Académique Documents

Professionnel Documents

Culture Documents

Babcock and Wilcox Boiler1

Transféré par

Oscar DorantesTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Babcock and Wilcox Boiler1

Transféré par

Oscar DorantesDroits d'auteur :

Formats disponibles

Babcock & Wilcox CFB Boilers—Design and Experience

F. Belin

M. Maryamchik

D.J. Walker

D.L. Wietzke

The Babcock & Wilcox Company

Barberton, Ohio, U.S.A.

Presented to: BR-1711

16th International Conference on FBC

May 13-16, 2001

Reno, Nevada, U.S.A.

Abstract B&W CFB boilers feature a two-stage solids separator. The

The distinctive feature of Babcock & Wilcox (B&W) CFB primary stage is an impact solids separator located at the fur-

boilers is a two-stage solids separation system consisting of the nace exit collecting the bulk of the solids (95-97%) that are then

impact-type primary solids separator (U-beams) and the sec- returned to the furnace by gravity. The primary separator is ar-

ondary multi-cyclone dust collector. Lessons learned from 15 ranged as an array (Figure 1) of U-shaped vertical elements (U-

years of B&W’s CFB technology application have been used to beams). The secondary separation stage, typically a multi-cy-

develop a reliable, low cost boiler design. Advantages of boil- clone dust collector (MDC), is located in the lower gas tem-

ers with a two-stage solids separation system are described. Op- perature region of the boiler convection pass, i.e., 480 F to

eration of B&W coal-fired CFB boilers over the last 10 years 950 F (250 C to 510 C). In some cases the first fields of an

has demonstrated high reliability of the two-stage solids sepa- electrostatic precipitator are used as the secondary separator.

rator. Superior solids collection efficiency of the two-stage sepa- The fine particles collected by the secondary separator are re-

rator provides higher furnace heat-transfer rate, ability to better turned to the furnace via a pneumatic (in earlier designs) or grav-

control furnace temperature, and increased residence time of ity transport system.

fine carbon and sorbent particles. As a result, the required boiler

The U-beam separator has evolved through three B&W CFB

performance is achieved with lower furnace height and smaller

boiler design generations:

boiler footprint. The current B&W IR-CFB boiler design is de-

scribed. Compactness of the IR-CFB makes it especially attrac-

• First generation (first started-up in1986) - All U-beams

(11 rows) installed external to the furnace with solids re-

tive for PC boiler retrofit applications. Considerations for IR-

cycle through non-mechanical controllable L-valves.(1)

CFB scale-up are provided.

• Second generation (first started-up in 1989) - Two rows

of in-furnace U-beams discharging collected particles

Background (about 70 % of incoming solids) directly to the furnace

The major distinction between circulating fluidized-bed and seven rows of external U-beams with solids recycle

(CFB) boilers competing in today’s market is in the type of the through L-valves. (2)

solids separator. CFB boilers with large cyclone separators con- • Third generation (first started-up in 1996) - Two rows of

nected to the furnace outlet (hot-cyclone type) were introduced in-furnace U-beams and three or four rows of external

in mid-1970s and are being offered by several boiler manufac- U-beams with all solids internally recycled within the

turers. CFB boilers with impact separators, offered by furnace (currently offered “IR-CFB”separator shown in

Babcock&Wilcox (B&W) and its licencees, entered the market Figure 2). (3)

more than ten years later and since then have been gaining wide As a result, dramatic simplification and cost reduction of

acceptance. the U-beam separator have been achieved.

Babcock & Wilcox 1

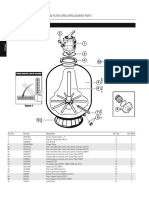

1. Sidewall Membrane Panel

2. U-Beam

3. Seal Baffle

Fig. 1 U-beam primary separators—plan view.

Over the same period, the design of the MDC separator has Fig. 3 Multicyclone dust collector.

been improved for better efficiency, reliability and maintain-

ability. The current design (Figure 3) has a top gas inlet and a sis for all new offerings including the most recent contract for a

side gas outlet. The cyclone elements have 9 in. (229 mm) di- 90 MWe IR-CFB in Tychy, Poland.

ameter regardless of boiler capacity. The cyclone sleeves and Operating experience of B&W coal-fired CFB boilers has

spin vanes are made of high hardness (550 BHN) material. The clearly confirmed their efficient performance and high reliability.

MDC solids recycle system has evolved from dense-phase pneu-

matic transport (first generation) to dilute-phase pneumatic

transport (second generation) to gravity conveying (third gen- Design Features

eration). The design of a solids separator is the core of a CFB com-

The second-generation CFB boiler at Ebensburg, Pennsyl- bustion technology since it has major impact on the boiler lay-

vania, in a cogeneration plant commissioned in early 1991, ex- out, cost, fuel and sorbent utilization, operational flexibility and

emplifies the long-term boiler performance. This boiler (Figure reliability. In all these aspects B&W’s CFB boilers with the two-

4) burns high-ash (average 45% ash) Western Pennylvania waste stage solids separation provide the following design features:

bituminous coal. The unit was designed for 55 MWe capacity

(211 tph steam flow), but was uprated in 1995 and again in a) High solids collection efficiency

1997 and since has been operated at 10% overload. Boiler per- The collection efficiency of the two-stage solids separator is

formance and availability are shown in Table 1 and Figure 5 intrinsically high due to the greater efficiency of the MDC in-

respectively. The Ebensburg plant received the Association of ternal collection elements. Higher solids collection efficiency

Independent Power Producers of Pennsylvania (ARIPPA) award helps to achieve greater inventory of fine circulating particles

for the highest availability among plants firing coal mine waste in the furnace that provides: a) higher furnace heat transfer rate,

fuels. b) ability to better control furnace temperature, and c) better

The CFB boiler at Southern Illinois University (SIU) in carbon and sorbent utilization due to the increased residence

Carbondale, Illinois, represents the third generation design. The time of fine particles.

boiler (Figure 6) was designed for 35 MWt output for cogen-

eration application, utilizing high-sulfur Illinois bituminous coal.

Boiler performance and availability are shown in Table 2 and

Figure 7, respectively. The third generation design was also used

for the Kanoria Chemical project in India and is the design ba-

Furnace Roof

Gas Flow

In -Furnace

U-Beams

External

In -Furnace U-Beams

U-Beams

Solids

External U-Beams Transfer

Hopper

Solids Transfer Hopper

Furnace

Fig. 2 IR-CFB primary particle collection system. Fig. 4 Ebensburg CFB boiler.

2 Babcock & Wilcox

Table 1

Ebensburg Operating Data

Operating Steam Flow, t/hr (klb/hr) 234 (516)

Steam Flow @ MCR, t/hr (klb/hr) 211 (465)

Steam Temperature, C (F) 512 (953)

Steam Pressure, MPa (psig) 10.6 (1540)

SH Steam Temperature Control Range, % 30-110

Load Turndown Ratio Without Auxiliary Fuel 5:1

Emissions

NOx, ppm (lb/106 Btu) <100 (<0.14)

SO2, ppm (lb/106 Btu) <300 (<0.60)

CO, ppm (lb/106 Btu) <230 (<0.20)

Ca/S Molar Ratio 2.1-2.4

b) Controlled furnace temperature

The furnace temperature is controlled in response to load

changes and variations of fuel and/or sorbent properties by con-

trolling the solids recycle rate from the MDC. The recycle rate

at high boiler loads is set to achieve the upper furnace density

required to maintain the target furnace temperature. At low loads,

the recycle rate directly controls the dense bed temperature. The

capacity of the MDC hoppers is used for solids transfer to and

from the furnace. Excessive solids collected by the MDC are

purged if needed. With B&W CFB boilers the load can be re-

duced without auxiliary fuel to 20% MCR.

Fig. 6 Southern Illinois University IR-CFB boiler.

c) Low auxiliary power

The auxiliary power requirement is lower for impact-sepa- gas flow pattern. This allows placement of in-furnace surfaces

rator type boilers since the total pressure drop across the two- as needed over the entire furnace height and width, including

stage separator (U-beams + MDC) is only 4 in. wc (1 kPa). In the region adjacent to the rear wall in the upper furnace. With

addition, high-pressure air blowers for fluidization of returning proven reliability of in-furnace heating surfaces, this makes

solids are not needed. unnecessary the use of external heat exchangers and allows se-

lection of the furnace height based on combustion/sulfur cap-

d) Uniform gas flow ture considerations rather than heating surface requirements.

The gases exiting from the furnace to the U-beam separator Combined with high collection efficiency of the two-stage sol-

across the furnace width provide for a uniform two-dimensional ids separator, this allows reduced furnace height.

Forced Outage Planned Outage Boiler Availability

100 1.9 1.2 1.4 1.8 1.8

1.5 0.7

3.9 2.6 2.2

5.3 1.3

Boiler Availability, Percent

5.6 4.2 3.4

2.9

2.8

95 8.4 9.4 4.5 6.6

5.6

90 98.0

95.0 94.0 95.6

94.8

91.6 93.0

85 89.7 89.4 90.8

89.1

80

0

1991 1992 1993 1994 1995 1996 1997 1998 1999 2000

(May-Dec.) (Jan.-July) (Jan.-June)

Fig. 5 Ebensburg boiler availability.

Babcock & Wilcox 3

Forced Outage

Table 2 Commissioning Outage

SIU Operating Data Planned Outage

Boiler Available

Steam Flow @ MCR, t/hr (klb/hr) 46 (101.5)

100

Steam Temperature, C (F) 399 (750) 1.4

4.9

Steam Pressure, MPa (psig) 4.4 (640) 95 11.0 10.3

Boiler Availability, %

10.7

SH Steam Temperature Control Range, % 40-100 90

95.1

Load Turndown Ratio Without Auxiliary Fuel 5:1 85 89.0 89.7 87.9

Emissions 80

NOx, ppm (lb/106 Btu) <100 (<0.14)

SO2, % removal 90 85

CO, ppm (lb/10 6 Btu) <200 (<0.17)

1997 1998 1999 2000

(Jul 15-Dec 31) (Jan-Jun)

Ca/S Molar Ratio 2.3

Fig. 7 SIU boiler availability.

e) High solids separator reliability vided to accommodate possible U-beam temperature deviations

U-beams and MDC have high reliability and low mainte- from the expected value based on average gas temperature leav-

nance since they do not include any maintenance-intensive com- ing the furnace. These margins eliminate the possibility of the

ponents such as refractory, loop-seals, expansion joints, vortex U-beams being damaged during operational upsets.

finders, etc. The U-beam design that has evolved through 15 Mechanical conditions of U-beams along with related boiler

years of operating experience has proven to be very reliable, thermal performance data have been monitored over the 10 years

requiring no maintenance. U-beam design criteria includes con- of operation at the Ebensburg CFB boiler. B&W confirmed that

servative assumptions of 25 year life of U-beam materials and erosion losses were negligible due to a tough, erosion-resistant

supports. The MDC internals require some maintenance during film formed on the surface of the U-beams. B&W also deter-

planned shutdowns; this expense has been minimal on the oper- mined that the material was resistant to corrosion and deforma-

ating B&W CFBs. tion when operated within the design margins.

The Ebensburg CFB boiler capacity was increased by 10%

f) Integral design/small footprint over original design. For evaluated economic reasons no other

The U-beam separator is integral with the boiler enclosure changes to the boiler were made to maintain the design tem-

providing for the most compact and cost-efficient boiler layout perature and excess air at the furnace exit. This resulted in more

similar to the conventional two-pass pulverized coal (PC) boiler. than three years of operation with local U-beam temperatures

This feature is especially important for retrofitting outdated PC approaching or exceeding the design margins.

boilers with CFB technology in repowering applications where After this three year period of operation with excessively

keeping the existing boiler “footprint” is highly desirable. high temperatures, signs of U-beam mechanical degradation

began appearing where the maximum temperatures or maximum

g) Minimal refractory use solids loading occur. Some U-beam channels began to flare, and

The amount of refractory used in the B&W CFB boilers is the mid-sections of several U-beams rotated up to 10 degrees

80-90% less than that used for similar capacity CFB boilers with from the original position. Also, several corrosion spots were

non-cooled hot cyclones and 40-50% less than CFB boilers with

found near the bottom of the rear-most rows of U-beams where

cooled cyclones. For B&W CFB boilers the start-up time is not

U-beams were covered with ash deposits. The current design

limited by rate of temperature rise of the refractory.

has been changed to avoid these degradations even during pro-

Two key areas important for design evaluation of CFB boil-

longed high-temperature operation.

ers with impact separators are high reliability of the two-stage

Regardless of some U-beam deformation observed as a re-

solids separator and its superior collection efficiency. The long-

sult of the off-design operating conditions, no deterioration of

term operating experience and test data provide the definite af-

boiler performance was detected and no U-beams have had to

firmation of the impact separator plus MDC design as described

in the following section. be replaced. Maintenance work on U-beams has been minimal,

consisting primarily of cleaning solids accumulated on the top

side of the alignment pans located near the bottom of U-beams,

Two-stage solids separator experience and an occasional repair of the pan and strap attachment welds.

The resilience of U-beams to operating conditions associ-

Reliability ated with excessive temperatures and increased gas velocities

U-beam experience. U-beams are conservatively designed contrasts to that of vortex finders (a part of hot-cyclones) which

to operate in the flue gas environment at the exit of the CFB are made of similar materials and exposed to a similar gas/sol-

furnace. B&W has selected U-beam materials–typically high ids environment.

nickel, high chromium, austenitic stainless steels–to resist ero- Vortex finder failures have been reported with a substantial

sion and corrosion while possessing adequate long-term strength detrimental effect on boiler performance and considerable main-

at the design temperatures. Substantial design margins are pro- tenance costs.

4 Babcock & Wilcox

MDC experience from the forced draft fan. Material velocity in the sloping re-

At Ebensburg, due to the waste coal’s high ash content and turn lines is low, resulting in low erosion potential. This design

ash abrasiveness, about 20% of the MDC internal elements are simplifies the recycle system, improves its reliability, and re-

being replaced during each yearly outage to avoid a loss of MDC duces power consumption.

efficiency. At other B&W CFB boilers burning high-sulfur bi- - Variable speed, inclined screw(s) are used at the MDC

tuminous coal, circulating solids are typically less abrasive as hopper discharge(s), in place of previously used rotary valves,

compared to the Ebensburg unit, and the MDC internal elements to control the flow rate of recycled solids. The solids in the

have either not required replacement or have been replaced as inclined screw provide the required pressure seal without the

needed during planned outages. At Southern Illinois University maintenance associated with the close-tolerance, machined sur-

(SIU) firing medium-ash high-sulfur coal, practically no ero- faces found in rotary valves.

sion of the internal elements has been detected since the start-

up four years ago. Solids Collection Efficiency

Maintenance work was needed on the Ebensburg pneumatic The only meaningful measure of CFB solids separation sys-

MDC solids recycle system which normally is done on line, or tem performance is the fractional solids collection efficiency.

during planned boiler outages. At SIU, where air-slide ash con- The overall collection efficiency depends on the size distribu-

veyors were used, virtually no maintenance work was needed tion of solids entering the separator and is not indicative of a

on the return system during four years of boiler operation. This separator’s ability to retain fine particles, most important for

system has been further simplified for new offerings. The sim- CFB boiler performance.

plicity and low maintenance features of the current MDC solids The fractional collection efficiency of the two-stage solids

return system design are discussed below (see “Design improve- separation system used in B&W CFB boilers is determined by

ments”). the efficiency of the second stage separator. The fractional col-

lection efficiency of the secondary separator (MDC) of B&W’s

Maintenance cost IR-CFB boiler at SIU is shown in Figure 8. The fractional col-

The maintenance cost of the solids separators in the B&W lection efficiency of the secondary separator was readily mea-

CFB boilers is intrinsically low. At Ebensburg, the total main-

surable during the tests of B&W CFB boilers. Samples of sol-

tenance cost for U-beams and L-valves over 10 years of opera-

ids passing and collected by the separator were analyzed for the

tion was about US$20,000. The average maintenance cost for

particle size distribution. The flow rate of collected solids was

the MDC was about $25,000 per year. There was no loss of power

determined by calibration of the recycle system feeder. The flow

generation due to U-beam or L-valve related problems and only

rate of passing solids (fly ash) was determined as the difference

a negligible loss of generation due to the load reduction during

between solids entering the boiler and the bed drain flow rate.

MDC recycle system problems and its on-line repairs.

The latter was determined from the heat balance of the screw

cooler.

Design improvements

A comparison of fly ash particle size distribution based on

A number of design improvements to the two-stage solids

published data for hot-cyclone CFB boilers(4,5,6,7) and measure-

separation system have been implemented based on experience

and design developments: ments taken at B&W’s CFB boiler at SIU is shown in Figure 9.

- Laboratory testing and boiler operating experience have One can see that the upper cut size of solids separation at 98%

shown that with proper design parameters, fewer rows of U- of passing solids is about 80 micron for the SIU IR-CFB. This

beams provide equal collection efficiency. The number of rows results in a high percentage of fine ash being recycled to the

of U-beams has been reduced to eliminate inactive rows thereby furnace, thus giving a high rate of heat transfer in the upper

reducing the space occupied by the separator as well as reduc- furnace as well as a high rate of calcium and carbon recycle.

ing pressure differential across the separator and the correspond-

ing auxiliary power requirement.

- The alignment pan at the bottom of each U-beam has been Current IR-CFB Design

reconfigured to form an open funnel which reduces solids accu- The following on-going projects illustrate the use of the IR-

mulation. Together with the reduced number of U-beam rows, CFB boiler in two different types of applications. The first one

this reduces solids accumulation at the bottom of the U-beams (Tychy) represents an application where there is no space re-

and the possibility of corrosion in this zone. straint for B&W’s IR-CFB boiler layout. The others (Nesvetay

- Variations such as fuel properties and limestone sizing and/ and Cherepet) are projects where the CFB boiler fits into the

or type, as well as other operational upsets, may cause prolonged same structure as the existing PC unit. (8)

gas temperature increase over the design temperature in the U-

beam zone. Also, U-beams lack protection from metal tempera- Tychy Power Plant (Poland)

ture excursions similar to those available for the superheater This boiler (Figure 10) will produce 700,000 lb/hr (317 t/hr)

metal (such as attemperators). Thus, wide design margins are steam at 1740 psi/1004F (120 bar/540C). The fuel is a high-ash

provided for the U-beams by specifying high quality materials bituminous coal with a possibility of co-firing biofuels (up to

for these off-normal conditions. U-beam materials and construc- 5% by heat input).

tions with an oxidation temperature limit as high as 2100 F The following unit description for the Tychy project is also

(1150 C) are used. a description of a “typical” IR-CFB design.

- Locating the MDC upstream of the economizer, and thereby The furnace and horizontal convection pass enclosure are

at higher elevation in the convection downpass, allows recy- top-supported and made of gas-tight membrane walls. The fur-

cling of the MDC solids to the lower furnace using a sloping nace contains four water-cooled division walls, plus two water-

gravity return line(s) with a small quantity of assist air taken cooled and six steam-cooled wing walls.

Babcock & Wilcox 5

100

Collection Efficiency, % 90

80

70

60

20 40 60 80 100

Particle Size, micron

Fig. 8 Fractional collection efficiency of MDC (IR-CFB at SIU).

Fuel is fed to the lower furnace through the front wall using

four air-assisted chutes. Limestone is injected pneumatically

through multiple points uniformly across the width of the fur-

nace near the bottom. Start-up fuel (light oil) is fired using five

burners mounted at the rear wall.

Separate fans supply primary and secondary air. Primary air

is introduced through the bubble cap grid at the furnace floor

with secondary air introduced uniformly across the furnace width

using nozzles at the front and rear walls sized to provide air Fig. 10 Tychy IR-CFB boiler.

distribution across the furnace.

The lower furnace is protected from erosion and corrosive falling down the wall along the surface profile of the tube panel,

conditions by a layer of low-cement, high-strength refractory. thereby eliminating the discontinuity adjacent to the tube. The

This material has proven to require little maintenance in the RDZ feature is applicable for enclosure walls and internal walls,

lower CFB furnace environment. The membrane tubes at the and has been proven effective in B&W CFB boiler commercial

upper edge of the refractory in the lower furnace are protected operation.

from erosion by the patented Reduced Diameter Zone (RDZ) The U-beam separator consists of two rows of in-furnace

(Figure 11). The RDZ consists of a reduced diameter tube sec- and three rows of external U-beams. Pendant superheater banks

tion mating to a specially shaped ceramic tile. The reduced di- are located downstream of the U-beams in the horizontal con-

ameter tube section on each tube slopes away from the solids vection pass. Steam from the drum flows through the side walls

of the pendant superheater enclosure, then through the primary

100

superheater bank followed by the wing walls and the secondary

superheater bank to the main steam outlet.

The MDC is located immediately downstream of the hori-

80 zontal convection pass. Further in the gas path it is followed by

Percent Passing

60

Furnace Wall

40 (inside)

20

1 5 10 50 100 200 300

Particle Size, Micron

Hot Cyclone (Ref. 4)

Hot Cyclone (Ref. 5)

Hot Cyclone (Ref. 6) Division Wall

Hot Cyclone (Ref. 7)

Two-Stage Solids Separation (B&W-SIU)

Fig. 9 Particle size distribution of fly ash for hot cyclones and

two-stage separation system. Fig. 11 Reduced Diameter Zone.

6 Babcock & Wilcox

the economizer and tubular air heater (air inside tubes). The air tile matter content). Based on test results for a similar fuel in

heater is side-split for the primary and secondary air. After the the 2.5 MWt CFB pilot unit at B&W’s Alliance Research Center,

air heater, gas flows through an electrostatic precipitator and the furnace height was increased about 30 ft (9 m) as compared to

two parallel ID fans to a stack. the PC boiler to attain the guaranteed combustion efficiency of

Solids collected by the MDC are recycled back to the fur- 97%. High combustion efficiency is achieved by utilizing effec-

nace through six recycle lines utilizing inclined screw convey- tive collection and recycle of fine solids from the MDC.

ors and gravity feed. Figure 12 shows how the new unit fits within the existing

bay when the only required modification to the building is a

Nesvetay Power Plant (Russia) height increase. The fore-to-aft footprint of this unit as com-

This project emphasizes the compactness of B&W’s IR-CFB pared to the Tychy unit is reduced by two means: a) placing

design providing unique benefits in retrofit applications. part of the superheater in the vertical downpass, thus reducing

This 50 MWe PC-boiler firing anthracite culm with up to the depth of the horizontal pass, and b) utilizing available space

40% ash content at the Nesvetay power plant in Russia will be for the air heater at the side of the downpass.

replaced with the same capacity CFB unit supplied by

Belenergomash of Belgorod, Russia, a licensee of B&W CFB Cherepet Power Plant (Russia)

technology. The plant space constraints require the CFB unit to The Cherepet plant (located at Tula region, 200 km south

fit within the plan area of the bay occupied by the PC boiler. from Moscow) has a total of eight PC-fired boilers, represent-

This determines furnace plan area and thus furnace gas veloc- ing four 150 MWe units (two boilers per turbine), considered

ity. Furnace height is then determined by the gas residence time for CFB repowering. Those boilers of 250 t/hr capacity feature

required for burnout of the very low-reactive fuel (4-5% vola- high steam parameters (2465 psia, 1013 F) and reheat. Two major

CFB Boiler PC Boiler (TP-230 type)

7600 3600 6400 8590 3360 3700

Fig. 12 Size comparison of PC boiler firing anthracite culm and its repowering CFB boiler.

Babcock & Wilcox 7

fuels to be fired are local high-ash, high-sulfur lignite and low- Conclusion

reactive, medium-ash bituminous coal. CFB boilers of Lessons learned from 15 years of B&W’s CFB technology

Belenergomash design will fit into the existing PC-boiler steel application have led to development of the reliable, low-cost

(Figure 13). IR-CFB boiler design. Long-term operating experience of the

IR-CFB scale-up. Since scaling-up the two-stage solids distinct two-stage solids separator has proven its high reliabil-

separator does not present a problem, the only issue of design- ity and superior collection efficiency. The main advantages of

ing larger capacity IR-CFB boilers is providing an acceptable this boiler design are higher furnace heat transfer rate, ability

furnace aspect ratio and acceptable gas velocity in the U-beams. to better control furnace temperature, and increased residence

With the current design approach, IR-CFB boilers with the de- time of fine carbon and sorbent particles. The IR-CFB boiler

sign similar to that described above are offered for capacities achieves the required performance with lower furnace height

up to 180 MWe (540 MWt). and smaller boiler footprint. This design is especially attrac-

tive for replacing existing obsolete PC boilers in the same space.

CFB Boiler PC Boiler (TP-240 type)

Fig. 13 Size comparison of PC boiler firing lignite and bituminous coal and its repowering CFB boiler.

8 Babcock & Wilcox

References

1. F. Belin, et al., “Waste Wood Combustion in Circulating 6. M. Gierse, “Aspects of the Performance of Three Differ-

Fluidized Bed Boilers,” Proceedings of the Second International ent Types of Industrial Fluidized Bed Boilers,” Proceedings of

Conference on Circulating Fluidized Beds, 1988. the 3rd International Conference on Circulating Fluidized Beds,

2. C. E. Price and D. J. Walker, “Coal and Waste Coal-Fired 1990.

Boilers Accumulate Operating Experience,” Proceedings of 12th 7. U. Muschelknautz and E. Muschelknautz, “Improvements

International Conference on Fluidized-Bed Combustion, 1993. of Cyclones In CFB Power Plants and Quantitative Estimation

3. F. Belin, et al. , “Update of Operating Experience of B&W on Their Effects on the Boiler Solids Inventory,” Proceedings

IR-CFB Coal-Fired Boilers,” Proceedings of 15th International of the 6 th International Conference on Circulating Fluidized

Conference on Fluidized-Bed Combustion, 1999. Beds, 1999.

4. D. R. Hajicek et al. , “The Impact of Coal Quality on 8. D.A. Shaposhnik and S.V. Berdin, “Issues of CFB Boilers

Circulating Fluidized Bed Combustor Performance,” EPRI Coal Design for Power Plant Retrofits,” VTI Science and Technol-

Quality Conference, 1992. ogy Seminar, 2001.

5. W. vom Berg and K.-H. Puch, “Verwertung von

Ruckstanden aus Wirbelschichtfeuerungsanlagen,” Vortrage

VGB – Konferenz, “Wirbelschihtsysteme 1992”.

Copyright © 2001 by The Babcock & Wilcox Company,

All rights reserved.

No part of this work may be published, translated or reproduced in any form or by any means, or incorporated into any information retrieval system,

without the written permission of the copyright holder. Permission requests should be addressed to: Market Communications, The Babcock &

Wilcox Company, P.O. Box 351, Barberton, Ohio, U.S.A. 44203-0351.

Disclaimer

Although the information presented in this work is believed to be reliable, this work is published with the understanding that The Babcock & Wilcox

Company and the authors are supplying general information and are not attempting to render or provide engineering or professional services.

Neither The Babcock & Wilcox Company nor any of its employees make any warranty, guarantee, or representation, whether expressed or implied,

with respect to the accuracy, completeness or usefulness of any information, product, process or apparatus discussed in this work; and neither The

Babcock & Wilcox Company nor any of its employees shall be liable for any losses or damages with respect to or resulting from the use of, or the

inability to use, any information, product, process or apparatus discussed in this work.

Babcock & Wilcox 9

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Codigos Error Crown SC 5245-40Document56 pagesCodigos Error Crown SC 5245-40MIGUEL PEÑA78% (9)

- Life in The Spirit SeminarDocument44 pagesLife in The Spirit SeminarOscar Dorantes100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Some Fanfic.Document342 pagesSome Fanfic.Aiva DanielPas encore d'évaluation

- Annex 2.1 Contingency Planning Template SchoolsDocument38 pagesAnnex 2.1 Contingency Planning Template SchoolsDanica Herealways88% (8)

- Coke Drum Repair Welch Aquilex WSI DCU Calgary 2009Document37 pagesCoke Drum Repair Welch Aquilex WSI DCU Calgary 2009Oscar DorantesPas encore d'évaluation

- Lighting Techniques For Photographing Model Portfolios - 01-20Document20 pagesLighting Techniques For Photographing Model Portfolios - 01-20Oscar DorantesPas encore d'évaluation

- Patented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Document3 pagesPatented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Oscar DorantesPas encore d'évaluation

- Numerical Study On Heat Transfer and Resistance Characteristics of Supercritical Water Inside Internally-Ribbed TubeDocument14 pagesNumerical Study On Heat Transfer and Resistance Characteristics of Supercritical Water Inside Internally-Ribbed TubeOscar DorantesPas encore d'évaluation

- CFD Analisys CoalDocument6 pagesCFD Analisys CoalOscar DorantesPas encore d'évaluation

- Association of Leisure-Time Physical Activity With Risk of 26 Types of Cancer in 1.44 Million AdultsDocument10 pagesAssociation of Leisure-Time Physical Activity With Risk of 26 Types of Cancer in 1.44 Million AdultsOscar DorantesPas encore d'évaluation

- Bituminous and Subbituminous Coal CombustionDocument19 pagesBituminous and Subbituminous Coal CombustionOscar DorantesPas encore d'évaluation

- "Blueprint" Your Pulverizer For Improved Performance: by Richard F. (Dick) Storm, PE, Storm Technologies IncDocument4 pages"Blueprint" Your Pulverizer For Improved Performance: by Richard F. (Dick) Storm, PE, Storm Technologies IncOscar DorantesPas encore d'évaluation

- 2015 Erosion Failure Analysis of CFBC BoilerDocument5 pages2015 Erosion Failure Analysis of CFBC BoilerOscar DorantesPas encore d'évaluation

- Pulverizers PDFDocument6 pagesPulverizers PDFOscar DorantesPas encore d'évaluation

- Pro SeriesDocument8 pagesPro SeriesOscar DorantesPas encore d'évaluation

- CIVA 2017 WebinarDocument21 pagesCIVA 2017 WebinarOscar DorantesPas encore d'évaluation

- Pro Series: S270T2, S310T2, S360T2 Sand Filter Series Replacement PartsDocument6 pagesPro Series: S270T2, S310T2, S360T2 Sand Filter Series Replacement PartsOscar DorantesPas encore d'évaluation

- Ready Reckoner N1Document2 pagesReady Reckoner N1manojPas encore d'évaluation

- Cooking Oil DisposalDocument1 pageCooking Oil DisposalKorawit Kongsan100% (1)

- Vehicle Delay AnalysisDocument12 pagesVehicle Delay AnalysisKRISHNA YELDIPas encore d'évaluation

- Usgbc Leed v3 NC - ChecklistDocument1 pageUsgbc Leed v3 NC - ChecklistRizkit SiregarPas encore d'évaluation

- Site Location: Maharana Pratap Isbt Kashm Gate, DelhiDocument6 pagesSite Location: Maharana Pratap Isbt Kashm Gate, DelhiMukesh SharmaPas encore d'évaluation

- 2018 Hyundai Kona - Spec SheetDocument4 pages2018 Hyundai Kona - Spec Sheetsergio davidsPas encore d'évaluation

- BP Disaster Averted Gulf of Mexico 2005Document24 pagesBP Disaster Averted Gulf of Mexico 2005Kim HedumPas encore d'évaluation

- Maximum Specific Gravity of Bituminous Mixtures (GMM) : Employer: Engineer: Ethiopia Road Authority (ERA)Document14 pagesMaximum Specific Gravity of Bituminous Mixtures (GMM) : Employer: Engineer: Ethiopia Road Authority (ERA)Guda GudetaPas encore d'évaluation

- Auction PricelistDocument7 pagesAuction PricelistEmanuel GabrielPas encore d'évaluation

- Nueva EcijaDocument2 pagesNueva Ecijaclaude terizlaPas encore d'évaluation

- BoQ Underpass LP7 - Juni 2010 PDFDocument7 pagesBoQ Underpass LP7 - Juni 2010 PDFalmirPas encore d'évaluation

- DE 2512/10 OCT/FRA-LHR: - Not For Real World NavigationDocument56 pagesDE 2512/10 OCT/FRA-LHR: - Not For Real World NavigationHendrikPas encore d'évaluation

- Mode Choice Modelling For Work Trips in Calicut City: Tushara T, Rajalakshmi P, Bino I KoshyDocument8 pagesMode Choice Modelling For Work Trips in Calicut City: Tushara T, Rajalakshmi P, Bino I KoshyjoemarPas encore d'évaluation

- Nortech Trinity - Dredging OpportunityDocument8 pagesNortech Trinity - Dredging OpportunityNORTECH TRINITYPas encore d'évaluation

- Spartan Memorial List Rev Mar 26 2019Document1 pageSpartan Memorial List Rev Mar 26 2019api-4491688530% (1)

- A Physical Description of FlightDocument16 pagesA Physical Description of FlightJonnathan555Pas encore d'évaluation

- Reading and Listening 3Document4 pagesReading and Listening 3Hải Anh TạPas encore d'évaluation

- Gmail - Booking Confirmation On IRCTC, Train - 22840, 17-Feb-2023, 2S, BBS - ANGLDocument1 pageGmail - Booking Confirmation On IRCTC, Train - 22840, 17-Feb-2023, 2S, BBS - ANGLBarun AgarwalPas encore d'évaluation

- Speeding Mitigation PlanDocument2 pagesSpeeding Mitigation PlanAnonymous Pb39klJPas encore d'évaluation

- Nilam Bekti Sumardhani-BTH-NKRHCD-BTJ-FLIGHT - ORIGINATINGDocument4 pagesNilam Bekti Sumardhani-BTH-NKRHCD-BTJ-FLIGHT - ORIGINATINGahlan zulfakhriPas encore d'évaluation

- Group DiscussionDocument2 pagesGroup Discussionaaashu77Pas encore d'évaluation

- Lifting Handling Instructions For Horizontal TanksDocument4 pagesLifting Handling Instructions For Horizontal TanksJitendra YadavPas encore d'évaluation

- Name of The Experiment: 2. Objective-: A. Primary Particulars Estimation: Given ParticularsDocument8 pagesName of The Experiment: 2. Objective-: A. Primary Particulars Estimation: Given ParticularsSakib RafeePas encore d'évaluation

- SCSH Individual WritingDocument5 pagesSCSH Individual WritingAsyraf AzimPas encore d'évaluation

- Physiology and Neurobiliogy 2275 UCONN Test 3Document8 pagesPhysiology and Neurobiliogy 2275 UCONN Test 3sin117Pas encore d'évaluation

- ECS-LO-4 Online-WrittenDocument11 pagesECS-LO-4 Online-WrittenM.Kishore Kumar100% (3)

- Physical Distribution: Role of Transportation in The Supply Cain Modes of TransportationDocument14 pagesPhysical Distribution: Role of Transportation in The Supply Cain Modes of TransportationJonathan EscamillanPas encore d'évaluation