Académique Documents

Professionnel Documents

Culture Documents

Spe 53001 Pa

Transféré par

samirquirogaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Spe 53001 Pa

Transféré par

samirquirogaDroits d'auteur :

Formats disponibles

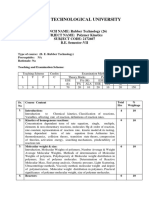

Mathematical Modeling of Secondary

Precipitation From Sandstone Acidizing

Y.-H. Li, SPE, J.D. Fambrough, SPE, and C.T. Montgomery, SPE, Arco E&P Technology

Summary minerals. The acidizing equilibrium chemistry includes 11 elements

Field and laboratory experience clearly demonstrates that, besides and 74 species, which embodies most of the dissolved or disasso-

primary dissolution, precipitation from both secondary and tertiary ciated species and other possible precipitates formed from the

reactions with aluminosilicates adversely affects matrix acid treat- reactions of the above minerals.

ment success. In the secondary reaction, fluosilicic acid from the

primary dissolution will further react with aluminosilicates to form Sandstone Acidizing Chemistry

hydrated silica on the matrix surface. In the tertiary reaction,

The chemical reactions between sandstone minerals and HCl/HF

aluminum fluoride also extracts aluminum from aluminosilicates to

are complex but reasonably understood on an individual basis.1, 2

form silica gel by lowering the fluoride/aluminum (F/Al) ratio in

However, the number and variety of minerals commonly found in

the solution. In the presence of a high concentration of metal ions,

sandstones, coupled with the complexity of the reactions involving

metal fluorides and fluosilicates are also likely to precipitate.

HF, HCl, silicates, and aluminosilicates, make a detailed acidizing

An optimum acidizing design package can be derived for a

chemistry description very challenging.

specific formation mineralogy and damage mechanism if this

complex reactive system can be modeled properly. A geochemical

model for acidizing has been developed for this purpose. The Primary Reaction. A reasonable simplification of the primary

numerical simulator is a reactive flow model that solves the reactive reaction in such a system is to lump minerals of similar reactivity.

system with both reaction kinetics and chemical equilibrium cal- Quartz reacts relatively slowly with HF, whereas aluminosilicates

culations. All possible reactions among all species in the system are (clay minerals, feldspars, and mica) react relatively rapidly.3-6

solved simultaneously. As acid spends, the computer simulation Hence, the HCl/HF/sandstone system can be approximated with

shows the progress of aluminosilicate dissolution and the formation two dissolution reactions as

of different precipitates as the change of dissolved species along the

reaction path occurs. The evolution of the damage skin can be Quartz 1 HF 3 H2 SiF6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . (1)

evaluated as simulation continues. On the basis of simulation,

different pumping schedules with different types of acids can be or SiO2 1 6HF 3 H2 SiF6 1 2H2 O . . . . . . . . . . . . . . . . . . . . (2)

quickly evaluated to optimize treatment volume and minimize

precipitation of hydrated silica and other precipitates. and

To validate the model, a series of laboratory coreflood tests has Aluminosilicates 1 HF 3 H2 SiF6 1 fluorides of Al, etc.

been fully analyzed. The results indicate that the formation of silica

gel is significant, on the basis of hydrofluoric acid (HF) effluent . . . . . . . . . . . . . . . . . . . . . . . . . . (3)

analysis. The same set of kinetic data derived from the laboratory

coreflood data adequately predicts and explains a sandstone acidiz- The reaction of K-feldspar with HF is given in Eq. 4 as an example;

ing field case. however, the reaction of other aluminosilicates (feldspar or clay)

would form similar species.

Introduction

KAlSi3 O8 1 ~n 1 3m!HF 1 ~16 2 n 2 3m!H1

It is always difficult to describe a reactive system that contains

numerous species by several reaction equations without including

3 K1 1 AlF~32n!

n 1 3SiF~42m!

m 1 8H2 O, . . . . . . . (4)

all other possible interactions among the species. Many simplifi-

cations to describe sandstone acidizing chemistry have been re- where index n may take any integer value in the range of 0 to 6,

ported, but a comprehensive solution or a systematic approach to and m 5 4 to 6. If n 5 1 and m 5 4, then three protons will be

encounter all possible interactions in an acidizing environment needed to advance the reaction. If n 5 2 and m 5 6, then four

requires a geochemical model, especially if secondary and tertiary protons will be generated as the reaction proceeds to the right side.

reactions are to be accounted for in the system. The geochemical SiF(42m) is shown as the general form of fluosilicic acid. SiF4 is an

m

model described here integrates both equilibrium and kinetically intermediate compound and will convert to SiF22 as it is being

6

controlled reactions into a comprehensive framework. The reactive consumed in the reactive system. SiF2 5 will coexist in solutions, but

system is based on a Gibbs free energy minimization technique with the majority of fluosilicic acid will be found as SiF22 6 or H2SiF6

kinetically controlled mineral dissolution. The numerical simulator because of equilibrium constraints. It is important to recognize that

has the following features: the model is an isothermal, aqueous- AlF(32n) is also in equilibrium. From 19F nuclear magnetic reso-

n

phase, one-dimensional (1D) radial flow simulator; staging is nance spectroscopy studies, a distribution of the fluoride on the

allowed for different injection fluids pumped in sequence; two sets aluminum has been reported.7–9 For example, at a F/Al ratio of 1.5,

of mineralogy are allowed— one for the rock and one for the Al31, AlF21, AlF1 21

and AlF1

2 , and AlF3 are all present, with AlF 2

damage; and porosity/permeability correlations are used to deter- each composing about 45% of the aluminum species and Al31 and

mine a changing skin factor with pump time and treatment volume. AlF3 each composing about 5%.

Ten species are allowed in the input file. These include two acids Examples of K-feldspar dissolution that illustrate the effect of the

[hydrochloric acid (HCl) and HF] and eight minerals (quartz, forms of fluosilicate and fluoaluminate ions on HF and proton

K-feldspar, Na-feldspar, kaolinite, smectite, illite, calcite, and si- consumption are

derite). Reaction kinetics are built in for the dissolution of all eight

KAlSi3 O8 1 13HF 1 3H1 3 K1 1 AlF21 1 3SiF4 1 8H2 O,

Copyright 1998 Society of Petroleum Engineers

. . . . . . . . . . . . . . . . . . . . . . . . . . (5)

This paper (SPE 53001) was revised for publication from paper SPE 39420, first

presented at the 1998 SPE International Symposium on Formation Damage Control

held in Lafayette, Louisiana, 18–19 February. Original manuscript received for review

KAlSi3 O8 1 18HF 3 K1 1 2H1 1 AlF21 1 3SiF22

6 1 8H2 O,

30 January 1998. Revised manuscript received 8 September 1998. Revised manu-

script approved 25 September 1998. . . . . . . . . . . . . . . . . . . . . . . . . . . (6)

SPE Journal, December 1998 393

KAlSi3 O8 1 20HF 3 K1 1 4H1 1 AlF1

2 1 3SiF6 1 8H2 O,

22

Aluminum and aluminum fluorides in solution can also react with

fluosilicic acid if the species with fewer fluorides are more reactive

. . . . . . . . . . . . . . . . . . . . . . . . . . (7) toward fluosilicic acid. This will convert more fluosilicic acid to

silica gel. One can write a balanced reaction for this process as

and KAlSi 3 O8 1 21HF 3 K1 1 5H1 1 AlF3 1 3SiF 22

6 1 8H2O.

1 1

6AlF21 1 SiF22

6 1 4H2 O 3 6AlF2 1 H4 SiO4 1 4H .

. . . . . . . . . . . . . . . . . . . . . . . . . . (8)

. . . . . . . . . . . . . . . . . . . . . . . . . . (15)

Proton creation or consumption is dependent upon the available

forms of aluminum fluorides and fluosilicic acids from the reactions The reaction is, in fact, in equilibrium because, once the fluoride

of aluminosilicates with HF. is associated with aluminum, it will be distributed among the

various aluminum fluoride species in accordance with its equilib-

Secondary Reaction. The secondary reaction of HF with alumi- rium behavior. A high proton concentration can also force hydrated

nosilicates is the reaction of fluosilicic acid derived from the silica to dissolve and rebalance the Al/F ratio in solution.

primary reaction with an aluminosilicate to form hydrated sil- Silica gel is a hydrated silica, so a high concentration of HF will

ica.10, 11 Two examples with K-feldspar and illite are given as force silica gel to dissolve following the same dissolution of silica

as known in the primary reaction,

1

6 1 6KAlSi3 O8 1 18H 1 10H2 O

SiF22

1

H4 SiO4 1 6HF 7 SiF22

6 1 2H 1 4H2 O. . . . . . . . . . . . . . (16)

1

3 6K 1 6AlF 21

1 18H2 SiO3 1 H4 SiO4 , . . . . . . . . (9)

Aluminum Salts. The dissolved aluminum can form six com-

and SiF 22

6 1 KAl3 Si3 O10 ~OH!2 1 6H1 1 4H2 O plexes with fluorine: AlF21, AlF1 2 22 32

2 , AlF3, AlF4 , AlF5 , and AlF6 .

(32n)

AlFn is a general form of fluoaluminic acid with n from 1 to 6.

3 K1 1 3AlF1

2 1 4H4 SiO4 . . . . . . . . . . . . . . . . (10) All can coexist and are controlled by equilibrium relationships in

the solution. AlOH21, Al(OH)1 2

2 , Al(OH)3, and Al(OH)4 can also

Dissolving the silicon in the aluminosilicate results in an amor- form. Walsh et al.13 showed that AlF3 and Al(OH)3 precipitates can

phous silica gel film. In addition, the silica in SiF22

6 also precipitates form during sandstone acidizing. AlF3 can precipitate if the HF

as silica gel. concentration is still high but the ratio HCl/HF is low. Al(OH)3 can

precipitate if both HF and HCl concentrations are low (i.e., toward

Tertiary Reaction. The tertiary reaction of HF with alumosilicates the end of the reaction from an initially strong HCl/HF acid

involves the further reduction of the F/Al ratio in dissolved alu- formulation).

minum fluoride species. The reaction extracts aluminum out of Calcium Fluoride. Calcite reacts very quickly and completely

aluminosilicates and leaves silica gel in the matrix.7, 8 An example with HCl acid, but, in the presence of HF, the reaction proceeds.

of the tertiary reaction with K-feldspar can be written as

CaCO3 1 2HF 3 CaF2 1 H2 O 1 CO2 . . . . . . . . . . . . . . (17)

AlF1 1

2 1 KAlSi3 O8 1 4H 1 4H2 O

CaF2 has a very low solubility. However, preflushing with HCl acid

3 K1 1 2AlF21 1 3H4 SiO2 . . . . . . . . . . . . . . . . . . (11) can minimize this reaction. An adequate preflush has to be injected

to remove all the carbonate material from the near-wellbore region

This reaction continues to reduce the F/Al ratio in the spent HF until

before an HF treatment. Calcium fluoride also forms from the

the remaining HCl is consumed.

reaction of calcium chloride completion fluid with HF.

Sodium and Potassium Fluosilicates and Fluoaluminates. The

Precipitates. Although acidizing reactions result in precipitation reaction products, fluosilicic acid and fluoaluminic acid, are readily

in some cases, some undesirable reactions can be avoided by soluble in water, but their potassium, sodium, and calcium salts are

following proper procedures and taking precautions. The following partially insoluble. The salts are formed by the following reactions.

gives the possible precipitates in sandstone acidizing and their

1

origins. 6 1 2K

SiF22 3 K2 SiF6 , . . . . . . . . . . . . . . . . . . . . . . . . . (18)

Colloidal Silica. Amorphous silica comes from clay and silicate

1

dissolution in HF. H2SiF6 extracts aluminum from any alumino- 6 1 2Na

SiF22 3 Na2 SiF6 , . . . . . . . . . . . . . . . . . . . . . . . (19)

silicate mineral and simultaneously deposits amorphous silica.

1

Hydrated silica can be in the forms of H2SiO3 (or SiO2:H2O) and and 6 1 Ca

SiF22 3 CaSiF6 . . . . . . . . . . . . . . . . . . . . . . . . (20)

H4SiO4 [or Si(OH)4 and SiO2:2H2O]. H2SiO3 has been identified as

amorphous silica in acidizing experiments.12 The difference be- Sodium and potassium fluosilicates precipitate from feldspar or

tween H2SiO3 and H4SiO4 is the degree of hydrolysis. Colloidal illite clay dissolving in HF or by seawater/brine mixing with spent

silica precipitation occurs when the HF initially present is nearly HF. These fluosilicate precipitates are more likely to form during

consumed and the solution contains a relatively high amount of the initial phases of the dissolution because high concentrations of

fluosilicate ions, SiF22

6 . When amorphous silica forms, it forms on

HF enhances the process. Additionally, fluosilicate can react with

the surface of clay and silt, resulting in a retardation of further clay calcite in the formation to form calcium fluosilicate. Dissolving

acidization. This results partly from the greater affinity of fluorine calcite around the wellbore with a preflush minimizes damage from

for aluminum than for silicon as this precipitate. Formation of K3AlF6, Na3AlF6, and Ca3(AlF6)2 has

also been reported.14 Thus calcium, potassium, and sodium ions

H2 SiF6 1 6Al31 1 4H2 O 3 6AlF21 1 6H1 1 H4 SiO4 . should not be mixed with either spent or unspent HF. Formation

water, which contains calcium chloride, sodium chloride, and

. . . . . . . . . . . . . . . . . . . . . . . . . . (12) potassium chloride, should be avoided. The only compatible salt

solution with HF is ammonium chloride.

This expression can be illustrated in two steps in Eqs. 13 and 14.

Iron Precipitates. Ferric hydroxide forms when acid spends and

Fluosilicate ions are hydrolyzed, and amorphous silica is deposited at

pH rises. Sources of ferric iron include some minerals, such as

the surface of the clay/fines. Simultaneously, HF is generated and

chlorite, siderite, and hematite, and tubing rust. These HCl-soluble

aluminum is preferentially removed from clay minerals, which results

minerals begin to precipitate gelatinous ferric hydroxide as the pH

in additional amorphous silica. Silica gel precipitation from the first

rises above 2.2. A preflush of HCl is used to remove most of the

step increases with HCl concentration, as illustrated in Eq. 13.

soluble iron. Ferrous hydroxide forms if the pH rises above 7.0. The

1 Fe21 is not considered to be a problem because ferrous hydroxide

6 1 2H 1 4H2 O 7 H4 SiO4 1 6HF, . . . . . . . . . . . . . (13)

SiF22

precipitates at pH between 7.7 and 9, which is normally above the

and 6Al31 1 6HF 7 AlF21 1 6H1. . . . . . . . . . . . . . . . . . . (14) pH of spent acid.

394 SPE Journal, December 1998

Model Description re-form. However, the model is set to prevent dissolution from

Chemical reactions between sandstone minerals and HCl/HF are exceeding its equilibrium limitation. The initial acidizing kinetics

complex. The intricacy of the various species interactions make data were derived from internal laboratory data and the litera-

quantifying the impact on specific species formation from a single ture.23-25 There may be several chemical formulas for each mineral.

process variable change almost impossible as reservoir and treat- The exact formulas used in the simulator are SiO2 for quartz, KAlSi3O8

ment conditions vary. Computer simulation can be helpful in for K-feldspar, NaAlSi3O8 for Na-feldspar, Al2Si2O5(OH)4 for kaolin-

resolving this and can be used in diagnosing the potential of ite, Al2Si4O10(OH)2 for smectite, KAl3Si3O10(OH)2 for illite, CaCO3 for

precipitates and maximizing treating efficiency. calcite, and FeCO3 for siderite. The exact dissolution equations used

The simulator is an isothermal, aqueous-phase, 1D radial flow in the model are summarized as

model. This is a reactive flow model simulating acid/mineral

reactions within a formation matrix. To mimic field operations, the SiO2 1 6HF 3 2H1 1 SiF2

6 1 2H2 O, . . . . . . . . . . . . . . . (21)

input file allows users to stage treatments with different injection

KAlSi3 O8 1 20HF 3 K1 1 4H1 1 AlF1

2 1 3SiF6 1 8H2 O,

22

fluids in sequence. One can specify two different sets of miner-

alogies, one for the formation matrix and one for the damage . . . . . . . . . . . . . . . . . . . . . . . . . . (22)

material. This allows the composition of the invading solids to be

different from the matrix mineralogy. Given a single mineral, the NaAlSi3 O8 1 20HF

native mineral and invading solid mineral can also have unique

properties in terms of reaction rates and the effect of the porosity 3 Na1 1 4H1 1 AlF1

2 1 3SiF6 1 8H2 O,

22

change on permeability.

The mass transfer equations for reactive species transport include . . . . . . . . . . . . . . . . . (23)

both convection and diffusion processes. The reaction calculations

use equilibrium reactions with options to include rate-controlled Al2 Si2 O5 ~OH!4 1 16HF 3 2H1 1 2AlF1

2 1 2SiF6 1 9H2 O,

22

reactions. Some of the chemical reactions are assumed to be in

equilibrium (modeled with Gibbs free energy minimization), . . . . . . . . . . . . . . . . . . . . . . . . . . (24)

whereas others are rate-limited (modeled with empirically deter-

mined kinetic rate equations).13, 15-18 The simulator allows an ar- Al2 Si4 O10 ~OH!2 1 28HF

bitrary combination of kinetic and equilibrium reactions as long as

it involves a sufficient number of chemical species. In general, if 3 6H1 1 2AlF1

2 1 4SiF6 1 12H2 O,

22

the reactions in a system are limited by the time domain of interest, . . . . . . . . . . . . . (25)

users have to provide reaction rates. The algorithm for equilibrium

calculations is based on a Gibbs free energy minimization routine KAl3 Si3 O10 ~OH!2 1 24HF

developed by Smith and Missen,19 thus freeing the system reaction

specifications with equilibrium constants. 3 K1 1 2H1 1 3AlF1

2 1 3SiF6 1 12H2 O,

22

Because mineral dissolution during an acidizing treatment is

dominated by the kinetically controlled process, all initial minerals . . . . . . . . . . . . (26)

in the system have their own kinetic expressions. After dissolution,

interactions of dissolved species and reprecipitation continue. Both CaCO3 1 H1 3 Ca21 1 HCO2

3, . . . . . . . . . . . . . . . . . . . (27)

dissolved species and reoccurring secondary precipitates are de-

rived from the equilibrium calculations. Nonuniform grid spacing and FeCO3 1 H1 3 Fe21 1 HCO2

3 . . . . . . . . . . . . . . . . . . (28)

along the radial direction is used to obtain better resolution around

the wellbore region where damage is the highest. A detailed chemical Although the actual reactions may be different from these expres-

description of all reactants and subsequent species can be obtained near sions, the sequential equilibrium calculations will convert the

the wellbore or at any location from the wellbore to a defined boundary reaction products to other species in the aqueous phase according

during the entire acidizing treatment. The sequential steps used in the to chemical equilibrium. Eqs. 29 and 30 illustrate two examples of

simulation calculations are flashing the initial composition, mass the secondary reaction in which fluosilicic acid reacts with alumi-

transfer calculation, kinetic calculation, equilibrium calculation, po- nosilicates to form hydrated silica,

rosity calculation, permeability calculation, and pressure profile cal- 1

culation. Separating the kinetically controlled mineral dissolution from 6 1 3NaAlSi3 O8 1 8H 1 16H2 O

SiF22

the equilibrium calculations and using minimum grid spacing without

altering chemical equilibrium speed up the simulations and allow the 3 3Na1 1 3AlF1

2 1 10H4 SiO4 , . . . . . . . . . . . . . . . (29)

model to run on a Pentium 133 PC in 5 to 10 minutes. 1

6 1 KAl3 Si3 O10 ~OH!2 1 6H 1 4H2 O

SiF22

Database for Chemical Equilibrium Calculations. The database 3 K1 1 3AlF1

2 1 4H4 SiO4 . . . . . . . . . . . . . . . . . . . (30)

for the sandstone acid reactive system contains 11 elements and 74

species. These 74 aqueous and mineral species are mainly derived Similar expressions can be given to the tertiary reaction. Note that

from 11 elements: H, Cl, F, Si, Al, K, Na, Ca, Fe, C, and O. The all aluminum fluorides are expressed as AlF1 2 and silica fluorides

required thermodynamic data for each species includes enthalpy are in the form of SiF22

6 . The chemical equilibrium calculations will

and Gibbs free energy at the standard state and a temperature redistribute the species from both secondary and tertiary reactions

function of the species’ heat capacity.20-22 Three main groups of with the appropriate concentrations in the system as explained in

soluble species in the database are aluminum fluorides (Al31, the primary dissolution.

AlF21, AlF1 2 22 32

2 , AlF4 , AlF5 , and AlF6 ), aluminum hydroxides For an unknown kinetic expression, dissolution reactions are

(AlOH21, Al(OH)1 2

2 , and Al(OH)4 ), and silica fluorides (SiF4 and assumed to be first order with respect to the concentrations of

SiF22

6 ). The precipitates from the aqueous-phase reactions are CaF2, solvent and the minerals. Quartz is minutely soluble in HCl but will

AlF3, Na2SiF6, K2SiF6, CaSiF6, and H4SiO4. readily dissolve in HF. A simple expression is

Kinetic Expressions. The input data include two acids (HCl and dCq

HF) and eight different minerals (quartz, Na-feldspar, K-feldspar, 2 5 kq ~HF!a ~Cq !, . . . . . . . . . . . . . . . . . . . . . . . . . . . . (31)

dt

kaolinite, smectite, illite, calcite, and siderite). All eight minerals

have their own irreversible dissolution expressions. The justifica- where C q 5 silica concentration. Aluminosilicates dissolve in HF

tion for an irreversible setup is that, in the acidizing treatment but also slightly dissolve in HCl. Aluminosilicate can further react

domain, there is not sufficient time for the dissolved minerals to with fluosilicic acid in the secondary reaction and with aluminum

SPE Journal, December 1998 395

fluoride in the tertiary reaction. To account for all these, the rate

equation is expressed as a function of multivariables as and ki 5 ko SD

fi n

fo

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (41)

dCa 1 1 The final skin can be calculated as

2 5 f ~HF, SiF21

6 , AlF2 , H , Ca !, . . . . . . . . . . . . . . . . (32)

dt

OFS D G S D

N

fi n

ri

where C a 5 aluminosilicate concentration. There are many com- S5 2 1 ln . . . . . . . . . . . . . . . . . . . . . . . (42)

binations that can furnish the above expression. In the model, fo ri21

i51

dCa The porosity/permeability correlation illustrated previously is a

2 5 ~ka1 ~H1!a 1 ka2 ~HF!b ~H1!c

dt general and simple expression. The proposed correlation for this

work is

1 e 1 f 1 g

1 ka3 ~SiF21

6 ! ~H ! 1 ka4 ~AlF2 ! ~H ! )Ca . . . . . . . . . (33)

PS D

d

k fi21 2 ~Vi, o 2 Vi ! ni

5 , . . . . . . . . . . . . . . . . . . . . (43)

is suggested. A precise expression requires laboratory experiments ko fi21

i51, N

on a given mineral to determine the form of the rate equation and

the coefficient and power index on the concentration terms. where N 5 the number of solid species, and V 5 the volume of a

A true kinetic rate expression should also include mass transfer specific mineral. This gives each individual mineral its own cor-

constraints, such as surface area. The rate expression as a function relation on the effect of a porosity change on permeability.

of mineral concentrations is a self-imposed rate limitation. In

addition to the concentration term, two multipliers to the rate Laboratory Data Validation

expression, which corrects for mineral surfaces not exposed to pore

The objective is to validate the acidizing geochemical model with

fluid in the acidizing system, are given. For inaccessible minerals,

a comprehensive laboratory acidizing experimental program.

this multiplier is

~C 2 Cmin! Laboratory Program. Lindsay26 carried out a series of acidizing

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (34) experiments in Berea sandstone. A high strength acid (12% HCl/3%

~Co 2 Cmin!

HF; no preflush) was injected through Berea plugs at five different

where C o is the mineral initial concentration and C min 5 an flow rates at both 77°F and 125°F. A total of 10 complete tests

empirical number; and, for silica gel coatings, the multiplier is (Runs 3 to 12) have been reported and provide details on HF

effluent concentrations vs. pore volumes (PV’s) of the acid injected,

CH4SiO4 along with porosity and permeability data of the tested cores. The

~1 2 u ! where u 5 . . . . . . . . . . . . . . . . . . . . . (35) core plugs used were 1 in. in diameter and 4 in. long with initial

CH4SiO4 , o

porosity about 18.6% and initial permeability around 100 md. The

u 5 the fraction of mineral coated by silica gel, and the denominator mineral composition includes quartz, feldspar, chlorite, illite, do-

is an empirical number. Both terms can be used to multiply the rate lomite, calcite, and siderite. Table 1 provides the flow rate and PV

expression to incorporate the mass transfer effect into the mineral injected during each experiment. The cores were injected with the

dissolution. HCl/HF acid up to more than 80 PV. This experimental program

is similar to acidizing in the very near wellbore region (i.e., 4 in.

Definition of Skin and Porosity/Permeability Correlations. from the wellbore).

Skin is a common name used in describing wellbore damage. It is

a parameter to accommodate a Darcy’s flow calculation for a Data Interpretations by Others. Lindsay’s data have been ex-

damaged wellbore. It is a dimensionless number and does not tensively analyzed in several sandstone acid two-component, four-

provide any information about how far damage penetrates into the component, and geochemical models.3-5, 16, 27 Three of these ex-

formation or how the damaging material is distributed in the pore periments (Runs 8, 9, and 12) have been well interpreted with a

space. The definition of skin can be described as four-component model that includes HF, two lumped minerals, and

SD SD

silica gel from a secondary reaction.27 Neither the two-component

ra kR ra nor the four-component model accounts for the room temperature

S 1 ln 5 ln . . . . . . . . . . . . . . . . . . . . . . . . . . . . (36) data. The U. of Texas KGEOFLOW geochemical model gives a

ro ka ro

better interpretation of six experiments at both temperatures.16 The

or S5 S DSD

kR

ka

2 1 ln

ra

ro

, . . . . . . . . . . . . . . . . . . . . . . . . . . . (37)

reported precipitates were K2SiF6, and AlF3. Silica gel was only

observed in Run 12. No reports were given on the final porosity and

permeability. This could be because the experiments assumed that

where S 5 skin, a dimensionless number; r a 5 damaged radius; the carbonates were completely dissolved after injecting about 2 PV

r o 5 wellbore radius; k a 5 damaged zone permeability; and k R 5 12/3 HCl/HF, and therefore, carbonates were not included in the

reservoir permeability. This leads to the expression for calculating KGEOFLOW simulation.

the flow rate in a damaged wellbore,

kR hDp

q5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (38) TABLE 1—EXPERIMENTAL PROGRAM CONDUCTED BY

m~S 1 ln~ra /ro !! LINDSAY

Skin is also a summation of individual skins as defined by

125°F 77°F

O OS DS D

N N

kR ri Run Flow Rate PV Run Flow Rate PV

S5 Si 5 2 1 ln . . . . . . . . . . . . . . . . . . . . (39) Number (mL/sec) Injected Number (mL/sec) Injected

ki ri21

i51 i51

10 0.327 25 4 0.342 88

In the damaged zone, the permeability increases inward into the

9 0.248 80 5 0.250 86

reservoir as the porosity increases with the radius. From the

assumption of a linear variation of porosity and a simple porosity 11 0.175 26 6 0.130 88

vs. permeability relationship,2 such as 8 0.128 81 7 0.063 83

12 0.063 30 3 0.062 87

fi 5 fo 2 a~D 2 ri ! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (40)

396 SPE Journal, December 1998

Experimental Results vs. Simulations From This Work. To

conduct coreflood simulations, the model was modified for a linear

flow. Table 2 gives the sandstone mineralogy used in the simula-

tion. These include quartz, K-feldspar, Na-feldspar, illite, calcite,

and siderite. Because dolomite and chlorite are not included in the

model, dolomite was replaced with calcite and chlorite was re-

placed with additional illite. These 10 tests are analyzed and

simulated in the model; the data fitting includes HF effluent,

porosity, and final permeability in the cores.

Figs. 1 and 2 (for 125°F) and Figs. 3 and 4 (for 77°F) present

both experimental and simulation results of HF effluent concen-

trations vs. PV of the acid injected for various injection flow rates.

Table 3 gives both measured and predicted porosity data for two

tests (Runs 10 and 11). Fig. 5 (for 125°F) and Fig. 6 (for 77°F) plot

the final data for all the tests from both experimental and predicted

permeabilities. The purpose is to illustrate that the model can do a

comprehensive interpretation rather than just fit several experi-

ments or several parameters. Table 4 furnishes the kinetic data used

in this exercise.

HF Consumption. Consumption of HF is an indication of the

degree of acidizing or silicate and aluminosilicate dissolution. The Fig. 1—HF effluent concentration from corefloods at 125°F.

conversions of aluminum to aluminum fluorides and silica to silica

fluorides are the main usage of fluoride. On the basis of HF

consumption (experimental vs. predicted), the model appears to

overpredict the flow rate effect, especially for the corefloods

conducted at 125°F. The reason is that the HF consumption does

not increase as much as the predictions with a decrease of flow rate

(or the consumption of HF in the experimental work does not

decrease as much as the model predictions with an increase of flow

rate). In the secondary reaction, fluosilicic acid (SiF226 ) is converted

to hydrated silica (H4SiO4). The filming effect from hydrated silica

gel reduces the reactive surface area and slows down the reaction.

The model may not impose the filming effect as severely as it

should. A severe filming effect will make the HF consumption less

sensitive to a flow rate change. The other reason is that, in the

secondary reaction, the conversion of fluosilicic acid to hydrated

silica reduces the total fluoride consumption from a total material

balance viewpoint. This also results in a smaller change in the net

HF consumption with respect to the flow rate changes. The con-

sumption of HF can serve as an indicator of the severity of the

hydrated silica formation. In other words, this also might indicate Fig. 2—Predicted HF effluent concentration for corefloods con-

that the real damage in the corefloods could be greater than that ducted at 125°F.

predicted by the model. These results support the recommendations

made by Paccaloni et al.28 of injecting acids at the highest rate

possible to minimize precipitation. This also supports the point that

the time that spent acid remains in the formation should be min-

imized.24, 29

Colloidal Silica. H4SiO4, or Si(OH)4, is perhaps the most im-

portant precipitating mineral in sandstone acidizing. Field experi-

ence and laboratory coreflood experiments have produced evidence

of the precipitation of Si(OH)4.2, 29-31 As reservoir minerals are

dissolved, aluminum and silica compete for the available fluorine.

Aluminum has the greater affinity for fluorine; so when the level

of free fluorine is reduced, silica precipitates in the form of Si(OH)4.

Fig. 7 and Table 5 show the sensitivity of silica gel precipitation.

In Fig. 7, the predicted upper curve was derived from a very high

conversion of SiF22 6 to H4SiO4. This results in a low consumption

of HF. This can also result in a low porosity in the core, as indicated

TABLE 2—MINERAL CONTENT USED IN SIMULATION

Mineral wt%

Quartz 70.0 Fig. 3—HF effluent concentrations for corefloods conducted at

K-feldspar 2.5 77°F.

Na-feldspar 2.5

Illite 15.0 in Table 5. The lower curve shows that, if H4SiO4 does not form and

Calcite 5.0 all dissolved silica remains as SiF22

6 , the consumption of HF will

Siderite 5.0 be very high and the HF effluent curve will be very low. This also

results in a high porosity in the core because no silica gel deposits

SPE Journal, December 1998 397

Fig. 6 —Experimental vs. predicted permeabilities of corefloods

conducted at 77°F (initial permeability about 100 md).

TABLE 4—KINETIC DATA

Activation Surface

Frequency Energy Area

Fig. 4 —Predicted HF effluent concentrations for corefloods Name Factor (Kcal/g mol) (m2/g)

conducted at 77°F.

Quartz 0.136E207 5.0 0.005

K-feldspar 0.135E205 8.0 1

TABLE 3—SECTIONAL POROSITIES DETERMINED BY Na-feldspar 0.760E206 8.0 1

CORE LABORATORIES vs. PREDICTED FOR TWO

ACIDIZING CORES Kaolinite 0.174E204 10.0 23

(INITIAL POROSITY: 18.6%) Smectite 0.361E205 9.5 82

Illite 0.776E205 10.0 113

Porosity

(%)

Run

Number Core Section Measured Predicted

10 Front 30.5 32.0

10 Middle 27.5 25.4

10 Back 24.9 19.4

11 Front 31.9 35.4

11 Middle 27.4 22.9

11 Back 25.2 20.1

Fig. 7—Effects of silica gel formation on HF consumption for the

coreflood conducted at 0.128 mL/sec and 125°F.

Fig. 5—Experimental vs. predicted permeabilities for corefloods

conducted at 125°F (initial permeability about 100 md).

predicted pore space occupied by silica gel during an acidizing

experiment can be as high as 30%.

AlF3(s) Precipitate. AlF3(s) is observed in the simulation, as

in the matrix. The sensitivity study related to HF consumption and illustrated in Fig. 9 for Run 9. Its formation in the pore space is on

porosity provides a confirmation of the degree of silica gel forming the same order of magnitude as silica gel. After forming, it dissolves

in the matrix during the coreflood. Fig. 8 shows a simulation of the slightly and slowly relative to silica gel formation. A duplicate of

formation and dissolution of silica gel in the core as a function of the Run 9 simulation at 200°F shows that silica gel exists in the

time or the PV’s of the acid injected. After 80 PV 12/3 HCl/HF same order of magnitude as that at 125°F, but AlF3(s) completely

pumped through the core, silica gel formed from the secondary disappears. This might explain why most flowback fluid analyses

reaction is completely dissolved. Dissolving silica gel is similar to show a high ratio of Al/Si. This ratio can be one to two orders of

dissolving quartz or silica. After most aluminosilicates have been magnitude greater than the Al/Si ratio present in the minerals

dissolved, the silica gel from the secondary reaction begins to because dissolved aluminum is in solution and silica precipitates are

dissolve as HF/HCl continues to be pumped through the core. The in the formation.23-25, 30

398 SPE Journal, December 1998

TABLE 5—SECTIONAL POROSITIES IN PERCENT

Degree Location in the Core

of Silica

Gel

Formation Front Middle Back

Low 30.9 31.8 31.5

Moderate 33.4 21.3 21.7

High 24.6 19.6 20.4

Fig. 10 —Simulated calcium fluoride formation during coreflood

at 0.248 mL/sec and 125°F.

Fig. 8 —Simulated silica gel formation and dissolution during

coreflood at 0.248 mL/s and 125°F.

Fig. 11—Simulated calcium fluosilicate formation during core-

flood at 0.248 mL/sec and 125°F.

Iron compounds can become a real possibility in carbonates, where

there is enough carbonate material present to cause the HCl acid to

spend completely. This condition is rarely found in sandstones and,

therefore, does not pose much of a problem in sandstone acidizing.

No iron precipitates were observed from the model simulation.

Calcite and Siderite Dissolution. Calcite reacts very quickly

and completely with HCl acid. In fact, the reaction rate is so fast

that kinetic data cannot be measured at room temperature. In simu-

Fig. 9 —Simulated aluminum fluoride formation during coreflood

lation, if the dissolution of calcite occurs instantaneously, a disconti-

at 0.248 mL/sec and 125°F.

nuity in the HF consumption will occur, which affects the other species

balance. To prevent this, a mass transfer limitation is imposed on the

CaF2 and CaSiF6 Precipitates. CaF2 and CaSiF6 will form, but calcite dissolution to obtain a smooth HF effluent concentration curve.

at lower magnitudes in comparison with silica gel or AlF3(s). Figs. A mass transfer constraint is also needed for siderite.

10 and 11 show the simulated results of CaF2 and CaSiF6 formation

at Run 9 conditions, respectively. An interesting observation is that Field Data Validation

the formation of CaF2 is ahead of the formation of CaSiF6. It The field case analyzed in this paper also comes from the litera-

appears that CaF2 has been displaced by CaSiF6. Because the ture.33 It involves a sandstone acidizing treatment in an offshore

thermodynamic data for CaSiF6 were created from the mixing Louisiana oil well. The well produces from a 40-ft gravel-packed

values of other species, the magnitude of both CaF2 and CaSiF6 zone in an unconsolidated, sandstone reservoir. A rate of only 1,222

formation might not be accurate. However, this shows that calcite BOPD was achieved from the expected 5,000 BOPD. An analysis

reacted with HF in the formation can form calcium precipitates. In concluded that the formation damage affecting this completion was

the presence of a high strength HCl, the problem should be much the result of formation clays swelling when they were contacted by

less severe. K2SiF6, is a potential precipitate from K-feldspar, illite, completion fluids and by fines migrating toward the wellbore

and spent HF, but was not observed in the simulations. A strong during production.

presence of calcium may suppress K2SiF6 formation. Thomas32 The original literature33 gives details of the formation matrix and

indicates that metal salt precipitation occurs at HF concentrations damage mineralogy of this well and the pumping schedule. For

of 3 wt% and above and that it can be reduced, but not eliminated, simulation purposes, the kinetic data generated from the laboratory

by high HCl concentrations. corefloods discussed in the above section were extrapolated to

Iron Precipitates. Although siderite existed in the Berea core, 218°F with the Arrhenius expression. The simulation results indi-

iron compounds are unlikely to precipitate in the presence of HCl. cated that the constraints may be because of the material balance

SPE Journal, December 1998 399

or the amount of acids needed to dissolve the damage. The damage

TABLE 6—FINAL SKINS FROM VARIOUS DAMAGE

skin was shown to be 204 initially and was reduced to 15.4 after DEFINITIONS

treatment. The simulated skins vary from 30 to 20.4, depending

upon how the damage is defined and how the damage material is 1-ft Damage Radius 1.5-ft Damage Radius

distributed in the void space of the matrix out to 1-ft radius.

Fig. 12 shows four examples of how the damage may be Damage Final Damage Final

deposited in a 1-ft radius away from the wellbore with an initial skin Definition* Skin Definition* Skin

of 204. Table 6 summarizes the simulated final skins with the

various definitions of the skin regarding invading solids distributed Uniform 20.44 Uniform 0.95

at both 1- and 1.5-ft radii. On the basis of the field results of a final Two-step 20.19 Two-step 3.02

skin of 15, the model provides a reasonable interpretation for the Three-step 2.57 Three-step 13.43

final skin in the range of 30 to 20.4 with 1-ft damage radius. There

Four-step 30.02 Four-step 77.82

is no reason to adjust the model for a perfect match. The issue is

how the damage can be better defined for a job design. The 20% * Illustrated in Fig. 12.

difference in the damage material packed in void space causes the

final skin to change from 30 to 20.4. This leads to the conclusion

that an increase in the treatment volume will eventually reduce the

skin from the treatment final skin of 15.4 to zero for this field case

if additional costs can be justified. essential to verify all thermodynamic and kinetic data used in the

model.

Conclusions 6. Methods for defining the damage mechanism and its distri-

bution remain an issue for sizing a treatment. A skin number is not

The geochemical model developed here is designed for routine sufficient to define the damage radius or damage profile. Appli-

matrix and treatment design to predict the interaction of fluids and cation of the geochemical model for engineering design remains a

minerals. It can be helpful in maximizing treating efficiency and challenge.

diagnosing the potential for precipitates to form. To a certain extent,

damaging precipitates can be avoided if the HCl/HF formulation is Nomenclature

properly matched to the formation mineralogy with the help of mod-

eling. This program furnishes a framework for this purpose. It still a, b, . . . , g 5 reaction order indices

needs refinement of the thermodynamic database for all species in- C a 5 aluminosilicate concentration per void vol-

cluded in the reactive system and more detailed specifications of the ume, g mol/ft3

kinetic equations. The general conclusions derived from this work C H4SiO4 5 silica gel concentration per void volume, g

follow. mol/ft3

1. Laboratory data validation and a field case prediction give C H4SiO4,o 5 an empirical number for silica gel concentra-

confidence in the model. tion per void volume, g mol/ft3

2. Decoupling dissolution kinetics of various minerals from C min 5 an empirical number of mineral concentration

equilibrium flash calculations and using minimum grid spacing per void volume, g mol/ft3

without altering chemical equilibrium speed up the calculations and C o 5 mineral initial concentration per void volume,

allow the simulation to be performed on a PC. g mol/ft3

3. Precipitation of colloidal silica appears inevitable and sub- C q 5 quartz concentration per void volume, g mol/

stantial. Colloidal silica occurs beyond the dissolution front and can ft3

extend into the reservoir. There is a balance between the primary D 5 distance from the wellbore to the boundary of

dissolution and secondary precipitation of colloidal silica. Higher the simulation domain, ft

flow rates correspond to less damage induced by acid. When h 5 formation height, ft

designing a job, there needs to be a compromise made in the k o 5 initial permeability, md

injection rate between efficient removal of damage and minimiza- k a 5 damaged zone permeability, md

tion of new damage by precipitation. k q 5 dissolution rate constant for quartz

4. AlF3(s) tends to disappear with an increase in reservoir tem- k a1, . . . , a4 5 dissolution rate constant for different mecha-

perature. In some cases, fluoride and fluosilicate salts, such as CaF2, nisms from 1 to 4

K3SiF6, Na2SiF6, and CaSiF6, occur within the dissolution of spent k R 5 reservoir permeability, md

HF and can be avoided with a preflush of HCl. k i 5 permeability at Location i, md

5. Key equilibrium data have to be carefully examined and n 5 power index for permeability/porosity corre-

detailed kinetic expressions have to be developed for a given lation

mineral. Validation of the model with flowback analysis of all dis- n i 5 power index of Species i for permeability/

solved species either from laboratory experiments or field samples is porosity correlation

Dp 5 pressure difference between the external

drainage radius and the well, psi

q 5 volumetric rate, B/D

r a 5 damaged radius, ft

r i 5 radius at Location i

r o 5 wellbore radius, ft

S 5 skin

S i 5 skin at Location i

t 5 time, seconds

V i 5 volume fraction of Species i, ft3

V i,o 5 initial volume fraction of Species i, ft3

a 5 regression constant for porosities at various

locations according to a given skin

u 5 fraction of surface covered by H4SiO4

m 5 fluid viscosity, cp

f i 5 porosity in the rock matrix at Location i

Fig. 12—Illustrations of the same initial skin number with differ- f o 5 initial porosity in the rock matrix

ent distribution of the damage material.

400 SPE Journal, December 1998

Acknowledgments 23. Almond, S.W., Brady, J.L., and Underdown, D.R.: “Prudhoe Bay Field

The authors thank Arco E&P Technology for their permission to Study: Return-Fluid Analysis,” JPT (April 1990) 466.

publish this paper. The chemical equilibrium calculations by the 24. Fambrough, J.D. and Newhouse, D.P.: “A Comparison of Short-Core

Gibbs free energy minimization were derived from the computer and Long-Core Acid Flow Testing for Matrix Acidizing Design,” paper

programs developed from the Stimulation, Logging, and Formation SPE 26186 presented at the 1993 SPE Gas Technology Symposium,

Damage Research Consortium at the U. of Texas in Austin under Calgary, 28–30 June.

supervision of Larry W. Lake and Robert S. Schechter. To make 25. Fambrough, J.D., Brady, J.L., and Almond, S.W.: “Return Fluid Anal-

these analyses possible, their contributions are also acknowledged ysis From the Sadlerochit Formation, Prudhoe Bay, Alaska: A Labo-

and greatly appreciated. ratory Study—Part II,” paper SPE 22079 presented at the 1991 SPE

Arctic Technology Conference, Anchorage, 29–31 May.

References 26. Lindsay, D.M.: “An Experimental Study of Sandstone Acidization,”

Report No. UT 76-1, Texas Petroleum Research Committee, U. of

1. Williams, B.B., Gidley, J.L., and Schechter, R.S.: Acidizing Funda-

Texas, Austin, Texas (1976).

mentals, Monograph Series, SPE, Richardson, Texas (1979) 6, 16–17.

2. Labrid, J.C.: “Thermodynamic and Kinetic Aspects of Argillaceous 27. Bryant, S.L.: “An Improved Model of Mud Acid/Sandstone Chemistry,”

Sandstone Acidizing,” SPEJ (April 1975) 117. paper SPE 22855 presented at the 1991 SPE Annual Technical Con-

3. McCune, C.C. et al.: “A New Model of the Physical and Chemical ference and Exhibition, Dallas, 6–9 October.

Changes in Sandstone During Acidizing,” SPEJ (October 1975) 361. 28. Paccaloni, G., Tambini, M., and Galoppini, M.: “Key Factors for

4. Fogler, H.S. and McCune, C.C.: “On the Extension of the Model of Matrix Enhanced Results of Matrix Stimulation Treatments,” paper SPE 17154

Acid Stimulation to Different Sandstones,” AIChE J. (1976) 22, 799. presented at the 1988 SPE Formation Damage Control Symposium,

5. Hill, A.D. et al.: “Theoretical and Experimental Studies of Sandstone Bakersfield, California, 8–9 February.

Acidizing,” SPEJ (February 1981) 30. 29. Shaughnessy, C.M. and Kunze, K.R.: “Understanding Sandstone

6. Gdanski, R.D.: “Kinetics of the Primary Reaction of HF Aluminosili- Acidizing Leads to Improved Field Practices,” JPT (July 1981) 1196.

cates,” paper SPE 37459 presented at the 1997 SPE Production Oper- 30. Gdanski, R.D. and Peavy, M.A.: “Well Return Analysis Causes Re-

ations Symposium, Oklahoma City, Oklahoma, 9–11 May. Evaluation of HCl Theories,” paper SPE 14825 presented at the 1986

7. Gdanski, R.D.: “Kinetics of Tertiary Reaction of Hydrofluoric Acid on SPE Formation Damage Control Symposium, Lafayette, Louisiana,

Aluminosilicates,” SPEPF (May 1998) 75. 26–27 February.

8. Shuchart, C.E. and Buster, D.C.: “Determination of the Chemistry of HF 31. Crowe, C.W.: “Precipitation of Hydrated Silica From Spent Hydroflu-

Acidizing With the Use of 19F NMR Spectroscopy,” paper SPE 28975 oric Acid: How Much of a Problem Is It?” JPT (November 1986) 1234;

presented at the 1995 SPE International Symposium on Oilfield Chem- Trans., AIME, 281.

istry, San Antonio, Texas, 14–17 February. 32. Fluid Selection Guide for Matrix Treatments, B. Piot and R. Thomas,

9. Shuchart, C.E. and Ali, S.A.: “Identification of Aluminum Scale With (eds.), Dowell, Tulsa, Oklahoma (1990) 9–23.

the Aid of Synthetically Produced Basic Aluminum Fluoride Complex- 33. Schaible, D.F. and Ayoub, J.A.: “Identification, Evaluation, and Treat-

es,” SPEPF (November 1993) 291. ment of Formation Damage, Offshore Louisiana,” paper SPE 14820

10. Gdanski, R.D. and Shuchart, C.E.: “Newly Discovered Equilibria Con- presented at the 1986 SPE Formation Damage Conference, Lafayette,

trol HF Stoichiometry,” JPT (February 1996) 145. Louisiana, 26–27 February.

11. Gdanski, R.D.: “Kinetics of the Secondary Reaction of HF on Alumi-

nosilicates,” paper SPE 37214 presented at the 1997 SPE International

Symposium on Oilfield Chemistry, Houston, 18–21 February. SI Metric Conversion Factors

12. Gdanski, R.D.: “Fluosilicate Solubilities Affect HF Compositions,” bbl 3 1.589 873 E201 5 m3

SPEPF (November 1994) 225; Trans., AIME, 297. cp 3 1.0* E203 5 Pazs

13. Walsh, M.P., Lake, L.W., and Schechter, R.S.: “A Description of ft 3 3.048* E201 5 m

Chemical Precipitation Mechanisms and Their Role in Formation Damage ft2 3 9.290 304* E202 5 m2

During Stimulation by Hydrofluoric Acid,” JPT (September 1982) 2097. ft3 3 2.831 685 E202 5 m3

14. “Chemical Stimulation,” Halliburton Modern Completion Practices °F (°F232)/1.8 5 °C

(1986) 2, 31–32. in. 3 2.54* E100 5 cm

15. Stohs, M.: “A Study of Metal Ion Migration in Soils from Drilling Mud psi 3 6.894 757 E100 5 kPa

Pit Discharges,” MS thesis, U. of Texas, Austin, Texas (1986). *Conversion factor is exact. SPEJ

16. Sevougian, S.D., Lake, L.W., and Schechter, R.S.: “KGEOFLOW: A

New Reactive Transport Simulator for Sandstone Matrix Acidizing,”

SPEPF (February 1995) 13. Ying-Hsiao Li is a senior principal research engineer with Arco

17. Li, Y.-H. et al.: “Waterflood Geochemical Modeling and a Prudhoe Bay E&P Technology in Plano, Texas. e-mail: yingli@arco.com. He

Zone 4 Case Study,” SPEJ (March 1997) 58. joined Arco in 1979 and has worked on a variety of research

18. Quinn, M.A., Lake, L.W., and Schechter, R.S.: “Designing Effective issues including synthetic fuels, coal, miscible flooding, phase

Sandstone Acidizing Treatments Through Geochemical Modeling,” behavior, formation damage, and stimulation. Li holds a BS

paper SPE 38173 presented at the 1997 SPE European Formation degree in chemical engineering from Tunghai U. and MS and

Damage Conference, The Hague, The Netherlands, 2–3 June. PhD degrees in chemical and fuels engineering from the U. of

Utah. John D. Fambrough is a senior research engineer at Arco

19. Smith, W.R. and Missen, R.W.: Chemical Reaction Equilibrium Analysis:

E&P Technology in Plano. He currently works on formation

Theory and Algorithms, John Wiley & Sons, New York City (1982). damage and acidizing issues. Before joining Arco, he was a

20. Wagman, D.D. et al.: “The NBS Tables of Chemical Thermodynamic senior chemist with BJ Services, where he worked in cementing,

Properties: Selected Values for Inorganic and C1 and C2 Organic sand control, and acidizing. Fambrough holds a BS degree in

Substances in SI Units,” J. Physical and Chemical Reference Data zoology and an MS degree in biology from Texas A&M U. Carl

(1982) 11, Supplement No. 2. T. Montgomery is Research Advisor for well stimulation at Arco

21. Robie, R.A., Hemingway, B.S., and Fisher, J.R.: “Thermodynamic Prop- E&P Technology in Plano, responsible for development and

erties of Minerals and Related Substances at 298.15°K and 1 Bar (105 transfer of stimulation technologies for Arco’s operating com-

Pascals) Pressure and at Higher Temperatures,” U.S. Geological Survey panies. He holds a BS degree from Colorado State U. and an MS

degree in biochemistry from Ball State U. A 1998 –99 Distin-

Bull. 1452, U.S. Government Printing Office, Washington, DC (1978).

guished Lecturer, Montgomery served on the SPE Editorial Re-

22. Hemingway, B.S., Hass, J.L. Jr., and Robinson, G.R. Jr., “Thermody- view Committee during 1984 –92 and as 1994 –95 SPE Produc-

namic Properties of Selected Minerals in the System Al2O3-CaO-SiO2- tion & Facilities Executive Editor. He also served as a member of

H2O at 298.15°K and 1 Bar (105 Pascals) Pressure and at Higher the Forum Series in North America Steering Committee during

Temperatures,” U.S. Geological Survey Bull. 1544, U.S. Government 1989 –92 and in 1996 and as chairman of the 1998 Forum on

Printing Office, Washington, DC (1982). Fracture Diagnostics.

SPE Journal, December 1998 401

Vous aimerez peut-être aussi

- Application of Two Methods To Evaluate Matrix Acidizing Using Real-Time Skin Effect in Saudi Arabia - SPE 73703, 2002Document7 pagesApplication of Two Methods To Evaluate Matrix Acidizing Using Real-Time Skin Effect in Saudi Arabia - SPE 73703, 2002alizareiforoushPas encore d'évaluation

- Spe 6607 Pa PDFDocument13 pagesSpe 6607 Pa PDFsamirquirogaPas encore d'évaluation

- Spe 2622 PaDocument8 pagesSpe 2622 PasamirquirogaPas encore d'évaluation

- Diccionario Ingles-Espanol PDFDocument295 pagesDiccionario Ingles-Espanol PDFJose Daniel ChamorroPas encore d'évaluation

- Drilling Rig Components Illustration - Komponen Utama PemboranDocument86 pagesDrilling Rig Components Illustration - Komponen Utama PemboranPuji LestariPas encore d'évaluation

- Spe 2622 PaDocument8 pagesSpe 2622 PasamirquirogaPas encore d'évaluation

- IPTC 12610 Petrophysical Evaluation of Gas Hydrate FormationsDocument11 pagesIPTC 12610 Petrophysical Evaluation of Gas Hydrate FormationssamirquirogaPas encore d'évaluation

- Petsoc 08 08 15 Ge PDocument3 pagesPetsoc 08 08 15 Ge PsamirquirogaPas encore d'évaluation

- State-Of-The-Art - Integrated Studies Methodologies - An Historical ReviewDocument17 pagesState-Of-The-Art - Integrated Studies Methodologies - An Historical ReviewsamirquirogaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Model Question Papers of 1st YearDocument29 pagesModel Question Papers of 1st Yearparinitha shatagopamPas encore d'évaluation

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityKathit VasavadaPas encore d'évaluation

- Carbon Dioxide Absorption Into Promoted Carbonate SolutionsDocument10 pagesCarbon Dioxide Absorption Into Promoted Carbonate SolutionsDunyu LiuPas encore d'évaluation

- CO2 Reforming of CH4 Over Supported Ru CatalystsDocument7 pagesCO2 Reforming of CH4 Over Supported Ru CatalystsPedro lopezPas encore d'évaluation

- SPM 2008 JUJ Pahang Chemistry DocumentDocument55 pagesSPM 2008 JUJ Pahang Chemistry DocumentApple KWPas encore d'évaluation

- Combined Science: Paper 0653/12 Multiple Choice (Core)Document20 pagesCombined Science: Paper 0653/12 Multiple Choice (Core)equakeroatsPas encore d'évaluation

- Multiple Char Combustion TutorialDocument19 pagesMultiple Char Combustion TutorialMuchammad FauziPas encore d'évaluation

- Indian Journal of Chemistry: Synthesis and cytotoxicity studies of thiazole analogs of the anticancer marine alkaloid dendrodoineDocument6 pagesIndian Journal of Chemistry: Synthesis and cytotoxicity studies of thiazole analogs of the anticancer marine alkaloid dendrodoineABBS FEN REJI T. F.Pas encore d'évaluation

- Chemical Kinetics FactorsDocument16 pagesChemical Kinetics FactorsjoasePas encore d'évaluation

- CHEMISTRY FOR ENGINEERS Syllabus Updated 91322Document13 pagesCHEMISTRY FOR ENGINEERS Syllabus Updated 91322Mark Cidric RoqueroPas encore d'évaluation

- Physical Science Notes-1Document216 pagesPhysical Science Notes-1Yaj CruzadaPas encore d'évaluation

- B216 Acid Neutralization With LimeDocument18 pagesB216 Acid Neutralization With Limeespirito2009100% (1)

- Lesson Plan DemoDocument6 pagesLesson Plan DemoQueenvierlyn Rupido0% (1)

- CH-314 Lab Experiment 7Document4 pagesCH-314 Lab Experiment 7Fatima tahirPas encore d'évaluation

- MSC Org Chem Notes GDDocument256 pagesMSC Org Chem Notes GDsalinips350% (2)

- ICSE Class 10 CHEMISTRY Previous Year Question Paper 2010Document8 pagesICSE Class 10 CHEMISTRY Previous Year Question Paper 2010Madhu SudanPas encore d'évaluation

- Kji NYISS5 M UDocument459 pagesKji NYISS5 M UAman PharmacyCollegePas encore d'évaluation

- Chapter 0 Front Pages To The EndDocument170 pagesChapter 0 Front Pages To The EndAhmad Syafiq Fauzan Mohd AsnawiPas encore d'évaluation

- 2019 Sec 4 Science Chemistry SA2 Singapore Sports SchoolDocument30 pages2019 Sec 4 Science Chemistry SA2 Singapore Sports School19Y1H GAO CHENZHANGPas encore d'évaluation

- Water As SolvantDocument6 pagesWater As SolvantMedPas encore d'évaluation

- 9701 s11 QP 13 PDFDocument16 pages9701 s11 QP 13 PDFNorbertus Krisnu PrabowoPas encore d'évaluation

- Photo InitiatorsDocument15 pagesPhoto InitiatorsJuan Antonio Tito Esp CalPas encore d'évaluation

- Green Diesel Production From Upgrading of Cashew Nut Shell Liquid PDFDocument11 pagesGreen Diesel Production From Upgrading of Cashew Nut Shell Liquid PDFDaniela J. TitusPas encore d'évaluation

- Ketones and Carboxylic Acids GuideDocument5 pagesKetones and Carboxylic Acids GuideAnindya AcharyaPas encore d'évaluation

- Organoboron and organosilicon chemistry tutorialDocument6 pagesOrganoboron and organosilicon chemistry tutorialBin RenPas encore d'évaluation

- PX PtaDocument39 pagesPX PtaAshok Sharma100% (1)

- ChemistryI IIDocument2 pagesChemistryI IINaman kPas encore d'évaluation

- IB CHEMISTRY TEST KineticsDocument5 pagesIB CHEMISTRY TEST KineticsBeeta KhannaPas encore d'évaluation

- Emailing Chemical Kinetics (Class 12)Document12 pagesEmailing Chemical Kinetics (Class 12)Bakul ShrivastavaPas encore d'évaluation

- FDG Production-Theory Operations-FDG Synthesis Chemistr1Document25 pagesFDG Production-Theory Operations-FDG Synthesis Chemistr1Cesar Adolfo SanchezPas encore d'évaluation