Académique Documents

Professionnel Documents

Culture Documents

Technical Information No. 12 Vermicular Graphite Cast Iron: Microstructure

Transféré par

Velina MilevaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Information No. 12 Vermicular Graphite Cast Iron: Microstructure

Transféré par

Velina MilevaDroits d'auteur :

Formats disponibles

1 CLAAS GUSS GmbH

Am Stadtholz 52, D – 33609 Bielefeld

Postfach 10 08 45, D – 33508 Bielefeld

Tel.: 0049 (0521) 93 15 –0

Fax: 0049 (0521) 93 15 –288

Technical Information No. 12 Internet: http://www.claasguss.de

E-mail: info@claasguss.de

Vermicular graphite cast iron

Microstructure terms of properties compared to lamellar

The designation “cast iron with graphite:

vermicular-type graphite (GJV)” is - Higher strength and elongation at

derived from the worm-like appearance fracture

of the graphite in a micrographic - Higher fracture toughness

specimen. The three-dimensional - Properties are less dependent on

structure becomes apparent in a the wall thickness

scanning electron microscope after the

metallic matrix has been removed by Compared to cast iron with spheroidal

etching. graphite, cast iron with vermicular

graphite offers the following advantages:

Vermicular graphite is a transitional form - Lower coefficient of thermal

between lamellar and spheroidal expansion

graphite, which occurs when the - Higher heat conductivity

material is deliberately given insufficient - Lower modulus of elasticity

treatment or treatment is interrupted in - Lower thermally induced internal

100 µm

the process of forming spheroidal stress level

graphite. - Better thermoshock resistance and

Unetched micrographic

lower tendency to distortion

specimen

Properties because of the aforementioned

Cast iron with vermicular graphite falls properties

between cast iron with lamellar graphite - Better damping capacity

and cast iron with spheroidal graphite - Better pouring properties

not only in terms of its microstructure (shrinkage, mold-filling

formation but in terms of its mechanical characteristics and fluidity)

and physical properties as well. It is

standardized in ISO standard 16112. The material is especially suitable for

Reference values for several key components which are exposed to both

properties are shown in Table 1. Similar thermal and mechanical stresses.

to cast iron materials with spheroidal Examples include cylinder heads,

graphite, these properties are heavily exhaust manifolds and brake parts, but

dependent on the ferrite-to-pearlite ratio vermicular graphite is also used for the

in the basic structure. manufacture of transmission domes for

cars and engine units for trucks and

Cast iron with vermicular graphite cars.

20 µm provides the following advantages in

Vermicular graphite in a

scanning electron microscope

Mechanical and physical properties of cast iron with vermicular graphite

Material grade Temp. GJV-300 GJV-350 GJV-400 GJV-450 GJV-500

1) 2

Tensile strength Rm N/mm 23°C 300 – 375 350 - 425 400 - 475 450 - 525 500 - 575

1) 2

0.2% yield strength Rp0,2 N/mm 23°C 210 – 260 245 - 295 280 - 330 315 - 365 350 - 400

Elongation to fracture A % 23°C 2.0 - 5.0 1.5 - 4.0 - 3.5 1.0 - 2.5 0.5 - 2.0

2

Modulus of elasticity kN/mm 23°C 130 -145 135 -150 140 -150 145 -155 145 -160

Poisson’s ratio 0.26 0.26 0.26 0.26 0.26

Thermal conductivity W/(m⋅K) 23°C 47 43 39 38 36

Coefficient of thermal

µm/(m K) 100ºC 11 11 11 11 11

expansion

Specific heat capacity J/(g⋅K) 100ºC 0.475 0.475 0.475 0.475 0.475

1) 2) 2

Wall thickness of 15 mm, modulus M = 0.75, Secant modulus (200-300 N/mm )

Vous aimerez peut-être aussi

- Iron Alloys PDFDocument6 pagesIron Alloys PDFsachinguptachdPas encore d'évaluation

- Tribology in Industry: C. Fragassa, N. Radovic, A. Pavlovic, G. MinakDocument12 pagesTribology in Industry: C. Fragassa, N. Radovic, A. Pavlovic, G. MinakenjpetPas encore d'évaluation

- Frp-Reinforced Concrete Design PDFDocument50 pagesFrp-Reinforced Concrete Design PDFJames NeoPas encore d'évaluation

- API 571 SummaryDocument17 pagesAPI 571 Summarymitesh100% (2)

- Solution Strengthened Ferritic Ductile Iron ISO 1083/JS/500-10 Provides Superior Consistent Properties in Hydraulic RotatorsDocument9 pagesSolution Strengthened Ferritic Ductile Iron ISO 1083/JS/500-10 Provides Superior Consistent Properties in Hydraulic RotatorsJason WuPas encore d'évaluation

- Cast Iron BrochureDocument6 pagesCast Iron BrochureReza MoghaddasiPas encore d'évaluation

- GraphiteDocument5 pagesGraphiteRoman KrautschneiderPas encore d'évaluation

- Welding InternationalDocument8 pagesWelding InternationalEko PrasetyoPas encore d'évaluation

- Fabrication of Ductil Iron Pipes and Fittings MafusaDocument5 pagesFabrication of Ductil Iron Pipes and Fittings MafusaAmar JabarPas encore d'évaluation

- Ductile Iron Casting Guide FEB05Document3 pagesDuctile Iron Casting Guide FEB05Aris YusepPas encore d'évaluation

- API 571 Quick ReviewDocument32 pagesAPI 571 Quick ReviewMahmoud Hagag100% (1)

- Struers Application Note - Metallographic Preparation of High Alloy Tool SteelDocument6 pagesStruers Application Note - Metallographic Preparation of High Alloy Tool SteelCan ERTANPas encore d'évaluation

- Tool SteelDocument6 pagesTool Steelsaifullah629Pas encore d'évaluation

- Annals 2004 2 26Document6 pagesAnnals 2004 2 26Mustafa OğuzhanPas encore d'évaluation

- Refractories NitaDocument11 pagesRefractories Nitanikunj chauhanPas encore d'évaluation

- Joining Silicon Nitride To Itself and To MetalsDocument5 pagesJoining Silicon Nitride To Itself and To MetalsVivek SinghPas encore d'évaluation

- Artigo Aco 174 PHDocument2 pagesArtigo Aco 174 PHricardoPas encore d'évaluation

- Ductle Iron Spec2Document18 pagesDuctle Iron Spec2윤병택Pas encore d'évaluation

- 2017 - Effect of Forging On Aluminum Matrix Nano Composites A Review - Rajesh PurohitDocument4 pages2017 - Effect of Forging On Aluminum Matrix Nano Composites A Review - Rajesh PurohitMahmood KhanPas encore d'évaluation

- Powder Metallurgy Diamond Tools - A Review of Manufacturing RoutesDocument8 pagesPowder Metallurgy Diamond Tools - A Review of Manufacturing RoutesJan KoPas encore d'évaluation

- API-571 Reference CardDocument7 pagesAPI-571 Reference CardLaith SalmanPas encore d'évaluation

- Dr. Rajat Kumar Roy (Magnetics Department NML) Rahul VermaDocument12 pagesDr. Rajat Kumar Roy (Magnetics Department NML) Rahul VermaRahul VermaPas encore d'évaluation

- Casting 2Document47 pagesCasting 2Hoza EssamPas encore d'évaluation

- Discontinuous Reinforcement: Table 4-1 .-Costs of A Representative Sample of MMC ReinforcementsDocument1 pageDiscontinuous Reinforcement: Table 4-1 .-Costs of A Representative Sample of MMC ReinforcementsSanjay GehlotPas encore d'évaluation

- High Strength Solutions To Your Toughest Reinforcement ChallengesDocument2 pagesHigh Strength Solutions To Your Toughest Reinforcement ChallengesLei WuPas encore d'évaluation

- AENG401 Rapor ŞablonuDocument3 pagesAENG401 Rapor ŞablonuGökçe DunluPas encore d'évaluation

- Case Hardening SteelsDocument52 pagesCase Hardening SteelsGururaja TantryPas encore d'évaluation

- Gupta 2008Document5 pagesGupta 2008MadePas encore d'évaluation

- Tool SteelDocument6 pagesTool SteelTahir AbbasPas encore d'évaluation

- Cast Iron Grades PDFDocument1 pageCast Iron Grades PDFAnurag JainPas encore d'évaluation

- API RP 571 Ref CardDocument7 pagesAPI RP 571 Ref Cardzainulabedine100% (1)

- Fiber Reinforced Polymer (FRP) MaterialsDocument35 pagesFiber Reinforced Polymer (FRP) MaterialskirtikamjhjhsgcssPas encore d'évaluation

- 2-CGI Mahmoud Essam, 2021Document8 pages2-CGI Mahmoud Essam, 2021Mahmoud Essam ElsaifyPas encore d'évaluation

- Joseph R.croteauDocument10 pagesJoseph R.croteauAnbarasi GurusamyPas encore d'évaluation

- (1997) Microstructure Degradation in Stainless Steel Weld Metals Due To Thermal and Mechanical HistoriesDocument7 pages(1997) Microstructure Degradation in Stainless Steel Weld Metals Due To Thermal and Mechanical HistoriesthiagoturraPas encore d'évaluation

- Strengthening Methods: Introduction To Strengthening Strengthening Mechanisms Strengthening of ColumnsDocument20 pagesStrengthening Methods: Introduction To Strengthening Strengthening Mechanisms Strengthening of Columnsbra22222Pas encore d'évaluation

- SKF-hibridos PrecisionDocument4 pagesSKF-hibridos PrecisionMaycon GuercheskiPas encore d'évaluation

- The Effect of Friction Stir Processing and Subsequent Rolling On The Superplastic Behaviour of Aluminium AlloysDocument8 pagesThe Effect of Friction Stir Processing and Subsequent Rolling On The Superplastic Behaviour of Aluminium AlloysSyaifur RohmanPas encore d'évaluation

- SimaDocument16 pagesSimaDeepakPas encore d'évaluation

- Effect of Laser Preheating The Workpiece On Micro End Milling of MetalsDocument9 pagesEffect of Laser Preheating The Workpiece On Micro End Milling of MetalsSivi KarudijanPas encore d'évaluation

- Casting LectureDocument168 pagesCasting LectureAnonymous rTWwAM0100% (1)

- High Metal AdhesionDocument9 pagesHigh Metal AdhesionSachin KothariPas encore d'évaluation

- Case-Study Commercial Iron-And-Steel Ladle Wds FinalDocument2 pagesCase-Study Commercial Iron-And-Steel Ladle Wds FinalAdrian BPas encore d'évaluation

- API 571 SummaryDocument7 pagesAPI 571 Summaryzackyat7976100% (1)

- Metals 08 00026Document13 pagesMetals 08 00026S.Mohana sundaramPas encore d'évaluation

- Types of Materials: MetalsDocument33 pagesTypes of Materials: MetalsKutsu ShidaPas encore d'évaluation

- 082 (2006)Document2 pages082 (2006)السيد ابراهيم عبدالعزيز عبداللهPas encore d'évaluation

- 1 Ceramic Fiber BoardsDocument2 pages1 Ceramic Fiber BoardsMahesh MishraPas encore d'évaluation

- Etals Nternational Imited: Table 9.3 Summary of Hot-Dipped Coatings, Their Structures and UsesDocument1 pageEtals Nternational Imited: Table 9.3 Summary of Hot-Dipped Coatings, Their Structures and UsesSSMPas encore d'évaluation

- Advanced Ceramics Excel in High-SpeedDocument4 pagesAdvanced Ceramics Excel in High-SpeedgzmyldsPas encore d'évaluation

- Colloid Process PDFDocument18 pagesColloid Process PDFMüslüm KOÇPas encore d'évaluation

- PDF Ca Repromat e 7 2012.en.40Document4 pagesPDF Ca Repromat e 7 2012.en.40Henry SunarkoPas encore d'évaluation

- Use of A Composite Material For Al Contact ApplicationsDocument6 pagesUse of A Composite Material For Al Contact Applicationsy3b2n6tq5Pas encore d'évaluation

- The Future of Composites in Gas Turbine EnginesDocument4 pagesThe Future of Composites in Gas Turbine EnginessenthilPas encore d'évaluation

- Precipitation Hardening: Theory and ApplicationsD'EverandPrecipitation Hardening: Theory and ApplicationsÉvaluation : 2 sur 5 étoiles2/5 (1)

- The Essentials of Material Science and Technology for EngineersD'EverandThe Essentials of Material Science and Technology for EngineersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Brand Oe. Part No. Model: Original Equipment Numbers vs. Kojen ModelDocument24 pagesBrand Oe. Part No. Model: Original Equipment Numbers vs. Kojen ModelVelina MilevaPas encore d'évaluation

- Leaflet English ILMEG Products ABDocument4 pagesLeaflet English ILMEG Products ABVelina MilevaPas encore d'évaluation

- 519379-Design A 100A Active Load To PDFDocument7 pages519379-Design A 100A Active Load To PDFVelina MilevaPas encore d'évaluation

- Quicklub Lubrication Systems: SSV Divider ValvesDocument4 pagesQuicklub Lubrication Systems: SSV Divider ValvesVelina MilevaPas encore d'évaluation

- CAN Troubleshooting Sheet v3Document1 pageCAN Troubleshooting Sheet v3Velina MilevaPas encore d'évaluation

- Bds en Iso 8469 2013Document20 pagesBds en Iso 8469 2013Velina MilevaPas encore d'évaluation

- Effective Use of Water in A System For Water Driven Hammer DrillingDocument10 pagesEffective Use of Water in A System For Water Driven Hammer DrillingVelina MilevaPas encore d'évaluation

- MatexDocument2 pagesMatexVelina MilevaPas encore d'évaluation

- Super TacDocument2 pagesSuper TacVelina MilevaPas encore d'évaluation

- AWS A10.1M-2007 Calibration and Performance Testing of Secondary Current Sensing Coils and Weld PDFDocument56 pagesAWS A10.1M-2007 Calibration and Performance Testing of Secondary Current Sensing Coils and Weld PDFVelina MilevaPas encore d'évaluation

- Laboratory Tests For The Drillability of Rock: Goodrich Test: Sievers J-ValueDocument2 pagesLaboratory Tests For The Drillability of Rock: Goodrich Test: Sievers J-ValueVelina MilevaPas encore d'évaluation

- Lagan Group Duleek Quarry enDocument5 pagesLagan Group Duleek Quarry enVelina MilevaPas encore d'évaluation

- Performance Prediction Cf128G: Male Rotor Tip Speed in M/sDocument4 pagesPerformance Prediction Cf128G: Male Rotor Tip Speed in M/sVelina MilevaPas encore d'évaluation

- Coriolis ReportDocument51 pagesCoriolis ReportVelina MilevaPas encore d'évaluation

- Level Ton ReportDocument72 pagesLevel Ton ReportVelina MilevaPas encore d'évaluation

- TDS Korrobond 65Document2 pagesTDS Korrobond 65Velina MilevaPas encore d'évaluation

- The Chemistry of Soap BubblesDocument15 pagesThe Chemistry of Soap BubblesGenesisCuervoCoronadoPas encore d'évaluation

- FINAL REPORT Coastal Markets PDFDocument58 pagesFINAL REPORT Coastal Markets PDFVelina MilevaPas encore d'évaluation

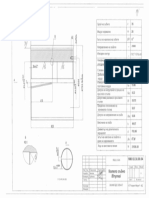

- Chertezh Zubna VtulkaDocument1 pageChertezh Zubna VtulkaVelina MilevaPas encore d'évaluation

- Blasting Plan TrenchDocument16 pagesBlasting Plan TrenchVelina Mileva100% (1)

- J1587 IntroductionDocument7 pagesJ1587 IntroductionVelina MilevaPas encore d'évaluation

- Laboratory Tests For The Abrasiveness of Rock 20120516154148Document4 pagesLaboratory Tests For The Abrasiveness of Rock 20120516154148Velina MilevaPas encore d'évaluation

- The Influence of Wood Moisture Content On The Process of Circular Rip-Sawing. Part I: Power Requirements and Specific Cutting ForcesDocument15 pagesThe Influence of Wood Moisture Content On The Process of Circular Rip-Sawing. Part I: Power Requirements and Specific Cutting ForcesVelina MilevaPas encore d'évaluation

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikPas encore d'évaluation

- Extruder TypesDocument36 pagesExtruder Typesrasheedshaikh2003Pas encore d'évaluation

- UCHDRIVE - Well Engineering and ConstructionDocument254 pagesUCHDRIVE - Well Engineering and ConstructionEmmanuel NPas encore d'évaluation

- Extra ExercisesDocument55 pagesExtra ExercisesJeremy Duann50% (2)

- PLT InterpretationDocument71 pagesPLT Interpretationdhiaa100% (2)

- Closed Form Solutions For Element Matrices of 4-Node Rectangular Plate Element Using IFMDocument10 pagesClosed Form Solutions For Element Matrices of 4-Node Rectangular Plate Element Using IFMMallesh NenkatPas encore d'évaluation

- Problem Explanation - 09-24-2010Document2 pagesProblem Explanation - 09-24-2010King OfheartsPas encore d'évaluation

- Sistema Electrico DL300Document5 pagesSistema Electrico DL300Juan Luque LPas encore d'évaluation

- The Impact of Airtightness On System Design: IiiiiDocument5 pagesThe Impact of Airtightness On System Design: IiiiiBen SyPas encore d'évaluation

- Air Drying by Pressure Swing Adsorption - Chihara-SuzukiDocument7 pagesAir Drying by Pressure Swing Adsorption - Chihara-SuzukiAndri SaputraPas encore d'évaluation

- 23 Roshan KumarDocument5 pages23 Roshan Kumarzoom_999Pas encore d'évaluation

- Mechanics of Deformable Bodies - Supplementary ProblemsDocument7 pagesMechanics of Deformable Bodies - Supplementary ProblemsDhenil ManubatPas encore d'évaluation

- Evaluación Corrosión TuberíasDocument21 pagesEvaluación Corrosión TuberíasyeeslavePas encore d'évaluation

- BITZER Output Data: Created On: 16/05/2017 16:44:22Document5 pagesBITZER Output Data: Created On: 16/05/2017 16:44:22Hasan Syaiful IPas encore d'évaluation

- F2 DP 2015 Ayas Mehmet MASTER THESIS - PdfinalcorrectionDocument66 pagesF2 DP 2015 Ayas Mehmet MASTER THESIS - PdfinalcorrectionSyed YousufuddinPas encore d'évaluation

- Zych 2016 Structural ConcreteDocument12 pagesZych 2016 Structural ConcreteJacky_LEOLEOPas encore d'évaluation

- Lab VivaDocument4 pagesLab VivaShweta JainPas encore d'évaluation

- IPCSD0602CA004M - Refrigeratore IPC 602 SIDEL R134a 440/3/60Document2 pagesIPCSD0602CA004M - Refrigeratore IPC 602 SIDEL R134a 440/3/60Joel Coaguila CosiPas encore d'évaluation

- Worksheet G11 Chemistry 11.1Document3 pagesWorksheet G11 Chemistry 11.1some guy on the internetPas encore d'évaluation

- Gas Turbine PowerplantDocument1 pageGas Turbine PowerplantVon A. DamirezPas encore d'évaluation

- Composite Building Case Study PDFDocument49 pagesComposite Building Case Study PDFkoglad100% (1)

- PSVDocument38 pagesPSVSajid Raza100% (1)

- 01-Steam Power Plant 26 OctDocument64 pages01-Steam Power Plant 26 OcthuusenaliPas encore d'évaluation

- PDFDocument16 pagesPDFŘïśhåbh ÇhåţúŕvëđîPas encore d'évaluation

- Chapter 7Document57 pagesChapter 7mr.anassahariPas encore d'évaluation

- Fatigue Analysis of Piping System Using Caesar IIDocument9 pagesFatigue Analysis of Piping System Using Caesar IIHmd Mokhtari100% (1)

- NASA Technical Paper 2256Document145 pagesNASA Technical Paper 2256Anonymous QFTSj1YPas encore d'évaluation

- Testing Methods For CompositesDocument26 pagesTesting Methods For CompositesRupayan RoyPas encore d'évaluation

- CH401 Transport Phenomena in ProcessesDocument3 pagesCH401 Transport Phenomena in ProcessesSakkeer A VPas encore d'évaluation

- Slope Indicator PDFDocument170 pagesSlope Indicator PDFAshrethPas encore d'évaluation