Académique Documents

Professionnel Documents

Culture Documents

Yoder-Flowmeter 0713 PDF

Transféré par

Bagus EfendiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Yoder-Flowmeter 0713 PDF

Transféré par

Bagus EfendiDroits d'auteur :

Formats disponibles

Custody transfer of natural gas:

cooperation leads to success

AGA and API helped make it possible, and suppliers responded with

flowmeters that conform to standards

By Jesse Yoder, Ph.D.

Custody transfer is flow’s fastest growing application, with the possible the National Bureau of Standards were the basis for flow equations used

exception of multiphase flowmeter applications, which also tend to be oil- by AGA and ASME since then. As a result, the AGA published its second

and-gas related. Custody transfer occurs when a fluid’s ownership passes report on orifice-plate metering, AGA-2.

from one entity to another. The need for custody transfer should be fairly Work in the United States was combined with that in Europe in the

obvious. The exploration and production (E&P) company is typically not late 1950s, and resulted in the issuance of ISO Standards R541 for orifices

the same as that which delivers to end-users. and nozzles and R781 for Venturis. A third AGA report on orifice meter-

Multiple custody-transfer points occur along the way, as gas travels in ing for custody transfer, called AGA-3, was published in 1955 and reis-

many cases thousands of miles from source to destination. In these cases, sued in 1992.

the E&P hands off to a gas distribution company. The distribution com-

pany then sells the gas to a utility that distributes it to individual buildings Turbine flowmeters

and homes. Turbine flowmeters are widely used for liquid and gas flow measure-

The main flowmeter types used for natural-gas custody transfer are: ment. One early use was to measure fuel on World War II military planes.

• Differential Pressure (DP) with primary elements A decade later, the gas industry had come to accept them for gas flow

• Turbine measurement. In 1981, the AGA issued its report, “Measurement of Fuel

• Ultrasonic Gas by Turbine Meters.” Since then, turbine meters have been widely

• Coriolis used for gas-flow measurement, including custody-transfer applications.

Because natural-gas custody transfer is such an important transaction, They are also widely used to measure liquid flows, including both water

involved parties abide by objective criteria that determine how the trans- and hydrocarbon flows.

fer takes place. In the United States, these criteria are mainly determined Turbine meters have a spinning rotor mounted on bearings in a hous-

by the American Gas Association (AGA) and the American Petroleum ing. The rotor has propeller-like blades that spin due to the current force

Institute (API). The AGA in particular has the lead in publishing reports as a fluid passes over it. Flow rate is proportional to the rotor’s rotational

governing natural-gas custody transfer, using different types of flowmeters. speed. Different means can detect rotor speed, including a mechanical

Given the different technologies involved, distinct reports exist for each shaft and an electronic sensor.

type of flowmeter used.

Ultrasonic flowmeters

DP flowmeters with primary elements The ultrasonic flowmeter market grew rapidly the past several years and

The history of DP flow measurement goes back to the late 1800s. Max the single most important reason is use of multipath ultrasonic meters

Gehre received one of the first patents on orifice flowmeters in 1896. for natural-gas custody transfer. The initial surge began in 1995, when

The first commercial orifice-plate flowmeter appeared in 1909, and was Groupe Europeen de Recherches GaziSres (GERG), published Technical

used to measure steam flow. Shortly thereafter, the oil-and-gas industries Monograph 8 — Present status and future research on multipath ultra-

began using orifice-plate flowmeters due to ease of standardization and sonic gas flowmeters. This technical document laid out criteria for instru-

low maintenance. In 1912, Thomas Weymouth of the United Natural ments that measure natural-gas flow for custody transfer. Its publication

Gas Co. did experimental work on measuring natural gas using orifice gave a major boost to sale of multipath ultrasonic flowmeters for natural

flowmeters. gas in Europe.

Increased orifice meter use captured the attention of several engineer- After the GERG document appeared in Europe, ultrasonic suppliers

ing organizations, including the AGA, API and the American Society of worked with AGA to obtain approval of a similar document in the United

Engineers (ASME). The National Bureau of Standards (NBS) also got States. AGA-9, published in June 1998, lays out criteria for natural gas

involved. In 1930, a joint AGA/ASME/NBS test program generated a buyers and sellers when using ultrasonic flowmeters for natural-gas cus-

coefficient-prediction equation based on extensive tests. In 1930, the AGA tody transfer. Its publication again increased sales of multipath ultrasonic

issued its first report, AGA-1, on use of DP flowmeters with orifice plates flowmeters. This trend continues today.

for custody-transfer purposes. Ultrasonic flowmeters also measure process and flare gas. Ultrasonic

In 1935, tests performed at Ohio State University in conjunction with meter use for gas flow measurement evolved substantially from the late

Flowmeter Solutions • July 2013

24

1970s when it was first attempted. Use of wetted sensors means greater meters. Now other companies have Coriolis flowmeters for line sizes above

accuracy. Insertion meters measure flare gas in stacks, and ultrasonic flow- 6 inches, including Endress+Hauser, KROHNE and Micro Motion.

meters are used widely in the chemical and refining industries. While the Endress+Hauser and Micro Motion mainly have bent-tube meters,

growth of ultrasonic meters to measure process and flare gases is not as while KROHNE’s large size meters are straight tube. While the straight

rapid as that of multipath meters for natural-gas custody transfer, it is still tube meters are long, they are less bulky than the bent tube meters of the

an important factor in the overall growth of ultrasonic meters. corresponding size. Currently Coriolis meters are available for 8, 10, 12,

14 and 16-inch line sizes. Most of these meters are aimed at the custody-

Coriolis flowmeters transfer market for oil & gas applications.

The AGA approved a report on Coriolis flowmeter use for natural-gas Custody transfer plays an important role in flow measurement. By its

custody transfer in 2003. This report is called AGA-11. Even though it means contracting parties find mutually agreeable conditions for trans-

often takes some time for end-users to adopt a new technology, this re- ferring fluids ownership from one to another. The work of AGA and

port has provided a significant boost to the use of Coriolis flowmeters for API helped make it possible, and suppliers responded with flowmeters

natural-gas flow measurement. that conform to AGA and API requirements. That led to users having

The API issued a draft standard titled, “Measurement of Single-Phase, custody-transfer applications. Cooperation among agencies, suppliers and

Intermediate, and Finished Hydrocarbon Fluids by Coriolis Meters,” end-users has helped make custody transfer among the fastest growing

added to the API Library in July 2012. A second draft standard called flowmeter markets.

“Measurement of Crude Oil by Coriolis Meters” has also been approved

by the API. Jesse Yoder, Ph.D., is president of Flow Research, Inc., a company he founded in

More than any other meter, Coriolis meters have line-size limitations. 1998. He has 26 years of experience as an analyst and writer in process control. Dr.

Due to the nature of the technology, Coriolis meters get large and un- Yoder specializes in flowmeters and other field devices, including pressure, level and

wieldy once they reach the 6-inch size. Even 3-inch and 4-inch meters are temperature products. He has written over 150 market research studies in industrial

quite large. Over 67% of Coriolis meter revenues are 2 inches in diameter automation and process control and has published over 200 journal articles. He re-

or less. cently authored Volume X: The World Market for Flowmeters, 4th Edition (www.

Despite the challenges involved, suppliers in the past several years have floweverything.com).

manufactured Coriolis flowmeters for line sizes of 8 to 16 inches. Rheonik

(now owned by GE Measurement) has long had large-line-size Coriolis

Advertiser Index

2013 CHEM SHOW................................................................21 KROHNE, Inc.........................................................................13

Brooks Instrument..................................... Inside Back Cover Rosemount Analytical, Emerson Process Management......1

CME, Div. Aerospace Control Products..............................15 Siemens Industry.......................................Inside Front Cover

Dwyer Instruments..................................................................3 Universal Flow Monitors.......................................................15

Eldridge Products, Inc..........................................................10 Water/Waste Processing......................................................19

Endress + Hauser, Inc.......................................... Back Cover

FLEXIM Americas Corp..........................................................5

Fluid Components International (FCI).................................17

Fox Thermal Instruments, Inc.................................................7

Greyline Instruments, Inc.......................................................8

Flowmeter Solutions • July 2013

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Tdb65pt2 Item5 Presentation LKrstic enDocument23 pagesTdb65pt2 Item5 Presentation LKrstic enBagus EfendiPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- WMF2017 McKinsey Franck BekeartDocument28 pagesWMF2017 McKinsey Franck BekeartBagus EfendiPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Krish - Moving Laggards To Early Adopters, NcKinsey & CoDocument18 pagesKrish - Moving Laggards To Early Adopters, NcKinsey & CoBagus EfendiPas encore d'évaluation

- WMF2017 McKinsey Franck BekeartDocument28 pagesWMF2017 McKinsey Franck BekeartBagus EfendiPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Tdb65pt2 Item5 Presentation LKrstic enDocument23 pagesTdb65pt2 Item5 Presentation LKrstic enBagus EfendiPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Krish - Moving Laggards To Early Adopters, NcKinsey & CoDocument18 pagesKrish - Moving Laggards To Early Adopters, NcKinsey & CoBagus EfendiPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Yoder-Flowmeter 0713 PDFDocument2 pagesYoder-Flowmeter 0713 PDFBagus Efendi100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Darkle Slideshow by SlidesgoDocument53 pagesDarkle Slideshow by SlidesgoADITI GUPTAPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- There Will Come Soft RainsDocument8 pagesThere Will Come Soft RainsEng ProfPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- 7 - Monte-Carlo-Simulation With XL STAT - English GuidelineDocument8 pages7 - Monte-Carlo-Simulation With XL STAT - English GuidelineGauravShelkePas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Plan Lectie Clasa 5 D HaineDocument5 pagesPlan Lectie Clasa 5 D HaineCristina GrapinoiuPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Installation Instructions INI Luma Gen2Document21 pagesInstallation Instructions INI Luma Gen2John Kim CarandangPas encore d'évaluation

- Logistic RegressionDocument7 pagesLogistic RegressionShashank JainPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Management PriniciplesDocument87 pagesManagement Priniciplesbusyboy_spPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Document5 pagesبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- BIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Document32 pagesBIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Md TayfuzzamanPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 5steps To Finding Your Workflow: by Nathan LozeronDocument35 pages5steps To Finding Your Workflow: by Nathan Lozeronrehabbed100% (2)

- Poster-Shading PaperDocument1 pagePoster-Shading PaperOsama AljenabiPas encore d'évaluation

- ChatGPT & EducationDocument47 pagesChatGPT & EducationAn Lê Trường88% (8)

- My BaboogDocument1 pageMy BaboogMaral Habeshian VieiraPas encore d'évaluation

- Pitch DeckDocument21 pagesPitch DeckIAPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Church and Community Mobilization (CCM)Document15 pagesChurch and Community Mobilization (CCM)FreethinkerTianPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Moral GPS: A Positive Ethic For Our Multicultural WorldDocument279 pagesMoral GPS: A Positive Ethic For Our Multicultural WorldLeonard Bowman75% (4)

- Polysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Document1 pagePolysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Carlos JiménezPas encore d'évaluation

- Arudha PDFDocument17 pagesArudha PDFRakesh Singh100% (1)

- Sabian Aspect OrbsDocument8 pagesSabian Aspect Orbsellaella13100% (2)

- Class 12 Physics Derivations Shobhit NirwanDocument6 pagesClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Pyramid Type Plate Bending MachineDocument10 pagesPyramid Type Plate Bending MachineAswin JosephPas encore d'évaluation

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasPas encore d'évaluation

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyDocument12 pagesIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsPas encore d'évaluation

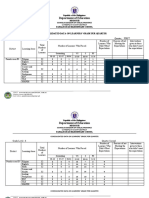

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDocument4 pagesDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaPas encore d'évaluation

- BPS C1: Compact All-Rounder in Banknote ProcessingDocument2 pagesBPS C1: Compact All-Rounder in Banknote ProcessingMalik of ChakwalPas encore d'évaluation

- Mahindra&mahindraDocument95 pagesMahindra&mahindraAshik R GowdaPas encore d'évaluation

- Javascript Notes For ProfessionalsDocument490 pagesJavascript Notes For ProfessionalsDragos Stefan NeaguPas encore d'évaluation

- TPDocument10 pagesTPfaisal gaziPas encore d'évaluation

- Uniform Motion WorksheetDocument8 pagesUniform Motion Worksheetnikhil patro100% (1)

- Homework 9Document1 pageHomework 9Nat Dabuét0% (1)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)