Académique Documents

Professionnel Documents

Culture Documents

4 Ijetst Masonary

Transféré par

YELLAMANDA SANKATITitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

4 Ijetst Masonary

Transféré par

YELLAMANDA SANKATIDroits d'auteur :

Formats disponibles

IJETST- Vol.

||05||Issue||03||Pages 6563-6568||March||ISSN 2348-9480 2018

International Journal of Emerging Trends in Science and Technology

IC Value: 76.89 (Index Copernicus) Impact Factor: 4.849 DOI: https://dx.doi.org/10.18535/ijetst/v5i3.04

Axial Load-Flexural Strength Interaction of Masonry Walls

Authors

Arjun Babukuttan , Athira Prakash2, Reshma Manoharan3, Soumya Gopi4

1

Jacob Alex5

1,2,3,4

Graduate Student, Department of Civil Engineering, Adi Shankara Institute of Technology, Kalady

5

Assistant Professor, Department of Civil Engineering, Adi Shankara Institute of Technology, Kalady

Abstract

In this paper, an analytical investigation of the axial load-flexural strength interaction of reinforced masonry

walls is carried. The curvature ductility of masonry walls is also evaluated for masonry walls with different

modes of reinforcement configurations under different levels of axial loads. Results from this paper indicate

that at low axial loads masonry walls exhibit sufficient ductility to be employed in areas of medium to high

seismicity

Keywords-Reinforced masonry, axial load, flexural strength, interaction, ductility.

Introduction The other variant of masonry structures involves the

Masonry is one of the oldest construction materials introduction of both vertical and horizontal steel.

in use. On basis of the constituent used for The vertical steel is used to increase the flexural

construction, masonry structures are classified as capacity of the wall, while the introduction of

unreinforced masonry structures, reinforced horizontal steel increases the shear capacity of the

masonry structures and confined masonry structures. wall. However, the introduction of horizontal

Most houses in rural India are masonry houses built reinforcement increases the bed joint thickness that

with either burnt clay brick or natural stone masonry. has a detrimental effect on the compressive strength

Technically, they are called Unreinforced Masonry of masonry. Nevertheless, Indian codes (IS-1905,

(URM) Houses; as they have masonry walls with no 1987) has not formulated any design or detailing

steel reinforcement embedded in them to improve code for reinforced masonry possibly as the quality

their behaviour during earthquakes. During an of bricks in our country, on an average are not

earthquake, unreinforced masonry (URM) walls are suitable for reinforced masonry. Bricks should be of

pushed sideways, along their length (in-plane) and high strength, dense and needs to have low rate of

thickness (out-of-plane) directions. When shaken moisture. A high rate of moisture absorption may

along their length, they develop diagonal cracks lead to corrosion of the reinforcement and loss in

along their length and/or separate at wall junctions. their strength. In addition, the absence of skilled

When walls collapse, they bring down the roof labour has limited the use of reinforced masonry in

along with them. This is the main reason for large India. All the afore-mentioned reasons have limited

loss of lives during earthquakes that have occurred research on reinforced masonry walls. However,

in different regions of the country. The poor research on RM walls subject to axial compression

performance of URM structures even under low to and shear has gathered momentum since the 1990s.

moderate seismicity (Sikkim 2011 and Nepal 2015) Reinforced masonry (RM) structural walls form the

has seen it use been banned in a few countries (New main lateral load resisting system in low to mid-rise

Zealand) through techno-legal regulations buildings, located in moderate/high seismic regions.

Arjun Babukuttan et al www.ijetst.in Page 6563

IJETST- Vol.||05||Issue||03||Pages 6563-6568||March||ISSN 2348-9480 2018

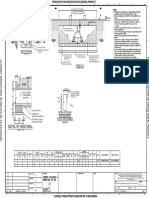

Compared to unreinforced masonry walls, RM walls strength and ductility. Two common ways of

have higher flexural and shear strengths and are detailing longitudinal reinforcement in RC walls are:

L=3270

expected to efficiently resist earthquake shaking (a) Uniform distribution of reinforcement along

through inelastic

d8=3170 actions. Proper design and 3270 the length of the wall, and (b) reinforcement

detailing of longitudinal

d7=2726 and transverse3170 concentrated at the two ends of the wall (see

d6=2289

reinforcements helps in achieving the required Fig 1 A and B).

d5=19742970

300

100 A

100

d2 =538 B

d3 =978

Figure 1: Detailing of longitudinal steel in RM walls

d4 =1416

Although, in-plane flexural strength of walls with Estimation of Axial Load, Flexural Capacity and

the two distributions are generally not too different Curvature

for the same amount of total reinforcement, the The axial load and the flexural strength of RM walls

former often results in enhanced shear strength and can be estimated from basic principles of mechanics

improved shear behaviour (displacement and considering equilibrium of forces, compatibility of

ductility) as it resists the propagation of diagonal strains and constitutive relations of materials, given

shear cracks in the wall. The flexural strength and in equations (1) to (3):

curvature ductility of RM walls sections can be f sci f msci Asci f m,avg txu f sti Asti P

determined from their axial load-moment (1)

interaction curves and non-linear moment-curvature Compatibility conditions

(M-Φ) curves. Curvature ductility is the general

m1 st 4

measure of ductile response of a section that (2)

depends on compressive strain of masonry, xu L' xu

compressive strength of masonry, yield strength and

strain of reinforcing steel and the level of axial load. The design flexural compressive σ-ε curve of

Typically sections subject to high axial loads have masonry is parabolic up to an ultimate strain of

very low curvature ductility as their failure is due to 0.003 with maximum compressive stress f'm (Fig.

the crushing of masonry. 3.A). Also, strain limits εu of 0.003 used are from

The M-Φ response curve must represent the experimental observations (Kaushik et al. 2007).

effective (cracked) flexural rigidity, flexural The value of 0.003 for εu corresponds to strain at

strength, and curvature ductility of the RM section. which vertical cracks are observed in the afore-

Strain levels in masonry and reinforcement at the mentioned experiment. The constitutive relation of

onset of critical damage states like cracking of masonry is defined by its design stress-strain curve

masonry, yielding of reinforcement bars in tension, given by:

and compression failure of masonry are used in the

2

estimation of flexural strength and curvature f m 0.85 f m' 2 (3)

u u

ductility. This paper proposes methods to arrive at

idealized multi-linear M-Φ curves of RM wall where :

sections with both uniformly distributed

Asti is the area of reinforcement bars in ith layer

reinforcement along the length of the wall and

under tension

reinforcement concentrated at the two ends of the

Asci the area of reinforcement bars in ith layer

wall, at different levels of axial stress.

under compression,

Arjun Babukuttan et al www.ijetst.in Page 6564

IJETST- Vol.||05||Issue||03||Pages 6563-6568||March||ISSN 2348-9480 2018

L' the distance of the extreme layer of strain in the outermost layer of reinforcement

reinforcement from the extreme layer in reaches a value of strain given in equation (4).

compression, fm,avg the average compressive 3. Crushing of masonry: This limit state is reached

stress in masonry when the strain in the extreme layer of compression

fsti the stress in ith layer of reinforcement bars reaches the crushing strain of masonry εu.

under tension Based on the above-mentioned limit states a P-M

fsci the stress in ith layer of reinforcement bars interaction envelope of RM sections under have

under compression (both estimated from stress- three distinct regions (see Fig 4 and 5);

strain characteristics of reinforcement bar) Balance point: It is defined as the point on the

fmsci the stress in masonry at the level of ith layer P-M interaction at which the strains in concrete

of reinforcement bars under compression and steel reach corresponding limiting strains in

xu the depth of neutral axis crushing and tension simultaneously. The axial

f'm the compressive strength of masonry load at this point is denoted as balanced axial

εu the compressive strain in masonry load Pbal.

corresponding to f'm Compression failure region (above balanced

and ε the ultimate strain in masonry at highly point): Region on the P-M interaction where the

compressed edge at peak stress. failure is characterised by the strains in the

The design flexural compressive σ-ε curve of HYSD extreme compressive fibre reaching the

bars (both tensile and compressive) has three parts crushing strain of masonry (εu). The axial load

is described in Fig. 3B. The limiting strain in the region is greater than Pbal.

corresponding to yielding of reinforcement bars Tensile failure region (below balance point): It

given by: is the region on the P-M interaction where the

failure is due to the tensile strain in the extreme

0.87 f y

y 0.002

(4) layer of reinforcement reaching aits yield. The

E s axial load in this region is lesser than the

where: balanced axial load Pbal.

Es: Youngs' modulus of reinforcing steel (200 GPa) In the following paper, P-M interaction and non-

Once the stresses in the reinforcing steel and linear M- Φ curves are developed for two reinforced

masonry are obtained, the axial load is calculated as masonry walls (wall A with uniformly distributed

in equation (1). The flexural strength of the RM steel and wall B with reinforced concentrated at the

wall is calculated by considering the moments of the two ends of the walls. The curvature ductility of the

tensile and compressive forces along the centroidal walls has been examined at various levels of axial

axis. Figure 4 A shows a typical axial load-bending stress.

moment (P-M) interaction (normalised to their

respective capacities) of RM walls. The failure of a

RM wall is defined by values of limiting states of

strains in masonry and the reinforcing steel. A limit

state is said to have reached when one of the

following limiting strains is attained:

1. Tensile cracking of masonry: This limit state is

reached when the tensile stress in the extreme edge

of masonry exceeds the tensile strength of masonry

(assumed to be zero in this research).

2. Yielding of extreme of reinforcement on tension

side: This limit state is reached when the tensile

Arjun Babukuttan et al www.ijetst.in Page 6565

IJETST- Vol.||05||Issue||03||Pages 6563-6568||March||ISSN 2348-9480 2018

1

B P>Pbal

P<Pbal

Normalised axial load

0.8

0.6

0.4

0.2

0

0 0.2 0.4 0.6 0.8 1

Normalised flexural strength

Fig. 4: Typical axial load-bending moment

interaction of RM walls

Fig. 2. Typical stress and strain distributions across

rectangular RM walls A) Entire section under A B C

t

ε m1= ε u ε m1= ε u ε m1< ε u

compression and B) Once tensile cracking εcs1

εcs1 εcs1

commences

xu

xu εcs2 xu εcs2 εcs2

L φ

εts3 εts3 εts3

2 2

εts4 = εy εts4 = εy

εts4 < εy

f m 0.85 f m'

u u Net

tension

Fig. 5: Strain variations across RM sections under

axial loads A) Above balance point B) At balance

point C) Below axial load

Axial Load-Flexural Capacity (P-M) Interaction

and Moment-Curvature (M- Φ )

0.87f y

The P-M interaction and M-Φ curves of two

reinforced masonry walls with reinforcing steel

detailing as given in Figure 1 is provided in this

sections. The curves are determined from simple

principle of mechanics considering equilibrium of

forces, compatibility of strains and constitutive

relations of materials. As per SP-7, the minimum

reinforcement in each orthogonal should be at least

0.07% of the gross area of the wall. In this paper the

εy P-M interaction and M- Φ curves of a wall with

dimensions of 3270*3000*200 mm (l*h*t) are

Fig. 3: Design stress-strain relation for A) masonry examined. The wall is constructed with concrete

and B) reinforcing steel masonry blocks (CMU) with block dimensions

Arjun Babukuttan et al www.ijetst.in Page 6566

IJETST- Vol.||05||Issue||03||Pages 6563-6568||March||ISSN 2348-9480 2018

400(l)*200(w)*100(h). The area of vertical by crushing of masonry rather than yielding

reinforcing steel is fixed as 0.1% of the gross cross- of steel.

sectional area of the wall. The reinforcing steel is Results also indicate that there is no effect of

detailed in two ways: the reinforcement detailing on either the

a) Uniform distribution of reinforcement along the curvature ductility or the effective flexural

length of the wall (Wall A, see Fig. 6A), and rigidity.

b) Reinforcement concentrated at the two ends of

the wall (wall B, see Fig 6 B). L=3270

d8=3170

The P-M interaction of walls A and B is shown in d7=2726

d6=2289

Fig. 5. From Fig.5 and table 1, one observes that the d5=1974

detailing of the reinforcement does not have an

100

effect on the axial load capacity of the wall. d3 =978

d2 =538

However, there is a 7.5% increase in the flexural d4 =1416

strength of the wall with reinforcement concentrated

3270

at the corner. 3170

The M-Φ curve of walls A and B subject to different 2970

300

100

levels of axial stresses are also investigated. In this

regard, M-Φ curves of the walls at an axial load of

0.21Pu (=Pbal), 0.4Pu (>Pbal) and 0.1Pu (<Pbal) are Fig. 6: Cross section of wall A uniformly

studied and reported in Fig. 7 and table 2. The distributed steel and wall B steel at corners

idealized bi-linear curve is obtained by equating the

energy dissipation capacity of the non-linear and

idealized bilinear M- Φ curve. So the area below the

non-linear and idealized bilinear M-Φ curve must be

0.4Pu

0.4Pu

the same. The moment capacity in the bilinear M-Φ

curve does not imply the design value. An estimate 0.21Pu

0.21Pu

0.1Pu

of curvature ductility (μ Φ) and effective flexural 0.1Pu

rigidity (defined as the initial slope of the bi-linear

curve) of walls A and B are studied and reported in Fig. 7: Axial load –bending moment interaction

Table 2. The flexural rigidity is expressed as a diagram for the wall A and wall B

function of the uncracked flexural rigidity. The

afore-mentioned parameters are estimated at axial

load demands of 0.4 Pu (above balance point),

0.21Pu (at balance point) and 0.1Pu (and below

balance point). Results from fig. 6-7 and table 2

indicate that:

Curvature ductility of walls A and B subject Fig. 8: Moment curvature relationship of wall A

to high axial loads (>Pbal) are low since their

failure is characterised by the compressive

failure (crushing) of masonry rather than

yielding of steel.

A drop in the effective flexural rigidities is

also observed at higher axial loads since the

failure of walls at high axial is characterised Fig. 9: Moment curvature relationship of wall B

Arjun Babukuttan et al www.ijetst.in Page 6567

IJETST- Vol.||05||Issue||03||Pages 6563-6568||March||ISSN 2348-9480 2018

Table 1: Axial load and bending moment capacity

of walls A and B

Wall # Axial Bending Balanced

load moment axial load, Pbal

capacity, capacity, Mu (kN)

Pu (kN) (kNm)

Wall A 5593 1717 1174

Wall B 5589 1845 1173

Table 2: Curvature ductility and effective flexural

rigidity of walls A and B

Axial Curvature Curvature Effective Effective

load ductility, ductility, flexural flexural

demand (μ Φ ) (μ Φ ) rigidity, rigidity,

(Wall A) (Wall B) (EIeff) (EIeff)

(Wall A) (Wall B)

0.4 Pu 1.83 1.69 0.71 0.75

0.21 Pu 4.57 4.38 0.86 0.88

0.1 Pu 12.3 12.84 0.92 0.91

Conclusions

The significant conclusions of this study are

enumerated below:

Results from this paper indicate that the

detailing of flexural reinforcement in a

masonry wall affects neither the curvature

ductility nor the initial flexural rigidity.

RM walls subject to low axial loads

demonstrate high curvature ductility thus

making a suitable substitute for RC frame

elements.

References

1. Bureau of Indian Standards, Draft National

Building Code – SP 7 (September 2015)

2. H.B.Kaushik, D.C.Rai and S.K. Jain,

"Uniaxial compressive stress – strain model

for clay brick masonry", Current Science,

Vol. 92, No. 4, pp. 497–501, 2007.

3. Sunitha, P., Goswami, R. and Murthy,

C.V.R (2016), "Idealized moment-curvature

curves of RC section for the pushover

analysis of R.C. frame elements", The Indian

Concrete Journal, Vol. No 90.

Arjun Babukuttan et al www.ijetst.in Page 6568

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- TDS - BGCPN 40W 30K LedDocument1 pageTDS - BGCPN 40W 30K LedYELLAMANDA SANKATIPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- 03 2013-Estt - AL-27032015Document1 page03 2013-Estt - AL-27032015YELLAMANDA SANKATIPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Section A-A corrected and Detail-1 revised structural drawingsDocument1 pageSection A-A corrected and Detail-1 revised structural drawingsYELLAMANDA SANKATIPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- TDS - BGCPN 40W 30K LedDocument1 pageTDS - BGCPN 40W 30K LedYELLAMANDA SANKATIPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- 117 Del HydDocument2 pages117 Del HydYELLAMANDA SANKATIPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- CERTIFICATE FROM HEAD OF SCHOOL FOR CEA REIMBURSEMENTDocument1 pageCERTIFICATE FROM HEAD OF SCHOOL FOR CEA REIMBURSEMENTayush67% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- CapDocument7 pagesCapYELLAMANDA SANKATIPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Waffle Slab Analysis by Different MethodsDocument4 pagesWaffle Slab Analysis by Different MethodsOscar Gabriel Moreno DiazPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- 1200 Audi (sht.1)Document1 page1200 Audi (sht.1)YELLAMANDA SANKATIPas encore d'évaluation

- Del To Leh July PDFDocument2 pagesDel To Leh July PDFYELLAMANDA SANKATIPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- PerimeterFenceSTNotes 11march'15Document2 pagesPerimeterFenceSTNotes 11march'15YELLAMANDA SANKATIPas encore d'évaluation

- Leh Del 117Document2 pagesLeh Del 117YELLAMANDA SANKATIPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Poer Cap DesDocument7 pagesPoer Cap DesYELLAMANDA SANKATIPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Design of Pinned Base Plate:-: Max Axial Case Max Uplift CaseDocument3 pagesDesign of Pinned Base Plate:-: Max Axial Case Max Uplift CaseYELLAMANDA SANKATIPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- F.R. & S.R. - PART III - Leave RulesDocument18 pagesF.R. & S.R. - PART III - Leave RulesYELLAMANDA SANKATIPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Del To Leh July PDFDocument2 pagesDel To Leh July PDFYELLAMANDA SANKATIPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- 117 Del HydDocument2 pages117 Del HydYELLAMANDA SANKATIPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Del To Leh July PDFDocument2 pagesDel To Leh July PDFYELLAMANDA SANKATIPas encore d'évaluation

- Thesis Crack Pattern DrawingsDocument8 pagesThesis Crack Pattern DrawingsYELLAMANDA SANKATIPas encore d'évaluation

- Search Passengers and Payments ConfirmationDocument2 pagesSearch Passengers and Payments ConfirmationYELLAMANDA SANKATIPas encore d'évaluation

- TicketDocument2 pagesTicketYELLAMANDA SANKATIPas encore d'évaluation

- 03 2013-Estt - AL-27032015Document1 page03 2013-Estt - AL-27032015YELLAMANDA SANKATIPas encore d'évaluation

- Search Passengers and Payments ConfirmationDocument2 pagesSearch Passengers and Payments ConfirmationYELLAMANDA SANKATIPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Notations English SymbolsDocument3 pagesNotations English SymbolsYELLAMANDA SANKATIPas encore d'évaluation

- List of FiguresDocument3 pagesList of FiguresYELLAMANDA SANKATIPas encore d'évaluation

- Notations English SymbolsDocument3 pagesNotations English SymbolsYELLAMANDA SANKATIPas encore d'évaluation

- Title No. Acknowledgements List of Tables List of Figures NotationsDocument5 pagesTitle No. Acknowledgements List of Tables List of Figures NotationsYELLAMANDA SANKATIPas encore d'évaluation

- Thesis ReferencesDocument6 pagesThesis ReferencesYELLAMANDA SANKATIPas encore d'évaluation

- List of TablesDocument1 pageList of TablesYELLAMANDA SANKATIPas encore d'évaluation

- Acknowedge MentDocument1 pageAcknowedge MentYELLAMANDA SANKATIPas encore d'évaluation

- Sanskar College Construction & Material ExamDocument5 pagesSanskar College Construction & Material Examaayush sharmaPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Workmanship StandardsDocument74 pagesWorkmanship StandardsgdtrenePas encore d'évaluation

- Cellular Lightweight ConcreteDocument7 pagesCellular Lightweight ConcreteAakanksha MishraPas encore d'évaluation

- Windposts and Masonry ReinforcementDocument16 pagesWindposts and Masonry ReinforcementakajsiPas encore d'évaluation

- Project Report Sample - Cement PlantDocument126 pagesProject Report Sample - Cement PlantArun Prasadh100% (2)

- BOX ACTION STRENGTHENS MASONRYDocument3 pagesBOX ACTION STRENGTHENS MASONRYVinay Chandwani0% (2)

- Design of LintelsDocument6 pagesDesign of LintelsAbheeshekGoelPas encore d'évaluation

- Product Details LightStrong AAC Block - ClientsDocument92 pagesProduct Details LightStrong AAC Block - ClientsYuki-Pauline NagatoPas encore d'évaluation

- Cement & Sand (1:3) : Quantities For 1 SQM 6 MM THK PlasterDocument4 pagesCement & Sand (1:3) : Quantities For 1 SQM 6 MM THK Plasterpremsai555Pas encore d'évaluation

- 02cost Estimate 16+500 To 31+800 Final 7-24 ApplDocument333 pages02cost Estimate 16+500 To 31+800 Final 7-24 Applnitish JhaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Schedule Breakdown for Grey Structure ConstructionDocument16 pagesSchedule Breakdown for Grey Structure Constructionaliengineer953Pas encore d'évaluation

- Type of Vaults Used: Rectangular Large Span Vault 15m X 8m Resting On Four CornersDocument2 pagesType of Vaults Used: Rectangular Large Span Vault 15m X 8m Resting On Four CornersHarshali PatilPas encore d'évaluation

- Brick MasonryDocument10 pagesBrick MasonrySamhithaPas encore d'évaluation

- Horizontal & Vertical Eccentricities in Mass and Stiffness DistributionDocument23 pagesHorizontal & Vertical Eccentricities in Mass and Stiffness Distributionmuktha mukuPas encore d'évaluation

- Line Spring Calculation by SPT-15.03.18Document6 pagesLine Spring Calculation by SPT-15.03.18Nazmul HassanPas encore d'évaluation

- PIPE CULVERT WITH CUSHION (1X1.2m) - (1x900) - 13+140-2Document1 pagePIPE CULVERT WITH CUSHION (1X1.2m) - (1x900) - 13+140-2Chandan VatsPas encore d'évaluation

- Cash Flow Summary For 3B+G+8 Mixed use apartment buildingDocument18 pagesCash Flow Summary For 3B+G+8 Mixed use apartment buildingÑatty MessawPas encore d'évaluation

- BUILDING TECHNOLOGY - MASONRY MORTARS AND PLASTERSDocument5 pagesBUILDING TECHNOLOGY - MASONRY MORTARS AND PLASTERSEricaa PamintuanPas encore d'évaluation

- MasonryDocument8 pagesMasonryMarito da Silva Alves0% (1)

- Seminar On Hydro Sector - ProceedingsDocument143 pagesSeminar On Hydro Sector - Proceedingsइंजि कौस्तुभ पवारPas encore d'évaluation

- New Zealand Society For EarthquakeDocument213 pagesNew Zealand Society For EarthquakeM Refaat FathPas encore d'évaluation

- Construction Material and Methods in AfghanDocument54 pagesConstruction Material and Methods in AfghanVictor394100% (1)

- 06 - Part A - UCRDocument2 pages06 - Part A - UCRkartick adhikaryPas encore d'évaluation

- Understanding Firewall BasicsDocument10 pagesUnderstanding Firewall BasicsFWICIPPas encore d'évaluation

- 0331 Brick and Block Construction Wo GuidanceDocument11 pages0331 Brick and Block Construction Wo GuidanceMoren AlfonsoPas encore d'évaluation

- Suphaa Adaadii Rate HaaraaDocument6 pagesSuphaa Adaadii Rate HaaraaBorana Asnake KumsaPas encore d'évaluation

- Assiut Cement PlantDocument17 pagesAssiut Cement PlantMahmoud RashadPas encore d'évaluation

- For Basements: Drylok®Document2 pagesFor Basements: Drylok®JohnPas encore d'évaluation

- Concrete Products: Technical GuideDocument56 pagesConcrete Products: Technical Guiderobertotoro2014Pas encore d'évaluation

- 7-Structural Design ReportDocument4 pages7-Structural Design ReportIbrahim KhanPas encore d'évaluation

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (137)

- Advanced Modelling Techniques in Structural DesignD'EverandAdvanced Modelling Techniques in Structural DesignÉvaluation : 5 sur 5 étoiles5/5 (3)

- Advanced Design Examples of Seismic Retrofit of StructuresD'EverandAdvanced Design Examples of Seismic Retrofit of StructuresÉvaluation : 1 sur 5 étoiles1/5 (1)

- Marine Structural Design CalculationsD'EverandMarine Structural Design CalculationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualD'EverandTransmission Pipeline Calculations and Simulations ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)