Académique Documents

Professionnel Documents

Culture Documents

Apc&sct Cie-1

Transféré par

Dhanush M H0 évaluation0% ont trouvé ce document utile (0 vote)

49 vues3 pagesThis document provides a question bank for a Process Control & Instrumentation Technology exam. It contains 14 multiple choice or short answer questions in Part A and 10 longer form questions in Part B. The questions cover topics like control systems, process characteristics, controller types and applications, signal transmission standards, and control loop diagrams.

Description originale:

CIE

Titre original

APC&SCT CIE-1

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides a question bank for a Process Control & Instrumentation Technology exam. It contains 14 multiple choice or short answer questions in Part A and 10 longer form questions in Part B. The questions cover topics like control systems, process characteristics, controller types and applications, signal transmission standards, and control loop diagrams.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

49 vues3 pagesApc&sct Cie-1

Transféré par

Dhanush M HThis document provides a question bank for a Process Control & Instrumentation Technology exam. It contains 14 multiple choice or short answer questions in Part A and 10 longer form questions in Part B. The questions cover topics like control systems, process characteristics, controller types and applications, signal transmission standards, and control loop diagrams.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

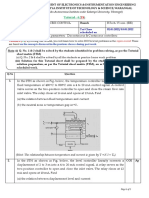

DEPARTMENT OF INSTRUMENTATION TECHNOLOGY

R V COLLEGE OF ENGINEERING

CLASS- 6th sem (AUTONOMOUS)

1st INTERNALS

SUBJECT: Process Control & Instrumentation Technology

Date:09/02/2016 Time:9:15- 11:15 am

Sub Code: 12IT63 Marks: 15+50 = 65

Note: Answer full questions from PARTS ‘A’ and ‘B’

QUESTION BANK

M CO BT

PART –A

1.1 A velocity control system has a range of 120 to 460 mm/s. If the set- 2 1 L5

point is 323 mm/s, and the measured value is 294 mm/s,

calculate the error as a percentage of span ?

1.2 Name the different types of discontinuous & continuous Controllers? 2 3 L1

1.3 Write the relation defining the controller output in percentage? 2 3 L3

Also, how do you define the percent of span error?

1.4 Denote the standard range of values for current transmission in 2 2 L2

industries? And, what is the industrial standard range suggested for

Pneumatic transmission?

1.5 For a 2-position controller, write: 2 3 L2

(1) Equation for controller output.

(2) Its input-output characteristic plot.

1.6 If a controller outputs a 4 - 20 mA current to FCE, & has an output of 2 3 L5

40 % w.r.t. the range, then determine the corresponding current value?

1.7 If a controller outputs a 4 - 20 mA current signal to the final control 2 2 L5

element and has a p=50%, then the corresponding current is ________.

1.8 How do you achieve self-regulation condition in steam-heated liquid- 2 1 L3

temperature control system?

2 1 L2

1.9 Differentiate between (1) Control, & (2) Regulation 1 1 L1

1.10 Describe Servomechanism.

1.11 The temperature in a large space needs to be controlled / regulated. 1 3 L2

Which controller would you design to regulate temperature there?

1.12 If a parameter is being controlled accurately by a controller & too 2 3 L5

much of chattering of the relay is observed, then what solution would

you suggest for smooth operation of the control system?

1.13 Which control system configuration has both data acquisition system 1 4 L5

& data output system to control multiple process parameters?

1.14 How would you define ‘Automatic Process Control’? 2 1 L1

PART –B

2 a Flow-rate in a pipeline needs to be controlled. By drawing the 5 1 L5

Physical Diagram of a Flow process control loop, develop its:

i Block Diagram.

ii Give all the details of pneumatic and electrical I or V signals

involved, and

iii Their Standard Ranges of values.

b With the help of a schematic diagram explain the operation of an 5 3 L3

ON/OFF control system, using Relays, which controls either heating

or cooling of a Oven.

3 a Suppose that a Liquid Level, ranging from 5.5 m to 8.6 m, is linearly 7 3 L5

converted to pneumatic pressure, ranging from 3 to 15 psi. What

Pressure will result from a level of 7.2 m? What Level does a pressure

of 4.7 psi represents?

b A Pressure Transducer’s transfer function is 44.5 mV/psi. The output 3 3 L4

voltage is measured at 8.86 V on a 3-digit Voltmeter. What can you

say about the value of the pressure?

4 a. A Temperature transducer measures temperature linearly with a static 4 3 L5

transfer function of 33 mV /deg.C and has a 1.5 sec Time-Constant.

Find output 0.95sec after the input changes from 20 deg.C to 41

deg.C. Find the error in temperature this represents.

b. Draw the Block-Diagram representation for : 8 5 L2

1. Direct Digital Control System, and

2. Supervisory Control System.

5. a. 3. Process control system using LAN.

4. PLC controlled oven system.

b. Explain with a neat diagram the “Self-Regulation” property of a 3 1 L2

process.

6. a. Describe with a schematic the following: 6 3 L2

1. Process Equation.

2. Process Load.

3. Self-Regulation.

b. How does a room air – conditioner work? Also explain it with respect 4 3 L2

to:

a. Process characteristics.

b. Features of the controller that you use for the purpose.

7. a. Draw the physical diagram of a closed loop Oven Temperature control 5 3 L2

system giving all the details of the standard signals involved, and draw

its block diagram?

b. Explain with a schematic the 2-position controller giving the 5 3 L2

mathematical model and a description of neutral zone.

8. a. In a temperature controlled oven a thermocouple is monted to measure 6 3 L5

temperature with a static transfer function of 33 mv/° C after the input

changes from 20°C to 41°C. Find the error in the measured

temperature?

b. With the help of a schematic diagram, explain how level of liquid in a 4 3 L2

tank can be controlled automatically? Explain the different control

concepts involved ?

9. A liquid level control system linearly converts a displacement of 2 - 3 10 3 L5

m into a 4 -20 mA control signal. A relay serves as the 2-position

controller to open or close an inlet valve. The relay closes at 12mA

and opens at 10mA. Find :

(1) The relation between displacement Level & Current, &

(2) The Neutral Zone in meters.

10 The temperature of water in a tank is controlled by a two-position 10 3 L5

controller. When the heater is off, the temperature drops at 2 K per

minute. When the heater is on, the temperature rises at 4 K per minute.

The set point is 323 K and the neutral zone is +/_ 2% of the set point.

There is a 0.5 min. lag at both the ON & OFF switch points. Find the

period of oscillation & plot the water temperature versus time.

Vous aimerez peut-être aussi

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsD'EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsPas encore d'évaluation

- Advanced Process ControlDocument2 pagesAdvanced Process ControlDhanush M HPas encore d'évaluation

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsD'EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsÉvaluation : 4 sur 5 étoiles4/5 (2)

- Midsem 2022-23Document2 pagesMidsem 2022-23Saffi SheikhPas encore d'évaluation

- Analog Circuit Design Volume Three: Design Note CollectionD'EverandAnalog Circuit Design Volume Three: Design Note CollectionÉvaluation : 3 sur 5 étoiles3/5 (2)

- Important Questions For E8651Document2 pagesImportant Questions For E8651YotriPas encore d'évaluation

- Mechatronics Question BankDocument3 pagesMechatronics Question BankPiyasa DasPas encore d'évaluation

- Unit2 MSDocument43 pagesUnit2 MSchandramohan murugan100% (1)

- 10 11648 J Acis 20140201 11 PDFDocument5 pages10 11648 J Acis 20140201 11 PDFwsa wsaPas encore d'évaluation

- Sinulink Doc 2 1Document3 pagesSinulink Doc 2 1samPas encore d'évaluation

- Control Loop HardwareDocument56 pagesControl Loop Hardwarecharleselitb92Pas encore d'évaluation

- Pet Engineering College - Vallioor: Me71-MechatronicsDocument7 pagesPet Engineering College - Vallioor: Me71-MechatronicslegenkillerPas encore d'évaluation

- ECEg6223 Sample Exam PDFDocument5 pagesECEg6223 Sample Exam PDFGenet BekelePas encore d'évaluation

- ON-OFF Temperature Control System Using MicroprocessorDocument4 pagesON-OFF Temperature Control System Using Microprocessorsoach123Pas encore d'évaluation

- Two Tank Non-Interacting Liquid Level SystemDocument9 pagesTwo Tank Non-Interacting Liquid Level SystemHimanshu JatPas encore d'évaluation

- IpcDocument3 pagesIpcJigna PatelPas encore d'évaluation

- Assignment 1Document5 pagesAssignment 1Karthik VyasPas encore d'évaluation

- MODEL 248 Multiple Arbitrary Function Generator User Manual REV 2.0Document17 pagesMODEL 248 Multiple Arbitrary Function Generator User Manual REV 2.0Nordlys OfficialPas encore d'évaluation

- Tutorial 1 2018Document6 pagesTutorial 1 2018EstherPas encore d'évaluation

- 04 Timer Counter DLLDocument37 pages04 Timer Counter DLLEldwinAdinataPas encore d'évaluation

- Taller Final de EjerciciosDocument7 pagesTaller Final de EjerciciosEduar QuirozPas encore d'évaluation

- Flow Control Trainer: Experiment No: 03Document3 pagesFlow Control Trainer: Experiment No: 03Musa KhanPas encore d'évaluation

- CPB 30004 - CHAPTER 1 - INTRO Sept 2014Document52 pagesCPB 30004 - CHAPTER 1 - INTRO Sept 2014Ashwin MPas encore d'évaluation

- Final ReportttttttDocument32 pagesFinal Reportttttttankitpanke100% (1)

- Project Report - PIDDocument45 pagesProject Report - PIDRohit Khajuria0% (1)

- Electrical Engineering Technology: Cambrian CollegeDocument12 pagesElectrical Engineering Technology: Cambrian CollegeGabrielGrecoPas encore d'évaluation

- Lab ReportDocument13 pagesLab ReportHemal MenukaPas encore d'évaluation

- Control Systems Lab ManualDocument67 pagesControl Systems Lab ManualRockstar Rich100% (1)

- PID Analitico Conversor BuckDocument8 pagesPID Analitico Conversor BuckOdair TrujilloPas encore d'évaluation

- 2018Ch85 - Pressure Controller FInal LabDocument12 pages2018Ch85 - Pressure Controller FInal LabAdeel AbbasPas encore d'évaluation

- PCVLDocument16 pagesPCVLabmuqeet2Pas encore d'évaluation

- AnswersDocument22 pagesAnswersVAIBHAV KESHAV MANGARPas encore d'évaluation

- ch19 - 1 PLC PDFDocument39 pagesch19 - 1 PLC PDFMASOUDPas encore d'évaluation

- Exp 7 Familiarization With The ChopperInverter Control Unit PDFDocument10 pagesExp 7 Familiarization With The ChopperInverter Control Unit PDFusmpowerlabPas encore d'évaluation

- Add Additional Information To Improve DiscoverabilityDocument5 pagesAdd Additional Information To Improve DiscoverabilityDereje Hailu0% (5)

- Adv Power ElectronicsDocument5 pagesAdv Power ElectronicsSumon DharaPas encore d'évaluation

- U18Ci606 Process Control B.Tech. VI Sem (EIE) 25.02.2022: Tutorial - 4Document2 pagesU18Ci606 Process Control B.Tech. VI Sem (EIE) 25.02.2022: Tutorial - 4Raviteja DhammishettyPas encore d'évaluation

- 000 Digital Control LecturesDocument67 pages000 Digital Control LecturesPX PRPas encore d'évaluation

- Mini Project Report-2Document26 pagesMini Project Report-2Remya Ramakrishnan0% (2)

- Instituto Tecnológico de Oaxaca: Examen Unidad I Y IiDocument4 pagesInstituto Tecnológico de Oaxaca: Examen Unidad I Y IiRaptor15mPas encore d'évaluation

- TICI Report1Document8 pagesTICI Report1razu1234Pas encore d'évaluation

- Digital ThermometerDocument5 pagesDigital ThermometerKannan AlagumuthiahPas encore d'évaluation

- LEC# 12-Process Control2020 PDFDocument18 pagesLEC# 12-Process Control2020 PDFShahidan KirkukyPas encore d'évaluation

- Robotics Chapter 8 - PLCsDocument16 pagesRobotics Chapter 8 - PLCstutorfelix777Pas encore d'évaluation

- TLE7242G-TLE8242-2L+-Application-Note KP KI V2 0Document13 pagesTLE7242G-TLE8242-2L+-Application-Note KP KI V2 0Larbi_Lakrout_7056Pas encore d'évaluation

- 17ME754 Mechatronics PLC and 8085Document9 pages17ME754 Mechatronics PLC and 8085Abhishek KumarPas encore d'évaluation

- Liquid Level Control System V2Document14 pagesLiquid Level Control System V2Shisanu SenPas encore d'évaluation

- PLC Based Sequential Batch Process Control SystemDocument11 pagesPLC Based Sequential Batch Process Control SystemAmol PawarPas encore d'évaluation

- CLL 361 Instrumentation & Automation: Munawar A. ShaikDocument28 pagesCLL 361 Instrumentation & Automation: Munawar A. ShaikRakeshKumarPas encore d'évaluation

- Experiment (1) Calibration and Characteristics of A Motorized ValveDocument41 pagesExperiment (1) Calibration and Characteristics of A Motorized ValveKhalid M MohammedPas encore d'évaluation

- Question BankDocument2 pagesQuestion BankSanatan DharmaPas encore d'évaluation

- Level Control in Horizontal Tank by Fuzzy-PID Cascade ControllerDocument5 pagesLevel Control in Horizontal Tank by Fuzzy-PID Cascade ControllerShivaji KaradPas encore d'évaluation

- Lab ManualDocument75 pagesLab ManualaathiraPas encore d'évaluation

- Assignment 01 MSD 17mte23Document4 pagesAssignment 01 MSD 17mte23Shahrukh Aleem JhatialPas encore d'évaluation

- PLC Based Control SystemDocument49 pagesPLC Based Control SystemNitin Prajapati100% (2)

- 1) Theoretical Background: 1-1) Function and DefinitionDocument13 pages1) Theoretical Background: 1-1) Function and DefinitionH. ZNADPas encore d'évaluation

- Problems On ON - OFF ControllerDocument8 pagesProblems On ON - OFF ControllerPiyulPas encore d'évaluation

- Final ControlDocument72 pagesFinal ControlUmang BiyaniPas encore d'évaluation

- Code No: 35110Document8 pagesCode No: 35110SRINIVASA RAO GANTAPas encore d'évaluation

- Library Membership Form EngDocument2 pagesLibrary Membership Form EngJayesh KhacharPas encore d'évaluation

- Transcribed Speech Roberto Mangabeira Unger at Social FrontiersDocument4 pagesTranscribed Speech Roberto Mangabeira Unger at Social Frontiersmarli_kaboomPas encore d'évaluation

- The Future of Money-Bernard Lietaer PDFDocument382 pagesThe Future of Money-Bernard Lietaer PDFJavier De Ory ArriagaPas encore d'évaluation

- Queuing Part 1 PDFDocument13 pagesQueuing Part 1 PDFabhaymainiPas encore d'évaluation

- EBEA Training PDFDocument100 pagesEBEA Training PDFAnonymous SQ5kprsQnPas encore d'évaluation

- Life Cycle AnalysisDocument14 pagesLife Cycle AnalysisAshesh PradhanPas encore d'évaluation

- Sastec2 - Technical Offer - 220kv Gis JSPL - Angul - Rev CDocument18 pagesSastec2 - Technical Offer - 220kv Gis JSPL - Angul - Rev CRakesh Kumar Singh (Phase 1B)Pas encore d'évaluation

- Collective SelfDocument3 pagesCollective Selfgabby tolentinoPas encore d'évaluation

- Chaos Theory and The Lorenz EquationDocument15 pagesChaos Theory and The Lorenz EquationloslogosehPas encore d'évaluation

- Ernest 1989Document22 pagesErnest 1989Alvenz Uswatun Meutia FajriPas encore d'évaluation

- Soil Survey Mapping - LectureNotes2Document132 pagesSoil Survey Mapping - LectureNotes2Udaya KumarPas encore d'évaluation

- Boundy8e PPT Ch03Document29 pagesBoundy8e PPT Ch03AndrewPas encore d'évaluation

- PISMDocument3 pagesPISMKishore KumarPas encore d'évaluation

- Tle Tech Draft 9 Q3 M1 1Document8 pagesTle Tech Draft 9 Q3 M1 1Princess Dirk DananPas encore d'évaluation

- EURASIA v8n4 OzgelenDocument10 pagesEURASIA v8n4 OzgelenSeptiana SariPas encore d'évaluation

- Practice Test For Pec 5Document10 pagesPractice Test For Pec 5Thuỳ Linh Đinh TháiPas encore d'évaluation

- Read - Edtpa Lesson Plan Car Spring 2015 Annotated 8Document7 pagesRead - Edtpa Lesson Plan Car Spring 2015 Annotated 8api-487235108Pas encore d'évaluation

- Taylor Stull C VDocument1 pageTaylor Stull C Vapi-314444915Pas encore d'évaluation

- Futuristic Nursing: M. Hemamalini M.SC (N) Senior Lecturer S.R.M. College of NursingDocument45 pagesFuturistic Nursing: M. Hemamalini M.SC (N) Senior Lecturer S.R.M. College of NursingJeyarani Karunanithi100% (1)

- Robots Drive SystemDocument28 pagesRobots Drive SystemDhalal AsmiPas encore d'évaluation

- The Threat of Ethical Accountants An Application of Foucault's Concept of Ethics To Accounting Education and Some Thoughts On Ethically Educating For The Other 1999 Critical PerspectivesDocument34 pagesThe Threat of Ethical Accountants An Application of Foucault's Concept of Ethics To Accounting Education and Some Thoughts On Ethically Educating For The Other 1999 Critical PerspectivesiportobelloPas encore d'évaluation

- H5-04-I Year 2011-12Document50 pagesH5-04-I Year 2011-12Rakesh KumarPas encore d'évaluation

- Henry Corbin and The Archetypal RealmDocument2 pagesHenry Corbin and The Archetypal RealmZeteticus100% (2)

- IC Project Tracking Template 8640 V1Document3 pagesIC Project Tracking Template 8640 V1eliiiiiiPas encore d'évaluation

- ADC7998 Driver ExplanationDocument10 pagesADC7998 Driver ExplanationRaghavendra GvrPas encore d'évaluation

- SINAMICS S120 Commissioning Manual 0306 EngDocument412 pagesSINAMICS S120 Commissioning Manual 0306 Engwww.otomasyonegitimi.com100% (1)

- Wuthering HeightsDocument26 pagesWuthering HeightsAbubakarr SankohPas encore d'évaluation

- Kali Lunix CommandDocument7 pagesKali Lunix CommandSubhash BhalekarPas encore d'évaluation

- Introduction To Fuzzy Logic Using MATLAB: S.N. Sivanandam, S. Sumathi and S.N. DeepaDocument5 pagesIntroduction To Fuzzy Logic Using MATLAB: S.N. Sivanandam, S. Sumathi and S.N. DeepaIrwan P Gunawan100% (1)

- Chem 1 SyllabusDocument10 pagesChem 1 SyllabusJaycee TualaPas encore d'évaluation

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- The Certified Oil and Gas Project ManagerD'EverandThe Certified Oil and Gas Project ManagerÉvaluation : 4 sur 5 étoiles4/5 (2)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Oil: An Overview of the Petroleum IndustryD'EverandOil: An Overview of the Petroleum IndustryÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesD'EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideD'EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideÉvaluation : 2 sur 5 étoiles2/5 (1)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesD'EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesÉvaluation : 5 sur 5 étoiles5/5 (7)

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation

- Deepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeD'EverandDeepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticePas encore d'évaluation

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbD'EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbÉvaluation : 4.5 sur 5 étoiles4.5/5 (11)

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsD'EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsPas encore d'évaluation

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsD'EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsPas encore d'évaluation

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonD'Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonPas encore d'évaluation

- The Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoD'EverandThe Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoPas encore d'évaluation

- Ship and Mobile Offshore Unit Automation: A Practical GuideD'EverandShip and Mobile Offshore Unit Automation: A Practical GuidePas encore d'évaluation

- Advanced Production Decline Analysis and ApplicationD'EverandAdvanced Production Decline Analysis and ApplicationÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationD'EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)