Académique Documents

Professionnel Documents

Culture Documents

Dynasty 280 OFI Quick Reference 263081A

Transféré par

ahmedCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dynasty 280 OFI Quick Reference 263081A

Transféré par

ahmedDroits d'auteur :

Formats disponibles

Tungsten Selection and Prep AC Waveshape Controls

Tungsten Type Application Notes Diameter Amp Range Feature Setting Arc Effect Weld Effect

Good all-around tungsten for 0.020" 5–20

2% Cerium AC Balance Control Reduces balling

both AC and DC welding. 0.040" 10–80

Controls arc cleaning action. 75% EN action and helps

1/16" 10–150 maintain point Bead

Adjusting the % EN of the AC

Excellent low amp starts for 3/32" 60–250 wave controls the width of

Current

1.5 –2% Lanthanum % EP

AC and DC welding. 1/8" 100–400 the etching zone surrounding 0

5/32" 160–500 the weld.

% EN

Minimum visible

Commonly used for DC welding, 3/16" 190–750 Time oxide removal (etching)

2% Thorium Note: Set the AC Balance control

not ideal for AC. 1/4" 325–1100

for adequate arc cleaning Increases balling

PURE TUNGSTEN (green) is NOT recommended!

See Owner’s Manual

(etching) action at the sides 50% EN action of the

For best results in most applications use a sharpened and in front of the weld puddle. electrode Bead

for more information. AC Balance should be fine-tuned

Current

cerium or lanthanum electrode for AC and DC welding. % EP

according to the amount of 0

Visible oxide

% EN

etching desired. removal (etching)

Tungsten Preparation: Sharpen tungsten for AC and DC welding with the Dynasty. Time

CORRECT INCORRECT IDEAL GRIND ANGLE RANGE AC Frequency Control Wider profile

Ideal preparation — stable arc Wrong preparation — wandering arc Controls the width of the arc

60 Hz ideal for buildup work

15˚ to 30˚ cone. Increasing the AC Bead

Straight ground Radial ground

Current

Frequency provides a more 0

% EP

Arc wander focused arc and increased % EN

Visible oxide

Stable arc

AC EFFECT directional control. Time removal (etching)

Blunt tip Pointed tip Note: Decreasing the AC

Slight meltback Frequency softens the arc and Narrower profile

Grinding Grinding

wheel wheel

of electrode tip broadens the weld puddle for a 120 Hz for fillet welds

wider weld. and automated Bead

Note: Do not use wheel for other jobs or tungsten can become contaminated.

Current

%

EP

%

EP applications

0

Tip: Blunting the tip of the electrode is sometimes done to help maintain consistent geometry and resist % EN % EN Visible oxide

tungsten erosion. This is especially helpful in AC when melt-back of the tungsten electrode is common. Time removal (etching)

Pulsed TIG Controls

The Pulsed TIG function switches the amperage from a high (peak) to a low (background) at a set rate (PPS). Pulsing can reduce

heat input by lowering the average amperage, increasing control of the weld puddle, penetration and distortion. The following

parameters can be adjusted for desired results:

Parameter Control Panel Abbreviation Adjustment

Pulses Per Second PPS Rate of pulsing between high and low

Low-Speed Pulse High-Speed Pulse

1 to 10 pulses per second (PPS) will produce a distinct 100 pulses per second (PPS) and higher helps to focus the arc

ripple pattern in the weld bead. Can be used to time filler for increased stability, penetration and travel speed. Increased

addition, reduce distortion and improve control. puddle agitation improves weld microstructure.

Focused arc increases travel speed

and penetration

Distinct ripple pattern Narrow bead and HAZ

Tip: Begin welding at factory default settings of 100 PPS, 40% peak and 25% background amps. Adjust the frequency (PPS)

MillerWelds.com to change width and appearance.

# 263081A © 2013 Miller Electric Mfg. Co.

Vous aimerez peut-être aussi

- Assignment No. 4 BlankDocument15 pagesAssignment No. 4 BlankahmedPas encore d'évaluation

- Btus, CFMS, and Gges DemystifiedDocument2 pagesBtus, CFMS, and Gges DemystifiedahmedPas encore d'évaluation

- Grade Structure Revamping TemplateDocument1 pageGrade Structure Revamping TemplateahmedPas encore d'évaluation

- Department OF Mechanical Engineering Technology: Heat Engines LaboratoryDocument2 pagesDepartment OF Mechanical Engineering Technology: Heat Engines LaboratoryahmedPas encore d'évaluation

- Department OF Mechanical Engineering Technology: Materials Testing LaboratoryDocument2 pagesDepartment OF Mechanical Engineering Technology: Materials Testing LaboratoryahmedPas encore d'évaluation

- Method of Calculating The Cooling Rate in HAZ During WeldingDocument6 pagesMethod of Calculating The Cooling Rate in HAZ During WeldingahmedPas encore d'évaluation

- Grinding Wheel SpecificationsDocument2 pagesGrinding Wheel SpecificationsahmedPas encore d'évaluation

- Measuring Metal Strength (Tensile & Impact Strength)Document5 pagesMeasuring Metal Strength (Tensile & Impact Strength)ahmedPas encore d'évaluation

- Drill Bit Size ChartDocument22 pagesDrill Bit Size ChartahmedPas encore d'évaluation

- Why Is "Cold Cutting" Superior To Plasma Cutting?Document9 pagesWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedPas encore d'évaluation

- What Is Hsla SteelDocument4 pagesWhat Is Hsla SteelahmedPas encore d'évaluation

- Deposition RateDocument4 pagesDeposition Rateahmed100% (1)

- ASGEpg187 PDFDocument3 pagesASGEpg187 PDFbkprodhPas encore d'évaluation

- To Be Free From Oil and Dirt ADAPTOR, CGA-022 To 1/4 NPT GDG PSMDocument1 pageTo Be Free From Oil and Dirt ADAPTOR, CGA-022 To 1/4 NPT GDG PSMahmedPas encore d'évaluation

- Corrosion and RustDocument9 pagesCorrosion and RustahmedPas encore d'évaluation

- Help Welding Calculation - WeldingDocument14 pagesHelp Welding Calculation - Weldingahmed100% (1)

- UNCUNF Threads - SizeDocument1 pageUNCUNF Threads - SizeahmedPas encore d'évaluation

- What Is Mild SteelDocument2 pagesWhat Is Mild SteelahmedPas encore d'évaluation

- Understanding Copper AlloysDocument1 pageUnderstanding Copper AlloysahmedPas encore d'évaluation

- Difference Between Pipe and Tube: ShapeDocument3 pagesDifference Between Pipe and Tube: ShapeahmedPas encore d'évaluation

- The National Institute For Occupational Safety and Health (Niosh)Document1 pageThe National Institute For Occupational Safety and Health (Niosh)ahmedPas encore d'évaluation

- Equipment Operation: Safety GuidelinesDocument4 pagesEquipment Operation: Safety GuidelinesahmedPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Level 2 Online BPDocument98 pagesLevel 2 Online BProbertduvallPas encore d'évaluation

- AYURVEDA Products CatalogDocument17 pagesAYURVEDA Products CatalogFoutanke TorodoPas encore d'évaluation

- 2022+ACCF+111+Class+test+2 Moderated+versionDocument8 pages2022+ACCF+111+Class+test+2 Moderated+versionLucas LuluPas encore d'évaluation

- Tle7 Ict TD M2 V3Document28 pagesTle7 Ict TD M2 V3Rowemar Corpuz100% (1)

- 3 - RA-Erecting and Dismantling of Scaffolds (WAH) (Recovered)Document6 pages3 - RA-Erecting and Dismantling of Scaffolds (WAH) (Recovered)hsem Al EimaraPas encore d'évaluation

- ASWP Manual - Section 1 - IntroductionDocument17 pagesASWP Manual - Section 1 - Introductionjmvm56Pas encore d'évaluation

- MT6580 Android Scatter FRPDocument7 pagesMT6580 Android Scatter FRPTudor Circo100% (1)

- Description Features: Maximizing IC PerformanceDocument1 pageDescription Features: Maximizing IC Performanceledaurora123Pas encore d'évaluation

- WCDMA19 Prfile Descriptions W19P8 08A APPRDocument254 pagesWCDMA19 Prfile Descriptions W19P8 08A APPRoaguilar83Pas encore d'évaluation

- Fatty AcidsDocument13 pagesFatty AcidsRaviraj MalaniPas encore d'évaluation

- Learning Activity Sheet Pre-Calculus: Science Technology Engineering and Mathematics (STEM) Specialized SubjectDocument26 pagesLearning Activity Sheet Pre-Calculus: Science Technology Engineering and Mathematics (STEM) Specialized SubjectJanet ComandantePas encore d'évaluation

- Financial Statements Ias 1Document34 pagesFinancial Statements Ias 1Khalid AzizPas encore d'évaluation

- Chapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16Document81 pagesChapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16mohamed hemdanPas encore d'évaluation

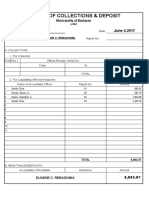

- RCD - SEF (Liquidating)Document40 pagesRCD - SEF (Liquidating)Chie NemzPas encore d'évaluation

- Javascript PrefiDocument66 pagesJavascript Prefiguendelyn omegaPas encore d'évaluation

- Ponce vs. Court of AppealsDocument7 pagesPonce vs. Court of AppealsMp CasPas encore d'évaluation

- Sacramento County Compensation Survey Board of SupervisorsDocument13 pagesSacramento County Compensation Survey Board of SupervisorsCBS13Pas encore d'évaluation

- Unit-4.Vector CalculusDocument32 pagesUnit-4.Vector Calculuskhatua.deb87Pas encore d'évaluation

- Curriculum Vitae: Mobile No: +917019900128 E-MailDocument5 pagesCurriculum Vitae: Mobile No: +917019900128 E-MailJay MPas encore d'évaluation

- AWP 4A Syllabus Fall 2021 (Misinformation)Document11 pagesAWP 4A Syllabus Fall 2021 (Misinformation)camPas encore d'évaluation

- Tes - 29 October 2021 UserUploadNetDocument120 pagesTes - 29 October 2021 UserUploadNetTran Nhat QuangPas encore d'évaluation

- Scriptcase MacrosDocument6 pagesScriptcase MacrosMeliana WangPas encore d'évaluation

- Cultures of The West A History, Volume 1 To 1750 3rd PDFDocument720 pagesCultures of The West A History, Volume 1 To 1750 3rd PDFtonnyPas encore d'évaluation

- Planting Guide For Rice 1. Planning and BudgetingDocument4 pagesPlanting Guide For Rice 1. Planning and BudgetingBraiden ZachPas encore d'évaluation

- Hex 33 X 80Document1 pageHex 33 X 80PurchasePas encore d'évaluation

- Docker Tutorial: Anthony BaireDocument99 pagesDocker Tutorial: Anthony BairesuderPas encore d'évaluation

- Issues in Corporate GovernanceDocument15 pagesIssues in Corporate GovernanceVandana ŘwţPas encore d'évaluation

- Principles of Public ExpenditureDocument1 pagePrinciples of Public ExpenditureNikhil Shenai100% (1)

- Republic V Mangotara DigestDocument3 pagesRepublic V Mangotara DigestMickey Ortega100% (1)

- Lorenzo JDocument2 pagesLorenzo Japi-528402595Pas encore d'évaluation