Académique Documents

Professionnel Documents

Culture Documents

Bigboss Cement Mill Data

Transféré par

herwinCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bigboss Cement Mill Data

Transféré par

herwinDroits d'auteur :

Formats disponibles

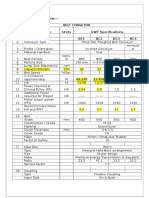

BIG BOSS CEMENT

PROCESS SPECIFICATION

Capacity

Feed size

Output product fineness - oversize

Output product fineness - size of screen

Diameter ( inside shell)

Length ( shell out to out )

Rotation speed ( 74 % critical speed)

Manufacturer

Type

Number of grinding compartments

Type of liner , 1st compartment

Type of liner , 2nd compartment

Grinding length, 1st compartment

Grinding length, 2nd compartment

Thickness of central shell

Thickness of sliding path shell

Thickness of shell under girth gear

Diameter of shoe bearings

Size of Hydrodynamic shoes

Material : Shell

Material : Endplate

Material : Partition grates

Material : Bearing

Material : Liner

Number of manholes

Water spray injection

Grinding media : type, material, hardness

Compartment no. 1 : Charge --filling & ball size

Compartment no. 2 : Charge --filling & ball size

Girth gear : Pitch dia., Number of teeth, Module, Width of tooth

Pinion :Qty,, Pitch dia., Number of teeth, Module, Width of tooth

Drive : Type , Installed power , Absorbed power--motor shaft at 27% filling, Specific power consumption

Main Reducers : Qty., Type, Reducing ratio, Input, Output

Auxiliary drive : Type, Qty., Mill rotation at low speed

S CEMENT

UNITS CEMENT BALL MILL

t/h 100 / 150

mm max 50

g/cm2 3200 Blaine

microns 325

mm 3800

mm 13000

rpm 21.7

FTM

ball mill

no. 2

lifting

ripple type liner w/dam rings

mm 4635

mm 7935

mm 48

mm 95

mm

mm 4990

mm 1260 X 760

A42CP ( tp 1010)

A42CP ( tp 1010)

laminated steel

babbit metal ( TP 3350)

cast chrome steel

no. 2

yes / no none

ball/cyl pebs, steel cast, 550 - 600 HB

123200 kgs, 32%, 90 to 50mm

246300 kgs, 32%, 50 to 20mm

Single Pinion Drive , 2500 kw, 2500 kw, 1776 rpm, 33.5 kwh/t

1 no., divised torque system, 67.59 , 980 rpm, 14.5 rpm

electrical, 1 no., 10 to 12 rph

Vous aimerez peut-être aussi

- SBU URB PlatformDocument6 pagesSBU URB PlatformMusaab MohamedPas encore d'évaluation

- Revised Data SheetDocument11 pagesRevised Data Sheetbashok20Pas encore d'évaluation

- Bi-Metal Tek Screw: Product DatasheetDocument1 pageBi-Metal Tek Screw: Product Datasheetbravo deltafoxPas encore d'évaluation

- RM1 TEKSCREW & SKYLIGHT CANVASSDocument7 pagesRM1 TEKSCREW & SKYLIGHT CANVASSCapitol Steel ConstructionPas encore d'évaluation

- PB Canang Mechine SpecsDocument1 pagePB Canang Mechine SpecsRely TokPas encore d'évaluation

- Husky G-PET - Product GuideDocument19 pagesHusky G-PET - Product GuideDawn UnderPas encore d'évaluation

- Noida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadDocument116 pagesNoida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadLOHITH N100% (1)

- EvolutionTekDatasheet PDFDocument1 pageEvolutionTekDatasheet PDFRobPas encore d'évaluation

- SE50EV AspecsMETRICDocument1 pageSE50EV AspecsMETRICJean AlexPas encore d'évaluation

- Tungsten Carbide Mill Rolls and Guide RollersDocument2 pagesTungsten Carbide Mill Rolls and Guide RollersQuy SopPas encore d'évaluation

- NPA104 enDocument4 pagesNPA104 enAdelino GasparPas encore d'évaluation

- Hitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164Document11 pagesHitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164patrickhoyer93Pas encore d'évaluation

- DS Berthiez enDocument12 pagesDS Berthiez enSanjay MehrishiPas encore d'évaluation

- Presentacion de ROCK DRILLDocument13 pagesPresentacion de ROCK DRILLsergio mataPas encore d'évaluation

- Multifunctional Lathe Machine CQ6232GZDocument4 pagesMultifunctional Lathe Machine CQ6232GZAbdelbasset ZaraiPas encore d'évaluation

- Tescpech - VIB. Screen & Primary Crusher 500 TPHDocument1 pageTescpech - VIB. Screen & Primary Crusher 500 TPHariyanagung29Pas encore d'évaluation

- Moment Connection DETAIL 2Document5 pagesMoment Connection DETAIL 2way2vaseemPas encore d'évaluation

- Plastic Injection Moulding Machines: Mega NH SeriesDocument12 pagesPlastic Injection Moulding Machines: Mega NH SeriesMarcelo BonePas encore d'évaluation

- 4 KL Reactor Data SheetDocument4 pages4 KL Reactor Data Sheetpankil patelPas encore d'évaluation

- HMT RM65 Radial DrillDocument2 pagesHMT RM65 Radial Drillsomnath213Pas encore d'évaluation

- Mag Drains Grated Outlets Cleanouts Product Range WebDocument16 pagesMag Drains Grated Outlets Cleanouts Product Range WebSopheareak ChhanPas encore d'évaluation

- CatalogueDocument8 pagesCataloguesriganeshmaharshiPas encore d'évaluation

- Tube Mill ChartDocument152 pagesTube Mill ChartppglPas encore d'évaluation

- CatlogDocument14 pagesCatlogKajal MathurPas encore d'évaluation

- MillDocument15 pagesMillChandan KumarPas encore d'évaluation

- Innovative Reliable EconomicalDocument2 pagesInnovative Reliable EconomicaliVAN čOLAKPas encore d'évaluation

- PR05 - Grid 2-BDocument123 pagesPR05 - Grid 2-BJustinPas encore d'évaluation

- Daemo Eng (2ba)Document20 pagesDaemo Eng (2ba)Jairresistenciagt123Pas encore d'évaluation

- 1500 IngDocument10 pages1500 IngAhmadPas encore d'évaluation

- Vertical Injection Molding MachineDocument6 pagesVertical Injection Molding MachineendeshawPas encore d'évaluation

- RollDocument20 pagesRollVicente GarcíaPas encore d'évaluation

- Tuc SandvikDocument2 pagesTuc SandvikYsraels Santisteban DurandPas encore d'évaluation

- Well P&A Program TestDocument6 pagesWell P&A Program TestThem Bui XuanPas encore d'évaluation

- Code Description Unit Basic Rate Asonor Just Before 01.04 2023 NoDocument1 pageCode Description Unit Basic Rate Asonor Just Before 01.04 2023 Noabhay kumarPas encore d'évaluation

- DW 2560 EngDocument2 pagesDW 2560 EngWaldemar JęczewskiPas encore d'évaluation

- Spec-Sheet DX200ADocument16 pagesSpec-Sheet DX200APurnama JayaPas encore d'évaluation

- CABEÇOTES - HTT - Stanki - Glubokogo - SverleniyaDocument12 pagesCABEÇOTES - HTT - Stanki - Glubokogo - Sverleniyacarolina lopesPas encore d'évaluation

- Strip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNDocument13 pagesStrip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNkushaljp8989Pas encore d'évaluation

- General SpecficationsDocument6 pagesGeneral SpecficationsesooPas encore d'évaluation

- Design of RC Plate Coupling BeamDocument5 pagesDesign of RC Plate Coupling BeamJai ThakkarPas encore d'évaluation

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraPas encore d'évaluation

- B Toku Construction-1Document8 pagesB Toku Construction-1harisPas encore d'évaluation

- Pump Vendor Moniba & PrecisonDocument2 pagesPump Vendor Moniba & Precisonkarthickeyanclass4Pas encore d'évaluation

- PSC1Document3 pagesPSC1amitkuknaPas encore d'évaluation

- Prabhu Reddy Erection & Fabrication Bill of October Month - 2021Document4 pagesPrabhu Reddy Erection & Fabrication Bill of October Month - 2021Shashidhar CholletiPas encore d'évaluation

- SC - CalculationDocument7 pagesSC - CalculationengineerPas encore d'évaluation

- 13 Series Industrial Grinder - BrochureDocument2 pages13 Series Industrial Grinder - BrochureAnil Kumar KnPas encore d'évaluation

- Gaintry Girder: A B A BDocument11 pagesGaintry Girder: A B A BPratikPas encore d'évaluation

- Timber: 650kg/m, Or750kg/m When It Is Air-DriedDocument9 pagesTimber: 650kg/m, Or750kg/m When It Is Air-DriedNegrea RobertPas encore d'évaluation

- KEDA Quotation of 2 3 4 Inch Mini Gold DredgerDocument3 pagesKEDA Quotation of 2 3 4 Inch Mini Gold DredgerShane CapstickPas encore d'évaluation

- Daily Mud Report No. 62: Bit Information Bit Hydraulics VOLUMES (BBL)Document5 pagesDaily Mud Report No. 62: Bit Information Bit Hydraulics VOLUMES (BBL)Tahir Iqbal. Kharpa RehanPas encore d'évaluation

- Ec254tr & Entire CalculationsDocument6 pagesEc254tr & Entire CalculationsVinay KPas encore d'évaluation

- Z-Carb JetStream SpeedFeedDocument2 pagesZ-Carb JetStream SpeedFeedalphatoolsPas encore d'évaluation

- SpecificationDocument6 pagesSpecificationMOHAMAD AMIR BIN HALIDPas encore d'évaluation

- QT Alu Scrap Recycling Line 5-10tonsDocument6 pagesQT Alu Scrap Recycling Line 5-10tonsMohammedPas encore d'évaluation

- OML Updated 190222Document1 pageOML Updated 190222Md Mehedi HasanPas encore d'évaluation

- Height Depth: The World's Is Determined by Our DrillingDocument2 pagesHeight Depth: The World's Is Determined by Our Drillingyo2k_123Pas encore d'évaluation

- RCC DesignDocument39 pagesRCC DesignMariappan .PPas encore d'évaluation

- Charge Inventory & CompositionDocument2 pagesCharge Inventory & CompositionherwinPas encore d'évaluation

- Charge Inventory & CompositionDocument2 pagesCharge Inventory & CompositionherwinPas encore d'évaluation

- Gypsum Weigh Feeder Calibration Report Trial # C-Factor Actual Totalizer Difference Tonnage 1 2 3 4 5 6Document2 pagesGypsum Weigh Feeder Calibration Report Trial # C-Factor Actual Totalizer Difference Tonnage 1 2 3 4 5 6herwinPas encore d'évaluation

- Grinding With Ball Mill Systems: SeparatingDocument64 pagesGrinding With Ball Mill Systems: SeparatingVishnu Vardhan . C100% (3)

- Baraoas Day Care CenterDocument1 pageBaraoas Day Care CenterherwinPas encore d'évaluation

- Cement ChemicalDocument1 pageCement ChemicalherwinPas encore d'évaluation

- A Method To Determine The Ball Filling, in Miduk Copper Concentrator SAG MillDocument5 pagesA Method To Determine The Ball Filling, in Miduk Copper Concentrator SAG MillherwinPas encore d'évaluation

- List of EmployeesdateDocument1 pageList of EmployeesdateherwinPas encore d'évaluation

- Rotary Dryer Start UpDocument2 pagesRotary Dryer Start UpherwinPas encore d'évaluation

- Bbci Process InterlocksDocument37 pagesBbci Process InterlocksherwinPas encore d'évaluation

- Compatibility Report For Ball Charge Design Mill 2Document3 pagesCompatibility Report For Ball Charge Design Mill 2herwinPas encore d'évaluation

- CCR Logsheet BbciDocument1 pageCCR Logsheet BbciherwinPas encore d'évaluation

- 2016-6-7 First 30% Delivered Equipment ListDocument2 pages2016-6-7 First 30% Delivered Equipment ListherwinPas encore d'évaluation

- Bbci Process InterlocksDocument31 pagesBbci Process InterlocksherwinPas encore d'évaluation

- Balik-Manggagawa Information Sheet: Appointment Date: January 05, 2016 09:00 AMDocument2 pagesBalik-Manggagawa Information Sheet: Appointment Date: January 05, 2016 09:00 AMherwinPas encore d'évaluation

- La Union Concrete Services IncDocument4 pagesLa Union Concrete Services IncherwinPas encore d'évaluation

- Transmission NoiseDocument5 pagesTransmission Noiseأحمد دعبس100% (1)

- Saint - Seiya - Cosmo - Fantasy - Guide by Bigolewom RutisDocument3 pagesSaint - Seiya - Cosmo - Fantasy - Guide by Bigolewom RutisAsael HyūgaPas encore d'évaluation

- SportsDocument18 pagesSportsRoger MelkoPas encore d'évaluation

- 1/2LH - PE Report Comments - Semester 1, 2020 - Tracey KennedyDocument2 pages1/2LH - PE Report Comments - Semester 1, 2020 - Tracey Kennedytracey kennedyPas encore d'évaluation

- Doosan DX35Z Track Excavator Service Repair Workshop Manua (SN 5001 and Up)Document10 pagesDoosan DX35Z Track Excavator Service Repair Workshop Manua (SN 5001 and Up)Manuals CE & AgPas encore d'évaluation

- Pekanbaru Film Equipment RentalDocument1 pagePekanbaru Film Equipment RentalAhmad Alfaruqi nasutionPas encore d'évaluation

- Front Chainwheel: Chain Guard TypeDocument1 pageFront Chainwheel: Chain Guard TypeStefan NeukamPas encore d'évaluation

- CMC ST 350: Compost TurnerDocument2 pagesCMC ST 350: Compost TurnerCarlosPas encore d'évaluation

- Charlie The Duck - DOS - ManualDocument1 pageCharlie The Duck - DOS - Manualemh.emhPas encore d'évaluation

- 01 To 15 AUGUST GAURAV BHAI DAILY PDFDocument508 pages01 To 15 AUGUST GAURAV BHAI DAILY PDFrupaPas encore d'évaluation

- DL650K9Document187 pagesDL650K9Juan Abraham AjpopPas encore d'évaluation

- Remote DuplicatorDocument7 pagesRemote DuplicatorDamir SasaPas encore d'évaluation

- Drumeo Edge 1627Document3 pagesDrumeo Edge 1627Tinavalw DenexwideaPas encore d'évaluation

- Nemesis Rules Summary V4Document6 pagesNemesis Rules Summary V4Xan CamposPas encore d'évaluation

- AuctionPricelist PDFDocument28 pagesAuctionPricelist PDFben foldsPas encore d'évaluation

- Sport Tournament 6 TeamsDocument18 pagesSport Tournament 6 TeamsChiekoi PasaoaPas encore d'évaluation

- 2nd Semester Pe and Health 11Document3 pages2nd Semester Pe and Health 11Mae Ann Daganos100% (3)

- JMC 2024 Question PaperDocument4 pagesJMC 2024 Question Paperlayden.jp6932Pas encore d'évaluation

- UntitledDocument3 pagesUntitledJaito GalindoPas encore d'évaluation

- U6 Term 1 College History - Days of Warden de SoysaDocument7 pagesU6 Term 1 College History - Days of Warden de SoysaShalila NanayakkaraPas encore d'évaluation

- The Stand User - GM BinderDocument11 pagesThe Stand User - GM BinderJeremiah HodgsonPas encore d'évaluation

- Recreation and Sport Management Template 1 1Document2 pagesRecreation and Sport Management Template 1 1api-689066520Pas encore d'évaluation

- Hose Management Guide: SN: 221 Lines Group - Tilt CylinderDocument66 pagesHose Management Guide: SN: 221 Lines Group - Tilt CylinderIsrael MirandaPas encore d'évaluation

- Production Release: Halliburton Energy Services Product Information ReportDocument7 pagesProduction Release: Halliburton Energy Services Product Information Reportalejandromarinch7Pas encore d'évaluation

- Baduk TerminologyDocument21 pagesBaduk Terminologyramez1863100% (1)

- Fourth Quarterly Test in Mathematics 6Document4 pagesFourth Quarterly Test in Mathematics 6Cher An JiePas encore d'évaluation

- 8 Week Bulk PDFDocument19 pages8 Week Bulk PDFLê Bá Thành PhúPas encore d'évaluation

- PE 101 ManualDocument24 pagesPE 101 ManualNicole VillenaPas encore d'évaluation

- Colombiaf 1Document1 pageColombiaf 1Alonso Pahuacho PortellaPas encore d'évaluation