Académique Documents

Professionnel Documents

Culture Documents

Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©

Transféré par

Manzar KhanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©

Transféré par

Manzar KhanDroits d'auteur :

Formats disponibles

Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©Compiled

by Goutham Rathinam, AweldI®, CWSIP 3.1 (TWI,UK)

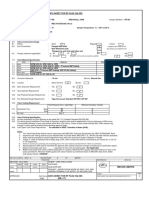

Code Reference Minimum Hydrostatic Testing Maximum Permissible Test Pressure Minimum Test Pressure Gages Test Temperature Limits Service

Calculation Hold Time

ASME BPVC Sec I PG-99.1 1.5 x Maximum Allowable Working No part of the boiler shall be subjected to a general Power Boiler:General

Pressure (MAWP) membrane stress greater than 90% of its yield strength

(0.2% offset) at test temperature. The primary

membrane stress to which boiler components are

subjected during hydrostatic test shall be taken into

account when designing the components.

ASME BPVC Sec I PG-99.2 The metal temperature shall not Power Boiler:General

exceed 120°F (50°C) during the

close visual examination

ASME BPVC Sec I PG-99.3.1 1.5 x MAWP Power Boiler:Super Heater

ASME BPVC Sec I PG-99.3.1 1.25 x MAWP Power Boiler:Other parts excluding

Boiler external piping

ASME BPVC Sec I PG-99.4.2 not less than 1½ times that Power Boiler:Other parts excluding

Test Pressure Boiler external piping

ASME BPVC Sec I PMB-21.1 3 x MAWP Miniature boiler pressure vessel

ASME BPVC Sec I PMB-21.2 1.5 x MAWP Power Boiler external piping

ASME BPVC Sec I A-22.9 1.5 x MAWP Power Boiler:Duplicate parts

ASME BPVC Sec I A-22.11.2 not less than 1½ times that Power Boiler:Duplicate parts

Test Pressure

ASME BPVC Sec III Div I NB NB-2330 (a) (2) not greater than RTNDT+ 60°F Nuclear:Class 1 Components

(RTNDT + 33°C)

RTNDT = Drop weight Impact

Toughness Test temperature

ASME BPVC Sec III Div I NB NB-3226 ( c ) (1) For Pm ≤ 0.67Sy Pm + Pb ≤ 1.35 Sy Nuclear:Class 1 Components

(2) For 0.67Sy < Pm ≤ 0.90Sy

Pm + Pb ≤ (2.15 Sy - 1.2Pm)

Pm - Primary membrane stress intensity;

Pb - Bending stress intensity

Sy - Yield Strength

ASME BPVC Sec III Div I NB NB-6221 (a) 1.25 x Design Pressure Nuclear:Class 1 Components

ASME BPVC Sec III Div I NB NB-6223 10 mins Nuclear:Class 1 Components

ASME BPVC Sec III Div I NB NB-6412 not less than 1½ times nor Nuclear:Class 1 Components

more than 4 times theTest

Pressure

ASME BPVC Sec III Div I NC NC-3218 (b) (1) For Pm ≤ 0.67Sy Pm + Pb ≤ 1.35 Sy Nuclear:Class 2 Components

(2) For 0.67Sy < Pm ≤ 0.90Sy

Pm + Pb ≤ (2.15 Sy - 1.2Pm)

Pm - Primary membrane stress intensity;

Pb - Bending stress intensity

Sy - Yield Strength

ASME BPVC Sec III Div I NC NC-6212 (b) not lower than RTNDT+ 60°F Nuclear:Class 2 Components

(RTNDT + 33°C)

ASME BPVC Sec III Div I NC NC-6221 (a) 1.25 x Design Pressure RTNDT = Reference Temperature Nuclear:Class 2 Components

ASME BPVC Sec III Div I NC NC-6223 10 mins Nuclear:Class 2 Components

ASME BPVC Sec III Div I NC NC-6412 not less than 1½ times nor Nuclear:Class 2 Components

more than 4 times theTest

Pressure

ASME BPVC Sec III Div I ND ND-6212 (b) not lower than RTNDT+ 60°F Nuclear:Class 3 Components

(RTNDT + 33°C)

RTNDT = Drop weight Impact

Toughness Test temperature

ASME BPVC Sec III Div I ND ND-6221 (a) 1.25 x Design Pressure Nuclear:Class 3 Components

ASME BPVC Sec III Div I ND ND-6223 10 mins Nuclear:Class 3 Components

ASME BPVC Sec III Div I ND ND-6412 not less than 1½ times nor Nuclear:Class 3 Components

more than 4 times theTest

Pressure

ASME BPVC Sec III Div I NE NE-3226 (a) (1) For Pm ≤ 0.67Sy Pm + Pb ≤ 1.35 Sy Nuclear:Class MC Components

(2) For 0.67Sy < Pm ≤ 0.90Sy

Pm + Pb ≤ (2.15 Sy - 1.2Pm)

Pm - Primary membrane stress intensity;

Pb - Bending stress intensity

Sy - Yield Strength

©Copyright: Goutham Rathinam and

www.weldingandndt.com Disclaimer: Prepared for Educational Purpose Only Page 1 of 5

Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©Compiled by Goutham Rathinam, AweldI®, CWSIP 3.1 (TWI,UK)

Code Reference Minimum Hydrostatic Testing Maximum Permissible Test Pressure Minimum Test Pressure Gages Test Temperature Limits Service

Calculation Hold Time

ASME BPVC Sec III Div I NE NE-6212 (b) not lower than RTNDT+ 60°F Nuclear:Class MC Components

(RTNDT + 33°C)

RTNDT = Drop weight Impact

Toughness Test temperature

ASME BPVC Sec III Div I NE NE-6221 1.2 x Design Pressure Nuclear:Class MC Components

ASME BPVC Sec III Div I NE NE-6223 10 mins Nuclear:Class MC Components

ASME BPVC Sec III Div I NE NE-6412 not less than 1½ times nor Nuclear:Class MC Components

more than 4 times theTest

Pressure

ASME BPVC Sec III Div I NH NH-6212 not lower than RTNDT+ 60°F Nuclear:Class 1 Components in Elevated

(RTNDT + 33°C) Temperature Service

RTNDT = Drop weight Impact

Toughness Test temperature

ASME BPVC Sec III Div I NH NH-6215 10 mins Nuclear:Class 1 Components in Elevated

Temperature Service

ASME BPVC Sec III Div I NH NH-6221 (a) 1.25 x Design Pressure Nuclear:Class 1 Components in Elevated

Temperature Service

ASME BPVC Sec III Div I NH NH-6400 not less than 1½ times nor Nuclear:Class 1 Components in Elevated

more than 4 times theTest Temperature Service

Pressure

ASME BPVC Sec III Div III WB-3225 (a) TO (d) (1) For Pm ≤ 0.67Sy Pm + Pb ≤ 1.35 Sy Nuclear:Class TC Transportation

(2) For 0.67Sy < Pm ≤ 0.90Sy Containments

Pm + Pb ≤ (2.15 Sy - 1.2Pm)

Pm - Primary membrane stress intensity;

Pb - Bending stress intensity

Sy - Yield Strength

ASME BPVC Sec III Div III WB-6212 not lower than RTNDT+ 60°F Nuclear:Class TC Transportation

(RTNDT + 33°C) Containments

RTNDT = Drop weight Impact

Toughness Test temperature

ASME BPVC Sec III Div III WB-6221 (a) 1.5 x Design Pressure Nuclear:Class TC Transportation

Containments

ASME BPVC Sec III Div III WB-6223 10 mins Nuclear:Class TC Transportation

Containments

ASME BPVC Sec III Div III WB-6412 (a) not less than 1½ times nor Nuclear:Class TC Transportation

more than 4 times theTest Containments

Pressure

ASME BPVC Sec III Div III WC-3218 (b) (1) For Pm ≤ 0.67Sy Pm + Pb ≤ 1.35 Sy

(2) For 0.67Sy < Pm ≤ 0.90Sy

Pm + Pb ≤ (2.15 Sy - 1.2Pm)

Pm - Primary membrane stress intensity;

Pb - Bending stress intensity

Sy - Yield Strength

ASME BPVC Sec III Div III WC-6212 not lower than RTNDT+ 60°F Nuclear:Class SC Storage Containments

(RTNDT + 33°C)

RTNDT = Drop weight Impact

Toughness Test temperature

ASME BPVC Sec III Div III WC-6221 1.25 x Design Pressure Nuclear:Class SC Storage Containments

ASME BPVC Sec III Div III WC-6223 10 mins Nuclear:Class SC Storage Containments

ASME BPVC Sec III Div III WC-6412 (a) not less than 1½ times nor Nuclear:Class SC Storage Containments

more than 4 times theTest

Pressure

ASME BPVC Sec III Div V ASME BPVC Sec III (1) For Pm ≤ 0.67Sy Pm + Pb ≤ 1.35 Sy Nuclear:High Temperature Reactors

Div I NB-3226 ( c ) (2) For 0.67Sy < Pm ≤ 0.90Sy

Pm + Pb ≤ (2.15 Sy - 1.2Pm)

Pm - Primary membrane stress intensity;

Pb - Bending stress intensity

Sy - Yield Strength

ASME BPVC Sec III Div V HBB-6212 not lower than RTNDT+ 60°F Nuclear:High Temperature Reactors

(RTNDT + 33°C)

RTNDT = Drop weight Impact

Toughness Test temperature

ASME BPVC Sec III Div V HBB-6215 10 mins Nuclear:High Temperature Reactors

©Copyright: Goutham Rathinam and

www.weldingandndt.com Disclaimer: Prepared for Educational Purpose Only Page 2 of 5

Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©Compiled by Goutham Rathinam, AweldI®, CWSIP 3.1 (TWI,UK)

Code Reference Minimum Hydrostatic Testing Maximum Permissible Test Pressure Minimum Test Pressure Gages Test Temperature Limits Service

Calculation Hold Time

ASME BPVC Sec III Div V HBB-6221 (a) 1.25 x Design Pressure Nuclear:High Temperature Reactors

ASME BPVC Sec III Div V HBB-6400 not less than 1½ times nor Nuclear:High Temperature Reactors

more than 4 times theTest

Pressure

ASME BPVC Sec IV HG-504 1.5 x MAWP Heating Boiler:General

ASME BPVC Sec IV HG-505 not less than 1½ times nor Heating Boiler:General

more than 4 times theTest

Pressure

ASME BPVC Sec IV HG-510 (2) 5 mins Heating Boiler:General

ASME BPVC Sec IV HG-510 (4) ( c ) Shop 1.5 x MAWP 10 psi (70 kPa) Heating Boiler:General

ASME BPVC Sec IV HG-510 (4) ( c ) 2.5 x MAWP or 60 psi (0.400 MPa) Heating Boiler:General

Assembled

ASME BPVC Sec IV HC-402.1 (b) not less than 1½ times nor Heating Boiler:Cast Iron

more than 4 times theTest

Pressure

ASME BPVC Sec IV HC-410.2 Shop 2.5 x MAWP or 60 psi (0.400 MPa) Heating Boiler:Cast Iron

ASME BPVC Sec IV HC-410.2 Assembled 1.5 x MAWP Heating Boiler:Cast Iron

ASME BPVC Sec IV HC-410.3 10 psi (70 kPa) Heating Boiler:Cast Iron

ASME BPVC Sec IV HA-406.1 (b) Shop 2.5 x MAWP or 60 psi (0.400 MPa) Heating Boiler:Cast Aluminium

ASME BPVC Sec IV HA-406.1 (C) Heating Boiler:Cast Aluminium

Assembled

ASME BPVC Sec IV HA-406.2 10 psi (70 kPa) Heating Boiler:Cast Aluminium

ASME BPVC Sec IV HLW-502.2 (b) not less than 1½ times nor Potable-Water Heaters

more than 4 times theTest

Pressure

ASME BPVC Sec IV HLW-505.1 1.5 x MAWP Potable-Water Heaters

ASME BPVC Sec IV HLW-505.2 10 psi (70 kPa) Potable-Water Heaters

ASME BPVC Sec VII 105.8 Test Pressure never exceed 1.5 x MAWP ASME Sec I, PG-99 requires that Care of Power Boilers

and typically is 1.25 x MAWP or lower pressure test water temperature

be a min. of 70°F (20°C) and a

ASME BPVC Sec VIII Div I UG-99 (b) 1.5 x MAWP x LSR⁴ max. of 120°F (50°C) to minimize Pressure Vessel

ASME BPVC Sec VIII Div I UG-99 (h) The metal temperature during a Pressure Vessel

hydrostatic test shall be

maintained at least 17°C (30°F)

above the minimum design metal

temperature of the vessel, but

ASME BPVC Sec VIII Div I UG-102 (b) not less than 1½ times nor need not exceed 50°C (120°F) to Pressure Vessel

more than 4 times theTest

Pressure

ASME BPVC Sec VIII Div I UCI-99 (a) for MAWP> 30 psi (200 kPa) 60 psi (400 kPa) Pressure Vessel

2 x MAWP

for MAWP< 30 psi (200 kPa)

2.5 x MAWP

ASME BPVC Sec VIII Div I UCD-99 (a) 2 x MAWP Pressure Vessel

ASME BPVC Sec VIII Div I ULT-99 1.4 x Design Pressure 15 mins 150°F (65°C) Pressure Vessel

ASME BPVC Sec VIII Div II 8.1.3.1 1.43 x MAWP Pressure Vessel

ASME BPVC Sec VIII Div II 8.1.4 (b) not less than 1½ times nor Pressure Vessel

more than 4 times theTest

Pressure

ASME BPVC Sec VIII Div II 8.2.1 (a) 1.43 x MAWP (Class 1) Pressure Vessel

ASME BPVC Sec VIII Div II 8.2.1 (a) 1.25 x MAWP X LSR (Class 2) Pressure Vessel

ASME BPVC Sec VIII Div II 8.2.4 The metal temperature during a Pressure Vessel

hydrostatic test shall be

maintained at least 17°C (30°F)

above the minimum design metal

temperature of the vessel, but

ASME BPVC Sec VIII Div III KT-311 1.25 x MAWP need not exceed 50°C (120°F) to Pressure Vessel

ASME BPVC Sec VIII Div III KT-320 TCV+ 17°C (30°F); TCV = 10°F (5.6°C) Pressure Vessel

Impact Test Metal Temperature

©Copyright: Goutham Rathinam and

www.weldingandndt.com Disclaimer: Prepared for Educational Purpose Only Page 3 of 5

Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©Compiled by Goutham Rathinam, AweldI®, CWSIP 3.1 (TWI,UK)

Code Reference Minimum Hydrostatic Testing Maximum Permissible Test Pressure Minimum Test Pressure Gages Test Temperature Limits Service

Calculation Hold Time

ASME BPVC Sec VIII Div III KT-410 not less than 1½ times nor Pressure Vessel

more than 4 times theTest

Pressure

ASME BPVC Sec XI IWA-5264 not less than 1½ times nor Inservice inspection of Nuclear Power

more than 4 times theTest Plant

Pressure

ASME BPVC Sec XI Table IWB-5230-1 Test Temperature, °F Test Pressure Inservice inspection of Nuclear Power

(°C) Plant

100 (40) or less 1.10Po

200 (95) 1.08Po

300 (150) 1.06Po

400 (200) 1.04Po

500 (260) or greater 1.02Po

Po is the reactor pressure corresponding to

ASME BPVC Sec XI IWC-5230 1.10 x System Pressure for systems with Design Inservice inspection of Nuclear Power

Temperature of 200°F (95°C) or Plant

ASME BPVC Sec XI IWC-5230 1.25 x System Pressure lesssystems with Design

for Inservice inspection of Nuclear Power

Temperature above 200°F (95°C) Plant

ASME BPVC Sec XI IWD-5230 1.10 x System Pressure for systems with Design Inservice inspection of Nuclear Power

Temperature of 200°F (95°C) or Plant

ASME BPVC Sec XI IWD-5230 1.25 x System Pressure lesssystems with Design

for Inservice inspection of Nuclear Power

Temperature above 200°F (95°C) Plant

ASME BPVC Sec XII TT-210 (a) (1) 1.3 x MAWP Transport Tanks

ASME BPVC Sec XII TT-210 (a) (3) metal temperature during Transport Tanks

hydrostatic test be maintained at

least 17°C (30°F) above the

minimum design metal and to

ASME BPVC Sec XII TT-240 not less than 1½ times nor minimize the risk of brittle Transport Tanks

more than 4 times theTest

Pressure

ASME BPVC Sec XII TP-410.3 (5) (b) 10 mins Transport Tanks

ASME B31.1 137.4.3 1.5 x Design Pressure 10 mins Pressure Piping

ASME B31.1 102.3.3 (B) circumferential (hoop) stress shall not exceed 90% of the Pressure Piping

yield strength (0.2% offset) at test temperature. In

addition, the sum of longitudinal stresses due to test

pressure and live and dead loads at the time of test,

excluding occasional loads, shall not exceed 90% of the

yield strength at test temperature.

ASME B31.2 237.4 1.5 x MAWP Pressure Piping

ASME B31.3 A345.4.2 1.5 x Design Pressure Pressure Piping

ASME B31.3 K345.4.2 1.25 x Design Pressure High Pressure Piping

ASME B31.4 437.4.1 1.25 x Design Pressure not less than 4 hrs General Pipeline

ASME B31.4 C437.4.1 1.1 x Design Pressure not less than 4 hrs Slurry Pipeline

ASME B31.5 538.4.2 (f) 10 min Refrigerent Piping

ASME B31.5 538.6 (a) 1.5 x Design Pressure Refrigerent Piping

ASME B31.8 816 1.25 x MAWP (Class 1) 2 hrs Line Pipe-Gas Transmission

ASME B31.8 816 1.5 x MAWP (Class 2,3,4) Line Pipe-Gas Transmission

ASME B31.8 851.12.1 (d) 1.1 x Maximum Allowable Operating Line Pipe-Gas Transmission

In Service Pressure

ASME B31.8 851.12.2 ½ hr Line Pipe-Gas Transmission

ASME B31.8 A847.2 1.25 x Maximum Allowable Operating Offshore Gas Transmission

ASME B31.8 A847.4 ( c ) 2 hrs Offshore Gas Transmission

ASME B31.9 937.3.4 (a) 1.5 x Design Pressure Building Service Piping

ASME B31.9 937.3.5 10 min Building Service Piping

ASME B31.11 1137.4.1 (2) 1.1 x Design Pressure not less than 4 hrs Slurry Transportation Piping

ASME B31.12 GR-5.17.1 1.5 x Maximum Allowable Operating Industrial Pipeline

In Service Pressure

ASME B31.12 GR-5.17.2 ½ hr Industrial Pipeline

In Service

ASME B31.12 IP-10.6.2 1.5 x Design Pressure Industrial Piping

ASME B31.12 PL-3.10.2 1.5 x Maximum Allowable Operating 2 hrs Industrial Pipeline

API 1111 8.2.4.1 125 % x Maximum Operating Pressure Offshore hydrocarbo Pipeline

API 510 5.8.3.1 1.3 x MAWP x (Stest temp/Sdesign temp) Stest In service inspection of Pressure Vessel

temp = allowable stress at test

temperature in ksi (MPa)

©Copyright: Goutham Rathinam and

www.weldingandndt.com Disclaimer: Prepared for Educational Purpose Only Page 4 of 5

Code Comparison of ASME Boiler and Pressure Vessel Codes, Pressure Piping and API Standard Practices: ©Compiled by Goutham Rathinam, AweldI®, CWSIP 3.1 (TWI,UK)

Code Reference Minimum Hydrostatic Testing Maximum Permissible Test Pressure Minimum Test Pressure Gages Test Temperature Limits Service

Calculation Hold Time

API 510 5.8.7.2 To minimize the risk of brittle In service inspection of Pressure Vessel

fracture during a pressure test,

the metal temperature should be

maintained at least 30 °F (17 °C)

above the MDMT or MAT for

vessels that are more than 2 in.

(5 cm) thick and 10 °F (6 °C)

API 572 9.7.2 above

To the MDMT

minimize or of

the risk MAT for

brittle In service inspection of Pressure Vessel

fracture during a pressure test,

the metal temperature should be

maintained at least 30 °F (17 °C)

above the MDMT or MAT for

vessels that are more than 2 in.

(5 cm) thick and 10 °F (6 °C)

API 579-1 3.6.2.3 above17°C

TCV+ the MDMT or MAT

(30°F);TCV for

= 10°F General

(5.6°C)

API RP 574 10.4.2 1.5 x Design Pressure Impact Test Metal Temperature Piping

API RP 1110 4.1.7-Spike Test > 1.25 x Design Pressure > 5 mins < 1 hour Pipeline

API RP 1110 4.1.7-Strength Test > 1.25 x Design Pressure > 4 hours Pipeline

API RP 1110 4.1.7-Leak Test > 1.25 x Design Pressure ≥ 2 hours Pipeline

©Copyright: Goutham Rathinam and

www.weldingandndt.com Disclaimer: Prepared for Educational Purpose Only Page 5 of 5

Vous aimerez peut-être aussi

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Abdomen - FRCEM SuccessDocument275 pagesAbdomen - FRCEM SuccessAbin ThomasPas encore d'évaluation

- Asimov Quick MathsDocument190 pagesAsimov Quick MathsDani Ibrahim100% (2)

- Zexel VRZ Pump PDFDocument12 pagesZexel VRZ Pump PDFalvarikokexPas encore d'évaluation

- Closure Weld RequirementsDocument1 pageClosure Weld RequirementsManzar Khan0% (1)

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasPas encore d'évaluation

- Section Viii Div 1 Div 2 Div ComparisonDocument2 pagesSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- PSV Sizing Tool API Based Calc Sheets PDFDocument11 pagesPSV Sizing Tool API Based Calc Sheets PDFLucas Farias0% (1)

- Asme Boiler and Pressure Vessel Code 2017Document6 pagesAsme Boiler and Pressure Vessel Code 2017kalpesh parmarPas encore d'évaluation

- Space DynamicsDocument37 pagesSpace Dynamicspurushottam KashyapPas encore d'évaluation

- The Temple of ChaosDocument43 pagesThe Temple of ChaosGauthier GohorryPas encore d'évaluation

- Purine Table Provides Foods Highest and Moderately High in PurinesDocument10 pagesPurine Table Provides Foods Highest and Moderately High in PurinesYohan Parulian SinagaPas encore d'évaluation

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Stage 2 TDBFPDocument56 pagesStage 2 TDBFPvijaykrishnatenneti100% (2)

- PSV Sizing Tool API Based Calc SheetsDocument11 pagesPSV Sizing Tool API Based Calc Sheetsvigneshpingkoo78750% (1)

- Sradham ChecklistDocument9 pagesSradham ChecklistpswaminathanPas encore d'évaluation

- Stair Construction and LayoutDocument13 pagesStair Construction and LayoutManzar Khan100% (1)

- Code PresentationDocument60 pagesCode PresentationwenigmaPas encore d'évaluation

- RPG-7 Rocket LauncherDocument3 pagesRPG-7 Rocket Launchersaledin1100% (3)

- Asme CSD-1 2009Document80 pagesAsme CSD-1 2009Mohd Idris Mohiuddin100% (2)

- 02 05 01 MB OkDocument35 pages02 05 01 MB OkdadrahimPas encore d'évaluation

- Module 8 - MaintDocument19 pagesModule 8 - MaintWilliam RuizPas encore d'évaluation

- Applying boiler codes to steam systemsDocument4 pagesApplying boiler codes to steam systemsChem.EnggPas encore d'évaluation

- AC Split Duct Midea.Document105 pagesAC Split Duct Midea.Muhammad FauzulPas encore d'évaluation

- PSV Sizing Tool - API BasedDocument11 pagesPSV Sizing Tool - API BasedJoseph Paul Ilagan0% (1)

- Change Gout - The Gout Diet PDFDocument2 pagesChange Gout - The Gout Diet PDFManzar Khan100% (1)

- 2016-6 TechPresentation McLaughlinDocument13 pages2016-6 TechPresentation McLaughlinMarco Aurelio FreschiPas encore d'évaluation

- Asme b31.1 Code JurisdictionDocument5 pagesAsme b31.1 Code JurisdictionSajin ChandranPas encore d'évaluation

- RECLASSIFICATION OF SRU EQUIPMENT TO ASMEDocument5 pagesRECLASSIFICATION OF SRU EQUIPMENT TO ASMEau9t5teyrPas encore d'évaluation

- LAMPIRAN Daftar Alat Residue Catalytic Cracking Unit PT PERTAMINA RU VI BalonganDocument15 pagesLAMPIRAN Daftar Alat Residue Catalytic Cracking Unit PT PERTAMINA RU VI BalonganRizqi AmaliyahPas encore d'évaluation

- Applying ASME Boiler Code To Steam Generation Systems - Chemical EngineeringDocument5 pagesApplying ASME Boiler Code To Steam Generation Systems - Chemical EngineeringAnonymous UoHUagPas encore d'évaluation

- PSV Preliminary Documents - Oxidizer BurnerDocument8 pagesPSV Preliminary Documents - Oxidizer BurnerEsneyPas encore d'évaluation

- DGSP - 04 Cumplimiento de Estándares - Lista de Normas y Códigos AplicablesDocument49 pagesDGSP - 04 Cumplimiento de Estándares - Lista de Normas y Códigos AplicablesMarilyn ArreazaPas encore d'évaluation

- 15522HE0253 Rev 0Document7 pages15522HE0253 Rev 0Fernando Ramírez CéspedesPas encore d'évaluation

- Pages From ASME - BPVC - 2013-Brochure-4Document1 pagePages From ASME - BPVC - 2013-Brochure-4CITRIXPas encore d'évaluation

- BHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)Document7 pagesBHEL, Tiruchirapalli-620014. Quality Assurance TECHNICAL DELIVERY CONDITION Product: Steel Castings. (Valves)abdulPas encore d'évaluation

- BHEL steel casting technical delivery conditionsDocument7 pagesBHEL steel casting technical delivery conditionspl_arunachalam79Pas encore d'évaluation

- ML041000284 PDFDocument19 pagesML041000284 PDFAnuj DeoPas encore d'évaluation

- Data Sheet 2 More 300# PV - RF - NT-79 PDFDocument1 pageData Sheet 2 More 300# PV - RF - NT-79 PDFSachin KumarPas encore d'évaluation

- Asme BPVC 2017: Strasse, Nr. PLZ, Ort Telefon E-Mail KontaktpersonDocument2 pagesAsme BPVC 2017: Strasse, Nr. PLZ, Ort Telefon E-Mail KontaktpersonMarcelino Navarrete EvaristoPas encore d'évaluation

- AsmeDocument55 pagesAsmeshamshirgaranPas encore d'évaluation

- Project Line Class Index: L3Rf Luberef Ii Pda Revamp Luberef Ii Pda RevampDocument3 pagesProject Line Class Index: L3Rf Luberef Ii Pda Revamp Luberef Ii Pda RevampkarthiPas encore d'évaluation

- BHEL steel casting technical delivery conditionsDocument6 pagesBHEL steel casting technical delivery conditionsalex hutaurukPas encore d'évaluation

- Sec 01 - Utilities and Meteorological DataDocument7 pagesSec 01 - Utilities and Meteorological DataeujualPas encore d'évaluation

- ANTAM Datasheet 10LAD21AA121 00Document1 pageANTAM Datasheet 10LAD21AA121 00heviPas encore d'évaluation

- Basic-01 - General Description of CCPPDocument18 pagesBasic-01 - General Description of CCPPMohammed LaminePas encore d'évaluation

- Especificacion B2AS1Document9 pagesEspecificacion B2AS1Jorge TaglePas encore d'évaluation

- Steam Needs Forecast for 1 Fertilizer Plant OperationDocument20 pagesSteam Needs Forecast for 1 Fertilizer Plant Operationnadra sagitaPas encore d'évaluation

- Data-Sheet: Lube Oil Pump PUMP TAG No.: 5K-201-G1ADocument2 pagesData-Sheet: Lube Oil Pump PUMP TAG No.: 5K-201-G1ANAHASALI11Pas encore d'évaluation

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalPas encore d'évaluation

- Reliability ImprovementDocument22 pagesReliability ImprovementONURPas encore d'évaluation

- Low Temperature Piping Technical SpecificationDocument6 pagesLow Temperature Piping Technical SpecificationFernando MaltempoPas encore d'évaluation

- Multi Pressure DistillationDocument19 pagesMulti Pressure DistillationHardik ChauhanPas encore d'évaluation

- CEAS Engine Data Report 6G80ME-C10.6 HL: Point Power Speed MEPDocument11 pagesCEAS Engine Data Report 6G80ME-C10.6 HL: Point Power Speed MEPMiriam PedersenPas encore d'évaluation

- ASME Section VIII Div 2 High-Pressure LOX Tank Thermal-Stress Fatigue Analysis PDFDocument6 pagesASME Section VIII Div 2 High-Pressure LOX Tank Thermal-Stress Fatigue Analysis PDFAkshay BordePas encore d'évaluation

- 2015 版 ASME BPVC 价格表Document3 pages2015 版 ASME BPVC 价格表firdaus_stPas encore d'évaluation

- H151Document2 pagesH151KalpanaBansalPas encore d'évaluation

- ITP-001 Rev. 00 - AGV - TANK - NESMADocument2 pagesITP-001 Rev. 00 - AGV - TANK - NESMAgayas416Pas encore d'évaluation

- Double Solenoid Valve Combined Pressure Regulator and Safety Valves Servo Pressure Regulator MBC-... - SE DN 65 - DN 100Document8 pagesDouble Solenoid Valve Combined Pressure Regulator and Safety Valves Servo Pressure Regulator MBC-... - SE DN 65 - DN 100Adilson Melo de MouraPas encore d'évaluation

- 104700-9191 Hyundai̇ Kia 2500Document5 pages104700-9191 Hyundai̇ Kia 2500BaytolgaPas encore d'évaluation

- Inspection & Test Plan for Ni-Al Bronze ValvesDocument4 pagesInspection & Test Plan for Ni-Al Bronze ValvesMuthazhagan SaravananPas encore d'évaluation

- Rev 01 Mud Gas Separator of Oil ServiceDocument3 pagesRev 01 Mud Gas Separator of Oil ServiceKanti LakhankarPas encore d'évaluation

- MPS SampleDocument8 pagesMPS SampleMuhamad Amar Hakimmie SuhaimiPas encore d'évaluation

- Series B02E3F Technical Information General DescriptionDocument13 pagesSeries B02E3F Technical Information General DescriptionhoiPas encore d'évaluation

- MESC specification for axial disc check valvesDocument9 pagesMESC specification for axial disc check valves김창배Pas encore d'évaluation

- Oil Test Report of BREBDocument2 pagesOil Test Report of BREBa s m firoz PrincePas encore d'évaluation

- Swing Check Valve Data Sheet: Comision Federal de ElectricidadDocument1 pageSwing Check Valve Data Sheet: Comision Federal de Electricidadjos ToricesPas encore d'évaluation

- Piping Letrolet AssessmentDocument17 pagesPiping Letrolet AssessmentmanuelPas encore d'évaluation

- Metal Temperature Requirements for Close Examination TestsDocument1 pageMetal Temperature Requirements for Close Examination TestsINSTRUCAL CALIBRATION SERVICESPas encore d'évaluation

- Routine Test Report SummaryDocument1 pageRoutine Test Report SummaryAbdul HamidPas encore d'évaluation

- B-Ii Steam Drum B-I Steam DrumDocument18 pagesB-Ii Steam Drum B-I Steam DrumashmitharajaPas encore d'évaluation

- Weld Matrix Sheet For MMPS Fire Fighting System ProjectDocument1 pageWeld Matrix Sheet For MMPS Fire Fighting System Projectvikas dahiyaPas encore d'évaluation

- Material Specification ChartDocument1 pageMaterial Specification ChartIdu Baz AzharPas encore d'évaluation

- P # NumberDocument4 pagesP # NumberManzar KhanPas encore d'évaluation

- Coating ConverterDocument1 pageCoating ConverterManzar KhanPas encore d'évaluation

- Coating Converter PDFDocument1 pageCoating Converter PDFManzar KhanPas encore d'évaluation

- PuttyDocument2 pagesPuttyJignesh PatelPas encore d'évaluation

- Carbon Pipe Dimensions WeightsDocument3 pagesCarbon Pipe Dimensions WeightsManzar KhanPas encore d'évaluation

- Security Door & Grille Catalogue 2007Document24 pagesSecurity Door & Grille Catalogue 2007Manzar KhanPas encore d'évaluation

- Rolled Pipe FormulaDocument1 pageRolled Pipe FormulaManzar KhanPas encore d'évaluation

- Cb51ab 709854 4046 B190 209c5ad0e PDFDocument61 pagesCb51ab 709854 4046 B190 209c5ad0e PDFManzar KhanPas encore d'évaluation

- Tig Welding BookletDocument26 pagesTig Welding BookletstiryakiiPas encore d'évaluation

- Technical Specifications For Tig WeldingDocument12 pagesTechnical Specifications For Tig WeldingManzar KhanPas encore d'évaluation

- Pipe Schedules PDFDocument2 pagesPipe Schedules PDFManzar KhanPas encore d'évaluation

- Lifebook Uh552 Lifebook Uh572: System Operating ManualDocument61 pagesLifebook Uh552 Lifebook Uh572: System Operating ManualManzar KhanPas encore d'évaluation

- Vedic MathsDocument220 pagesVedic Mathstargettutorials5740100% (7)

- Kiya Bad Mazhab Syed HainDocument22 pagesKiya Bad Mazhab Syed HainManzar KhanPas encore d'évaluation

- Esaal e SawabDocument33 pagesEsaal e SawabPeyam_e_HaqPas encore d'évaluation

- Chapter 10Document32 pagesChapter 10Shahadatuliskandar RosliPas encore d'évaluation

- PWI PWA 10pg 24Document10 pagesPWI PWA 10pg 24Manzar KhanPas encore d'évaluation

- FPD 1314 eDocument4 pagesFPD 1314 eManzar KhanPas encore d'évaluation

- Final Decision W - Cover Letter, 7-14-22Document19 pagesFinal Decision W - Cover Letter, 7-14-22Helen BennettPas encore d'évaluation

- De Thi HSG Tinh Binh PhuocDocument9 pagesDe Thi HSG Tinh Binh PhuocDat Do TienPas encore d'évaluation

- Chemistry of FormazanDocument36 pagesChemistry of FormazanEsteban ArayaPas encore d'évaluation

- Maureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichDocument20 pagesMaureen L. Walsh - Re-Imagining Redemption. Universal Salvation in The Theology of Julian of NorwichAni LupascuPas encore d'évaluation

- Religion in Space Science FictionDocument23 pagesReligion in Space Science FictionjasonbattPas encore d'évaluation

- Digital Communication QuestionsDocument14 pagesDigital Communication QuestionsNilanjan BhattacharjeePas encore d'évaluation

- 24.postpartum Period-Physiological Changes in The MotherDocument16 pages24.postpartum Period-Physiological Changes in The MotherHem KumariPas encore d'évaluation

- SRS Design Guidelines PDFDocument46 pagesSRS Design Guidelines PDFLia FernandaPas encore d'évaluation

- Henry Stevens - Hitler's Flying Saucers - A Guide To German Flying Discs of The Second World War New Edition (2013, Adventures Unlimited Press) - Libgen - lc-116-120Document5 pagesHenry Stevens - Hitler's Flying Saucers - A Guide To German Flying Discs of The Second World War New Edition (2013, Adventures Unlimited Press) - Libgen - lc-116-120sejoh34456Pas encore d'évaluation

- Brochure Personal CareDocument38 pagesBrochure Personal CarechayanunPas encore d'évaluation

- Sri Radhakrishna SwamijiDocument43 pagesSri Radhakrishna SwamijiNarayana IyengarPas encore d'évaluation

- Convocation ProgramDocument125 pagesConvocation ProgramZirak TayebPas encore d'évaluation

- Garlic Benefits - Can Garlic Lower Your Cholesterol?Document4 pagesGarlic Benefits - Can Garlic Lower Your Cholesterol?Jipson VarghesePas encore d'évaluation

- Chemistry Implementation: Name: Rasheed Campbell School: Kingston College Candidate #.: Centre #: 100057Document12 pagesChemistry Implementation: Name: Rasheed Campbell School: Kingston College Candidate #.: Centre #: 100057john brownPas encore d'évaluation

- TILE QUOTEDocument3 pagesTILE QUOTEHarsh SathvaraPas encore d'évaluation

- Gauss Contest: Grade 8Document4 pagesGauss Contest: Grade 8peter100% (1)

- Magnetic Pick UpsDocument4 pagesMagnetic Pick UpslunikmirPas encore d'évaluation

- 1010 PDS WLBP 170601-EN PDFDocument4 pages1010 PDS WLBP 170601-EN PDFIan WoodsPas encore d'évaluation

- WK 43 - Half-Past-TwoDocument2 pagesWK 43 - Half-Past-TwoKulin RanaweeraPas encore d'évaluation

- Home Brewing Log Sheet PDFDocument2 pagesHome Brewing Log Sheet PDFStefanita0% (1)

- QP (2016) 2Document1 pageQP (2016) 2pedro carrapicoPas encore d'évaluation

- Handout Tematik MukhidDocument72 pagesHandout Tematik MukhidJaya ExpressPas encore d'évaluation

- Update On The Management of Acute Pancreatitis.52Document7 pagesUpdate On The Management of Acute Pancreatitis.52Sebastian DeMarinoPas encore d'évaluation

- Interpreting Piping and Instrumentation DiagramsDocument41 pagesInterpreting Piping and Instrumentation DiagramsFredric Tun100% (2)

- Problem SolutionsDocument5 pagesProblem SolutionskkappaPas encore d'évaluation