Académique Documents

Professionnel Documents

Culture Documents

Ajmshadiqurrahman QMS Audit

Transféré par

ajmshadiqurrahman0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues9 pagesAjmshadiqurrahman QMS Audit

SBZ.SBZ.SBZ.SBZ

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentAjmshadiqurrahman QMS Audit

SBZ.SBZ.SBZ.SBZ

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues9 pagesAjmshadiqurrahman QMS Audit

Transféré par

ajmshadiqurrahmanAjmshadiqurrahman QMS Audit

SBZ.SBZ.SBZ.SBZ

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 9

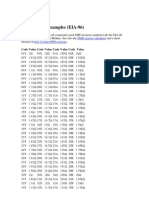

East West Industrial Park Ltd.

Chaydana, National University,

Gazipur.

Internal Audit/QMS Audit Form

Unite:

Audit By Agreed By Date of audit :

RAW MATERIAL RECEIPT/ INSPECTION

QA SYSTEM Fabric Storage Yes No Partially

1 Is there fabric inventory area?

2 Is there any quarantine area?

3 Are Non-conforming materials identified and segregated

4 Are there palates or racks for fabric storage?

5 Is there any location system for fabric storage?

6 Fabric Rolls or covered in plastic bags

7 Stock keeping records

8 Color assessment testing / Fabric inspection

9 Is The factory aware of the customer's lighting policy?

10 Light box model:

11 LIGHT BOX ware calibrated by thread party

Calibration certificate provided -

12

what is the valued time period

13 Is there records kept for each dye lot?

14 Is there GSM measuring scale

15 GSM measuring scale ware calibrated by thread party

Calibration certificate provided -

16

what is the valued time period

17 Is there any GSM check record

18 No. of inspection machines 3

19 Availability of color standard Given By Buyer approved

20 Check for shading

21 Is there inspection system? D 65 Type of Inspection system used 4Point

22 Fabric inspection standard available

23 % of inspection 10% & 100% Does this cover dye lots / Batches

24 Is there inspection records kept?

25 Are these records analyzed?

26 Current inspection system Insufficient Sufficient

27 Lighting at Inspection Area

28 Cleanliness Unacceptable Improvement req. Acceptable

29 Tidiness Unacceptable Improvement req. Acceptable

Details :

COMMENTS : Still not provided customer lighting policy

QMS Audit (Technical) Page 1 of 9

Trim and Accessories:

QA System in Trims Warehouse YES NO Partially

1 Is there clear and enough storage area?

2 Is there enough racks and plats?

3 Is there trims inventory area?

4 Is there any quarantine area?

5 Are non-conforming materials identified and segregated

6 Is there material storage and bin card system?

QTY QUAL COLOR OTHERS

7 Type of inspection carried out in trim

Details:

8 Is there trims inspection system?

% (percentage) AQL

Which system following

9

Details

10 Is there inspection records kept?

11 Are these records analyzed?

12 Is there separate inspection area?

13 Current inspection system Insufficient Sufficient

14 Lighting at inspection area

15 Cleanliness Unacceptable Improvement req. Acceptable

16 Tidiness Unacceptable Improvement req. Acceptable

Details :

Comments :

Label Management (warehouse): Yes No Partially

1 Is there label trims inventory area?

2 Is there any label quarantine area?

3 Are non-conforming materials identified and segregated.

4 Is there secured labeling storage cupboard?

5 Is there labeling inventory, Issue, receive, balance stock register?

6 Are these records are treatable?

7 Labels & tickets are stored securely and separately, Buyer, Style & Size wais?

8 Are extra labels & tickets returned to warehouse?

9 Is there approved trim card Given by Merchandiser

10 Which departments will get a copy of trim card? Quality

11 Labels are sourced from approved suppliers?

12 Is there trims inspection system?

% (percentage) AQL

13 Which system following

Details….

14 Is there inspection records kept?

15 Are these records analyzed?

16 Current inspection system Insufficient Sufficient

17 Lighting at inspection area

DETAIL : We have good light system at inspection area above 1000 Lux.

Comments :

QMS Audit (Technical) Page 2 of 9

SAMPLE ROOM Yes No Partially

1 Dose the factory have a sample room?

2 If yes , please complete the following

3 If no , Then treat as N/A.

4 Equipment / Facility

Initial Manual Computer

Which

Grading Manual Computer Garber

software

Marker Manual Computer

5 Does the factory have a dummy / Fitting mannequin?

If yes, please give details:

Condition of

Excellent Good Satisfactory Fair Poor

Equipment

6 Design & development /Pre production

7 Does factory develop ITS own pattern?

Initial pattern Fit pattern Pre-Production pattern Bulk pattern

If no, please give details:

8 Are there clear records of the date and changes to patterns?

9 Is there design risk assessment system?

10 If yes when will do the design risk assessment? Development

11 Which deportments are participating in the design risk assessment?

12 Is the design risk assessment record being communicate to pattern room

What samples are sewn in the factory?

ST Fit Seal TOP

1 concept Size set. Pilot run.

13 sample sample Sample

Sample Sample Sample Sewing Sewing

Sewing line

room room room line line

14 Dose the factory assess shrinkage on bulk fabric

15 How? Every roll wise ….. cm /………….cm cut fabric send to wash

16 Are record maintained for shrinkage assessment?

17 Are there any before wash measurement size chart?

18 It is easy to identify different shrinkage marker?

19 Who will check the garment?

20 Production specification sheet.

21 What details are recorded in the production specifications?

Design Raw Sealed

Make up Labeling Size chart Comments

Sketch material sample

22 Who will get a copy of the production specification?

Merchandi Line In line End of line

QAM PM Others Merchandiser

ser supervisor inspector inspector

PRE-PRODUCTION SAMPLE/PLANNING/PRE-PRODUCTION MEETING Yes No Partially

Where will the pre production

1 Sample room Sewing line

sample manufactured

What will be Carried Out on Sample Review?

Product Manufacture Compliance

2 Aesthetic Fitting Measurement

safety feasibility /legislation

Workmanship Customer comments

3 Who approves the production sample? Buying house

4 Will a pre-production meeting be carried before production starts?

QMS Audit (Technical) Page 3 of 9

Who will be Involved in the PP meeting?

5 Sample / IE / Production Finishing

Merchandiser Planning Quality All

Pattern Maintenance team team

6 What will be discussed? About Cutting, Sewing, Finishing, Packing, Product Safety, etc.

7 Is there a critical path plan?

8 Are there daily / weekly target set for the sewing line?

9 How is the target level being calculated?

10 How does the factory plan in on target

11 Is there any action plan record

12 Cleanliness Unacceptable Improvement req. Acceptable

Tidiness Unacceptable Improvement req. Acceptable

Lighting Insufficient Sufficient

Details:

Comments :

CUTTING ROOM / Equipments and Quality System Yes No Partially

1 What is the cutting capacity per day? Tops Bottom

2 Is there enough fabric storage area for par day cutting capacity

3 Is there fabric relaxation area?

4 Is there any relaxation process?

5 How is this arranged? According to process

6 Are there any fabric relaxation records?

4 No of Cutting Tables: …….. Pcs Wide width: Narrow width:

5 Straight knife …..…. Set

6 Round knife …..…. Set

7 Band knife ……… Pcs

8 Edge cutter ……... Pcs

9 Computer cutter …..…. Set

10 Die cutter ……... Set

11 When not in use how are the blades stored? In side sharp tools box

12 Is there secured cupboard for store the equipments and sharp tools?

13 Equipment and tools cupboard where identified

14 Is the a tool control on daily basis issue & receive register with stock record

How long using a cutting blade and

15 Maximum 03 cutting

what basis it re-placing

16 How is marker attached to the lay? Pins Clamps Tape Adhesive paper

17 Those Items are issue and receive record on daily basis with stock record

18 Color continuity card Is there

19 Under what lighting conditions is color

20 Batch awareness. / use of fabric DYE lot no?

21 Separating roll by paper waste / Fabric strips

22 Are panels numbered

23 Are bundles / Panels inspected

24 Is there any bundle / Panel Inspection record

25 What are they inspecting for?

26 % of over cut % of re cut

QMS Audit (Technical) Page 4 of 9

Fusing Section Yes No Partially

1 Is there any fusing machinery?

2 Flat bed Detail Widths

Continues Detail Widths

3 Fusing machines ware calibrated by thread party

Calibration certificate provided -

4

what is the valued time period

5 Does factory have a maintenance schedule for these machines?

6 Frequency of Maintenance? Twice daily Daily Monthly

7 Describe maintenance activities Schedule maintenance

8 Machine calibration Bi-hour Twice a day Once a day

Temperature checks L - M - R Using thermal paper Using thermocouple

9 Is pressure evenness checked? L-M-R Frequency

10 Are time / Machine speed checked? If yes then how?

11 Are fusing reports available for every fabric?

12 Which interlining companies provide these? Supplier

13 Which of the following Parameters are detailed? Glue Line Temperature Pressure

Fusing Time Peel Bond strength requirement

14 Fabric specific fusing conditions checked prior to fusing

Glue line temp. Peel bond strength Adhesive appearance after fusing

Time

L -M - R L - M - R hand feel check against report

How is Peel Bond strength

15 Checking with help off bond strength check meter

checked?

16 Is fusing (Thermal) shrinkage checked?

17 How? We are checking with muck up as per belt with

18 Is there any Template for check the Shrinkage?

20 Cleanliness Unacceptable Improvement req. Acceptable

Tidiness Unacceptable Improvement req. Acceptable

Lighting Insufficient Sufficient

Work in progress Low Balanced Bottlenecks

Details :

Comments :

Sewing Room Quality

LABEL MANAGEMENT (SEWING ROOM) Yes No Partially

1 QTY of label issue will be depend on Bundle qty Bundle qty + Wastage

2 Is extra quantity returned to the trim store?

3 Are Labels returned when there is a style change?

4 Are single size labels distributed at a time?

5 How are remakes or repairs handled?

6 Is trim card available in sewing line?

7 Is there mockups displayed with clear work Instruction

IN-LINE EXAMINATION Yes No Partially

8 Are sewing operation instructions available at each sewing machine?

Do instructions include

9 Machine setup Workmanship Trimming

guidelines for?

10 FOR? Quality Appearance

Details:

QMS Audit (Technical) Page 5 of 9

11 Random inspection of sewing standards at sewing machines

12 Bundle inspection No of pieces Inspected

13 Inspection frequency Per hour Per 4 hours Per shift Other

14 Trimming instructions/standard available

15 Sewing operators trim each piece where Front side there

16 Trimming at of line

17 Is there an internal inspection being carried out on trim garments?

18 Who carries out this Quality inspector

19 How? AQL ….. As per lot

20 Inspection at end of line

21 No. of end line inspector ………person (Par line)

What do they

22 Workmen ship Measurement Sewing in label Size check Label position

inspect for?

23 Clear separation of GMTS not inspected/Inspected/Faulty GMT

24 Is poorly trimmed garments return to the trimming section?

25 Are inspectors trimming the garment during inspection?

26 Are inspectors able to retrieve approval sample for reference?

27 Are inspector given a detailed production sheet?

28 Record keeping Record passed to QM

29 Are record analysis? For what purpose

30 Cleanliness Unacceptable Improvement req. Acceptable

Tidiness Unacceptable Improvement req. Acceptable

Lighting Insufficient Sufficient

Work in progress Low Balanced Bottlenecks

Details :

Comments :

NEEDLE/METAL CONTAMINANTS CONTROL IN THE SEWING SECTION Yes No Partially

1 Is there a needle control policy

2 Are needle controlled for line change

3 Are record kept

4 Are needles exchanged on a 1 for 1 basis?

5 Who retains broken part? Operators Line supervisors Maintenance Needle Controller

6 Record keeping?

7 Tape all the broken needle part of a set

8 How long are record kept Less than 18 Months 18 + Months

9 Are hand sewing needles controlled with daily records?

10 Are hand tools controlled?

11 Is there a policy /contingency plan if needle fragments are not found?

12 Is there secured needle control room?

13 In their trained needle controller?

14 Details

Comments:

BUTTON / POPPER ATTACH SECTION Yes No Partially

1 Are lock stitch button machines used?

2 Are thread wipers /Are blowers used?

QMS Audit (Technical) Page 6 of 9

3 Are machines serviced at least every 4 weeks?

4 Are visual attachment standards available at machine?

5 Are technical data sheets available for metal component?

6 Are pinch setting checked at least twice a day per machine?

7 Are results recorded in graph from?

8 Are components stored in locked cupboard when not in use?

9 Is a button procedure in place for bobbin/ spool change (Bingo card)?

10 Is the first button attached on to spare fabric after change

11 Is the last button attached cut off the garment after change?

12 Are record kept?

13 Is a pull tester used?

14 Are pull tests carried out at least twice a day per machine?

15 Are all tests carried out on true mockups?

16 Are results stored with tested specimens?

17 Is there snap machine?

18 Type of the machine Manual Semi auto Pneumatic

19 If any pneumatic machine calibration?

20 Snap attaching area portioned?

21 Cleanliness Unacceptable Improvement req. Acceptable

Tidiness Unacceptable Improvement req. Acceptable

Lighting Insufficient Sufficient

Work in progress Low Balanced Bottlenecks

Details :

Comments :

FINAL TRIMMING / INSPECTION SECTION Yes No Partially

1 Is there a trimming process before final inspection?

2 Is the trimming process done?

3 Is there an internal audit being carried out on trimmed garment?

The trimming process Sewing process End of line

4 A group Helpers

is done by operators inspector

5 Condition of clippers Excellent Good Satisfactory Fair Poor

6 No of inspector

7 Random.............. 100% inspection……… Others……………

8 Record keeping

9 Are record analysis For what process

10 Clear segregation of inspected/not inspected?

11 Is there a quarantine area for rejected goods?

12 Are functionality tests carried out on buttons/snaps etc?

13 Are kids garments turned inside out and checked?

14 Cleanliness Unacceptable Improvement req. Acceptable

Tidiness Unacceptable Improvement req. Acceptable

Lighting Insufficient Sufficient

Work in progress Low Balanced Bottlenecks

Details :

Comments :

QMS Audit (Technical) Page 7 of 9

PRESSING Yes No Partially

1 Dose the factory have a pressing room?

2 Equipment/Facility

Slatted/ Vacuum folding Hoffman

Steam iron Carousel Dolly

Wooden table table table type presser

3 Garment hanging facility/System Rack Other Stand

4 Condition of the pressing covers Acceptable Unacceptable

5 Condition of equipment Excellent Good Satisfactory Fair Poor

6 Approval / reference sample available in this section?

7 Is there packing and finished goods strong area?

8 Is the size of the storage area adequate to store finished good

9 Is there secured metal free zone?

10 Is the issuing tag guns controlled?

11 Broken needle control?

12 Guns/ Records / needle stored in locked cupboard?

METAL DETECTION SECTION Yes No Partially

13 Is there a metal detector?

14 Is metal detection the last process?

15 Metal detector locan

16 Static table top Conveyer Hand held

17 Ferrous sphere card 1.2 mm 1.0 mm

18 Calibration point check 9 point

19 Frequency :

20 Record maintain

21 Record analyzed

22 Accurate measuring tool for checking 9 points

23 Machine supplier calibration certificate renewed?

24 Calibration certificate valued time line

25 During visit was 1. mm test card detected on all 9 points

26 Robust procedure in place to retrieve contaminant?

27 Reserve box for quarantined goods?

28 Dose a metal detect record exit for finishing?

29 Is a box for destroyed goods available?

30 Dose a metal detect record exit for samples?

31 Dose a metal detect record exist for AQL’d stock?

32 Are detected goods identified by colored sticker?

33 Dose metal detectors have a security key switch?

34 Is sensitivity dial securely covered and locked

35 Dose supervisor hold key to restart machine?

36 Goods that fall outside MFZ are rechecked?

37 Sub contracted goods detected before issuing to production.

38 Quarantine procedure adhered to for sub contracted goods?

Cleanliness Unacceptable Improvement req. Acceptable

Tidiness Unacceptable Improvement req. Acceptable

Lighting Insufficient Sufficient

Work in progress Low Balanced Bottlenecks

Details :

QMS Audit (Technical) Page 8 of 9

comments :

INDEPENDENT QA/QC-IN-LINE / FINAL INSPECTION Yes No Partially

1 Dose the factory have an independent AQL team?

2 How many person in the team

3 How does the team report to quality Manager / AGM / GM

4 Is there a quality manager in the factory?

5 Responsibility QC system QA System Raining Product safety

6 No of buyer certified QC

7 QA department report to

8 Quality control (workmanship) AQL Critical Major Minor

9 When will AQL be carried out

10 Packing accuracy inspection

11 Packing accuracy system AQL Other

12 Record maintained?

CUSTOMER QA-IN-LINE / FINAL INSPECTION Yes No Partially

13 Quality control (workmanship) AQL Critical Major Minor

14 When will AQL be carried out

15 Packing accuracy inspection

16 Packing accuracy system AQL Other

17 Record maintained?

18 Who will analyze the report

19 What for

20 Is there any shipment release order

COMMENTS:

Signature...

Auditor GM CEO Director

END OF REPORT

QMS Audit (Technical) Page 9 of 9

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Metco 16C 10-040Document8 pagesMetco 16C 10-040JSH100Pas encore d'évaluation

- SMD Resistor ExamplesDocument5 pagesSMD Resistor Examplesmarcbuss100% (1)

- Kohler 14 20 RES Parts Manual TP 6806 2016 06Document76 pagesKohler 14 20 RES Parts Manual TP 6806 2016 06peleniusPas encore d'évaluation

- Advance Concrete PDFDocument33 pagesAdvance Concrete PDFUdom RithPas encore d'évaluation

- DP1100Document3 pagesDP1100tunradotPas encore d'évaluation

- 4 Contamination Control 2Document61 pages4 Contamination Control 2Vijay RajaindranPas encore d'évaluation

- LCD TV W DVD PDFDocument5 pagesLCD TV W DVD PDFINJESBGPas encore d'évaluation

- 04 Surveys Cattell PDFDocument16 pages04 Surveys Cattell PDFBrenda MaggPas encore d'évaluation

- HHW 35 m6 GBDocument6 pagesHHW 35 m6 GBSuper WhippedPas encore d'évaluation

- Parameters by Functional CategoryDocument6 pagesParameters by Functional Categoryapi-3819698Pas encore d'évaluation

- Project Steel - Final ReportDocument42 pagesProject Steel - Final Reportashikur rahmanPas encore d'évaluation

- Presented By:: Rafi Sheikh Sheeraz Malik Syed Ahmed Ali Umair Ali Waqar AmeenDocument34 pagesPresented By:: Rafi Sheikh Sheeraz Malik Syed Ahmed Ali Umair Ali Waqar AmeenSyed Ahmed AliPas encore d'évaluation

- Standard Terms & Conditions of Sale Pre-Engineered BuildingsDocument18 pagesStandard Terms & Conditions of Sale Pre-Engineered BuildingsHongducBuiPas encore d'évaluation

- Liquid Gas Absorption ProcessDocument89 pagesLiquid Gas Absorption ProcessMohd Masri A. RazakPas encore d'évaluation

- Product Catalogue: Your Specialist in Flow DrillingDocument64 pagesProduct Catalogue: Your Specialist in Flow DrillingВасяPas encore d'évaluation

- VNX Unified Storage ManagementDocument3 pagesVNX Unified Storage ManagementNicolePas encore d'évaluation

- Getting Started With Java: Atul PrakashDocument20 pagesGetting Started With Java: Atul PrakashOwsozeroPas encore d'évaluation

- Handling Tickets Is Called Issue Tracking System.: Sap SDDocument6 pagesHandling Tickets Is Called Issue Tracking System.: Sap SDNaveen KumarPas encore d'évaluation

- 211 A3 211 Summary ResultsDocument14 pages211 A3 211 Summary ResultsElmer Gonzalo Sullca ZapataPas encore d'évaluation

- Lectures - Mass TransferDocument36 pagesLectures - Mass TransferaaaPas encore d'évaluation

- Introduccion To PhysicsDocument475 pagesIntroduccion To PhysicsLyvsPas encore d'évaluation

- Tutorial Questions and Answers - 2011Document10 pagesTutorial Questions and Answers - 2011Jan ScarPas encore d'évaluation

- Water Technology 2015 2016 1Document86 pagesWater Technology 2015 2016 1Srinivas AkHilPas encore d'évaluation

- Maison À BordeauxDocument5 pagesMaison À BordeauxSpam TestPas encore d'évaluation

- Pavement Evaluation and Overlay Des - DR MSA - LatestDocument103 pagesPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruPas encore d'évaluation

- Export Dataset To PDF in ASP NetDocument2 pagesExport Dataset To PDF in ASP NetWilliamPas encore d'évaluation

- Catalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoDocument78 pagesCatalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoAlexis SanchezPas encore d'évaluation

- Ceramic Materials: Introduction!: MCEN90014: Materials ! ! !dr. K. Xia! ! ! !1!Document5 pagesCeramic Materials: Introduction!: MCEN90014: Materials ! ! !dr. K. Xia! ! ! !1!hamalPas encore d'évaluation

- ThanksDocument17 pagesThankssselvanjhcPas encore d'évaluation

- SY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical ReferenceDocument88 pagesSY-5SSM V1.1 SY-5SSM/5 V1.1 Super 7 Motherboard: User's Guide & Technical Referencealopezcuervo82190% (1)