Académique Documents

Professionnel Documents

Culture Documents

Method Statement For Ductwork Leakage Testing: Guthrie Engineering (S) Pte LTD Marina Bay Residences

Transféré par

Nguyễn Hồng TháiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Method Statement For Ductwork Leakage Testing: Guthrie Engineering (S) Pte LTD Marina Bay Residences

Transféré par

Nguyễn Hồng TháiDroits d'auteur :

Formats disponibles

GUTHRIE ENGINEERING (S) PTE LTD

MARINA BAY RESIDENCES

METHOD STATEMENT FOR DUCTWORK LEAKAGE

TESTING

Preparation Work before testing

1. Make sure that the right type of test rig is available for the job. A rig is suitable for high pressure

leakage testing is seldom suitable or economic for testing low or medium pressure ductwork, and vice

versa.

2. Note that leakage testing is always done under positive pressure even when the ductwork is to operate

under negative pressure.

3. Testing should be completed before insulation or enclosure of duct and before terminal units.

4. Inspect all duct sections to make sure that factory applied sealants have not been damaged in transit.

Make good where any damage is noticed.

5. Ensure the correct gasket material has been supplied for your situation and the application is in

accordance with the manufacturer’s instructions and then apply the sealants as necessary.

6. Pay special attention to the sealing of joints that will be difficult to reach after erection of the ductwork.

7. Fix the blanking plates or other types of temporary seal in the positions shown by the drawing.

8. At the earliest opportunity agree with the client or his clerk of works on a testing programme or method

statement.

9. Ensure that the ductwork has been correctly manufactured and site sealant correctly applied it is

essential that a preliminary test is carried out before presentation to the client.

Sequence of Test

1. Prepare test sheet.

2. Connect and adjust test apparatus to correct pressure.

3. Read off leakage rate.

4. Reseal if necessary (allow time to cure).

5. Maintain test for 15 mins.

6. Switch off and allow to zero.

7. Reapply test pressure and check reading.

8. Record details on test sheet and obtain signature.

9. If these preliminary tests show that the leakage is over the limit, then:

a. Look for any obvious places where there may be leaks, for example, an open access door or missing

or punctured polythene blanks.

b. Reseal or correct where you have found the leakage source.

c. Repeat the test after allowing enough time for the sealant to set.

10. When satisfied with the results of the preliminary tests, then:

a. Offer the section to the client’s representative for formal acceptance.

b. A permanent record of tests must be retained.

c. As test are satisfactorily completed, remove all blanking off devices.

GUTHRIE ENGINEERING (S) PTE LTD

7 STOREY INDUSTRIAL DEVELOPMENT AT DEPOT ROAD

STANDARD TESTING PROCEDURE FOR FANCOIL UNIT

Vous aimerez peut-être aussi

- Reinforcement Pad Leak Test Procedure - Method StatementDocument6 pagesReinforcement Pad Leak Test Procedure - Method StatementJaveed A. KhanPas encore d'évaluation

- Method Statement - HVAC Duct Leakage Testing ProcedureDocument7 pagesMethod Statement - HVAC Duct Leakage Testing ProcedureSyed TouqeerPas encore d'évaluation

- Completion Equipment ChecklistDocument3 pagesCompletion Equipment ChecklistYougchu LuanPas encore d'évaluation

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahPas encore d'évaluation

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeePas encore d'évaluation

- Pneumatic Test - Write UpDocument7 pagesPneumatic Test - Write UpDilip0% (1)

- LEAK TEST Method Statement Ponticelli & Total Petroleum.Document7 pagesLEAK TEST Method Statement Ponticelli & Total Petroleum.Fasola Lawal100% (4)

- Sprinkler MethodDocument6 pagesSprinkler Methodakram husseinPas encore d'évaluation

- Testing Preparation and ExecutionDocument2 pagesTesting Preparation and ExecutionCharlie Dela RosaPas encore d'évaluation

- Method Statement For The Installation of Water Treatment PlantDocument12 pagesMethod Statement For The Installation of Water Treatment Plantafraz_xec89% (18)

- Hydrostatic Testing: Anyone To Stand Near The Ends of The Assembly While It Is Under PressureDocument1 pageHydrostatic Testing: Anyone To Stand Near The Ends of The Assembly While It Is Under PressureMuhammad Azlan AhmadPas encore d'évaluation

- Duct Leakage Test ProcedureDocument6 pagesDuct Leakage Test Procedurerefri24100% (1)

- Installation of Firefighting SystemDocument2 pagesInstallation of Firefighting SystemvenkatPas encore d'évaluation

- Pressure Testing Fire Water LineDocument9 pagesPressure Testing Fire Water Linesharif339Pas encore d'évaluation

- Hydrotest Procedure C 6 23Document19 pagesHydrotest Procedure C 6 23savanth jayaramPas encore d'évaluation

- Method Statement For Drainage & Vent PipingDocument6 pagesMethod Statement For Drainage & Vent Pipingsujan19800% (1)

- Installation, Assembly and Test Procedure: Kamos Patented Kammprofil GasketDocument16 pagesInstallation, Assembly and Test Procedure: Kamos Patented Kammprofil Gasketjayhuacat7743Pas encore d'évaluation

- Hot-Tapping ProceduresDocument2 pagesHot-Tapping ProceduresBensmatPas encore d'évaluation

- Method Statement For Refrigerant Piping Installation and Pressure TestingDocument4 pagesMethod Statement For Refrigerant Piping Installation and Pressure TestingRyan WongPas encore d'évaluation

- MS of Hydrotest Procedure SSDP Rev CDocument39 pagesMS of Hydrotest Procedure SSDP Rev CRachel FloresPas encore d'évaluation

- Fluid Sealing Standards For NMEJ StandardsDocument9 pagesFluid Sealing Standards For NMEJ Standardsamol1321Pas encore d'évaluation

- Pressure Testing of Pipelines: CR Asia GroupDocument7 pagesPressure Testing of Pipelines: CR Asia Groupvishal bailurPas encore d'évaluation

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDocument5 pagesRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatPas encore d'évaluation

- Assignment 5Document7 pagesAssignment 5Sharizada KanapiyevaPas encore d'évaluation

- Chamber Test of BOPDocument7 pagesChamber Test of BOPadeelsn100% (2)

- Method of Statement VBDocument9 pagesMethod of Statement VBAhmed IrakyPas encore d'évaluation

- Method of Statement For Pressure Testing ProceduresDocument3 pagesMethod of Statement For Pressure Testing ProceduresBen Lim82% (11)

- Pneumatic Testing Procedure For PipelinesDocument3 pagesPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinPas encore d'évaluation

- Air Leak TestingDocument5 pagesAir Leak Testingkusdiyanta100% (2)

- Task Method StatementsDocument18 pagesTask Method StatementsnikzafriPas encore d'évaluation

- Method of Statement Testing of PipeDocument5 pagesMethod of Statement Testing of PipevpamatyaPas encore d'évaluation

- Guidelines For Hydrostatic Leak TeatingDocument4 pagesGuidelines For Hydrostatic Leak TeatingClyde CoopperPas encore d'évaluation

- Skimming Job GeneralDocument5 pagesSkimming Job Generalvishal bailurPas encore d'évaluation

- Method Statement Upvc Above GroundDocument2 pagesMethod Statement Upvc Above GroundMohammad AbrarPas encore d'évaluation

- Boiler Installation and SetupDocument30 pagesBoiler Installation and Setupcakhokhe100% (1)

- Method of Statement For Pressure Test PDFDocument2 pagesMethod of Statement For Pressure Test PDFBen Lim0% (1)

- METHOD STATEMENT FOR HYDRO-TESTING OF CONDENSATE DRAIN PIPINGDocument7 pagesMETHOD STATEMENT FOR HYDRO-TESTING OF CONDENSATE DRAIN PIPINGAnish KumarPas encore d'évaluation

- Method Statement For DuctworksDocument4 pagesMethod Statement For DuctworksJAY ROD AWITPas encore d'évaluation

- Commissioning Checklist For Sewerage Pumping StationsDocument3 pagesCommissioning Checklist For Sewerage Pumping Stationssajidziyan67% (3)

- Pneumatic Testing Procedure For Mechanical EquipmentDocument39 pagesPneumatic Testing Procedure For Mechanical EquipmentCepi Sindang KamulanPas encore d'évaluation

- SVQ Level 3 Carpentry & Joinery Skills Test GuideDocument19 pagesSVQ Level 3 Carpentry & Joinery Skills Test Guideian griffinPas encore d'évaluation

- Method Statement Piping Works DABBIYADocument11 pagesMethod Statement Piping Works DABBIYAsivaparthiban100% (3)

- Pressure Testing ProcedureDocument7 pagesPressure Testing ProcedureChristopher uche100% (1)

- PRO-EnV-SITE-SPV-031 - A - IFR - Gross Leak Test and Service Test ProcedureDocument2 pagesPRO-EnV-SITE-SPV-031 - A - IFR - Gross Leak Test and Service Test Procedurerizki projectPas encore d'évaluation

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahPas encore d'évaluation

- Wet Scrubber ManualDocument15 pagesWet Scrubber ManualYusak Santoso Use100% (1)

- Method Statement - Drain PipingDocument17 pagesMethod Statement - Drain PipingAnish KumarPas encore d'évaluation

- Installation Procedure Kamos RTJ GasketDocument16 pagesInstallation Procedure Kamos RTJ Gasketekhwanhakim100% (3)

- GGG-STD-ONM-0005 - Live and New Pipeline Connection Procedure - Rev 01Document12 pagesGGG-STD-ONM-0005 - Live and New Pipeline Connection Procedure - Rev 01oleg safaniukPas encore d'évaluation

- Vessel Pressure TestingDocument3 pagesVessel Pressure Testingalokbdas100% (1)

- Vacume Box Test ProcedureDocument5 pagesVacume Box Test ProcedureFarhan Sheikh100% (2)

- Rreinforcement Pad Leak Test ProcedureDocument5 pagesRreinforcement Pad Leak Test ProcedureAmin Thabet100% (1)

- Fsa PSJ 701 06 PDFDocument9 pagesFsa PSJ 701 06 PDFAshitava SenPas encore d'évaluation

- Choke manifold HP test offline rig unitDocument1 pageChoke manifold HP test offline rig unitayhamPas encore d'évaluation

- Procedure for safe isolation of hydrocarbon pipingDocument6 pagesProcedure for safe isolation of hydrocarbon pipingkategord0% (1)

- Method of Statement FirefightingDocument10 pagesMethod of Statement FirefightingswamyPas encore d'évaluation

- Method of Statement FirefightingDocument10 pagesMethod of Statement FirefightingJesin Abdul Jaleel A82% (11)

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamD'EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- HVAC - Duct ConstructionDocument75 pagesHVAC - Duct ConstructionGaapchu100% (2)

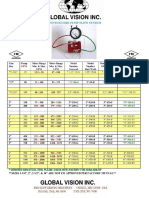

- Single-Screw Chiller-Rating Output: Daikin Industries, LTDDocument1 pageSingle-Screw Chiller-Rating Output: Daikin Industries, LTDNguyễn Hồng TháiPas encore d'évaluation

- Water Cooled Centrifugal Chiller: Technical Data SheetDocument2 pagesWater Cooled Centrifugal Chiller: Technical Data SheetNguyễn Hồng TháiPas encore d'évaluation

- Venturi Fire Pump Test Meter - FM Approved-Made in USA - Dong Ho Do Nuoc Bom Chua Chay Venturi IVA VIETNAMDocument2 pagesVenturi Fire Pump Test Meter - FM Approved-Made in USA - Dong Ho Do Nuoc Bom Chua Chay Venturi IVA VIETNAMNguyễn Hồng TháiPas encore d'évaluation

- Pressure Leak Testing GuideDocument20 pagesPressure Leak Testing Guidefezzeh kabiri kenari100% (1)

- MS-E-001 MV Recloser Installation WorkDocument11 pagesMS-E-001 MV Recloser Installation WorkNguyễn Hồng TháiPas encore d'évaluation

- Water Cooled Centrifugal Chiller: Technical Data SheetDocument2 pagesWater Cooled Centrifugal Chiller: Technical Data SheetNguyễn Hồng TháiPas encore d'évaluation

- Van An ToànDocument5 pagesVan An ToànNguyễn Hồng TháiPas encore d'évaluation

- Hdpe SpecDocument34 pagesHdpe SpecjimmylmpPas encore d'évaluation

- Hdpe SpecDocument34 pagesHdpe SpecjimmylmpPas encore d'évaluation

- Piping Pressure TestDocument2 pagesPiping Pressure TestNguyễn Hồng TháiPas encore d'évaluation

- Claim ListDocument52 pagesClaim Listsui1981100% (2)

- Piezoelectric Cantilever Prototype For Energy Harvesting in Computing ApplicationsDocument4 pagesPiezoelectric Cantilever Prototype For Energy Harvesting in Computing ApplicationsEsthi KusumaPas encore d'évaluation

- Laser Welding Steel Wheel RimsDocument5 pagesLaser Welding Steel Wheel RimsSamanthaPereraPas encore d'évaluation

- Concrete Cube Compression TestDocument3 pagesConcrete Cube Compression TestTanu RdPas encore d'évaluation

- Saniware CatalogueDocument90 pagesSaniware CatalogueSewei SiewPas encore d'évaluation

- Microstructure and Mechanical Properties of Polypropylene/ Polycarbonate BlendsDocument4 pagesMicrostructure and Mechanical Properties of Polypropylene/ Polycarbonate BlendsMonali ChhatbarPas encore d'évaluation

- 1 Introduction To Bridge EngineeringDocument46 pages1 Introduction To Bridge EngineeringRYAN JOSEPH QUIMOPas encore d'évaluation

- Optimize HV Series Belt Drive Fan Product SpecsDocument5 pagesOptimize HV Series Belt Drive Fan Product SpecsTanveer AzizPas encore d'évaluation

- Design of ChimneyDocument13 pagesDesign of Chimneyjay_p_shahPas encore d'évaluation

- FIVDocument60 pagesFIVSaurabh Shukla100% (2)

- Precast HandbookDocument179 pagesPrecast HandbookFernando LopezPas encore d'évaluation

- Hysol MB 50Document2 pagesHysol MB 50Vusal HasanovPas encore d'évaluation

- Introduction To Boundary LayerDocument14 pagesIntroduction To Boundary LayerAyman KeirPas encore d'évaluation

- Tools and Materials of ConstructionDocument10 pagesTools and Materials of ConstructionvoyferPas encore d'évaluation

- Demolish and Extension BoQ - Supply and Installation - 141019Document3 pagesDemolish and Extension BoQ - Supply and Installation - 141019Patrick SipatelaPas encore d'évaluation

- 5 PilecapDocument6 pages5 PilecapMaheshPas encore d'évaluation

- Fire Protection ProductsDocument56 pagesFire Protection ProductsHector Dario Tobon BenjumeaPas encore d'évaluation

- Chapter 2Document19 pagesChapter 2rain583Pas encore d'évaluation

- LECTURE No. 7. LOW MELTING CRYOGENIC ALLOYS-MARAGING-SUPERALLOYSDocument8 pagesLECTURE No. 7. LOW MELTING CRYOGENIC ALLOYS-MARAGING-SUPERALLOYSBizuayehu Tadesse AzenePas encore d'évaluation

- WB4303EDocument1 pageWB4303EcwiksjPas encore d'évaluation

- Stone Slope StabilityDocument9 pagesStone Slope Stabilitypakbilal1Pas encore d'évaluation

- Sertifikat ASTM 1BDocument18 pagesSertifikat ASTM 1BPrasetya Siregar100% (1)

- Applications of Second Law of ThermodynamicsDocument18 pagesApplications of Second Law of Thermodynamicss100% (1)

- Implementing Intelligent Sootblowing ControlDocument6 pagesImplementing Intelligent Sootblowing ControlenjineringPas encore d'évaluation

- Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular Duct (Fluid Exp 5)Document9 pagesAir Flow Velocity and Pressure Coefficient Around The 90o Rectangular Duct (Fluid Exp 5)hayder alaliPas encore d'évaluation

- Qcs 2010 Part 15 Hot Weather Concreting PDFDocument6 pagesQcs 2010 Part 15 Hot Weather Concreting PDFRotsapNayrbPas encore d'évaluation

- Awwa Manual M11 - 1Document1 pageAwwa Manual M11 - 1agung_gpePas encore d'évaluation

- Pages Fs2005 Protective - Coating Rev 2Document6 pagesPages Fs2005 Protective - Coating Rev 2roshanmechPas encore d'évaluation

- House that Rains Light and ColorDocument16 pagesHouse that Rains Light and Colorrupali latePas encore d'évaluation

- Reference Data - Metric Conversion ChartDocument20 pagesReference Data - Metric Conversion ChartmshedidPas encore d'évaluation