Académique Documents

Professionnel Documents

Culture Documents

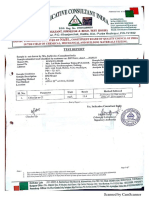

Instrument Name Id No. Make Range Least Count Calibration Agency Certificate No. Calibration Date Calibration Due Status

Transféré par

puri160 évaluation0% ont trouvé ce document utile (0 vote)

45 vues8 pagesERTTKY

Titre original

cc

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentERTTKY

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

45 vues8 pagesInstrument Name Id No. Make Range Least Count Calibration Agency Certificate No. Calibration Date Calibration Due Status

Transféré par

puri16ERTTKY

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 8

Instrument Least Calibration Certificate Calibration Calibration

Id No. Make Range Status

Name Count Agency No. Date Due

PRESSURE LBSTPL/PG- (0-70) 2 Certificate

WIKA QSI QSI/2825/18/01 08.01.18 08.01.19

GAUGE 01 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-70) 2 Certificate

WIKA QSI QSI/2826/18/01 08.01.18 08.01.19

GAUGE 02 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-70) 2 Certificate

WIKA QSI QSI/2827/18/01 08.01.18 08.01.19

GAUGE 03 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-70) 2 Certificate

WIKA QSI QSI/2828/18/01 08.01.18 08.01.19

GAUGE 04 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-70) 2 Certificate

WIKA QSI QSI/2829/18/01 08.01.18 08.01.19

GAUGE 05 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-70) 2 Certificate

WIKA QSI QSI/2830/18/01 08.01.18 08.01.19

GAUGE 06 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-7) 0.2 Certificate

WIKA QSI QSI/2831/18/01 08.01.18 08.01.19

GAUGE 07 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-7) 0.2 Certificate

WIKA QSI QSI/2832/18/01 08.01.18 08.01.19

GAUGE 08 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-7) 0.2 Certificate

WIKA QSI QSI/2833/18/01 08.01.18 08.01.19

GAUGE 09 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-420) 5 Certificate

WIKA QSI QSI/2834/18/01 08.01.18 08.01.19

GAUGE 10 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-420) 5 Certificate

WIKA QSI QSI/2835/18/01 08.01.18 08.01.19

GAUGE 11 Kg/cm² Kg/cm² Missing

PRESSURE LBSTPL/PG- (0-7) 0.2

WIKA

GAUGE 12 Kg/cm² Kg/cm² Fresh Calibration Certificate Needed

PRESSURE LBSTPL/PG- (0-7) 0.2

WIKA

GAUGE 13 Kg/cm² Kg/cm² Fresh Calibration Certificate Needed

PRESSURE LBSTPL/PG- (0-10) 0.2

AKARI

GAUGE 14 Kg/cm² Kg/cm² Fresh Calibration Certificate Needed

PRESSURE LBSTPL/PG- (0-10)

JANATICS 0.5 bar

GAUGE 15 Bar Fresh Calibration Certificate Needed

PRESSURE LBSTPL/PG- (0-10) 0.2

AKARI

GAUGE 16 Kg/cm² Kg/cm² Fresh Calibration Certificate Needed

Pending Works of Slack Adjuster for Freight & Coaching Stock

of Indian Railways as per QMS-07:2000

(Revision 0)

Para

Requirement of

no.

manufacturing/testi Action to Responsible Target

of Status

ng process as per be taken Person Date

spec

STR

.

2.Requirements

General & Manufacturing Facilities

2.3 Manufacturers shall Air cutter

have dust free should be

Niladri

assembly, inspection installed at

Bhattavharya 19-06-

and testing shop. assembly, Not Done

Goswami Da 2018

inspection

Ashish Pramanik

and testing

shop.

2.4 Plant & Machinery

2.4.1 Minimum two One more

numbers Multistart Multistart

Thread milling/Thread Thread

rolling machine for milling

thread cutting on machine to

Desai Sir

adjuster spindle. be installed . M/c

Layout-

Specify arrived

R.K.Mishra Done.

area, Layout Dies- 22-

Civil Works-

& foundation 07-2018

Goswami Da

to be done.

Dies

required for

adjuster

spindle

2.4.2 Minimum two Thread

numbers special formation of

purpose Tapping Adjuster Nut

Machines for thread & Leader Declaration

CNC- Soumen

cutting on adjuster Nut will be for using

Lathe- 22-06-

nut and leader nut. done at lathe

R.K.Mishara,Sar 2018

Lathe & cnc instead of

oj

machine tapping M/c

instead of

tapping

machine

2.4.3 Following dedicated

general purpose Turret- We

machines shall be used CNC

available: for adjuster

Centre Lathe, Turret, nut & leader

Capstan, Grinding, nut

Drilling Power Saw, formation

Shearing, Copy

turning (preferably) Shearing-

are required for Need to shift

shearing, partings, from PEW.

turning, milling, Contact

CNC- Soumen

Shapping, grinding, person 19-06-

Shearing - Available

drilling, boring etc., to Nabin 2018

R.K.Mishra

adjuster nut leader Sharma

nut, traction sleeve,

clutch ring, Adjuster

tub socket, Leader

nut casing, Spindle

sleeve, Ear Bushing,

Safety collar, Leader

nut flange, Clutch

sleeve, Adjuster tube,

Actuating sleeve,

Barrel, Adjuster Ear,

Barrel Head etc.

2.4.5 One pneumatic press Need to shift

of 10 kg capacity for from SAM. Not

pneumatic fixture Contact Available 19-06-

R.K.Mishara

required to assemble person (Hand Tool 2018

traction unit in barrel. Sumit Available)

Agarwal

2.5 Facilities for surface treatment

2.5.4 At least one Need to

posimeter for calibrate

P.Puri Done. Done

measuring thickness

should be available.

2.6 Other accessories

2.6.2 Tool room facility –

the manufacturer (c) Twist drill

should ensure grinding

following tool room machine

facilities with web

(a)Universal milling thinner-

machine Need to

(b) External cylinder purchase

grinding for different (e)

type of gauges Mechanical

(c) Twist drill grinding comparators

machine with web for checking

1.Twist Drill

thinner gauges,

& Universal

(d) Slip gauge box segmented

tool Cutter-

(inspection grade) plug gauge

Mailed for

(e) Mechanical and cylinder

Quotation

comparators for gauges.-

to Pathak

checking gauges, Dhar babu

segmented plug co ordinate

2.Mechanic

gauge and with Indranil C) Desai Sir

al C) & H)

cylinder gauges. & make a e & f) Sanjay

Comparator 22-06-

(f) Flowting carriage proposal Dhar

& Flowting 2018

micrometer for letter . h) Asish

Micrometer E) & F)

checking screw plug (f) Flowting Pramanik &

- Mailed for 19-06-

gauges. carriage Sanjay Dhar

Quotation 2018

(g) Sine bar and sine micrometer i) Dhar Babu

to Yuzuki /

centre for checking

Proposal

(h) Universal tool and screw plug

Letter not

cutter grinder gauges.-

made

(i) Lapping machine Dhar babu

3.Lapping

(j) Common co ordinate

Machine-

measuring with Indranil

Mailed for

instruments & make a

Quotation

proposal

letter .

(h) Universal

tool and

cutter

grinder-

Need to

purchase

(i) Lapping

machine-

Need to

purchase

3.0 TESTING FACILITIES

Manufacturer should

have arrangement of

checking piston

stroke, ‘e’ dimension,

brake block clearance Mock up

Not

3.2 over wheel thread arrangeme

Available

etc. in mock up i.e. nt

simulating the actual

condition of rolling

stock of different

types.

3.4 Manufacturer should Calibration

have load testing need to be

machine of 500 kgs done

capacity for testing 20-06-

P.Puri Done.

take up spring, 2018

payout/payin clutch

spring and barrel

spring.

3.8 Performance, Should trial

Performanc

Endurance ,

S.Kundu , e&

Vibration, Loss of 19-06-

Sanjoy Dhar & Endurance

Force & Tension Test 2018

Ashish Pramanik testing not

Testing Rig availble

done

but not ready for work

3.10 Suitable Available

shadowgraph but

machine with magnificatio

sufficient n is not as

magnification (30 per

Not 20-06-

times minimum) for requirement. Sanjay Dhar

Available 2018

detailed checking of Dhar babu

threaded profile of co ordinate

Adjuster spindle, with Indranil

adjuster nut and to solve the

leader nut. matter

3.11 Ensure that a One more

Endurance test rig is Pay-in &

available with Pay off

microprocessor data machine

recording system need to

conforming the manufaactur

requirements as e in house.

stipulated in

Amendment No. 2 of Ashish Pramanik Not ready 19-06-

07-ABR-92(Rev.). & Saroj for Testing 2018

The rig should have

provision to record

applied tensile load

(3650 kg), piston

velocity (60 cm/pin),

2mm indexing

increment for each 10

cycles over a range of

approximate 550mm

for IRSA-600 and

400mm for IRSA-

450. Data should be

recorded and

documented on one

lakh cycles.

QUALITY CONTROL REQUIREMENTS

4.1 The firm must have

ISO:9000 or QS

certification for the

product for which the

approval is sought Need to P.Puri 22-06-

Done.

and should be modify R.K Mishra 2018

broadly covered in

scope of certification

for manufacture and

supply.

STATUS OF PENDING GAUGES

SL ITEM GAUGES STATUS REMARKS

1 LEADER NUT CASING DEPTH GAUGE Declarion to be submited S. Dhar

DEPTH GAUGE

2 TRACTION SLEEVE Declarion to be submited S. Dhar

TYPE-1

DEPTH GAUGE

3 TRACTION SLEEVE Declarion to be submited S. Dhar

TYPE-2

4 TRACTION SLEEVE GAP GAUGE Declarion to be submited S. Dhar

THREAD RING

5 LOCK SCREW GAUGE (GO & Available / Coming Today Soumen

NO-GO)

CONCENTRICIRY

6 LEADER NUT FLANGE CHECKING Available / Coming Today Soumen

GAUGE

PLUG GAUGE (

7 ADJUSTER NUT Declarion to be submited S. Dhar

GO & NO-GO)

8 ADJUSTER NUT GAP GAUGE Declarion to be submited S. Dhar

THREAD PLUG

9 LOCK NUT GAUGE (GO & Available / Coming Today Soumen

NO-GO)

10 LEADER NUT FLANGE PLUG GAUGE Available / Coming Today Soumen

11 LEADER NUT FLANGE GAP GAUGE Available / Coming Today Soumen

THREAD RING

12 LEADER NUT CASING GAUGE (GO & Available / Coming Today Soumen

NO-GO) M97x2

THREAD PLUG

13 SAFTY COLLER Available / Coming Today Soumen

GAUGE

THREAD RING

14 ADJUSTER SPINDLE Thread formation under process Saroj ji

GAUGE

THREAD

CALLIPER

15 ADJUSTER SPINDLE GAUGES (GO & Declarion to be submited S. Dhar

NO-GO) IS 2643

G1/2'' PARALLEL

TAPPER PLUG

16 LEADER NUT CASING Available / Coming Today Soumen

GAUGE

TAPPER PLUG

17 TRACTION SLEEVE Available / Coming Today Soumen

GAUGE

18 CLUTCH RING TAPPER GAUGE Available / Coming Today Soumen

TAPPER PLUG

19 ACTUATING SLEEVE Available / Coming Today Soumen

GAUGE TYPE-1

TAPPER PLUG

20 ACTUATING SLEEVE Available / Coming Today Soumen

GAUGE TYPE-2

CONCENTRICIRY

21 BARREL CHECKING Available / Coming Today Soumen

GAUGE

PLUG GAUGE (GO

22 DOG PIN Available / Coming Today Soumen

& NO-GO)

STATUS Count of GAUGES

Declarion to be submited 7

Available / Coming Today 14

Thread formation under process 1

Grand Total 22

Vous aimerez peut-être aussi

- Chapter 08 HomeworkDocument40 pagesChapter 08 HomeworkFatboy9146% (24)

- Calibraciones TransDocument47 pagesCalibraciones TransjuankielecPas encore d'évaluation

- MF 440 Xtra Narrow (Tier II) PDFDocument2 pagesMF 440 Xtra Narrow (Tier II) PDFlmn_grss100% (1)

- Hvac BomDocument6 pagesHvac BomTagel MarkosPas encore d'évaluation

- Heat Exchanger Specification SheetDocument32 pagesHeat Exchanger Specification SheetWijayantoPas encore d'évaluation

- Sizing Sheet Dengan Cv. 133 PDFDocument3 pagesSizing Sheet Dengan Cv. 133 PDFJoko WisnugrohoPas encore d'évaluation

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi OktaviantiPas encore d'évaluation

- KPD-TAY Integrated Development Project Phase-II DatasheetDocument2 pagesKPD-TAY Integrated Development Project Phase-II Datasheetm.shehreyar.khanPas encore d'évaluation

- GPG291 Designer's Guide To The Options For Ventilation and Cooling 2001Document40 pagesGPG291 Designer's Guide To The Options For Ventilation and Cooling 2001IppiPas encore d'évaluation

- Lecture 5 Syringe PumpsDocument15 pagesLecture 5 Syringe PumpsDimas EboyPas encore d'évaluation

- BH Pneumatic Piston Vibrator Operation ManualDocument17 pagesBH Pneumatic Piston Vibrator Operation ManualChristian Paul Salazar SanchezPas encore d'évaluation

- Bomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFDocument68 pagesBomba Rexroth A10v 063 Ek1ds - 53R VSD 62 K15P PDFmarianoPas encore d'évaluation

- A037 Ds 01 Water MonitorDocument1 pageA037 Ds 01 Water MonitorshabahatPas encore d'évaluation

- List of Calibration DraftDocument8 pagesList of Calibration DraftNarendra VermaPas encore d'évaluation

- Calibrated Instruments 2018Document11 pagesCalibrated Instruments 2018amitPas encore d'évaluation

- Checking AidsDocument1 pageChecking AidsTausifur RahmanPas encore d'évaluation

- Master List of Pressure Gauge - 27.06.22Document25 pagesMaster List of Pressure Gauge - 27.06.22byjurpPas encore d'évaluation

- KALIBRASI ALAT MITRAPAK-RecordDocument10 pagesKALIBRASI ALAT MITRAPAK-RecordfebiPas encore d'évaluation

- Instrument Master ListDocument3 pagesInstrument Master ListNarendra VermaPas encore d'évaluation

- 5000W ABS Taita TaiwanDocument1 page5000W ABS Taita TaiwanPhạm Thanh TùngPas encore d'évaluation

- Optimized for TEG Regeneration Skid Weight SummaryDocument3 pagesOptimized for TEG Regeneration Skid Weight SummaryVineeth KrishnaPas encore d'évaluation

- MEDICAL GRADE PAPER SPECIFICATIONDocument1 pageMEDICAL GRADE PAPER SPECIFICATIONApoorva PattnaikPas encore d'évaluation

- 1009 Do FabillaDocument4 pages1009 Do FabillaAn DaPas encore d'évaluation

- Monthly Stock Checklist 2019: Updated: 10-Jan-19Document2 pagesMonthly Stock Checklist 2019: Updated: 10-Jan-19matarekPas encore d'évaluation

- NCs Dec 2014 ObjEvidDocument30 pagesNCs Dec 2014 ObjEvidHamidPas encore d'évaluation

- Jindal Industries Pvt. Limited: Offer List/Sampling Plan (As Per ASTM A53/Approved QAP)Document7 pagesJindal Industries Pvt. Limited: Offer List/Sampling Plan (As Per ASTM A53/Approved QAP)Vikas Mani TripathiPas encore d'évaluation

- Inventory StatusDocument19 pagesInventory StatusMuhaiminul IslamPas encore d'évaluation

- Rich Gas Pre Cooler - E101 A-BDocument4 pagesRich Gas Pre Cooler - E101 A-B29031978Pas encore d'évaluation

- Rumus KonversiDocument2 pagesRumus KonversiMochamad JilanPas encore d'évaluation

- Calibration Procedure / Calibration Schedule: Anand Seamless Tubes PVT LTDDocument1 pageCalibration Procedure / Calibration Schedule: Anand Seamless Tubes PVT LTDQualityPas encore d'évaluation

- SC-400.10AQR1 Supplement 1 0Document3 pagesSC-400.10AQR1 Supplement 1 0SetyohdWPas encore d'évaluation

- Summary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)Document1 pageSummary Sheet: AS ATTACHED OFFER LIST (QA/LVL/2300/01 & QA/LVL/2300/02)GobinderSinghSidhuPas encore d'évaluation

- Boiler MIURA - LX-300-16Document2 pagesBoiler MIURA - LX-300-16LuizPauloCostaPas encore d'évaluation

- Costing Tob $allDocument3 pagesCosting Tob $allvikas guptaPas encore d'évaluation

- Refined Sugar Grade Two in Bags of 1000 KG.: Amalfi Otero Laboratory PlantDocument1 pageRefined Sugar Grade Two in Bags of 1000 KG.: Amalfi Otero Laboratory Plantramon riquelme navarroPas encore d'évaluation

- BP2800Document4 pagesBP2800Praveen KumarPas encore d'évaluation

- Packing List: Pt. Powerindo Prima PerkasaDocument1 pagePacking List: Pt. Powerindo Prima PerkasaRandyPas encore d'évaluation

- Modified BitumensDocument6 pagesModified BitumensDonPas encore d'évaluation

- Inventory Report for PT. Merapi Bintang PersadaDocument173 pagesInventory Report for PT. Merapi Bintang PersadaWahyu WijayadiPas encore d'évaluation

- Consultalotes - Det - 2022-08-02T105104.945Document3 pagesConsultalotes - Det - 2022-08-02T105104.945João FernandesPas encore d'évaluation

- Carbon Dioxide Pure GasDocument2 pagesCarbon Dioxide Pure GasMumahmmad Rizwan RPas encore d'évaluation

- ITC Limited - Paperboards and Specialty Papers Division: Specification SheetDocument1 pageITC Limited - Paperboards and Specialty Papers Division: Specification SheetApoorva PattnaikPas encore d'évaluation

- Synchro Raw MaterialDocument19 pagesSynchro Raw MaterialRana TayyabPas encore d'évaluation

- List of EquipmentDocument5 pagesList of Equipmentsiddhi jadhavPas encore d'évaluation

- ROUTE ANALYSIS SKSV - SKBODocument14 pagesROUTE ANALYSIS SKSV - SKBOYuranny Quimbay BarriosPas encore d'évaluation

- I-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Document5 pagesI-GIO-631-104140-HD-P-302-Rev - 0 (HD OI GG)Martin DanzePas encore d'évaluation

- Specification Sheet Rev 1Document12 pagesSpecification Sheet Rev 1nishanth NTPas encore d'évaluation

- AURORA CHRISTINE (9214862) : Fuel Analysis Operational ReportDocument3 pagesAURORA CHRISTINE (9214862) : Fuel Analysis Operational ReportHanafi Yusuf AviansyahPas encore d'évaluation

- Hygrotech Solu Cal Calcium Nitrate LabelDocument1 pageHygrotech Solu Cal Calcium Nitrate LabelGAGROTECH GAGROTECHPas encore d'évaluation

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirPas encore d'évaluation

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirPas encore d'évaluation

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirPas encore d'évaluation

- PSV Relief Load Input DataDocument1 pagePSV Relief Load Input DataMedha MahajanPas encore d'évaluation

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARIPas encore d'évaluation

- Riello Rs M 64Document56 pagesRiello Rs M 64Hugo Trujillo CPas encore d'évaluation

- MTD - QF.17.01CalibrationDocument2 pagesMTD - QF.17.01CalibrationvinothPas encore d'évaluation

- QT14-0896-MD-000 Equipment Datasheets Rev.2Document13 pagesQT14-0896-MD-000 Equipment Datasheets Rev.2emadsafy20002239Pas encore d'évaluation

- Abb Parts Fiser68569303Document3 pagesAbb Parts Fiser68569303Musa MgazaPas encore d'évaluation

- Rough / Semifinish Fine Boring Head - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerDocument3 pagesRough / Semifinish Fine Boring Head - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerSigma ToolingsPas encore d'évaluation

- 33K Single Stand VT SupportDocument6 pages33K Single Stand VT SupportNNANYELU CHINWUBAPas encore d'évaluation

- BHCN 3900 TS 20255E 0920 EnglishDocument72 pagesBHCN 3900 TS 20255E 0920 EnglishmonitorsamsungPas encore d'évaluation

- KLJ Hdpe BK 9606 Arat AratDocument1 pageKLJ Hdpe BK 9606 Arat AratDinesh SinghPas encore d'évaluation

- COA MT. Sinar Srikandi 07.08.23Document2 pagesCOA MT. Sinar Srikandi 07.08.23Boby Royan Naira AzdlilPas encore d'évaluation

- Consultalotes - Det - 2022-08-01T151223.694Document3 pagesConsultalotes - Det - 2022-08-01T151223.694João FernandesPas encore d'évaluation

- Limitorque PT Series: Worm Gear OperatorsDocument2 pagesLimitorque PT Series: Worm Gear Operatorsfelipe castellanosPas encore d'évaluation

- Calibracion de Freno y DireccionDocument24 pagesCalibracion de Freno y DireccionMantenimiento Mecanico BiddlePas encore d'évaluation

- Cracking Chatterjee MST 2006Document5 pagesCracking Chatterjee MST 2006puri16Pas encore d'évaluation

- COMPLAS2017-11 - Three-Dimensional Numerical AnalysisDocument8 pagesCOMPLAS2017-11 - Three-Dimensional Numerical Analysispuri16Pas encore d'évaluation

- Curriculum Vitae: DebabratamaityDocument2 pagesCurriculum Vitae: Debabratamaitypuri16Pas encore d'évaluation

- Tubular Products Jubail - BrochureDocument28 pagesTubular Products Jubail - Brochurepuri16Pas encore d'évaluation

- HP 01 2020 Tip Linde Graf tcm17-585707Document3 pagesHP 01 2020 Tip Linde Graf tcm17-585707puri16Pas encore d'évaluation

- Version of Record:: ManuscriptDocument32 pagesVersion of Record:: Manuscriptpuri16Pas encore d'évaluation

- Specification For Eoi 1471327185Document4 pagesSpecification For Eoi 1471327185puri16Pas encore d'évaluation

- Weld Defect - WikeepidiaDocument5 pagesWeld Defect - Wikeepidiapuri16Pas encore d'évaluation

- Difference Between Stainless Steel Grade 304 and 202Document6 pagesDifference Between Stainless Steel Grade 304 and 202puri16Pas encore d'évaluation

- FAV Air Brake CK 407Document13 pagesFAV Air Brake CK 407puri16Pas encore d'évaluation

- RHF CatalogDocument4 pagesRHF Catalogpuri16Pas encore d'évaluation

- Ensayos de Impacto E23Document28 pagesEnsayos de Impacto E23Juan LeonPas encore d'évaluation

- Kljcashckiasjc, MDocument1 pageKljcashckiasjc, Mpuri16Pas encore d'évaluation

- Quality Audit Report SummaryDocument27 pagesQuality Audit Report Summarypuri16Pas encore d'évaluation

- Certificate: IRIS Certification™ Rules:2017 and Based On ISO/TS 22163:2017Document1 pageCertificate: IRIS Certification™ Rules:2017 and Based On ISO/TS 22163:2017puri16Pas encore d'évaluation

- Magnetic Stirrer With Heating (280degree C) - M - S. Contech Instruments Limited, Navi Mumbai - ID - 10600886562Document7 pagesMagnetic Stirrer With Heating (280degree C) - M - S. Contech Instruments Limited, Navi Mumbai - ID - 10600886562puri16Pas encore d'évaluation

- Flyer 2019 - 2Document3 pagesFlyer 2019 - 2puri16Pas encore d'évaluation

- Water ReportDocument2 pagesWater Reportpuri16Pas encore d'évaluation

- Daily Report N FormatDocument12 pagesDaily Report N Formatpuri16Pas encore d'évaluation

- Material Substance Composition ReportingDocument19 pagesMaterial Substance Composition Reportingpuri16Pas encore d'évaluation

- Zinc Phosphating - Zinc Phosphate Coating - Zinc PhosphatizingDocument2 pagesZinc Phosphating - Zinc Phosphate Coating - Zinc Phosphatizingpuri16Pas encore d'évaluation

- GL Huyett EngineeringHandbookDocument95 pagesGL Huyett EngineeringHandbookSwetha PattelaPas encore d'évaluation

- A) RRC Group D Syllabus: MathematicsDocument1 pageA) RRC Group D Syllabus: Mathematicspuri16Pas encore d'évaluation

- 3618 Pre TreatmentDocument16 pages3618 Pre TreatmentSubhajit DasPas encore d'évaluation

- Contract ReviewDocument1 pageContract Reviewpuri16Pas encore d'évaluation

- Management Programme Term-End Examination June, 2018 Ms-057: Maintenance ManagementDocument2 pagesManagement Programme Term-End Examination June, 2018 Ms-057: Maintenance Managementpuri16Pas encore d'évaluation

- Supply Chain MITESD - 273JF09 - Lec01Document15 pagesSupply Chain MITESD - 273JF09 - Lec01shilratnaPas encore d'évaluation

- ReportDocument1 pageReportpuri16Pas encore d'évaluation

- ZT200 Datasheet EnglishDocument4 pagesZT200 Datasheet Englishanon_952142563Pas encore d'évaluation

- 1 1110111014 Green Paint 1.00 20SAB Paint LTRDocument1 page1 1110111014 Green Paint 1.00 20SAB Paint LTRpuri16Pas encore d'évaluation

- PHYS 211 6.STATIC 1ST CONDITION MergedDocument36 pagesPHYS 211 6.STATIC 1ST CONDITION MergedLEEPas encore d'évaluation

- Schneider Electric - TeSys Contactors - Catalogue ChapterDocument132 pagesSchneider Electric - TeSys Contactors - Catalogue ChapterdoniPas encore d'évaluation

- Tension Structures: A. Buchholdt BSC PHDDocument10 pagesTension Structures: A. Buchholdt BSC PHDRoach Gabriele SandersonPas encore d'évaluation

- Chapter 5 Rev 3 Tramming CirucitsDocument4 pagesChapter 5 Rev 3 Tramming CirucitsAnonymous 340A7vnwV1Pas encore d'évaluation

- Design Requirements of Generators Applied To Low-Head Hydro Power PlantsDocument9 pagesDesign Requirements of Generators Applied To Low-Head Hydro Power PlantsЖивотаЛазаревићPas encore d'évaluation

- Product SpecificationDocument6 pagesProduct SpecificationJosé MacedoPas encore d'évaluation

- Elder Equipments PVTDocument7 pagesElder Equipments PVTGeorge GPas encore d'évaluation

- EngMech - Lecture 1.1Document18 pagesEngMech - Lecture 1.1omay12Pas encore d'évaluation

- CHAPTER2 -منهج جديد pdf2- m PDFDocument39 pagesCHAPTER2 -منهج جديد pdf2- m PDFmohammed elobidePas encore d'évaluation

- Simulate Piccolo Tube Anti-Icing System with CFDDocument7 pagesSimulate Piccolo Tube Anti-Icing System with CFDsanjoshi21Pas encore d'évaluation

- Keep 316Document68 pagesKeep 316AdityaPas encore d'évaluation

- Cruise Control System (CCS) ,: 1.6 ltr./74 KW Simos, Engine Code AEH, 1.6 ltr./74 KW Simos, Engine Code AKLDocument4 pagesCruise Control System (CCS) ,: 1.6 ltr./74 KW Simos, Engine Code AEH, 1.6 ltr./74 KW Simos, Engine Code AKLBrett MercadoPas encore d'évaluation

- FluidDocument84 pagesFluidVishal SalvePas encore d'évaluation

- LNT PricelistDocument104 pagesLNT PricelistmbhangalePas encore d'évaluation

- Eclaté Technique Fusion APDocument1 pageEclaté Technique Fusion APaadPas encore d'évaluation

- Series Low Pressure Centrifugal PumpDocument4 pagesSeries Low Pressure Centrifugal PumpDaniel CortezPas encore d'évaluation

- Ata 52Document70 pagesAta 52Geovanni Riquelme LooPas encore d'évaluation

- Cat 740Document16 pagesCat 740たつき タイトーPas encore d'évaluation

- PIPE FLANGE DIMENSIONSDocument5 pagesPIPE FLANGE DIMENSIONSViral ParmarPas encore d'évaluation

- Catalogo Motores Hidraulicos DanfossDocument40 pagesCatalogo Motores Hidraulicos DanfossTiago RezendePas encore d'évaluation

- Guidelines For Industrial Gas Cylinder (Design, Construction, Handling, Inspection and TestingDocument3 pagesGuidelines For Industrial Gas Cylinder (Design, Construction, Handling, Inspection and TestingLisa FosterPas encore d'évaluation

- ShamrockDocument12 pagesShamrockFerdinand LizadaPas encore d'évaluation

- Course Outline (For Student)Document3 pagesCourse Outline (For Student)hahahaPas encore d'évaluation