Académique Documents

Professionnel Documents

Culture Documents

IK1M Sootblower

Transféré par

bigsteve90880 évaluation0% ont trouvé ce document utile (0 vote)

212 vues2 pagesIK1M Sootblower

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentIK1M Sootblower

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

212 vues2 pagesIK1M Sootblower

Transféré par

bigsteve9088IK1M Sootblower

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

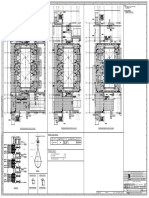

IK-1M™

Part Retractable Sootblower

General on an individual basis to provide element across the boiler.

The IK-1M™ is a part maximum cleaning result. Blowing medium, controlled by

retractable sootblower designed an integral poppet valve, is

to clean the heat transfer Jet Elements transmitted to the nozzles on

surfaces of boilers firing ash The IK-1M™ jet element is the element through a feed tube

producing fuels. permanently located inside the to provide the required cleaning

Applications include coal or oil boiler and is available in a energy. The complete

fired boilers, economisers, air variety of materials to match mechanism is supported and

heaters, fluidised bed, waste strength, temperature and protected by a rigid beam.

heat, HRSG, Co-Gen and corrosion requirements for each

Biomass boilers. unique region of your boiler. Operating Cycle

Material selection is based on The operating cycle begins with

Cleaning Principle the flue gas composition and the IK-1M™ in the fully-

The IK-1M™ cleans the heating gas temperatures. retracted position. When power

surfaces with jets of high is applied to the drive motor, the

pressure air or steam. A series Drive Arrangement carriage moves forward and a

of nozzles, positioned on a The carriage has a travelling trip pin on the carriage operates

travelling jet element, traverses motor drive, which, through the poppet valve linkage to

the cleaning area before reduction gearing and a lead open the poppet valve, thus

returning to the rest position screw, translates the carriage admitting blowing medium to

ready for the next cycle. The along a supporting guide tube.

element is permanently located A lance tube, attached to the

inside the boiler and is designed carriage, propels a multi-jet

the cleaning element. The normally operated from a maintenance purposes.

carriage continues its forward remote panel in the control

movement until a trip bracket room. Control options available Health & Safety

operates the front limit switch. include, local push-buttons on All Diamond Power®

This action reverses the drive the terminal box and operation sootblowers are provided with

motor rotation and the carriage from an individual starter box protective guard arrangements

movement. As the carriage adjacent to the soot blower. to provide personnel safety from

reaches its retracted position, Once started the IK-1M™ goes moving parts and hot surfaces

the trip pin again operates the through its cleaning cycle in full compliance with the EU

valve linkage to close the valve. automatically. Limit switches Machinery Directive.

The trip bracket operates the control the extent of travel and

rear limit switch to stop the are automatically reset at the

Options:

sootblower at the rest position. end of the cleaning cycle.

Oscillating carriage design

The IK-1M™ can also be

available.

Operating Controls operated manually in the event

The IK-1M™ sootblower is of power failure and for

Specifications:

Blower Travel/Coverage Travel up to 1,500mm / Coverage up to 18,500mm

Motor Data Single Electric Motor: 0.55 kW, TEFC, IP55

Travel Speed 10.2mm/s with 25mm Helix

Blowing medium valve Diamond Power® mechanically operated poppet valve with integral pressure adjustment.

Blowing Medium Steam or air up to 128barg at 500°C.

Feed tube material 304 Stainless Steel, ground and polished OD

Jet Tube Carbon steel, low alloy chromium molybdenum steel and high alloy stainless steel.

3

Plus Pressure Seal Air 0.54-1.8 Nm /min 150mm W.G. above furnace pressure.

Protection Fully guarded in compliance with EC Machinery Directives.

www.diamondpower.co.uk

This information contained herein is solely for informational purposes and is not

offered, nor should be construed as a warranty or contractual obligation. Diamond

Power International, Inc. reserves the right to make design or material changes

without notice.

©2013 Diamond Power International, Inc. All rights reserved. DPSL-4110-0613-01

Vous aimerez peut-être aussi

- Asset Integrity Management A Complete Guide - 2020 EditionD'EverandAsset Integrity Management A Complete Guide - 2020 EditionPas encore d'évaluation

- Root Cause Failure AnalysisDocument12 pagesRoot Cause Failure AnalysisHaidar YafiePas encore d'évaluation

- CAT DewranceDocument93 pagesCAT DewranceHorvatAladar100% (1)

- Tanjung Jati B Training: SootblowersDocument26 pagesTanjung Jati B Training: SootblowersKaremBenzema100% (3)

- 04 AD 0042 Burner Maintenance FloorDocument1 page04 AD 0042 Burner Maintenance FloorPradip Tapan BanerjeePas encore d'évaluation

- T20 Retractable SootblowerDocument4 pagesT20 Retractable SootblowerBadukwangPas encore d'évaluation

- Sootblowing System PDFDocument8 pagesSootblowing System PDFilhamPas encore d'évaluation

- ASME PTC 17-1991-Reciprocating IC Engines HighlightedDocument40 pagesASME PTC 17-1991-Reciprocating IC Engines Highlightedlahiru1983100% (1)

- Sop BoilerDocument3 pagesSop BoilerBentar ELcPas encore d'évaluation

- Clyde Bergemann PDFDocument6 pagesClyde Bergemann PDFenjineringPas encore d'évaluation

- Boiler & AuxiliariesDocument13 pagesBoiler & Auxiliariesprats123456Pas encore d'évaluation

- Cable Trench Installation Guide PDFDocument12 pagesCable Trench Installation Guide PDFecruz_yhwhPas encore d'évaluation

- Prominent Equipment Catalogue 2011Document751 pagesProminent Equipment Catalogue 2011saber66Pas encore d'évaluation

- Api StandartDocument2 pagesApi Standartyg89Pas encore d'évaluation

- Birkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Document52 pagesBirkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Mark RomeroPas encore d'évaluation

- Technical Bulletin: AudcoDocument12 pagesTechnical Bulletin: AudcoHrushikesh ReddyPas encore d'évaluation

- Valve SymbolsDocument20 pagesValve Symbolsrajesh100% (1)

- Coal Burner Write UpDocument3 pagesCoal Burner Write UpSagala Giridhar100% (1)

- Sealing Gasket (ENKA)Document6 pagesSealing Gasket (ENKA)Apras TyoPas encore d'évaluation

- Specification For PE Pipes FittingsDocument32 pagesSpecification For PE Pipes FittingsFlorian_AngererPas encore d'évaluation

- Steam Separator and Steam Trap Are Almost Same in FunctionDocument7 pagesSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERPas encore d'évaluation

- Flame ScannerDocument72 pagesFlame ScannerRavi Sankar MuthuPas encore d'évaluation

- Table of Content: Elbow Trimming ProcedureDocument5 pagesTable of Content: Elbow Trimming ProcedureMechanical Static WRKPas encore d'évaluation

- Atlas Copco Air Hoists and Trolleys UK Tcm795-1621198Document8 pagesAtlas Copco Air Hoists and Trolleys UK Tcm795-1621198Urip S. SetyadjiPas encore d'évaluation

- Inspection On EconomiserDocument2 pagesInspection On Economiserkrishna50% (2)

- CompressorDocument29 pagesCompressorShashi Naganur100% (1)

- Section 9-Inspection-Philosophy PDFDocument20 pagesSection 9-Inspection-Philosophy PDFWinsonLimHuiWahPas encore d'évaluation

- IGB016.E1-Centrifugal Fan New PDFDocument13 pagesIGB016.E1-Centrifugal Fan New PDFSusan LamPas encore d'évaluation

- CatalogueDocument429 pagesCatalogueHarkamal SinghPas encore d'évaluation

- Forbes Marshall Turbine Bypass ValvesDocument28 pagesForbes Marshall Turbine Bypass Valveser_sanjaypatelPas encore d'évaluation

- Know About Power Cord TypesDocument5 pagesKnow About Power Cord TypesHassan MalikPas encore d'évaluation

- Quick-Opening Closures SurveyDocument13 pagesQuick-Opening Closures SurveyAjmi HmidaPas encore d'évaluation

- Persta Gate Valves PDFDocument52 pagesPersta Gate Valves PDFSalah InhgaruoPas encore d'évaluation

- NUTORK Pneumatic ActuatorDocument13 pagesNUTORK Pneumatic ActuatorAkmal ZuhriPas encore d'évaluation

- Persta Industrie eDocument140 pagesPersta Industrie ezoraze32Pas encore d'évaluation

- Probar Flowmeter: Product Data Sheet 00813-0100-4761 Ds-4010Document128 pagesProbar Flowmeter: Product Data Sheet 00813-0100-4761 Ds-4010tungluongPas encore d'évaluation

- Hopkinson Valves IOM ManualDocument7 pagesHopkinson Valves IOM ManualGiorgiana RosuPas encore d'évaluation

- Elastomers: Dr. Dmitri KopeliovichDocument10 pagesElastomers: Dr. Dmitri KopeliovichBara Giat PrakarsaPas encore d'évaluation

- Commissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaDocument21 pagesCommissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaParthiban KarunaPas encore d'évaluation

- Animasi PLTUDocument4 pagesAnimasi PLTUAngjuang Adi Panji PratamaPas encore d'évaluation

- Taijune Fire Tube Steam BoilerDocument8 pagesTaijune Fire Tube Steam BoilerAjay GoswamiPas encore d'évaluation

- Vacuum - Condenser Presentasi 2Document17 pagesVacuum - Condenser Presentasi 2Neon PhoerbaPas encore d'évaluation

- Manajemen Rantai Pasok Komoditas Ternak Eed29e7a PDFDocument16 pagesManajemen Rantai Pasok Komoditas Ternak Eed29e7a PDFWahdaniahPas encore d'évaluation

- GB 5296.1-2012 (GB5296.1-2012) - Translated English of Chinese StandardDocument12 pagesGB 5296.1-2012 (GB5296.1-2012) - Translated English of Chinese StandardZheng WenruiPas encore d'évaluation

- Sree TB 0002Document12 pagesSree TB 0002Tanmoy DuttaPas encore d'évaluation

- Weldolet InfoDocument4 pagesWeldolet InfoChoon Wei WongPas encore d'évaluation

- Control Valve Calibration (ABB Positioner)Document2 pagesControl Valve Calibration (ABB Positioner)farrukh MajeedPas encore d'évaluation

- Control Valve CharacteristicsDocument3 pagesControl Valve CharacteristicsgifitrianggraeniPas encore d'évaluation

- 5 Poppet ValvesDocument14 pages5 Poppet ValvesVIJAYIOCLPas encore d'évaluation

- Pltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)Document5 pagesPltu: Boiler Stoker:: Sesuai Data Unit: Sesuai Data Unit: Mei 2020 (Rev 00)sandrositohangPas encore d'évaluation

- Tank Inspectiom ChecksheetDocument3 pagesTank Inspectiom Checksheetyskushwah16100% (1)

- Steam Blowing - Disturbance Factor Discusstion2 PDFDocument5 pagesSteam Blowing - Disturbance Factor Discusstion2 PDFchem_taPas encore d'évaluation

- Speed & Load Control of TurbineDocument12 pagesSpeed & Load Control of Turbinekalaivani sPas encore d'évaluation

- D720-Standard Test Method For Free-Swelling Index of CoalDocument5 pagesD720-Standard Test Method For Free-Swelling Index of CoalTitin KustiniPas encore d'évaluation

- Steam Power Plant and CoalDocument74 pagesSteam Power Plant and CoalRahul SoniPas encore d'évaluation

- Coal BurnerDocument11 pagesCoal BurnerGeorge Markas50% (2)

- Manual Dci DX LPRDocument24 pagesManual Dci DX LPRsaiful anwarPas encore d'évaluation

- Ik 545Document2 pagesIk 545Xuân Định LêPas encore d'évaluation

- 580sk Turbo 1993 (dc5)Document20 pages580sk Turbo 1993 (dc5)bitubogdanPas encore d'évaluation

- Engine Power: SAE J1349, Net 345kw (463 HP) @1,800 RPM Operational Weight: 70,100kg - STD. Bucket Capacity (SAE) : 3.0 4.5 MDocument20 pagesEngine Power: SAE J1349, Net 345kw (463 HP) @1,800 RPM Operational Weight: 70,100kg - STD. Bucket Capacity (SAE) : 3.0 4.5 Mpoeloe nagaPas encore d'évaluation

- TechSessionI Benchmarking SartorDocument33 pagesTechSessionI Benchmarking Sartorbigsteve9088Pas encore d'évaluation

- Effects of High Fuel Loading and CO2 Dilution On Oxymethane IgnitionDocument27 pagesEffects of High Fuel Loading and CO2 Dilution On Oxymethane Ignitionbigsteve9088Pas encore d'évaluation

- Building Design Process and Cost Swegon 2008Document67 pagesBuilding Design Process and Cost Swegon 2008bigsteve9088Pas encore d'évaluation

- Project Big GreenDocument23 pagesProject Big Greenbigsteve9088Pas encore d'évaluation

- Data Center Cooling PDFDocument16 pagesData Center Cooling PDFGonzalo Prado100% (1)

- Erjiang Hu, Xiaotian Li, Xin Meng, Yizhen Chen, Yu Cheng, Yongliang Xie, Zuohua HuangDocument10 pagesErjiang Hu, Xiaotian Li, Xin Meng, Yizhen Chen, Yu Cheng, Yongliang Xie, Zuohua Huangbigsteve9088Pas encore d'évaluation

- Primer ArticuloDocument9 pagesPrimer ArticuloOsvaldo OrozcoPas encore d'évaluation

- Gas Turbine Parts Life ExtensionDocument27 pagesGas Turbine Parts Life Extensionbigsteve9088Pas encore d'évaluation

- Carbon: Piyas Chowdhury, Huseyin Sehitoglu, Richard RateickDocument12 pagesCarbon: Piyas Chowdhury, Huseyin Sehitoglu, Richard Rateickbigsteve9088Pas encore d'évaluation

- Explosion Protection - Using The DatabaseDocument39 pagesExplosion Protection - Using The Databasebigsteve9088Pas encore d'évaluation

- Designing TurbogeneratorDocument6 pagesDesigning TurbogeneratorMadhan GopalPas encore d'évaluation

- Steam Turbine GeneratorsDocument13 pagesSteam Turbine GeneratorsPiNGPooNGPas encore d'évaluation

- Article Excerpts From Cec Report 1702Document34 pagesArticle Excerpts From Cec Report 1702bigsteve9088Pas encore d'évaluation

- GER 3695e GE Aeroderivative Gas Turbines Design and Operating FeaturesDocument24 pagesGER 3695e GE Aeroderivative Gas Turbines Design and Operating FeaturesTony AppsPas encore d'évaluation

- ABB Manual PDFDocument264 pagesABB Manual PDFСемён СемёновичPas encore d'évaluation

- Fundamentals of Generator ProtectionDocument124 pagesFundamentals of Generator ProtectionZaks More100% (1)

- Vibration IsolationDocument14 pagesVibration IsolationYogesh100% (7)

- APN-053 Auxiliary Devices For Generator Protection PDFDocument24 pagesAPN-053 Auxiliary Devices For Generator Protection PDFbigsteve9088Pas encore d'évaluation

- Sermaloy J Diffused Slurry Aluminide Coating: AdvantagesDocument1 pageSermaloy J Diffused Slurry Aluminide Coating: Advantagesbigsteve9088Pas encore d'évaluation

- Brushless Excitation System of Turbo GeneratorDocument8 pagesBrushless Excitation System of Turbo Generatorbigsteve9088Pas encore d'évaluation

- Balance This! - Peg&TdfDocument22 pagesBalance This! - Peg&TdfMarimuthu AyyamperumalPas encore d'évaluation

- 30 PTT Motor Maintenance Mersen PDFDocument14 pages30 PTT Motor Maintenance Mersen PDFMohamed ShabanPas encore d'évaluation

- High-Temperature Low-Cycle-Fatigue and Crack-Growth BehaviorDocument331 pagesHigh-Temperature Low-Cycle-Fatigue and Crack-Growth Behaviorbigsteve9088Pas encore d'évaluation

- EP05 2003-NonDestructiveExaminationDocument21 pagesEP05 2003-NonDestructiveExaminationbigsteve9088Pas encore d'évaluation

- Rotor Bore Inspections PDFDocument1 pageRotor Bore Inspections PDFbigsteve9088Pas encore d'évaluation

- Coolprop PDFDocument79 pagesCoolprop PDFakbarfarrazPas encore d'évaluation

- 05pipenetwork Analysis PDFDocument49 pages05pipenetwork Analysis PDFbigsteve9088Pas encore d'évaluation

- 1295 ThomasDocument6 pages1295 Thomasbigsteve9088Pas encore d'évaluation

- Actuators: On Hirth Ring Couplings: Design Principles Including The Effect of FrictionDocument21 pagesActuators: On Hirth Ring Couplings: Design Principles Including The Effect of Frictionbigsteve9088Pas encore d'évaluation

- 3 Thermal Barrier CoatingDocument10 pages3 Thermal Barrier CoatingHernan GirautPas encore d'évaluation

- Triumph Service Bulletin 1954Document98 pagesTriumph Service Bulletin 1954tr_freundePas encore d'évaluation

- Coroa e Pinhao MBDocument1 pageCoroa e Pinhao MBtoninhomelotti_53173Pas encore d'évaluation

- Grumman AA-5B 1977-79 POH SearchableDocument192 pagesGrumman AA-5B 1977-79 POH Searchablesplyn100% (1)

- SGN 1793532Document2 pagesSGN 1793532Hai Thang BaPas encore d'évaluation

- XC40 2018Document8 pagesXC40 2018Najib JonPas encore d'évaluation

- Stray Current Calculation and Monitoring in DC Mass-Transit SystemsDocument8 pagesStray Current Calculation and Monitoring in DC Mass-Transit SystemsPrasenjit DeyPas encore d'évaluation

- LED Lighting Distribution Types: Quick Reference Guide Type IDocument2 pagesLED Lighting Distribution Types: Quick Reference Guide Type IwsilvacPas encore d'évaluation

- MSC Vietnam Gazette Issue 3Document8 pagesMSC Vietnam Gazette Issue 3Ho NaPas encore d'évaluation

- Receipt, Storage, Erection & Processing of Transformer at SiteDocument71 pagesReceipt, Storage, Erection & Processing of Transformer at Sitep m yadavPas encore d'évaluation

- Motor Vehicles Act, 1988 PDFDocument15 pagesMotor Vehicles Act, 1988 PDFDhwanit RathorePas encore d'évaluation

- Research DesignDocument2 pagesResearch DesignRAMAKRISHNANPas encore d'évaluation

- Central in ADocument18 pagesCentral in AJorge A. Moreno PitonesPas encore d'évaluation

- The Alaska-Siberia Connection. The World War II Air Route (Texas A&m Univ.)Document148 pagesThe Alaska-Siberia Connection. The World War II Air Route (Texas A&m Univ.)dopeyagainPas encore d'évaluation

- 40tonx58 Span-CraneDocument7 pages40tonx58 Span-CraneKoresh KhalpariPas encore d'évaluation

- Soal PAS Ganjil Bahasa Inggris 12 2022Document3 pagesSoal PAS Ganjil Bahasa Inggris 12 2022Ermina carterPas encore d'évaluation

- Tugboat - ULUCAYDocument6 pagesTugboat - ULUCAYudelmarkPas encore d'évaluation

- Master (Unlimited) Orals Report - 2023-11 - Frood - PassDocument5 pagesMaster (Unlimited) Orals Report - 2023-11 - Frood - PassAnish MohandasPas encore d'évaluation

- MRL - Paint Crayon-2Document1 pageMRL - Paint Crayon-2Febriono AdiPas encore d'évaluation

- Manual Road Side Dust Cleaning MachineDocument11 pagesManual Road Side Dust Cleaning MachineKALYAN KUMAR100% (1)

- 2023 CSW BrochureDocument2 pages2023 CSW BrochureWNDUPas encore d'évaluation

- Sea of Thieves Player Guide-1Document25 pagesSea of Thieves Player Guide-1AloPas encore d'évaluation

- Community ChecklistDocument3 pagesCommunity Checklistasdf521Pas encore d'évaluation

- WBM - 2018-02 - Top 50 WineriesDocument164 pagesWBM - 2018-02 - Top 50 Wineriesbwright888Pas encore d'évaluation

- Upaya Percepatan Pembangunan Jalan Tol Trans SumateraDocument9 pagesUpaya Percepatan Pembangunan Jalan Tol Trans Sumateradina15amaliaPas encore d'évaluation

- Tad740-1032-1630-1631 & TWD740-1210-1232-1630Document68 pagesTad740-1032-1630-1631 & TWD740-1210-1232-1630Rath Asypaden100% (1)

- Hydraulic Elevator Drives: Product OverviewDocument4 pagesHydraulic Elevator Drives: Product OverviewDxPas encore d'évaluation

- Install Torque Strut at Front AxleDocument4 pagesInstall Torque Strut at Front AxleNoir OctobrePas encore d'évaluation

- Cokaliong Vs UcpbDocument11 pagesCokaliong Vs UcpbRavenFoxPas encore d'évaluation

- Aventador Oil ChangeDocument4 pagesAventador Oil Changeharmeet kaur100% (2)

- Rini - Operating Table RiEye Mk2 (Edited)Document2 pagesRini - Operating Table RiEye Mk2 (Edited)jalan jalanPas encore d'évaluation

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceD'EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResiliencePas encore d'évaluation

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!D'EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Pas encore d'évaluation

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsD'EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050D'EverandA Pathway to Decarbonise the Shipping Sector by 2050Pas encore d'évaluation

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersD'EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsD'EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsPas encore d'évaluation

- Renewable Energy: A Very Short IntroductionD'EverandRenewable Energy: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsD'EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsPas encore d'évaluation

- Gas-Liquid And Liquid-Liquid SeparatorsD'EverandGas-Liquid And Liquid-Liquid SeparatorsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Global Landscape of Renewable Energy FinanceD'EverandGlobal Landscape of Renewable Energy FinancePas encore d'évaluation

- ISO 50001: A strategic guide to establishing an energy management systemD'EverandISO 50001: A strategic guide to establishing an energy management systemPas encore d'évaluation

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerD'EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerPas encore d'évaluation

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977D'EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Pas encore d'évaluation

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successD'EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Grid-Scale Energy Storage Systems and ApplicationsD'EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuPas encore d'évaluation

- The Way Home: Tales from a life without technologyD'EverandThe Way Home: Tales from a life without technologyÉvaluation : 4 sur 5 étoiles4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsPas encore d'évaluation