Académique Documents

Professionnel Documents

Culture Documents

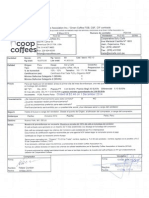

Foodsafety20180607 DL

Transféré par

José Abel Rodríguez VallejoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Foodsafety20180607 DL

Transféré par

José Abel Rodríguez VallejoDroits d'auteur :

Formats disponibles

J u n e n J u ly 2 018

FSM6718pg1-2,67-68.indd 1 6/11/18 1:36 PM

The Podcast for

Food Safety Professionals

Produced by the Food Safety Magazine editorial team – the leading media brand in food

safety for over 20 years. Each episode features news and trends, or another surprise segment,

followed by a conversation with a food safety professional who shares their experiences

and insights about the important job of safeguarding the world’s food supply.

The Biggest Issues Discussed by Some of the Biggest Names

• Best Practices • Culture • HACCP • FSMA (a lot!) • Foodservice • Audits • GFSI • Sanitation

• Process Validation • Allergens • Process Control • Food Fraud • Norovirus • Produce

• Lessons Learned from Outbreaks • Preparing for Inspections • and a lot more

• Dave Theno • Larry Keener • Lone Jespersen • Steve Taylor • John Spink • Joe Corby

• Scott Brooks • Bill Sperber • Mike Taylor • David Acheson • Patricia Wester • Hal King

• Will Daniels • Lee-Ann Jaykus • Mike Cramer • Bill Marler • Mike Robach

25+ Episodes available

New episodes posted twice a month

Produced by

Listen and subscribe on your favorite podcast player

or visit our website: www.foodsafetymagazine.com/podcast

FSM6718pg1-2,67-68.indd 2 6/11/18 1:36 PM

6 powerful

propellers to accelerate expert science

and technology solutions in

life science

Proven Preparation, Tailored Pharma Expert Pharma & State-of-the-Art Lab & Pioneering Lab Trusted Analytical

Separation, Filtration & Biopharma Raw Biopharma Manufacturing Production Materials Water Solutions Products

& Testing Products Material Solutions & Testing Services

The life science business of Merck KGaA,

Darmstadt, Germany operates as

MilliporeSigma in the U.S. and Canada.

MilliporeSigma, the vibrant M, Milli-Q, Millipore, SAFC, BioReliance,

Supelco and Sigma-Aldrich are trademarks of Merck KGaA, Darmstadt,

MilliporeSigma has brought together the world‘s Germany or its affiliates. All other trademarks are the property of their

leading Life Science brands, so whatever your life respective owners. Detailed information on trademarks is available via

publicly accessible resources.

science problem, you can benefit from our expert

© 2018 Merck KGaA, Darmstadt, Germany and/or its affiliates.

products and services. All Rights Reserved.

To find out how MilliporeSigma can help you work,

visit SigmaAldrich.com/advancinglifescience

#howwesolve

LSCI17UKLO0737_FoodSafetyMag_Advert_MilliporeSigma.indd 4 20/12/2017 11:51

FSM6718pg3-9,60-61Final.indd 3 6/6/18 3:44 PM

June/July 2018

Vol. 24, No. 3

FEATURES COLUMNS

10 Hygienic Zoning

28 COVER STORY The Importance of Hygienic Zoning to

The Foreign Supplier Verification Prevent Product Contamination

By Richard Brouillette

Program: Boon or Bane?

By Dr. Ramakrishnan Nara 14 Op-Ed

The Costs of Foodborne Illness,

Product Recalls Make the Case for

40 BAKED GOODS Food Safety Investments

Handling Food Safety Risks By Stephen Ostroff, M.D.

in a Retail Bakery 16 Testing

By Patricia Marden, B.Sc., Jennifer Forrester, B.Sc., M.Ed., Investigation and Identification of Physical

Contaminants in Food

Becky Swayne, B.Sc., Sadie Pulk, M.A., M.B.A., REHS,

By Samuel S. Liu, Ph.D.

and Ann Marie McNamara, Ph.D.

20 Food Safety Insights

Listeria: An Important Focus of

46 FOOD SAFETY CULTURE Environmental Monitoring

Company Culture and the Path to By Bob Ferguson

Improved Food Safety: Setting the Tone 22 Packaging

Ensuring the Safety of Food Contact

to Support a Strong Food Safety Culture Materials: GMPs and Beyond

By Lone Jespersen, Ph.D., Mike Robach, By George G. Misko, Esq.

Mark Beaumont, Ph.D.,

26 Natural Source Testing

John Helferich, and Sara Mortimore

Have Your Natural Ingredients Been

Adulterated?

54 FOOD DEFENSE By Anna Lykkeberg and Jasmine Garside

Current State of Intentional DEPARTMENTS

Adulteration 6 Editor’s Letter 60 Product Showcase

By The Food Protection and 8 News Bites 67 Advertisers Index

Defense Institute

Editorial Advisory Board Veny Gapud Gillian Kelleher Martin Mitchell

Food Safety Consultant Wegmans Food Markets Certified Laboratories/RFA

Gary Ades, Ph.D. Michael M. Cramer Tatjana Golikova, Ph.D. Hal King, Ph.D. Theodora Morille-Hinds, M.Sc.

G&L Consulting Group Ajinomoto Windsor National University of Food Public Health Innovations LLC The Kellogg Company

Technologies

Reginald W. Bennett Will Daniels Jeffrey L. Kornacki, Ph.D. Robert Powitz, Ph.D., M.P.H., RS

CFSAN, U.S. FDA IEH Laboratories & Consulting Kathy Gombas Kornacki Microbiology Solutions Inc. R.W. Powitz & Associates

Group Food Safety Consultant

Robert E. Brackett, Ph.D. Gina (Nicholson) Kramer, RS/REHS Thomas M. Sauer

IIT, Institute for Food Safety and Kurt E. Deibel, Ph.D. Margaret D. Hardin, Ph.D. Savour Food Safety International™ Food Safety Consultant

Health Heinz North America IEH Laboratories & Consulting Group

Sean Leighton, M.Sc., M.B.A. Darryl Sullivan

John N. Butts, Ph.D. Jonathan W. DeVries, Ph.D. Craig Henry, Ph.D. Cargill Inc. Covance Laboratories

Land O’Frost General Mills/Medallion Labs Intro Inc.

Huub L.M. Lelieveld John G. Surak, Ph.D.

Brian Campbell William Fisher Lone Jespersen, Ph.D. Global Harmonization Initiative Surak and Associates

Kroger Clackamas Bakery GFTC, retired Cultivate

Ann Marie McNamara, Ph.D. Wendy White, M.Sc.

Larry Cohen Timothy A. Freier, Ph.D. Larry Keener, CFS, PCQI Target Corporation Golden State Foods

Treehouse Foods Mérieux NutriSciences Intl. Product Safety Consultants

4 Food Safety Magazine

FSM6718pg3-9,60-61Final.indd 4 6/5/18 4:17 PM

Safer Food.

Our Responsibility.

Poultry growers, processors, and retailers

need non-antibiotic solutions to meet today’s

consumer demands.

Original XPC™ works naturally with the biology of

the bird to help maintain immune strength.

A strong immune system promotes:

P Animal health & well-being

PMore efficient production

PSafer food from farm to table

Diamond V Immune Strength for Life™

75

B U I L D I N G O N

YEARS OF

TRUST

D I A M O N D V For more information, visit www.diamondv.com

FSM6718pg3-9,60-61Final.indd 5 6/5/18 1:25 PM

Editor’s Letter

A Year of Milestones

CEO, The Target Group Inc. Don Meeker

T his year marks a number of milestones, the least of which

is my 10-year anniversary with this magazine. (How time

flies!) Most important, however, is the 25-year anniversary of

Publisher Stacy Atchison

In the Clear Bobby Meeker

Editorial Director Barbara VanRenterghem, Ph.D.

Director of Sales Adam Haas

the Jack in the Box Escherichia coli O157:H7 outbreak. Can we

Art Director/Production Craig Van Wechel

pause for a moment to think about how far

Digital Editor Tiffany Maberry

we’ve come, while at the same time realizing

Circulation Manager Andrea Karges

how much left there is to do?

Administrative Manager Allison Demmert-Poland

It was a year ago that we started our Publishing Office 1945 W. Mountain St.

podcast, Food Safety Matters, featuring none Glendale, CA 91201

other than Dr. Dave Theno as our inaugural Main 818.842.4777

Fax 818.955.9504

guest. Jack in the Box featured prominently customerservice@foodsafetymagazine.com

in that conversation with him. And only a short month Production Office 1113 Ellis Street

later, he was taken from us: gone but certainly not forgotten. Ft. Collins, CO 80524

Phone 970.484.4488

Countless guests of the podcast after him have spoken of his

craig@foodsafetymagazine.com

leadership and inspiration. I credit Dave with introducing

Editorial

the concept of food safety culture, long before the term itself Barbara VanRenterghem, Ph.D. • 508.210.3149

began to take hold. barbara@foodsafetymagazine.com

This year, we marked our 1-year podcast anniversary Tiffany Maberry • 678.853.1062

speaking with attorney Bill Marler, again with some emphasis tiffany@foodsafetymagazine.com

on his role in the Jack in the Box event. Additionally, this Advertising Sales

Bobby Meeker • 818.842.2829

year’s Food Safety Magazine Distinguished Service Award bobby@foodsafetymagazine.com

will be presented to Dr. Darin Detwiler, who lost his son, Adam Haas • 321.804.4319

Riley, because of the Jack in the Box outbreak, at the annual adam@foodsafetymagazine.com

meeting of the International Association for Food Protection

in Salt Lake City in July. At that same meeting, Dr. Ann

Marie McNamara, one of our Editorial Advisory Board

Food Safety Magazine (ISSN 1084-5984) is published bimonthly by

members, will be delivering the John H. Silliker lecture on

The Target Group Inc., 1945 W. Mountain St., Glendale, CA 91201;

“Heroes Past and Future.” It’s no secret, given her history at (818) 842-4777; Fax (818) 955-9504; E-mail info@foodsafety-

magazine.com. Periodicals Postage Rate paid at Glendale, CA, and

Jack in the Box, what she will talk about. additional mailing offices. Subscriptions: Free to qualified subscribers

As we remember those tragic events of 25 years ago, let’s as defined on the subscription card; $85.00 per year for nonqualified

subscribers. Back Issues: $10.00 per copy, prepaid. Change of Address:

also not forget the critically important work that everyone, Notices should be sent promptly; provide old mailing label as well as

from the CEO to the line worker, does to safeguard the new address. Allow two months for change. Editorial Contributions:

Unsolicited manuscripts should be submitted to: Barbara

world’s food supply. And let’s not forget to tip our hats once VanRenterghem, Ph.D., Editorial Director at: barbara@foodsafety-

again to Dave, for showing us the way it’s done. magazine.com. Notice—Every precaution is taken to ensure accuracy

of content; however, the publishers cannot accept responsibility for

the correctness of the information supplied or advertised or for any

Best Regards, opinion expressed herein. Postmaster: Send address changes to Food

Safety Magazine, 1945 W. Mountain St., Glendale, CA 91201. ©2018

by The Target Group Inc. All rights reserved. Reproduction in whole or

part without written permission is strictly prohibited. The publishers

do not warrant, either expressly or by implication, the factual accuracy

Barbara VanRenterghem, Ph.D. of the articles or descriptions herein, nor do they so warrant any views

or opinions offered by the authors of said articles and descriptions.

Editorial Director

6 Food Safety Magazine

FSM6718pg3-9,60-61Final.indd 6 6/5/18 1:25 PM

Because better detection

equals better protection.

Kikkoman LuciPac A3 Sanitation System

The Kikkoman LuciPac A3 Sanitation System is an innovative, new test for

hygiene monitoring that offers better detection and higher sensitivity.

Just as easy and fast to use as conventional ATP tests, but its patented A3

technology has been proven to find food residue that other products miss.

Find what you have been missing. www.KikkomanA3.com

LuciPac

TM

Official Distributor

Find out more at IAFP, July 9-11. See a demonstration at Kikkoman Booth 1010 or Weber Scientific at Booth 711

FSM6718pg3-9,60-61Final.indd 7 6/5/18 1:25 PM

News Bites

IAFP Names Detwiler to Receive Food Safety Magazine

Eurofins as Distinguished Service Award

Recipient of Food Safety Magazine has recently announced that Darin Detwiler,

Ph.D., will receive the magazine’s Distinguished Service Award at

the Black Pearl the 2018 Annual Meeting of the International Association for Food

Award Protection (IAFP), July 8–11, in Salt Lake City.

Detwiler, currently the assistant dean at Northeastern University’s

The International Asso-

ciation for Food Protection College of Professional Studies, will be presented with the award dur-

(IAFP) has selected Eurofins ing the IAFP awards reception and banquet on Wednesday, July 11.

Scientific Inc. as the 2018 Detwiler’s work at the university includes quality assurance su-

recipient of the prestigious pervision for all undergraduate and graduate programs. He is also a

Black Pearl Award. Spon- professor of food regulatory policy, responsible for the development

sored by F&H Food Equip- and instruction of courses related to food safety, global economics of

ment Company, the Black food and agriculture, and food policy for graduate students who work

Pearl Award will be present- in the food industry. He additionally advises industry and govern-

ed at IAFP’s Annual Meeting ment agencies, addressing food safety and authenticity issues in the U.S. and abroad. After the

in Salt Lake City in July. loss of a son to Escherichia coli in a landmark outbreak 25 years ago, he consulted with the U.S.

This honor is given an- Department of Agriculture (USDA) in strengthening food safety policies, particularly in the ar-

nually to one company for eas of consumer education, product labeling, and the agency’s pathogen reduction program. In

its efforts in advancing food addition to serving in various educational and advisory capacities, he has done committee work

safety and quality through that includes appointments to two terms as a member of the National Advisory Committee on

consumer programs, em- Meat and Poultry Inspection for USDA, where his work improved standards and policies related

ployee relations, educational to risk-based sampling. As the senior policy coordinator for a national food safety organization,

activities, adherence to stan- he evaluated pertinent regulatory issues for the USDA and the U.S. Food and Drug Adminis-

dards, and support of the tration (FDA) as a consumer advocate in their stakeholder advisory group. He later

goals and objectives of IAFP. served two terms as a council member for the Conference for Food Protection,

The Eurofins mission is identifying and addressing emerging problems of food safety to influence model

to contribute to a safer and laws and regulations among all government agencies. Detwiler received his doc-

healthier world by providing torate of law and policy from Northeastern University with a research focus

innovative and high-quality on state implementation of the FDA Food Safety Modernization Act.

laboratory and advisory ser- Past recipients of the award include Reginald Bennett, M.Sc., Dane

vices for all food industries. Bernard, M.Sc., Larry Beuchat, Ph.D., Robert L. Buchanan, Ph.D., John

With a commitment to out- N. Butts, Ph.D., Keith Ito, Allen Katsuyama, Connie Kirby, M.Sc., John W.

standing client service, Euro- Larkin, Ph.D., Huub Lelieveld, Barbara Masters, D.V.M., Ann Marie McNamara,

fins has grown to become a Ph.D., William Sperber, Ph.D., Steve Taylor, Ph.D., David Theno, Ph.D., Bruce

global leader in food safety. Tompkin, Ph.D., and Don L. Zink, Ph.D.

ONLINE & Meat Lobbying Group Argues for USDA Regulation

OF NOTE of “Clean Meat”

The U.S. Cattlemen’s Association (USCA) has filed a federal petition with the U.S.

www.eatright.org/homefoodsafety Department of Agriculture (USDA) in an attempt to keep some meat producers

The Academy of Nutrition and Dietetics is the world’s from referring to their products as “meat.” What these producers make is actu-

largest organization of food and nutrition professionals; ally known as “clean meat,” which is grown by way of technology and animal

it was founded in Cleveland, Ohio, in 1917 by a visionary cells instead of traditional animal slaughter. USCA’s petition to the USDA is

group of women dedicated to helping the government somewhat groundbreaking as the group usually tends to oppose any regulation

conserve food and improve the public’s health and nutri- involving meat production.

tion during World War I. Today, the academy has over In addition to banning the use of the term “meat,” USCA would like USDA

100,000 credentialed practitioners committed to

to be the only agency regulating the small producers that make clean meat. This

improving the nation’s health and advancing the

would mean that the U.S. Food and Drug Administration would not be involved in

profession of dietetics through research,

education, and advocacy, including overseeing clean meat. A successful petition from USCA could keep clean meat from

home food safety. gaining ground in the market and crowding out conventional meat.

8 Food Safety Magazine

FSM6718pg3-9,60-61Final.indd 8 6/5/18 1:25 PM

BizTracks

Rubber Fab Granted Patent for X-Ray-Inspectable PolySkope Labs Receives AOAC Certification

Materials PolySkope Labs has announced that it has received AOAC

Rubber Fab has been granted a patent for their X-ray Research Institute’s Performance Tested Method Certifica-

opaque polymeric materials, which complements their exist- tion for its revolutionary PolySkope 1.0 modular, multiplex

ing patent for metal-detectable gaskets. The new patent is a pathogen detection kits (Certificate no. 041801). This initial

fundamental part of the Detectomer® portfolio from Rubber approval certifies that PolySkope 1.0 is equivalent to standard

Fab, which encompasses a full range of detectable sanitary reference methods for the detection of all target pathogens in

gaskets and O-rings. These products provide food manufac- ready-to-eat deli turkey, raw ground beef, fresh spinach, and

turers with enhanced functionality, allowing them to reduce stainless steel environmental surfaces. PolySkope 1.0 can now

their process risks through better detection of nonmetallic be used by ISO 17025-accredited labs in the U.S. and certain

contaminants. international markets.

People & Places SUN Automation Group is pleased to announce that

Greg Jones has been promoted to vice president of global

The Institute of Food Science & Technology is pleased sales and aftermarket.

to announce that its past president, Margaret Patterson, Dynamic Conveyor Corporation has announced that

Ph.D., has been elected as a fellow of the International Andrew Hartline has been hired as sales

Academy of Food Science and Technology. manager to support the growing company. Jones

The National Livestock Producers Associa- NSF International awarded Hal King, Ph.D., founder

tion has recently hired Kraig Roesch as CEO. Patterson and CEO of Public Health Innovations LLC, as this year’s

Richard Fordyce has been appointed to recipient of the Food Safety Leadership Award.

serve as administrator of the U.S. Department of Agricul- Hartline Michael Best has announced that Emily R. Lyons has

Roesch ture’s Farm Service Agency. joined the firm as an associate in the transactional practice group.

F R O M F O O D S A F E T Y M A G A Z I N E

Exclusive Food Safety Culture Collection

From the authors

“This special edition of Food Safety Magazine helps your

company navigate this landscape of food safety; it was de-

signed and written to continue the ‘by leaders, for leaders’

theme of GFSI and complement its position with practical

advice and learnings.”

“Nineteen leaders present five articles, and each article

complements a dimension of the GFSI framework.”

“Each article highlights specific takeaways with guidance

on how to achieve goals within your organization.”

Lone Jespersen, Ph.D., and Mike Robach

Download the

complete collection today!

go.foodsafetymagazine.com/culture

See page 46 in this issue for the first installment

Sponsored by:

J u n e n J u ly 2 018 9

FSM6718pg3-9,60-61Final.indd 9 6/7/18 9:13 AM

HYGIENIC ZONING

By Richard Brouillette

The Importance of Hygienic Most food processing facilities are

not recent buildings; therefore, alterna-

tive measures preventing cross-contami-

Zoning to Prevent Product nation from existing sources need to be

assessed, and barriers and hurdles put

in place to protect exposed ready-to-eat

Contamination

(RTE) products. Some of the sources to

consider will be air, people, and materi-

als.

To assess microbial risk, processors

will determine whether RTE products

can support growth of spoilage microor-

ganisms or pathogens, or their survival.

Based on this determination, barriers

Different plants require and hurdles will be identified to protect

the product. A product supporting the

different approaches for growth of pathogenic or spoilage micro-

organisms will require more protection

zoning to prevent foodborne illness and quality

issues than a product in which microbes

I

will die off. The barriers may not only

be part of the infrastructure but may

f you are building a food processing facility, when do also be part of the product package

you begin thinking about hygienic zoning? Starting itself. A product that is pasteurized in

from the principles that the production environment package, aseptically filled, or retorted

should not be a source of biological, chemical, or will be protected by its packaging from

physical contamination for the product, we will ex- potential microbial contamination after

amine the different steps to mitigate those risks. the microbial log reduction; therefore,

The commercialization process really begins with the the building may not need to offer as

location of the property. If the piece of land is located much protection as it will for an RTE

in proximity to other industries presenting a biological product exposed to the environment

hazard (e.g., near a slaughter plant or waste disposal after the microbial reduction step. The

site), chemical contaminants (oil refinery, chemical building and infrastructure need to pro-

plant, contaminated soil, etc.) or physical contaminants vide the necessary conditions for prod-

(particles emitted during harvest, dust/sand storm, ucts to be made in hygienic conditions.

etc.), the barriers and hurdles necessary to protect food Different audit schemes and stan-

product are likely to be more robust than for a facility dards define hygienic zones differently.

located away from such contaminants. Before the different areas are named, it

The next question is where to locate the building on is useful to understand the risk to the

the property. Again, we would want to limit potential product. Some questions to consider:

contamination; if there is a retention pond or wastewa- Does the product already contain a haz-

ter treatment plant, the food processing building should ard? Is the product formulation bacteri-

be located farther away. Or if the property has a low cidal? Will pathogenic/spoilage organ-

point where water can accumulate, the building should isms survive in the RTE product? Will

be on higher ground. The Grocery Manufacturers As- pathogenic/spoilage organisms grow in

sociation facility design checklist is a useful tool to assess the RTE product?

different risks from buildings and infrastructure.1 The For example, in a bakery, the flour

checklist applies to greenfield land; some sections can receiving/storage and mixing areas basi-

also be used for existing facilities. cally have the same microbial risk (flour

10 Food Safety Magazine

FSM6718pg10-27,62-64Final.indd 10 6/5/18 1:26 PM

FS 2018 FullPage Ad Feb/Mar Opt3.qxp_Layout 1 1/9/18 5:09 PM Page 2

Introducing the

LuciPac Sanitation System

TM

Find what you’ve been missing.

Superior sensitivity leaves food residue

with no place to hide.

The Most Advanced Sanitation

Hygiene System Available

• Only Kikkoman’s new patented

System detects ATP+ADP+AMP

– ATP can be unstable and

decompose into ADP and AMP

– Conventional systems that test for

ATP alone may fail to find the true

presence of contamination and

may produce false negatives

• Results may be an order of

magnitude or higher than other

tests on the market

Because Better Detection Equals

Better Protection

Be sure to ask D WINN

AR

about our FREE

AW

IN

G

Luminometer Legendary for quality and great prices since 1959

Program!

LAB

IER

800-328-8378 • weberscientific.com RA

PL

TO RY SUP

O

FSM6718pg10-27,62-64Final.indd 11 6/5/18 1:26 PM

HYGIENIC ZONING

should be assumed to be contaminated etc., like soft cheeses such as Brie. As in size. This will typically require HEPA

with different pathogens), while the mentioned earlier, we will examine po- filters or a MERV 13 filter. The room

baked goods after the oven should have tential barriers and hurdles for different where the RTE product is exposed will

low microbial counts. Ideally, to prevent sources of contamination. also need to be positively pressurized to

microbial cross-contamination, there There are other reasons to separate other areas of the building to prevent

should be a physical separation (wall, different areas of the same hygiene level mold from entering the room through

doors, etc.) between the raw flour area by using barriers such as walls. For ex- openings, such as doors, pass-throughs,

and the baked goods; a facility may ample: etc. Typically, if the product is sensitive

also decide to place a wall between the • Preventing allergen cross-contami- to mold growth, the positive pressure

mixing area and the oven to manage nation between areas with different will be 0.05 inch in a water column.

the heat generated by the oven. Areas allergen profiles Keeping in mind that some bacteria

presenting the same risk may still need • Preventing species cross-contamina- are smaller than mold and mold spores,

to have physical separation for reasons tion in meat and poultry facilities if there is a risk of potential bacterial

other than potential microbial, chemi- • Maintaining claims such as genetical- cross-contamination from surrounding

cal, or physical cross-contamination. In ly modified organism-free, organic, properties (e.g., the facility is close to

this example, the baked goods are less or kosher/halal a farm or slaughter plant) or inside the

likely to support the growth of spoilage • Wet-cleaned and dry-cleaned areas plant (e.g., aerosols are generated), the

organisms and pathogens than other The European Hygienic Engineering filters will have a higher HEPA rating

RTE products, such as lunchmeat and & Design Group has provided simple and the positive air pressure might need

soft cheese. The latter may require more definitions of various hygienic zones to be higher.

stringent barriers and hurdles. and guidance to prevent biological, The product may be protected from

Table 1 shows examples of the micro- chemical, and physical cross-contamina- the environment if it is kept fully en-

bial susceptibility of different products. tion.2 closed, for example, in pipes or pressur-

There are many useful sources of infor- ized vessels. If a product that has a high-

mation to assess the microbial risks; for Protection from Environmental Air er risk of contamination will be made

example, many models are accessible Contamination in an existing facility making lower-risk

at www.foodrisk.org or by consulting While it is generally rare for patho- products, it is possible to create a “new”

with a competent microbiologist. Once gens to be transmitted by air, mold environment for the product by packag-

the microbial risk is known, the level of spores can be a source of microbial ing it in a filler that has its own HEPA

protection can be determined. Ideally, contamination, resulting in quality filter and positive air pressure.

product that can support the growth and potential food safety defects. If the Other methods to control the qual-

of pathogens would not be exposed to product can support mold growth, the ity of the environmental air exist. Some

the environment, but some foods need air should be filtered to remove mold companies are using ozone generators

to be exposed during processing, aging, spores that can be as small as 1 micron or UV treatments. These systems are

Hygiene Zones Type of Products Examples considered hurdles more than barriers

and require additional validation and

Non-Production Zones No exposed product in this type Outside the building, office areas,

of area storage areas verification to demonstrate their effec-

tiveness over an extended period under

Low-Risk Areas Raw agricultural commodities Raw meat, raw milk, flour

plant operating conditions.

that are likely to contain patho-

With time, the industry has also

gens/spoilage microorganisms

OR realized that controlling moisture and

Products with bactericidal Retorted products, some sauces, temperature can be critical to prevent-

formulation or with a microbial dressings, etc. ing microbial growth inside the room.

reduction step once in the final In general, keeping the room cooler and

package the humidity lower help delay microbial

Medium-Risk Areas Postmicrobial reduction step or Hot-filled/packed products, etc. growth in the production environment,

products that will not support the which reduces the risk of cross-contam-

growth of pathogens or spoilage ination. In existing facilities, moisture

microorganisms can also be reduced by eliminating

High-Risk Areas Postmicrobial reduction step or Some RTE refrigerated products such environmental sources, such as by re-

products that may support the as soft cheeses, lunchmeat, etc. placing foot baths or door foamers with

growth of pathogens or spoilage dry foot baths, by addressing any water

microorganisms leaks as quickly as possible, or by install-

Table 1. Microbial Susceptibility of Different Products ing dehumidifying systems.

12 Food Safety Magazine

FSM6718pg10-27,62-64Final.indd 12 6/5/18 1:26 PM

HYGIENIC ZONING

Protection from People production areas and entrances where planned.

Once the positioning of the walls employees and contractors can enter di- In addition to waste areas mentioned

delimiting the different production rectly from the outside. These entrances above, other areas such as sanitation

areas is decided, people may still need will also need to have hurdles (e.g., rooms, employee welfare rooms, and

to move between the different areas. changing hairnets, smocks, footwear outdoor smoking areas may be shared

Ideally, people and material movements brushes and sanitizers, handwash sta- by employees working in areas with dif-

between a low-risk or raw product area tions, or hand sanitizers) for employees ferent levels of hygiene. Risk from these

and a high-risk or RTE product area are reentering production areas. areas will also need to be considered

limited or completely avoided. When and managed.

designing a new facility, this objective Protection from the Movement of Employee training is equally impor-

can be achieved by planning people and Materials tant. When new employees are hired or

material traffic to keep paths from cross- A key concept to prevent cross- when there is a change in the hygienic

ing. In existing facilities, passive barriers, contamination is to have the materials zoning program, it is important to

such as lines painted on the floor, may flow in one direction. explain the reasons

be needed to provide visual clues to Depending on the “Different audit behind the different

the employees about the separation be- material, this will be rules and behaviors

tween the different zones. Using differ- from the lower- to the they need to adopt.

ent colors of paint that can also match higher-risk area or vice schemes and standards Having physical barri-

the employee hairnets can provide an versa. If we look at ers and active hurdles

additional reminder. For example, lines the different types of define hygienic zones will promote behaviors

delimiting low-risk areas might be paint- materials: that will prevent cross-

ed in green, signs directing people to • Product should contamination.

that area can also be green and employ- flow from the low- differently.” The effectiveness of

ees working in the low-risk area may risk to the high-risk the hurdles and em-

be wearing green hairnets, while signs area by passing through the micro- ployee behaviors can be verified using

and hairnets for the medium-risk areas bial reduction step. different programs. The environmental

might be yellow and ones for high-risk • Packaging material should be re- monitoring program should include

areas might be red. ceived and stored close to the high- swab sites from the transition points to

Once the physical barriers or indica- risk area to limit the potential for verify the effectiveness of the hurdles.

tions are in place, hurdles are needed to cross-contamination associated with Audits of Good Manufacturing Practices

prevent contamination from nonpro- moving packaging through the low- and behavioral observations are other

duction areas or sources, which include risk area. tools to verify whether employees are

employees, visitors, and contractors • Waste should be transported from following the rules to prevent cross-con-

coming from outside the plant or of- the area where it is generated to a tamination. If the product is susceptible

fice area of the plant to the production nonproduction area or to a low-risk to mold growth, environmental air can

areas. In general, production entrances area. It should not be going from be monitored for mold count.

will be equipped with hairnet/beard net the low-risk to the high-risk area. Finally, whether you are thinking

stations, handwash stations, and foot- If the recycling/compactor area is about building a new facility or modi-

wear sanitizers. The level of control may shared between low-risk and high-risk fying an existing one, it takes a multi-

depend on the hygienic zone entered. products, precautions must be taken functional team and time to determine

For example, when entering a low-risk when waste containers are returned the optimum hygienic design that will

area, employees may walk through a to the high-risk area (e.g., cleaning consider all the different aspects of

footwear sanitizer in a transition area; the inside and outside of the waste effective zoning to ensure both opera-

however, when entering into a high- container, sanitizing the wheels). tional efficiency and safe food. n

risk area, employees may change their • When designing a new facility or

shoes to dedicated ones or don aprons modifying the wastewater system of Richard Brouillette is the food safety director at

or smocks over their uniform in a ves- an existing one, the wastewater line Commercial Food Sanitation.

tibule. Entrances to high-risk areas can for the low-risk product should not

be equipped with active hurdles, where be connected to the one from the References

employees need to activate the hand- high-risk product. 1. Grocery Manufacturers Association. 2010.

washing station to open the door. • Utensils and tools used in high-risk Facility Design Checklist. gmaonline.org.

Thought should also be given to areas are often dedicated and stored 2. European Hygienic Engineering & Design

remote entrances to production areas; in those areas. Sufficient space for Group. Hygienic Design Principles for Food

for example, if roof access is located in storage and cleaning should be Factories (VDMA Verlag, 2014).

J u n e n J u ly 2 018 13

FSM6718pg10-27,62-64Final.indd 13 6/5/18 1:26 PM

OP-ED

By Stephen Ostroff, M.D.

The Costs of Foodborne 2012, the Grocery Manufacturers Asso-

ciation (GMA) and the Food Marketing

Institute estimated that the average cost

Illness, Product Recalls Make for a food recall in the United States

was $10 million. That number was just

for the direct costs to the company,

the Case for Food Safety such as the retrieval and disposal of the

recalled product. There are also indirect

costs, including lawsuits, damage to a

Investments company’s or product’s reputation, and

sales losses.

GMA also did a survey of several

dozen multi-national corporations, and

18 percent indicated they had been

involved in recalls with estimated costs

between $30 million and $99 million

each. Another 5 percent said they had

Prevention, not reaction been involved in recalls that cost more

than $100 million.

These days, FDA gets involved in

about 700 food-related recalls per year.

Some are small and some are big. Some

S

involve undeclared allergens or misla-

beling, some involve particulates (e.g.,

ince assuming the role of deputy commissioner glass, metal, or plastic), and some are

for foods and veterinary medicine at the U.S. due to microbial contamination.

Food and Drug Administration (FDA) in 2016, If anything, the cost of a recall today

I’ve had numerous occasions to speak publicly is higher than it was in 2012. But even if

about food safety. On one of these occasions, you use the 2012 average figure of $10

I was part of a panel asked to address this topic: Taking million and multiply it by 700 recalls,

food safety from risk management to growth generator. that comes out to $7 billion in direct

Knowing that many in the food industry look at costs alone to industry annually. Throw

regulations as something that costs them money—money in another $3 billion for the indirect

that could be invested instead in such areas as product costs to industry, and you’re talking a

innovation, facility upgrades, marketing, or other profit- lowball estimate of $10 billion a year. In

generating components of the company—I want to focus addition, there are numerous examples

here as well on the growth-generating potential of food of significant damage to the reputation

safety regulations. of brands and commodities, with an

Let’s consider some statistics on the economic accompanying loss of market share. In

cost of foodborne illness in the United States, such some instances, market share never fully

as medical expenses and deaths, along with lost wages recovers or takes years to occur. There

and economic productivity. A 2014 estimate from the are reasons to think the indirect costs of

U.S. Department of Agriculture placed the direct and recalls could be much higher.

indirect costs associated with illnesses caused by major Food safety problems are not bad

foodborne pathogens at $15.6 billion per year. A more just for companies that recall products.

recent estimate from Ohio State University that covered Even companies that market products

all causes of foodborne illness, not just illness from the similar to a recalled food can suffer,

major foodborne pathogens, was at least $55.5 billion. too. The worst thing that can happen

And what about costs associated with food recalls? In to a food sector or the food industry is

14 Food Safety Magazine

FSM6718pg10-27,62-64Final.indd 14 6/5/18 1:26 PM

OP-ED

the loss of consumer confidence due to Just imagine a scenario in which and the food industry is building a

recalls or disease outbreaks. food recalls were cut in half. That saves culture of food safety, not only in the

Every food safety incident that is industry at least $5 billion per year and United States but around the world as

prevented, whether from the standpoint prevents a lot of foodborne illness. A well. That will save money and generate

of industry or consumers, is nothing 25 percent decrease in foodborne illness growth. Most importantly, it will pro-

short of money in the bank. For indus- saves at least $4 to $14 billion per year. mote health and save lives. n

try, that $10 billion in recall costs is I hope that with full implementa-

money that can be invested in growth- tion of FSMA, we achieve that and Stephen Ostroff, M.D., is the deputy commissioner

generating activities. For consumers, more. The partnership between FDA for foods and veterinary medicine at FDA.

there are billions in healthcare costs

associated with foodborne illness that

come out of their pockets and could be

used in other ways.

Food safety regulations can also

generate growth in developing coun-

tries. This summer, the World Bank is

expected to publish a report that shows

the economic impact of food safety

hazards, the consequences of the lack

of food safety capacity, and the scale

of economic returns from food safety

investments in developing countries.

This work should help make the case for

devoting policy and public resources to

strengthening food safety protections in

low- and middle-income countries. That

not only improves the domestic food

supply in those countries but also facili-

tates exports. After all, the FDA Food

Safety Modernization Act (FSMA) re-

quires imported foods to meet the same

food safety standards as foods produced

domestically.

But most importantly, as someone

who works at an agency that promotes

public health through regulation, I

know that food safety is good public

health. That’s why FDA has, for the last

7 years, worked so hard to implement

the FSMA requirements that will move

the food safety system from one that

reacts to problems to one that prevents

them from occurring.

The food industry has worked co-

operatively with FDA to implement

FSMA. The vast majority of food pro-

ducers want to protect their customers

from harm, and many have provided

key feedback as the FSMA regulations

have taken shape. These same food pro-

ducers want to protect their brand and

want to be known for having high food

safety standards. Food safety is good for

business.

J u n e n J u ly 2 018 15

FSM6718pg10-27,62-64Final.indd 15 6/5/18 1:26 PM

TESTING

By Samuel S. Liu, Ph.D.

Investigation and Physical contaminants are also re-

ferred to as physical hazards or foreign

matter. Shrew teeth in a crop product

Identification of Physical or a piece of wire in a meat product are

examples. Glass pieces, metal fragments,

bone chips, and pits may all cause

Contaminants in Food serious harm when ingested. Com-

mon examples of bodily harm include

lacerations of the lips, the inside of the

mouth, teeth, gums, tongue, throat,

esophagus, stomach, and intestine, and

even choking. Children and seniors are

at greater risk and have the highest inci-

Steps for the investigation of dence of such harm.

Government agencies, food produc-

physical contaminants in your ers, manufacturers, distributors, and

retailers must all protect the health of

plant the consumer as one of their most im-

portant objectives and responsibilities.

If there is any evidence or reason to be-

A

lieve there are physical contaminants in

a food product that may cause illness or

mericans spend about $500 billion on food injury to consumers, government agen-

annually.1 When we consume food or drink, cies, including the U.S. Food and Drug

we expect to enjoy it and do not expect to Administration (FDA) and the U.S. De-

get sick or injured. Ingestion of a piece of a partment of Agriculture (USDA) Food

hard or sharp material such as glass or metal Safety and Inspection Service (FSIS),

could cause an unsuspecting consumer severe injury, reject the food product from sale in the

require surgery, or have deadly consequences. Therefore, U.S. market or request food recalls.

food contamination has always been a major concern of Huge economic losses to businesses

the U.S. government, the food industry, and consumers. may occur when a physical hazard is

Most physical contaminants of foods, such as pieces discovered. There were 456 food recalls

of hard plastic or wood, can cause consumers immedi- in the U.S. in 2017 and 764 food recalls

ate injury; this includes all types of foods, including in 2016, which were announced by

beverages, bottled water, and nutritional and functional FDA and FSIS. Of those, foreign matter

products. Any physical material in food that does not caused 42 recalls in 2017 and 44 recalls

belong in the product may be classified as a physical in 2016.2,3 According to FSIS,4 16.51

contaminant. million pounds of food were withdrawn

Sources Examples of Contaminants

Field Rocks/stones/sand, asphalt, metals/bullets, concrete particles, bones, wood fragments,

and thorns

Processing Glass, ceramic/shards, metal fragments, staples, blades, clips, needles, keys,

screws, magnet fragments, washers, bolts, screening, plastic, grease/lubricants,

rubber, insulation/seal materials, nail polish, jewelry, coins, pieces of gloves, finger

cots, bandages, cigarette butts, gum, bones, pits, fruit stones, nut & animal shells,

medications/tablets/capsules, wood, pens, and pencils

Storage and distribution Metal, plastic, and wood fragments

Table 1. Sources of Physical Contaminants in Foods

16 Food Safety Magazine

FSM6718pg10-27,62-64Final.indd 16 6/5/18 1:26 PM

Introducing Listeria Right Now™

Listeria Right Now is a revolutionary new enrichment-free environmental

monitoring tool for Listeria detection providing actionable results in

less than 60 minutes. This means you can test your environment and

immediately take corrective actions to fix issues before they become

serious problems.

• Conduct investigations in near real-time after positives.

• Perform vectoring more easily.

• Be more flexible and proactive with your environmental testing program.

Call us now to learn more or visit:

http://foodsafety.neogen.com/en/listeria-right-now

800-234-5333 (USA/Canada) • 517-372-9200

foodsafety@neogen.com • foodsafety.neogen.com

FD1076_Listeria Right Now – FP ad.indd 1 7/20/2017 11:00:14 AM

FSM6718pg10-27,62-64Final.indd 17 6/5/18 1:26 PM

TESTING

from the market following 56 food can be introduced into food products jewelry, insects/filth, insulation, bone,

recalls because of extraneous materials accidentally during harvesting or at any plastic, personal effects, bullets/BB

from 2015 to 2017. point during processing due to poor shot, and needles.5 Table 1 provides a

procedural practices anywhere in the summary of common sources.

Causes of Physical Contamination food chain, including manufacturing,

Physical contaminants in food could storage, transportation, or retail. The Investigation and Identification of

come from either external sources, such so-called Dirty Dozen, the 12 most Physical Contaminants

as metal fragments, or internal sources, common foreign material contaminants Food companies work hard to keep

such as bone particles and pits. They in food, are glass, wood, stones, metal, their products free of contaminants.

Investigation and control of physical

SPONSORED CONTENT contaminants in food should be con-

ducted throughout the whole processing

Foreign Object Detection Technology Update: chain or in food testing laboratories.

With accurate and timely informa-

Multiscan Metal Detection tion, a thorough investigation can be

Finding metal foreign carried out in testing laboratories in a

objects in food is vital to food cost-effective and efficient manner. It is

essential to have a professional investi-

safety and quality. Inspection

gation team with appropriate resources

for such contaminants is

and equipment to help food company

usually located at the end

quality assurance staff troubleshoot

of the line as the last line of

consumer complaints and answer ques-

defense before a product is on tions as to what the contaminants and

its way to the consumer. Yet, their sources are. It is often necessary to

1- to 2-frequency digital metal apply integrated, multidimensional ap-

detectors, ubiquitous in food proaches for complicated investigations.

plants over the past 25+ years, have come with key barriers to achieving 100 Comprehensive investigation can de-

percent metal-free products. Among the most difficult applications are dairy, mand microscopy-based examinations

meat, poultry, and bread. plus chemical techniques, on-site ex-

aminations, Fourier transform-infrared

Challenges include: (FTIR) analysis, and other techniques.

1. Finding anything, anywhere in any product—all of the time: Consider the The investigation processes and screen-

production volume in one of your lines in just one day and the different ing procedures depend on the particular

types of metal that might be in your factory or in the ingredients. physical contaminants and their sourc-

2. The use of electromagnetic fields to find things that are magnetic and es. The procedures can be combined or

conductive: Most food products are wet, have salt, or contain minerals,

modified methods found from the fol-

lowing: AOAC International, American

which, when subjected to electromagnetic fields, also look magnetic and

Spice Trade Association, FDA’s Mac-

conductive. Therefore, ignoring the product and finding the metal are not

roanalytical Procedures Manual, FDA’s

easy.

Laboratory Information Bulletins, USDA’s

3. The very small signals from small metal foreign objects: When a factory foreign matter identification docu-

has many possible noise sources, they can confuse the metal detector ments, the United States Pharmacopeia,

electronics and software. and other compendious sources.

A new approach to metal detection—called multiscan—overcomes the In general, special investigation pro-

limitations of previous technologies. At the critical control point in your cedures include:

process, this new technology can scan up to five completely adjustable • Inspect and target suspected sources

frequencies at a time to find metal types and sizes that were previously of physical contaminants

undetectable. The result? Reducing the probability of an escape by many • Identify the foreign matter

orders of magnitude. Think of it as having up to five metal detectors back • Determine or evaluate the root cause

to back in your production line; with multiscan, metals undetectable at one or sources

frequency can be detected at another. These procedures consist of eight

To learn more about multiscan, available now in the Thermo Scientific steps:

Sentinel Multiscan Metal Detector, visit www.thermofisher.com/SentinelFSM. 1. Target contaminants. In many

cases, it is necessary to select a suitable

18 Food Safety Magazine

FSM6718pg10-27,62-64Final.indd 18 6/5/18 1:26 PM

TESTING

investigational procedure, including materials, such as synthetic polymers. ity, flexibility, flammability, temperature

sample inspection, preparation, and Spectroscopic techniques can reveal resistance, etc.

identification of target contaminants. specific functional groups of a chemical 4. Perform a chemical examination.

The sources of contamination are di- material. For example, different plastics Chemical analysis, including an elemen-

verse, whether individual or related, or may be identified by FTIR analysis. tal analysis, can reveal characteristic

even unknown. Often, little is known Physical properties can be classified by features that enable an understanding

about the contaminants, how many many characteristics and features, such of chemical properties. Histochemical

there might be, what size, what their as size, shape, thickness, magnetic char- staining techniques are useful to test

regulatory status might be, or whether acteristics, solubility, buoyancy, elastic- the chemical and (continued on page 62)

they might be in a food mixture.

Preexamination steps allow judg-

ments to be made as to whether the

targets can be separated by size, shape,

Do Your Products Conform

mass or magnetic properties, the type of

samples and contaminants (e.g., organic

to Your Brand Requirements

or inorganic), amount, circumstances of

contamination, and levels. It is normally and Regulations?

required to conduct resampling, inspec-

tion, macroscopic examination, extrac-

tion, filtration, floating, sieving, burn-

Partner with the product inspection

ing, dyeing, and further examination experts to ensure they do!

using X-ray, metal detectors/magnets,

and other screening or targeting tech-

nologies. An example might be to use

magnets to gather and identify ferrous

metal particles from liquid samples.

2. Identify contaminants. Once the

suspected foreign matter screening pro-

cedures are carried out using stereo or

dissecting microscopic examinations as

a starting point, one can obtain detailed

evidence, identifying the morphology

and deciding what methods of analysis

should be applied. For example, if a

complainant believes that pieces of

glass were observed by the naked eye

in a food, it may be that the material

consists of rocks, salt, sugar, plastics,

minerals, struvite, or tartrate crystals.

If needed, a compound microscope,

bright-field/dark-field microscope, po-

larized microscope, or scanning electron

microscope could be applied to reveal

more details. Further tests are deter-

mined based on the results of micro- Metal Detection X-Ray Inspection Checkweighing Vision Inspection

scopic examinations. Selection of such Customized Material Handling Global Field-based Service

analytical strategies may require a com-

bination of techniques or the develop-

ment of multidisciplinary approaches, Visit us at the

depending on contaminant conditions Food Safety Summit

and the goals of the investigation. Booth 507

Rosemont, IL

3. Conduct physical property tests. May 8-10, 2018

A polarized microscope is used to dis-

play birefringent properties from some

www.mt.com/pi

J u n e n J u ly 2 018 19

FSM6718pg10-27,62-64Final.indd 19 6/6/18 8:43 AM

FOOD SAFETY INSIGHTS

By Bob Ferguson

Listeria: An Important Focus that they collect, roughly 15 percent

indicated that they would be decreasing

their sampling, and the remaining one-

of Environmental Monitoring half indicated that they would be mak-

ing no change (Figure 1). Interestingly,

of those reducing their sampling, the

average reduction was about 18 percent,

but for those increasing their sampling,

the average increase was 107 percent.

These numbers, however, do not tell

the entire story, and the data are skewed

Looking at changes in Listeria by some very large producers who are

planning very large changes in their test

testing volumes.

For instance, of those companies

that indicated that they would be re-

I

ducing their testing volumes, the five

companies with the largest change rep-

t is no secret that food processors are battling Lis- resented approximately 70 percent of

teria. The number of reported incidents and recalls

Food Safety Insights is a related to Listeria has been increasing, and proces- 50.3%

sors are making efforts to rid their facilities of har-

collaboration between

borage organisms. And, of course, South Africa is

recovering from what is understood to be the world’s 35.2%

Food Safety Magazine

largest and most deadly listeriosis outbreak in history.

and the food safety In the U.S., these concerns for food safety, as well

as new regulations and guidelines, particularly the U.S. No

market experts at Food and Drug Administration (FDA) draft guidance

14.5%

published in mid-2017, have processors reevaluating

Strategic Consulting Inc. their testing programs—especially their environmental

monitoring (EM) programs. The onset of Food Safety

to bring you the latest Modernization Act (FSMA) compliance dates and the

Increase No Change Decrease

accompanying inspections along with the prospect of

market research, insights, Figure 1. How will your environmental

FDA “swab-a-thons” has only accelerated this trend.

monitoring program for Listeria change next

and trends in food It was clear to us that testing for Listeria was grow-

year?

ing faster than perhaps any other microbiological test-

safety, analytical testing, ing category, and we wanted to find out more. the change and a volume of just under

In February, we surveyed 262 food processors 30,000 samples annually. Of those in-

diagnostics, laboratory across all processing categories, including 200 in the dicating that they would increase their

U.S. and Canada and 62 international processors. We sampling, the five companies with the

services, sanitation, and asked about overall test volumes and how they have largest change represented about 90

changed or may be changing in the next few years. We percent of the change in the sample and

related topics in quality also asked questions about specific changes to their 100%

about 330,000 samples annually—an

Listeria testing programs. increase in sample volume more than

10 times that of the reduction.32.0%

and safety testing and

Changing Patterns in Testing

Percent of processing plants

assurance in the food The trend is that the larger com-

When asked if they would be changing the volume

65.0%

panies that have already been doing a

of EM testing for Listeria, about 35 percent indicated 82.1%

higher volume of samples are refining

and beverage industry.

that they would be increasing the number of samples their programs but making only 40.0%

modest

11.7%

20 Food Safety Magazine

6.6% 23.3% 28.0%

11.3%

0 – 19 20 – 100 > 100

FSM6718pg10-27,62-64Final.indd 20 6/5/18 1:26 PM

Number of samples analyzed per week

FOOD SAFETY INSIGHTS

reductions in the test volumes. Those reported a similar plan: Later this year, 100%

large companies that have been doing they will be increasing their EM test

fewer samples will be dramatically in- volume significantly, but the numbers 32.0%

creasing their test volumes from perhaps of samples for Listeria that they collect

Percent of processing plants

tens to up to hundreds of samples per at each plant will increase from tens to 65.0%

week. Many of these companies include hundreds of samples each week. 82.1%

a few large companies with multiple Another company planned to take 40.0%

locations. a somewhat different approach. A few

We spoke to several of these pro- years ago, in anticipation of regulatory 11.7%

cessors to get more information. One and inspection changes, they increased

processor that indicated that they were their EM sampling and doubled the 6.6% 23.3% 28.0%

planning to reduce their EM sample number of samples that they were col- 11.3%

volumes told us that they were changing lecting for both Salmonella and Listeria. 0 – 19 20 – 100 > 100

Number of samples analyzed per week

their program to take a more focused Although they were regularly collecting

Outside commercial lab

approach. They had been taking several EM samples, most of the increase in

Central corporate lab In-plant lab

hundred samples each week throughout their sample numbers came from “seek

Figure 2. Where are your EM samples

the plant, but this changed about 2 and destroy” sampling programs that

analyzed?

years ago. At that time, they adjusted they conducted three times per year.

their EM program to collect fewer They found this to be an effective way ported in December-January 2017, in

samples for pathogen analysis in key to hunt for difficult areas that may have which approximately two-thirds of pro-

problem areas, or, as they indicated, been missed by routine sampling. Fol- cessor locations will primarily outsource

they adjusted from a “shotgun” to a lowing their FSMA compliance date, sample analysis, but this results in a

“rifle” approach. The sample sites were they received an FDA inspection that 50/50 split in terms of overall pathogen

developed using data collected over included a “swab-a-thon.” They were sample volume.

previous years; this approach allowed happy to report that the FDA sampling

them to identify key problem areas and found no positive samples, but they An Opportunity for Testing Labs

reduce the sampling they conducted nonetheless increased their sampling Based on the data from this survey,

in those areas, which were shown to be projects to quarterly, further increasing as well as data that we have collected

under better control. their overall volumes another 10–15 for other projects, we anticipate that

percent. sample analysis for Listeria will be the

Intensifying Efforts against Listeria Many will be wondering where fastest growing category in food safety

In other interviews, processors told these samples will be analyzed. As we microbiology for the next few years. As

us about their plans to dramatically in- have seen in the past, where companies the largest companies set the standard,

crease their Listeria sampling, particularly send their samples for analysis largely others will follow, and we would expect

their EM sample volume. One com- depends on their sample volumes. As this trend to continue for the next 2 to

pany reported that they are dramatically shown in Figure 2, smaller and midsize 3 years until companies have completed

changing their program, with an aim users overwhelmingly send their sam- the adjustments of their programs and

to find and eliminate Listeria harbor- ples out to a commercial lab, but above growth levels off at this increased level.

age sites and as a response to the FDA the 100-samples-per-week threshold, the This increase in demand for Liste-

guidance released in 2017. Their plan balance tends to favor using a central- ria tests will drive competition in the

will include increasing their overall EM ized corporate lab or an in-plant lab. diagnostic and laboratory market, and

sampling volume approximately two- This figure shows the selection based on we can expect to see new products and

fold. They reported that all EM testing the number of facilities, but when the offerings emerge to capture this new

will increase, including tests for other data are weighted for volume, the num- demand.

pathogens, but the primary driver of the ber of samples being sent to commercial Processors are clearly attacking the

increase will be Listeria, mentioning that labs is roughly 50–55 percent of the to- Listeria issue. It is now up to the diag-

“we had been doing hundreds of Listeria tal sample volume in the survey. This is nostic companies and laboratories to

samples per month and will now be expected, as the few, very large facilities help them meet the challenge. n

doing hundreds of samples per week.” with high sample volumes tend to have

They also mentioned that end-product access to a central lab or in-plant lab, Bob Ferguson is the managing director of Strategic

testing will increase somewhat, but less whereas the higher-number-but-smaller- Consulting Inc. and can be reached at

than 10 percent, and routine microbiol- volume users are much more likely to foodsafetyinsights@gmail.com or on Twitter at

ogy will be unchanged. send their samples to an outside lab. @SCI_Ferguson.

Another company we spoke with This is consistent with the data we re-

J u n e n J u ly 2 018 21

FSM6718pg10-27,62-64Final.indd 21 6/5/18 1:26 PM

PACKAGING

By George G. Misko, Esq.

Ensuring the Safety of tion of food. Section 402 of the act de-

fines “adulterated food” as food that:

• Contains any poisonous or deleteri-

Food Contact Materials: ous substances “which may render”

food injurious to health;

• Contains an uncleared food additive;

GMPs and Beyond

• Consists in whole or in part of any

filthy, putrid, or decomposed sub-

stance, or if it is otherwise unfit for

food;

• Is prepared, packed, or held under

insanitary conditions where it may

have become contaminated with filth

Requirements for food or may have been rendered injurious

to health;

companies to ensure the • Is in a container that is composed,

in whole or part, of any poisonous

safety of food packaging or deleterious substance “which may

render” food injurious to health.

The FD&C Act defines “food” to in-

T

clude food additives and defines a “food

additive” as “any substance the intended

he U.S. Food and Drug Administration (FDA) use of which results, or may reasonably

announced in January 2018 that it was exercis- be expected to result…in its becoming

ing enforcement discretion with respect to a component or otherwise affecting the

the Food Safety Modernization Act (FSMA) characteristics of any food,” unless the

Foreign Supplier Verification Program (FSVP) substance is generally recognized as safe

requirements for importers of food contact substances or the subject of an exemption. This

(FCSs). The news was met with a sigh of relief by the can include substances that are added

industry. The reasons for FDA’s decision centered on directly to food and that may become a

the vastly different hazard profiles and risks presented component of food indirectly, such as

between FCSs and traditional food. through packaging materials.

In meetings and through written correspondence, Prior to 2000, the only means to ob-

food packaging industry representatives had pointed tain FDA clearance for FCSs that were

out to FDA that requiring importers of FCSs to comply food additives was through the submis-

with the FSVP regulation would impose a burden that sion of a food additive petition. Once

is not commensurate with the risk presented. Many submitted, it would then take an average

importers of FCSs source materials from hundreds of of 2 to 4 years for FDA to promulgate

suppliers through a complex supply chain; yet, packag- and publish a formal regulation.

ing materials do not have a history of being a source of During a congressional hearing

foodborne illnesses. held in 1958 on the FD&C Act, it was

FDA cited its premarket review and oversight of pointed out that with respect to pack-

FCSs, and the regulatory framework for these substances aging materials, FDA was being called

as reasons for exercising enforcement discretion with upon to spend an inordinate amount

regards to FCSs and the FSVP regulation. of resources on a potential hazard that

There are some overriding requirements that apply time had shown was virtually no hazard

to both conventional food and food packaging. Chief at all.1 Industry kept pressing the point

among these is the Federal Food, Drug, and Cosmetic with the U.S. Congress and FDA, which

Act of 1938 (FD&C Act) prohibition on the adultera- finally paid off with the enactment of

22 Food Safety Magazine

FSM6718pg10-27,62-64Final.indd 22 6/5/18 1:26 PM

Are you protected from

cross-contamination?

ITEC bootwashers provide the optimal solution to the most

critical source of cross-contamination: Employee footwear.

Automatic walk

through sole washer

ITEC Frontmatec Hygiene full page ad 7x10 inches.indd 1 3/22/2018 10:25:58 AM

FSM6718pg10-27,62-64Final.indd 23 6/5/18 1:26 PM

PACKAGING

the Food and Drug Administration them. Current GMPs for food3 describe the toxicity profile of the impurity and

Modernization Act of 1997 (FDAMA), the methods, equipment, facilities, and its dietary exposure must be considered.

which introduced a new framework for controls for producing food and pre- Oftentimes, with materials cleared by

obtaining FDA clearance of FCSs. scribe the minimum sanitary and pro- FDA by way of an FCN, these issues are

More specifically, FDAMA autho- cessing requirements for producing safe considered and dealt with by the inclu-

rized the Food Contact Notification and wholesome food. sion of specifications in the FCN itself.

(FCN) program. This program allows Pursuant to FSMA, the current GMP Sometimes, where FCSs may be cleared

a manufacturer or supplier of an FCS requirements for human food were by a regulation, this is not the case as

to submit an FCN that includes the updated in 2015. Among the changes the substance may not have been recog-

identity and intended use of the new were new requirements to establish nized as a carcinogen at the time it was

FCS, along with data supporting the Hazard Analysis and Risk-Based Preven- regulated, and even if it had been, some

conclusion that the substance is safe tive Controls for food products, which of the specifications may have been set

for its intended use. If shift the focus from so long ago as to now be woefully out

FDA does not object “There are responding to food- of date. A dated regulation does not

to an FCN submission borne illness to pre- relieve a manufacturer’s responsibility to

within 120 days, then

the new FCS, or mate-

some overriding venting it. Since FCSs

are rarely the cause

ensure a suitably pure product.

In addition to purity requirements,

rials made with it, may of foodborne illness, the GMP requirements for food packag-

be marketed. requirements GMPs for them, which ing apply to the use level of an additive.

So, what does this only specify generic This means that an FCS may be used

have to do with Good

Manufacturing Practic-

that apply to both requirements, were not

updated under FSMA.

only in an amount necessary to achieve

its function or purpose, and must also

es (GMPs)? Well, just The most critical not contain impurities at levels suffi-

as hazard and risk are conventional food and GMP requirement for cient to adulterate the food.

important elements packaging materials is The GMP regulation for FCSs speci-

in determining how

food packaging and

food packaging.” that they be suitably

pure for their intended

fies general rather than the detailed re-

quirements specified for conventional

other contact materials use. This means that food. The procedures that a manufac-

should be regulated and the extent of the FCS may not impart anything to turer of FCSs should follow to ensure

public resources that should be expend- food that can make it harmful or del- compliance with the GMP regulation

ed on them, so too are these important eterious to health, or impart an off-taste will vary based on the specific product

considerations in assessing the type and or -odor to food. While rare, off-taste and the manufacturing process. For ex-

nature of GMP controls needed to en- and -odor issues in food packaging do ample, a GMP program for a manufac-

sure the safety of FCSs. arise. In 2010, Kellogg voluntarily re- turing facility that produces defoamers

As a precursor to this discussion, it is called 28 million boxes of cereal due to for food contact paper products will dif-

important to note that even if an FCS complaints of off-taste and smell. It was fer from one for a plant that produces

is cleared by FDA and complies with postulated that the wax paper liners in trays for microwaveable foods.

the specifications and limitations set out the cereal boxes were releasing hydro- A well-designed GMP program will

in an applicable regulation of an FCN, carbons, including methylnaphthalene. address the entire production cycle of

its use will violate the FD&C Act if it Kellogg filed suit against its supplier of FCSs and products. This should include

does not also comply with the GMP the liners to recover the damages it in- raw materials, manufacturing equip-

regulation for food packaging materials, curred due to the faulty liners, and the ment and procedures, personnel, testing

“General provisions applicable to indi- liner manufacturer then interpleaded its procedures to ensure product purity,

rect food additives.”2 This regulation is coating supplier as the liable party. and quality control of finished prod-

central to ensuring the safety of FCSs in An important part of suitable purity ucts, along with record-keeping. Other

the U.S. involves the need to ensure that residual considerations for an effective GMP

components of starting materials are program are discussed below.

Good Manufacturing Practices sufficiently low that their presence will Assessment of raw materials should

GMPs ensure that products meet not result in a health or safety concern. include confirmation that specifications

food safety, quality, and legal require- Most of these concerns center upon are met. This may include obtaining

ments. Since the hazard profiles and harm from chronic exposure to certain certificates from suppliers that show

risk presented for conventional food substances that may be suspected of car- that raw materials are cleared for their

and FCSs are very different, FDA has cinogenic potential or other such health intended use by FDA or test results,

issued separate GMP regulations for hazards. In evaluating these impurities, such as migration testing. In addition,

24 Food Safety Magazine

FSM6718pg10-27,62-64Final.indd 24 6/5/18 1:26 PM

PACKAGING

suppliers should be contractually obli- The Framework Regulation specifies The seven principles of an HACCP

gated to notify their customers of any that food contact materials and articles program are:

significant changes. The impact of any must be manufactured in accordance • Conduct a Hazard Analysis;

changes in raw materials or processes with GMPs, so that they do not transfer • Identify the Critical Control Points

should be evaluated before they are their constituents to foodstuffs in quan- (CCPs) where control can be applied

implemented. Finally, food contact and tities that could endanger human health to prevent, eliminate, or reduce a

nonfood contact materials should be or bring about an unacceptable change hazard;

stored separately. in the composition of the food or its • Determine limits for each CCP;

Manufacturing procedures should organoleptic properties. • Establish monitoring to ensure that

be written out and available at work- Once legal safety requirements are limits are being met at each Control

stations. The written procedures met, customers may require further as- Point;

should include spe- surance that FCSs and • Establish corrective actions when

cific raw materials and products are safe and limits are not met;

amounts, identifica-

“The most critical of a certain quality. • Establish record-keeping procedures;

tion of critical points For instance, many • Verify that the program is working.

in production that GMP requirement for food manufacturers, In summary, FDA’s GMP regulation

need monitoring, and especially large in- for indirect additives is fairly general

required testing. Pro- ternational ones, are and includes the following requirements

cedures that should

packaging materials is mandating that their for food contact materials and their

be taken to correct packaging suppliers be components: They should be suitably

any deviations should that they be suitably Global Food Safety pure and comply with other provisions

also be specified. All Initiative (GFSI) certi- of the FD&C Act; they must not render

employees should be fied. food unfit for consumption; and they