Académique Documents

Professionnel Documents

Culture Documents

8.2 Dse 4 Steps To Successful Synchronising: Commissioning

Transféré par

lucasDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

8.2 Dse 4 Steps To Successful Synchronising: Commissioning

Transféré par

lucasDroits d'auteur :

Formats disponibles

Commissioning

8.2 DSE 4 STEPS TO SUCCESSFUL SYNCHRONISING

Synchronising and load sharing is often considered to be a complex subject. In fact, it is very simple

when broken down into smaller steps.

After following the Commissioning section of this manual, the DSE 4 Steps must be followed before

any parallel operation is attempted.

The following information is a short form guide only, intended as a memory jogger once the steps are

fully understood.

The full video presentation of the 4 Steps is available on the DSE website. www.deepseaplc.com.

Registration on the website is required. This is free of charge, along with all other downloads.

Page 171 of 188 057-254 ISSUE: 2

Commissioning

8.2.1 CONTROL

CAUTION!: Failure to perform the Control steps results in poor control over the engine

and alternator. This causes long and unstable synchronising as well as unstable kW and kvar

load sharing.

NOTE: For further details of module configuration, refer to DSE Publication: 057-238

DSE8610 MKII Configuration Suite PC Software Manual.

8.2.1.1 DETERMINING CONNECTIONS AND SETTINGS FOR GOVERNORS

Setting up the Governor (Adjustment of SW1 and SW2)

Before You Start

1. Ensure that the generator is connected to a DEAD BUS BAR WITH NO LOADS connected.

2. With the generator breaker open, set the generator to run at the Nominal Frequency without the

DSE module connected to the Governor. To achieve this you will have to adjust the settings on

the governor.

3. Connect the DSE module to the Governor once completed. The DSE controller connects only to

the “-” and “IN” terminals and provides the varying DC voltage to simulate the turning of a

potentiometer. The Analogue output terminals of the DSE controller are connected as follows.

Note that the “+” terminal of the governor is left unconnected.

Adjustment of Governor SW1

4. Start the generator and ensure that the breaker is left open.

5. Check the direction of drive by increasing and decreasing SW1. If the frequency increases whilst

SW1 is being decreased tick the option ‘Output Reversed’. If moving SW1 does not change the

frequency, check the wiring to the governor for faults.

6. Adjust the SW1 setting for the Governor until the generator runs at Nominal Frequency (50 Hz

or 60 Hz)

7. Stop the generator. SW1 is now complete and needs to be left alone.

057-254 ISSUE: 2 Page 172 of 188

Commissioning

Adjustment of Governor SW2

8. Increase the setting of the Nominal Frequency by 2.5 Hz (52.5 Hz or 62.5 Hz)

9. Start the generator. With the breaker open the generator will run at setting of SW1 (50 Hz or 60

Hz).

10. Close the generator breaker onto a DEAD BUS BAR WITH NO LOADS connected. The

generator frequency shall start to increase towards the new Nominal Frequency setting (52.5 Hz

or 62.5 Hz) however it may not achieve this.

11. Adjust SW2 to allow the frequency to increase to the new Nominal Frequency (52.5 Hz or 62.5

Hz)

12. Keep adjusting SW2 further to ensure Governor Drive reads within 75% to 85%, the sign of the

drive (+ or - percentage) does not matter.

13. Stop the Generator

14. Decrease the setting of the Nominal Frequency by 2.5 Hz (47.5 Hz or 57.5 Hz)

15. Start the generator. With the breaker open the generator will run at setting of SW1 (50 Hz or 60

Hz).

16. Close the generator breaker onto a DEAD BUS BAR WITH NO LOADS connected. The

generator frequency shall start to decrease towards the new Nominal Frequency (47.5 Hz or 57.5

Hz).

17. SW2 is then adjusted further to ensure Governor Drive reads within 75% to 85%, the sign of the

drive (+ or - percentage) does not matter. Note that any change made to the lower percentage

will be the same for the upper percentage. For example, if the lower percentages from 70% to

75%, the upper will increase from 80% to 85%.

18. Change the setting of the Nominal Frequency back to the actual Nominal Frequency (50 Hz or 60

Hz).

Page 173 of 188 057-254 ISSUE: 2

Commissioning

8.2.1.2 DETERMINING CONNECTIONS AND SETTINGS FOR AVRS

NOTE: Determining the settings of SW1 and SW2 for the AVR MUST only be done once

the setup for SW1 and SW2 for the governor has been complete. Changing engine speed

affects the level of voltage produced.

Setting up the AVR (Adjustment of SW1 and SW2)

Before You Start

1. Ensure that the generator is connected to a DEAD BUS BAR WITH NO LOADS connected.

2. With the generator breaker open, set the generator to run at the Nominal Voltage without the

DSE module connected to the AVR. To achieve this you will have to adjust the settings on the

AVR.

3. Connect the DSE module to the AVR once completed. The DSE controller connects only to the “-

” and “IN” terminals and provides the varying DC voltage to simulate the turning of a

potentiometer. The Analogue output terminals of the DSE controller are connected as follows.

Note that the “+” terminal of the AVR is left unconnected.

Adjustment of AVR SW1

4. Start the generator and ensure that the breaker is left open.

5. Check the direction of drive by increasing and decreasing SW1. If the voltage increases whilst

SW1 is being decreased tick the option ‘Output Reversed’. If moving SW1 does not change the

voltage, check the wiring to the AVR for faults.

6. Adjust the SW1 setting for the AVR until the generator runs at Nominal Voltage (230V for

example).

7. Stop the generator. SW1 is now complete and needs to be left alone.

057-254 ISSUE: 2 Page 174 of 188

Commissioning

Adjustment of AVR SW2

8. Increase the setting of the Nominal Voltage by 10% (230 v to 253 V for example)

9. Start the generator. With the breaker open the generator will run at setting of SW1 (230V for

example).

10. Close the generator breaker onto a DEAD BUS BAR WITH NO LOADS connected. The

generator voltage shall start to increase towards the new Nominal Voltage setting (253V for

example) however it may not achieve this.

11. Adjust SW2 to allow the voltage to increase to the new Nominal Voltage setting (253V for

example)

12. Keep adjusting SW2 further to ensure AVR Drive reads within 75% to 85%, the sign of the drive

(+ or - percentage) does not matter.

13. Stop the Generator

14. Decrease the setting of the Nominal Voltage by 10% (207 V for example)

15. Start the generator. With the breaker open the generator will run at setting of SW1 (230V for

example).

16. Close the generator breaker onto a DEAD BUS BAR WITH NO LOADS connected. The

generator voltage shall start to decrease towards the new Nominal Voltage (207 V for example).

17. SW2 is then adjusted further to ensure AVR Drive reads within 75% to 85%, the sign of the drive

(+ or - percentage) does not matter. Note that any change made to the lower percentage will be

the same for the upper percentage. For example, if the lower percentages from 70% to 75%, the

upper will increase from 80% to 85%.

18. Change the setting of the Nominal Voltage back to the actual Nominal Voltage (230 V for

example).

Page 175 of 188 057-254 ISSUE: 2

Commissioning

8.2.2 METERING

CAUTION!: Failure to perform the Metering steps results in incorrect power factor and kW

calculations leading to problems with kW and kvar load sharing if not corrected.

WARNING!: Do not disconnect this plug when the CTs are carrying current.

Disconnection open circuits the secondary of the C.T.’s and dangerous voltages may then

develop. Always ensure the CTs are not carrying current and the CTs are short circuit

connected before making or breaking connections to the module.

8.2.2.1 CTS ON THE RIGHT PHASE

Check to ensure that the CTs on L1, L2 & L3 are connected to their respective connection on the DSE

module.

This is tested by loading the generator with a purely resistive load (around 10% of the generator’s

size) across the three phases. If the CTs are wired correctly to the DSE module, it displays unity

power factor (1.0 pf) across all three phases. If unity power factor is not displayed the CTs have been

wired to the wrong phases on the DSE module.

8.2.2.2 CTS IN THE RIGHT DIRECTION

NOTE: Checking that the CTs are on the right phase MUST be completed prior to checking

if the CTs are in the correct direction. CTs on the wrong phase also cause negative kWs.

Check to ensure that the CTs on L1, L2 & L3 have been mounted for the correct orientation for current

flow and that the S1 and S2 have not been swapped over.

This is tested by loading the generator with a purely resistive load (around 10% of the generator’s

size) across the three phases. If the CTs’ S1 and S2 are wired to correctly to the DSE module, it

displays positive kW. If negative kWs is displayed the CTs’ S1 and S2 have been swapped around.

057-254 ISSUE: 2 Page 176 of 188

Commissioning

8.2.3 COMMUNICATIONS

CAUTION!: Failure to perform the Communications steps results in the controllers being

unable to communicate to the other DSE controllers leading to problems during load sharing.

NOTE: For further details of module configuration, refer to DSE Publication: 057-238

DSE8610 MKII Configuration Suite PC Software Manual.

Check to ensure that all the modules are connected on the MSC link and are communicating

correctly.

This is tested by connecting the DSE module to a PC with the DSE Configuration Suite PC Software

installed and going to the SCADA | Generator | Multi-Set section. The number of Sets On The Bus

must be the same as the number of DSE8x10s on the MSC link. The number of Mains Controllers ON

The Bus must be the same as the combined number of DSE8x60s and DSE8x80s on the MSC link.

If these numbers do not match up there is a fault on the MSC link. To find the module with the fault,

connect into each module individually until the Sets On The Bus or Mains Controllers ON The Bus

reports 1.

If these numbers do match up the MSC link is working correctly. A further test to perform is to ensure

that the module detects when the MSC link fails. This is tested by removing the MSC link connection

from any module on the MSC link. The numbers shown in SCADA | Generator | Multi-Set change to

reflect the failure and an MSC Failure alarm appears on the module’s display.

Page 177 of 188 057-254 ISSUE: 2

Commissioning

8.2.4 SYNC CHECKS

CAUTION!: Failure to perform the Metering steps results in in serious damage to the

system (breakers, bus bars, alternators, engines etc) caused by out of sync closures.

Check to ensure that all the module’s sensing cables have been connected to the correct phases and

that the generator’s load switch has been correctly connected. Failing to perform such tests may lead

to the DSE module sensing both sides of the breaker as in sync

This is tested by starting the generator with the DSE module and ensuring the generator load switch is

left open (activate an input configured for Generator Load Inhibit). Then the generator common bus is

to be made live, this is achieved by starting another generator and closing its load switch. Across the

open load switch, connect a voltage meter to measure the AC voltage when the DSE module shows

the two supplies in sync.

057-254 ISSUE: 2 Page 178 of 188

Commissioning

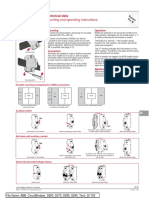

8.2.4.1 INCORRECTLY WIRED BREAKER

When the DSE module’s synchroscope shows the two supplies in sync, if the voltage meter shows a

voltage difference the breaker is wired incorrectly. This is shown in the example below.

Page 179 of 188 057-254 ISSUE: 2

Commissioning

8.2.4.2 CORRECTLY WIRED BREAKER

When the DSE module’s synchroscope shows the two supplies in sync, if the voltage meter shows no

voltage difference the breaker is wired correctly. This is shown in the example below.

057-254 ISSUE: 2 Page 180 of 188

Vous aimerez peut-être aussi

- Practical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsD'EverandPractical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsPas encore d'évaluation

- RAI S ManualDocument2 pagesRAI S ManualNesil Abiera0% (1)

- Fundamentals of The RectennaDocument37 pagesFundamentals of The RectennaWilfredo A MolinaPas encore d'évaluation

- Asymmetric Behavior of Propeller-Rudder SystemDocument13 pagesAsymmetric Behavior of Propeller-Rudder Systemsumardiono10Pas encore d'évaluation

- Armored Cable For Hazardous LocationsDocument29 pagesArmored Cable For Hazardous Locationsjonalyn asuncionPas encore d'évaluation

- Simatic PC Basead ControlDocument29 pagesSimatic PC Basead ControlSam eagle goodPas encore d'évaluation

- Magnetic Pick UpsDocument4 pagesMagnetic Pick UpslunikmirPas encore d'évaluation

- Allen Bradley-PLC5 Programming GuideDocument147 pagesAllen Bradley-PLC5 Programming Guideborre005Pas encore d'évaluation

- Autopilot ManualDocument73 pagesAutopilot ManualRyk BroPas encore d'évaluation

- AVR GAVR 15data Leiras - 2Document2 pagesAVR GAVR 15data Leiras - 2Argee PadauanPas encore d'évaluation

- Pro Act - TDocument120 pagesPro Act - TCarlos TorrezPas encore d'évaluation

- EC&M Branch Circuits - Part 1Document6 pagesEC&M Branch Circuits - Part 1jobpei2Pas encore d'évaluation

- AP28 Autopilot: Operator ManualDocument126 pagesAP28 Autopilot: Operator ManualChris Wooley100% (1)

- Grounding MaterialsDocument32 pagesGrounding MaterialsSatyaPas encore d'évaluation

- AP50 Installation PlusDocument142 pagesAP50 Installation PlusPeterJBloomPas encore d'évaluation

- Diddi Automation DiagramDocument87 pagesDiddi Automation DiagramRK PanchalPas encore d'évaluation

- Panelboards - Electrical Design GuideDocument1 pagePanelboards - Electrical Design GuidezelitePas encore d'évaluation

- 26-Chapter 4 Short Circuit Analysis Working-Equipment EvaluationDocument13 pages26-Chapter 4 Short Circuit Analysis Working-Equipment EvaluationRyan Anthony UmaliPas encore d'évaluation

- A. Mitsubishi Generator Set Diesel Lineup From EuropeDocument8 pagesA. Mitsubishi Generator Set Diesel Lineup From Europeyudi handokoPas encore d'évaluation

- Synchronous Generator J.Majumder MIE Senior FacultyDocument18 pagesSynchronous Generator J.Majumder MIE Senior FacultyQuang Tiên100% (1)

- Distribution Transformer - Instruction ManualDocument23 pagesDistribution Transformer - Instruction ManualZulfadhliPas encore d'évaluation

- ConduitsDocument10 pagesConduitsSiddiqui Abdul KhaliqPas encore d'évaluation

- Value of Lost LoadDocument7 pagesValue of Lost LoadLuis AntonioPas encore d'évaluation

- Equipment Damage Curves CapacitorsDocument2 pagesEquipment Damage Curves CapacitorsrobertoseniorPas encore d'évaluation

- DNV Rules For Electrical Instal at IonsDocument80 pagesDNV Rules For Electrical Instal at Ionsnzjohn100% (3)

- ISOC Control GenreatorsDocument4 pagesISOC Control GenreatorsStuart Robinson100% (1)

- RLC 1st ManualDocument141 pagesRLC 1st Manualjaved shaikh chaandPas encore d'évaluation

- Wireless Power Transmission and Reception Using Solar Power Satellites and RectennaDocument18 pagesWireless Power Transmission and Reception Using Solar Power Satellites and RectennaPradeep CheekatlaPas encore d'évaluation

- Tender Specifications: Please Rename The File Before Deliver To Third Party (Remember To Delete This Window)Document11 pagesTender Specifications: Please Rename The File Before Deliver To Third Party (Remember To Delete This Window)dhruvPas encore d'évaluation

- Insulation Test SystemDocument12 pagesInsulation Test SystemYi Fang YuePas encore d'évaluation

- MCM xcx-231 PrewiewDocument4 pagesMCM xcx-231 Prewiewmujo_11Pas encore d'évaluation

- 1212-02-15kV Delta Delta Padmount TransformerDocument11 pages1212-02-15kV Delta Delta Padmount TransformerpraveenniteenPas encore d'évaluation

- Cable Tray Size As Per National Electrical Code-2002. Article 3Document5 pagesCable Tray Size As Per National Electrical Code-2002. Article 3Vishnu Vardhan Reddy BaitintiPas encore d'évaluation

- Flatpack2 24V-2 PDFDocument2 pagesFlatpack2 24V-2 PDFFURIVANPas encore d'évaluation

- Electrical Preventive Maintenance of Air Circuit BreakersDocument6 pagesElectrical Preventive Maintenance of Air Circuit BreakersPierre Enrique Carrasco FuentesPas encore d'évaluation

- Manual Eaton DS IiDocument28 pagesManual Eaton DS IiAdrian RodriguesPas encore d'évaluation

- Calculate The Suitable Capacitor Size in Farads & kVAR For PF ImprovementDocument4 pagesCalculate The Suitable Capacitor Size in Farads & kVAR For PF ImprovementmaungsoekhinPas encore d'évaluation

- HIO TouchScreenDocument4 pagesHIO TouchScreenMaitry ShahPas encore d'évaluation

- ELEC4612-12 Exp 2 Power FlowDocument5 pagesELEC4612-12 Exp 2 Power FlowDavid VangPas encore d'évaluation

- Experiment 2: Level Transmitter CalibrationDocument13 pagesExperiment 2: Level Transmitter CalibrationMuhammad FawwazPas encore d'évaluation

- Generator TheoryDocument4 pagesGenerator TheoryRachit KhannaPas encore d'évaluation

- 841 VCB HVF&HVG Catalogue 2012.1Document56 pages841 VCB HVF&HVG Catalogue 2012.1Sergio Ignacio Zurita VargasPas encore d'évaluation

- Parallel Operation of Synchronous Generators-V3Document70 pagesParallel Operation of Synchronous Generators-V3John Patrick CeldaPas encore d'évaluation

- 7420p008 Uptimax Ni-CD BatteryDocument16 pages7420p008 Uptimax Ni-CD BatteryNazif HawariPas encore d'évaluation

- DECS 200 ManualDocument181 pagesDECS 200 ManualJorge CervantesPas encore d'évaluation

- IAS28P4Document8 pagesIAS28P4anexi01Pas encore d'évaluation

- TP 6719Document16 pagesTP 6719Willy Alexander RamirezPas encore d'évaluation

- Iec Sit Sit Sepam CurveDocument1 pageIec Sit Sit Sepam Curveyadav_sctPas encore d'évaluation

- WW-MFR2 (Multifunction Relay)Document4 pagesWW-MFR2 (Multifunction Relay)KT MENONPas encore d'évaluation

- E-23 Shore Connection BoxDocument27 pagesE-23 Shore Connection Boxcengiz kutukcuPas encore d'évaluation

- AECMSGuideRevision 20091120Document104 pagesAECMSGuideRevision 20091120kmattaiPas encore d'évaluation

- SDC35/36 User's Manual: Single Loop ControllerDocument288 pagesSDC35/36 User's Manual: Single Loop ControllerAlex Horia0% (1)

- Overview of IEEE Color BooksDocument9 pagesOverview of IEEE Color Bookssalsa222100% (1)

- Motors and The NECDocument7 pagesMotors and The NECjonathandacumosPas encore d'évaluation

- 25 Ohms Ground Resistance HistoryDocument3 pages25 Ohms Ground Resistance HistoryBen E100% (1)

- FMDS0523 - Emergency and Standby Power SystemsDocument16 pagesFMDS0523 - Emergency and Standby Power SystemsAnonymous dZOTH3qxJPas encore d'évaluation

- Braking Resistor UnitDocument11 pagesBraking Resistor UnitpwmvsiPas encore d'évaluation

- DSE 4 Steps To Successful SynchronisingDocument11 pagesDSE 4 Steps To Successful SynchronisingCristof100% (1)

- Control: Programmable Display For Use in Vehicles and Off-Highway MachineryDocument6 pagesControl: Programmable Display For Use in Vehicles and Off-Highway MachinerylucasPas encore d'évaluation

- Voltage Regulation Performance of Smart Inverters: Power Factor Versus Volt-VAR ControlDocument6 pagesVoltage Regulation Performance of Smart Inverters: Power Factor Versus Volt-VAR ControllucasPas encore d'évaluation

- T6N 800 TMA 800-8000 3p F F: General InformationDocument2 pagesT6N 800 TMA 800-8000 3p F F: General InformationlucasPas encore d'évaluation

- Easypact Cvs Lv510317Document2 pagesEasypact Cvs Lv510317lucasPas encore d'évaluation

- PV-STATCOM: A New Smart Inverter For Voltage Control in Distribution SystemsDocument12 pagesPV-STATCOM: A New Smart Inverter For Voltage Control in Distribution SystemslucasPas encore d'évaluation

- AGC 200 Automatic Gen-Set Controller Data Sheet AGC 200 Advanced Gen-Set Controller Data SheetDocument13 pagesAGC 200 Automatic Gen-Set Controller Data Sheet AGC 200 Advanced Gen-Set Controller Data SheetlucasPas encore d'évaluation

- L Series Process Control 5418 2834 Firmware Release Explanation of Software ChangesDocument2 pagesL Series Process Control 5418 2834 Firmware Release Explanation of Software ChangeslucasPas encore d'évaluation

- 3RT10441BB44 Datasheet enDocument8 pages3RT10441BB44 Datasheet enlucasPas encore d'évaluation

- ECU MS 6pdf PDFDocument78 pagesECU MS 6pdf PDFlucas100% (4)

- LXC31X0 LXC31X0 LXC31X0 LXC31X0 Series Series Series Series Genset Genset Genset Genset Controller Controller Controller ControllerDocument28 pagesLXC31X0 LXC31X0 LXC31X0 LXC31X0 Series Series Series Series Genset Genset Genset Genset Controller Controller Controller ControllerlucasPas encore d'évaluation

- 3RT10441BB44 Datasheet enDocument8 pages3RT10441BB44 Datasheet enlucasPas encore d'évaluation

- 1SDA060268R1 t6n 800 pr221ds Ls I in 800 3p F FDocument2 pages1SDA060268R1 t6n 800 pr221ds Ls I in 800 3p F FlucasPas encore d'évaluation

- User Guide Imeon 9 12 enDocument20 pagesUser Guide Imeon 9 12 enlucasPas encore d'évaluation

- EDF SK 1-1 - 1HYB800001-090B (Latest)Document130 pagesEDF SK 1-1 - 1HYB800001-090B (Latest)ashton.emsliePas encore d'évaluation

- Caterpillar-Diesel Generator Set-Continuos PDFDocument6 pagesCaterpillar-Diesel Generator Set-Continuos PDFJOSE LUIS FALCON CHAVEZPas encore d'évaluation

- Product Data Sheet: Circuit Breaker Compact NS1250N, 50 Ka at 415 VAC, Micrologic 2.0 Trip Unit, 1250 A, Fixed, 4 Poles 4dDocument3 pagesProduct Data Sheet: Circuit Breaker Compact NS1250N, 50 Ka at 415 VAC, Micrologic 2.0 Trip Unit, 1250 A, Fixed, 4 Poles 4dAlan Jesus BrunPas encore d'évaluation

- ABB - Fuses Vs FuselessDocument18 pagesABB - Fuses Vs Fuselesskhalid100% (1)

- SP43 Machine & MaintenanceDocument207 pagesSP43 Machine & Maintenanceorhan kızmazPas encore d'évaluation

- Installation Guide JAT710E 26Document136 pagesInstallation Guide JAT710E 26prasad kandavarapuPas encore d'évaluation

- WiringDocument23 pagesWiringNoel NantesPas encore d'évaluation

- GW - HT 1500V - User Manual-EN (01-57) (31-57)Document27 pagesGW - HT 1500V - User Manual-EN (01-57) (31-57)Marcos GomesPas encore d'évaluation

- PSAFDocument8 pagesPSAFSmitha Patel100% (1)

- Low Voltage Switchgear or LV SwitchgearDocument3 pagesLow Voltage Switchgear or LV SwitchgearYasir JamilPas encore d'évaluation

- Mounting and Operating Instructions: Technical DataDocument12 pagesMounting and Operating Instructions: Technical DataryoPas encore d'évaluation

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.Pas encore d'évaluation

- DS - 20211104 - SG6250HV-MV Datasheet - V2.0 - ENDocument2 pagesDS - 20211104 - SG6250HV-MV Datasheet - V2.0 - ENJesica SantibañezPas encore d'évaluation

- CASE STUDY - Office DesignDocument48 pagesCASE STUDY - Office DesignDiya NeogiPas encore d'évaluation

- Captive Motor-Transformer PDFDocument11 pagesCaptive Motor-Transformer PDFAmorn Thumrat100% (1)

- West Bengal State Electricity TransmissiDocument28 pagesWest Bengal State Electricity TransmissiRituparna MandalPas encore d'évaluation

- SIPROTEC 5, Overcurrent Protection, Manual 9 C53000-G5040-C017-9, Edition 05.2018Document30 pagesSIPROTEC 5, Overcurrent Protection, Manual 9 C53000-G5040-C017-9, Edition 05.2018Nguyễn MẫnPas encore d'évaluation

- Schneider Legacy Products - GV3ME40Document3 pagesSchneider Legacy Products - GV3ME40farrelsyafiraPas encore d'évaluation

- Prisma TT Catalogue V2Document12 pagesPrisma TT Catalogue V2Mohammed AbdelsalamPas encore d'évaluation

- Home Inspection For 102 Pindar CrescentDocument57 pagesHome Inspection For 102 Pindar CrescentStacy MurphyPas encore d'évaluation

- Cd-Ii Max 51120Document232 pagesCd-Ii Max 51120Melissa Macias67% (3)

- Luck Now DocumentDocument552 pagesLuck Now DocumentMohanraj NidumoluPas encore d'évaluation

- Gek 36378D PDFDocument14 pagesGek 36378D PDFoso0214Pas encore d'évaluation

- Power Distribution at NFC EeeDocument70 pagesPower Distribution at NFC EeeTeEbhan ChAnthira SeEkaranPas encore d'évaluation

- Comparison Between Model and Experiment in Studying The Electric ArcDocument5 pagesComparison Between Model and Experiment in Studying The Electric ArcDavid LagarejoPas encore d'évaluation

- Switch YardDocument3 pagesSwitch YardkavinatamainarayanPas encore d'évaluation

- Tes P 119 05 R0Document8 pagesTes P 119 05 R0boopelectraPas encore d'évaluation

- AS/NZS 5033:2014: Revisions To The Grid-Connected PV Systems: Design and Installation Training Manual, 7th EditionDocument12 pagesAS/NZS 5033:2014: Revisions To The Grid-Connected PV Systems: Design and Installation Training Manual, 7th EditionravinderPas encore d'évaluation

- Annual Protection Maintenance On 10MVA Transformer T1 at Chavuma Substation - 2022Document17 pagesAnnual Protection Maintenance On 10MVA Transformer T1 at Chavuma Substation - 2022Friday HaankumbaPas encore d'évaluation

- Omicron PTL User Manual EnuDocument29 pagesOmicron PTL User Manual EnuimuPas encore d'évaluation