17Document5 pages17Jai DeepPas encore d'évaluation

- Onward Journey Ticket Details: ID Proof NoteDocument2 pagesOnward Journey Ticket Details: ID Proof NoteJai DeepPas encore d'évaluation

- 27Document4 pages27Jai DeepPas encore d'évaluation

- Jar Physics Revision 4'Document7 pagesJar Physics Revision 4'Jai DeepPas encore d'évaluation

- Cop Exam AppDocument53 pagesCop Exam AppMontel BerretoPas encore d'évaluation

- 01Document7 pages01Jai DeepPas encore d'évaluation

- DGCA User Manual RegistrationDocument101 pagesDGCA User Manual RegistrationJai DeepPas encore d'évaluation

- Character CertificateDocument1 pageCharacter CertificateJai DeepPas encore d'évaluation

- Character CertificateDocument1 pageCharacter CertificateJai DeepPas encore d'évaluation

- DGCA User Manual RegistrationDocument101 pagesDGCA User Manual RegistrationJai DeepPas encore d'évaluation

- Aircraft Electricity & Electronics EisminDocument428 pagesAircraft Electricity & Electronics EisminJai Deep92% (38)

- Jar Physics Revision1Document4 pagesJar Physics Revision1Jai DeepPas encore d'évaluation

- JAR 66 Module 1 Exam Practice Exam Mathematics: This Is Exam Number 1Document55 pagesJAR 66 Module 1 Exam Practice Exam Mathematics: This Is Exam Number 1Ashwin GaneshPas encore d'évaluation

- JAR PHYSICS REVISION TOPICSDocument4 pagesJAR PHYSICS REVISION TOPICSVaibhav RathodPas encore d'évaluation

- Jar Physics Revision 3Document4 pagesJar Physics Revision 3Jai DeepPas encore d'évaluation

- ReadmeDocument4 pagesReadmeJai DeepPas encore d'évaluation

- JAR PHYSICS REVISION TOPICSDocument4 pagesJAR PHYSICS REVISION TOPICSVaibhav RathodPas encore d'évaluation

- Operator E-Jets News Rel 114Document24 pagesOperator E-Jets News Rel 114Jai DeepPas encore d'évaluation

- Towing operations aircraft pilot cockpit obstructionsDocument15 pagesTowing operations aircraft pilot cockpit obstructionsmpusPas encore d'évaluation

- Photoshop CS5 Read MeDocument11 pagesPhotoshop CS5 Read Meali_mohammed_18Pas encore d'évaluation

- ASQR-01 Rev 13 Form 1 UpdatedDocument6 pagesASQR-01 Rev 13 Form 1 UpdatedPhucPas encore d'évaluation

- IAQG SCMH-3.4.2-Foreign-Object-Damage-FOD-Prevention-Program-Guidance-Material-Rev-C-Dated-17APR2018Document32 pagesIAQG SCMH-3.4.2-Foreign-Object-Damage-FOD-Prevention-Program-Guidance-Material-Rev-C-Dated-17APR2018LiherPas encore d'évaluation

- FOD Prevention - IUTY2013Document59 pagesFOD Prevention - IUTY2013Trần Triệu PhongPas encore d'évaluation

- Unit 27: Airfi Eld Operations: Unit Code: Y/602/5693 QCF Level 3: BTEC National Credit Value: 7 Guided Learning Hours: 56Document16 pagesUnit 27: Airfi Eld Operations: Unit Code: Y/602/5693 QCF Level 3: BTEC National Credit Value: 7 Guided Learning Hours: 56JamesPas encore d'évaluation

- © 2018 MHI Canada Aerospace, Inc. All Rights Reserved. Proprietary and ConfidentialDocument19 pages© 2018 MHI Canada Aerospace, Inc. All Rights Reserved. Proprietary and ConfidentialSwampfootPas encore d'évaluation

- A Study of Foreign Object Damage (FOD) and Prevention Method at The Airport and Aircraft Maintenance AreaDocument10 pagesA Study of Foreign Object Damage (FOD) and Prevention Method at The Airport and Aircraft Maintenance AreaSergio RomeroPas encore d'évaluation

- Evolution of Airfield Design Philosophies - Rollings - 98Document11 pagesEvolution of Airfield Design Philosophies - Rollings - 98Tim LinPas encore d'évaluation

- Chapter 10Document333 pagesChapter 10Esteban Elias Marquez Escalante0% (1)

- Level5 TCMax LiteratureDocument28 pagesLevel5 TCMax LiteratureAnkit Sharma100% (1)

- Dual Ignitors and Continuos Ignition in Jet EnginesDocument5 pagesDual Ignitors and Continuos Ignition in Jet Enginesa_sharafieh100% (1)

- Suas 2023 RulesDocument33 pagesSuas 2023 RulesDylan KwongPas encore d'évaluation

- AFO AS POL 09 0001 - 2 0 Pedestrian SafetyDocument27 pagesAFO AS POL 09 0001 - 2 0 Pedestrian SafetymugishabobPas encore d'évaluation

- Getting Dirty: Testing C-17 Airfield Performance in Dirt and Mud Landing ZonesDocument8 pagesGetting Dirty: Testing C-17 Airfield Performance in Dirt and Mud Landing ZonesBlaze123xPas encore d'évaluation

- AFA SOP DA20 Normal Procedures-Chapter 4 Rev01SON enDocument114 pagesAFA SOP DA20 Normal Procedures-Chapter 4 Rev01SON encod modernwarfarePas encore d'évaluation