Académique Documents

Professionnel Documents

Culture Documents

ISO & DIN Specs - Hydraulic - Final

Transféré par

David PomaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ISO & DIN Specs - Hydraulic - Final

Transféré par

David PomaDroits d'auteur :

Formats disponibles

Industrial Lubricants

Specifications – Hydraulic Oils

DIN 51524 Classifications

Specification Description

Lubricants have additives that protect from corrosion, oxidation and wear, plus

DIN 51524 additives increasing their viscosity index (VI >140, pressure >100 bar). They are

HVLP intended for universal application, however the biggest advantage is provided

when used in external hydraulic systems.

Lubricants have additives from corrosion, oxidation and wearing (VI >80-100,

DIN 51524

pressure >100bar). They are intended for universal application and they are

HLP

recommended for use in internal hydraulic systems.

Lubricants have additives protecting from corrosion and oxidation (VG >80-100,

DIN 51524 HL pressure >100bar). They are recommended for use in low pressure internal

hydraulic systems.

ISO 11158 Hydraulic Fluids

Specification Description

ISO 11158 HL R&O Type

ISO 11158 HM R&O with Anti-wear

ISO 11158 HV R&O, with Anti-wear and high VI

ISO 6743-4 Classification

Specification Description

ISO – L – HH Mineral lubricants without corrosion inhibitors

ISO – L – HL Lubricants HH with oxidation-reduction and anticorrosive additives

ISO – L – HM HL lubricants with wear reducing additives

ISO – L – HR HL lubricants with a high viscosity index

ISO – L – HV HM lubricants with a high viscosity index

ISO – L – HG HM lubricants with shock resistant features

ISO – L – HS Synthetic liquids

Industrial Lubricants

Specifications - Hydraulic Oils

ISO 6743-4 Classification of Fireproof Hydraulic Liquids

Specification Description

ISO – L – HFAE Emulsion, oil-in-water

ISO – L – HFAS Chemical combinations in water

ISO – L – HFB Emulsion, water-in-oil

ISO – L – HFC Water / glycol

ISO – L – HFDR Phosphorus esters – without water

ISO – L – HFDS Chlorinated hydrocarbons – without water

ISO – L – HFDT HFDR / HFDS mixtures

ISO – L – HFDU Anhydrous liquids, more resistant than HFDR, HFDS or HFDT

ISO 6743-4 Classification of Biodegradable Hydraulic Liquids

Specification Description

ISO – L – HETG Triglycerides (vegetable oils)

ISO – L – HEES Synthetic esters

ISO – L – HEPG Polyglycols

Industrial Lubricants

Specifications - Hydraulic Oils

Parker Denison

Category Type Application Pump Type Condition

Suitable for systems where

R&O Type Piston 350bar, 100C and

HF-1 there is minimal metal to

fluid Pumps 1200 – 1800 rpm

metal contact

200ba, 100C and

2500rpm

Conventio

HF-2 Suitable for most vane pumps Vane Pumps Non ferrous pumps:

nal A/W

250bar, 70C,

1800rpm

Vane Pump: 200bar

High wear protection and high max, 2500 rpm, 100C

thermo-oxidative stability. max

Piston &

HF-0 Anti-wear Include metal deactivators to

Vane Pumps Piston Pump: 350bar,

protect non ferrous metals at

high temperatures 100C max and 1200 –

1800rpm

Vane pump: 100bar,

Water in oil Vane and piston pump (down Piston & 65C and 1800rpm

HF-3

emulsion rated conditions) Vane Pumps Piston: 250bar, 60C,

1800rpm

Water

HF-4 Glycol Fire Resistant HF

solutions

Phosphate

HF-5 Fire resistant HF

ester

Vous aimerez peut-être aussi

- ISO & DIN Specs - Hydraulic - Final PDFDocument3 pagesISO & DIN Specs - Hydraulic - Final PDFDavid Poma100% (2)

- Viscosity Index Improvers and ThickenersDocument20 pagesViscosity Index Improvers and ThickenerskhilpatiPas encore d'évaluation

- Paratone 8083 PDSDocument2 pagesParatone 8083 PDSBa NuPas encore d'évaluation

- Lubricants: 11 February 2014Document2 pagesLubricants: 11 February 2014Thai TrinhPas encore d'évaluation

- ISO 6743 - 4 - Hydraulic OilDocument8 pagesISO 6743 - 4 - Hydraulic OilNokiabhre WijayaPas encore d'évaluation

- Kluber-Brochure Lubrication of Various ComponentsDocument17 pagesKluber-Brochure Lubrication of Various ComponentsjalalPas encore d'évaluation

- VTK Varnish Potential Test Kits PDFDocument1 pageVTK Varnish Potential Test Kits PDFEduardo CramerPas encore d'évaluation

- Gear Lubrication 3Document9 pagesGear Lubrication 3rashm006ranjan100% (1)

- EIC N 1001 0 Hydraulic FluidsDocument13 pagesEIC N 1001 0 Hydraulic FluidsCharitha LiyanagamaPas encore d'évaluation

- Maintenance Tips On OilDocument12 pagesMaintenance Tips On OilAndrea StonePas encore d'évaluation

- Chapter 3 Lubrication Formulation and Lubrication SelectionDocument57 pagesChapter 3 Lubrication Formulation and Lubrication SelectionNadia Syamira Saaidi100% (1)

- Lubricant GlossaryDocument8 pagesLubricant GlossaryAli KhanPas encore d'évaluation

- Industrial Handbook 15 - 05 - 15 PDFDocument150 pagesIndustrial Handbook 15 - 05 - 15 PDFvjzsocoolPas encore d'évaluation

- FUCHS LUBRITECH Product RangeDocument76 pagesFUCHS LUBRITECH Product RangeBurak GüleşPas encore d'évaluation

- Lubricants For Textile Industry - Spinning / Preparation MachinesDocument6 pagesLubricants For Textile Industry - Spinning / Preparation MachinesAbd Allatife AlshehabiPas encore d'évaluation

- HiTEC-5200 PDS PDFDocument2 pagesHiTEC-5200 PDS PDFharulyPas encore d'évaluation

- List of Products Related To Danieli Standard 0.000.001 - Rev.15Document11 pagesList of Products Related To Danieli Standard 0.000.001 - Rev.15cottePas encore d'évaluation

- Iso TS 6521-2-2021Document16 pagesIso TS 6521-2-2021wodonit136Pas encore d'évaluation

- Hydraulic Fluid CategoriesDocument3 pagesHydraulic Fluid CategoriesJako MishyPas encore d'évaluation

- Industrial Lubricants - Viscosities Equivalent ISO-VG GradeDocument3 pagesIndustrial Lubricants - Viscosities Equivalent ISO-VG GradeArifinPas encore d'évaluation

- Hydraulic FluidsDocument20 pagesHydraulic FluidsRamirez Indeleble100% (1)

- Hydraulic FluidDocument6 pagesHydraulic FluidDesiree Cena CapunoPas encore d'évaluation

- Lubricants For The Manufacturing IndustryDocument20 pagesLubricants For The Manufacturing IndustrynarenjiPas encore d'évaluation

- Mil L 2105DDocument17 pagesMil L 2105Dkamal arabPas encore d'évaluation

- Filtracion Lubricantes NuevosDocument100 pagesFiltracion Lubricantes NuevosHernan Andres GarciaPas encore d'évaluation

- Shell Risella X 420: Specifications, Approvals & RecommendationsDocument2 pagesShell Risella X 420: Specifications, Approvals & RecommendationsHUM CIREBON DFLTS100% (1)

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezPas encore d'évaluation

- Viscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument39 pagesViscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoraliePas encore d'évaluation

- Kluber Synthetic OilDocument14 pagesKluber Synthetic OilRajiv SrivastavaPas encore d'évaluation

- Rating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDocument8 pagesRating of Hydraulic Fluids For Rexroth Hydraulic Components Re90235 - 2015-02 PDFDennis Huanuco CcamaPas encore d'évaluation

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoPas encore d'évaluation

- Basic of Lubricant and Lubrication-2Document34 pagesBasic of Lubricant and Lubrication-2Dhanie EndaPas encore d'évaluation

- Common Position Paper 2012 Signed B7 PDFDocument5 pagesCommon Position Paper 2012 Signed B7 PDFcarbasemyPas encore d'évaluation

- SAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-2010Document11 pagesSAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-2010Irfan ShaikhPas encore d'évaluation

- Gulf Lubricants Brief ProfileDocument10 pagesGulf Lubricants Brief Profileatripathi2009100% (1)

- BROCHURE Premium Greases Guide TNRDocument7 pagesBROCHURE Premium Greases Guide TNRRezhaPas encore d'évaluation

- Base Fluids and Additives For Fire Resistand Hydraulic FluidsDocument8 pagesBase Fluids and Additives For Fire Resistand Hydraulic FluidseduardoaffrePas encore d'évaluation

- Industrial Lubrication and TribologyDocument16 pagesIndustrial Lubrication and TribologyBonifacio Bagual JrPas encore d'évaluation

- General Discussions On Lubricating OilsDocument59 pagesGeneral Discussions On Lubricating OilsHari PurwadiPas encore d'évaluation

- Irganox L57Document10 pagesIrganox L57Atekeh Sadat NajafiPas encore d'évaluation

- Gear OilsDocument3 pagesGear OilsPurchase ZenoilPas encore d'évaluation

- Pub Role Additives v4 LODocument20 pagesPub Role Additives v4 LOTudor RatiuPas encore d'évaluation

- En Additin RC 2540Document3 pagesEn Additin RC 2540Dinesh babuPas encore d'évaluation

- TT Lubricating Oils Greases Shelf Life RecommendationsDocument2 pagesTT Lubricating Oils Greases Shelf Life RecommendationsmarymydaughterPas encore d'évaluation

- Lubrication TestDocument12 pagesLubrication TestIrsa Septiawan100% (1)

- CASE STUDY 2 - SteelDocument19 pagesCASE STUDY 2 - SteelAnkit UjjwalPas encore d'évaluation

- Afton Industrial Overview Booklet 2019Document11 pagesAfton Industrial Overview Booklet 2019Clairin LohPas encore d'évaluation

- Fire Retardant Hydraulic FluidsDocument12 pagesFire Retardant Hydraulic FluidsPRASAD SANAPPas encore d'évaluation

- Design Engineer's Guide - Selecting A Lubricant For Ball ScrewsDocument10 pagesDesign Engineer's Guide - Selecting A Lubricant For Ball ScrewsDat RomanPas encore d'évaluation

- Guide To EM Bearing LubricationDocument12 pagesGuide To EM Bearing LubricationAnonymous alQXB11EgQ100% (1)

- Industrial Grease Lubricant Application GuideDocument2 pagesIndustrial Grease Lubricant Application GuideOscar Cruz100% (2)

- ATF LubricantDocument35 pagesATF LubricantTung NguyenPas encore d'évaluation

- GreaseDocument3 pagesGreaseWac GunarathnaPas encore d'évaluation

- Contamination Control Part2Document3 pagesContamination Control Part2Othman MansoorPas encore d'évaluation

- Viscosity ClassificationsDocument6 pagesViscosity ClassificationsDarmawan PutrantoPas encore d'évaluation

- Setiima Screw Pump Catalogue PDFDocument10 pagesSetiima Screw Pump Catalogue PDFargpPas encore d'évaluation

- HL200M Dri-Prime Pump: Features SpecificationsDocument2 pagesHL200M Dri-Prime Pump: Features SpecificationsbernardPas encore d'évaluation

- Process Pumps: Made by KSBDocument16 pagesProcess Pumps: Made by KSBEdgar CalatayudPas encore d'évaluation

- Screw Pump 40 - 80 Bar - Olaer - de PDFDocument12 pagesScrew Pump 40 - 80 Bar - Olaer - de PDFAbdoEmanuelMalverdiPas encore d'évaluation

- Brochure HouillonDocument2 pagesBrochure HouillonDavid PomaPas encore d'évaluation

- Viscosidad Tablas de Conversiones - ASTM D2161-05 PDFDocument26 pagesViscosidad Tablas de Conversiones - ASTM D2161-05 PDFEdwin GarzónPas encore d'évaluation

- PDS Lubrizol CV7101 PDFDocument3 pagesPDS Lubrizol CV7101 PDFDavid PomaPas encore d'évaluation

- Gulf TEC Plus 10W-40 (06.2012)Document1 pageGulf TEC Plus 10W-40 (06.2012)David PomaPas encore d'évaluation

- Wärtsila App Lube 34 50 SG Data SpecsDocument6 pagesWärtsila App Lube 34 50 SG Data SpecsDavid Poma100% (2)

- Overview of Mitsubishi Services: Download All Pages PDFDocument27 pagesOverview of Mitsubishi Services: Download All Pages PDFiswandyPas encore d'évaluation

- ISO & DIN Specs - Greases - FinalDocument1 pageISO & DIN Specs - Greases - FinalDavid PomaPas encore d'évaluation

- Turbine Oil Oxidation Stability Test PDFDocument2 pagesTurbine Oil Oxidation Stability Test PDFDavid PomaPas encore d'évaluation

- Lube Points in Automobiles - Final PDFDocument1 pageLube Points in Automobiles - Final PDFDavid PomaPas encore d'évaluation

- TD Operators ManualDocument2 pagesTD Operators ManualDavid PomaPas encore d'évaluation

- ISO & DIN Specs - Hydraulic - FinalDocument3 pagesISO & DIN Specs - Hydraulic - FinalDavid PomaPas encore d'évaluation

- TD Operators ManualDocument84 pagesTD Operators Manualsivan_sg1800Pas encore d'évaluation

- Gulf Oil Lub PDFDocument25 pagesGulf Oil Lub PDFDavid Poma100% (2)

- GLXXNuto H SeriesDocument2 pagesGLXXNuto H SeriesDavid PomaPas encore d'évaluation

- ACEA Specs FinalDocument3 pagesACEA Specs FinalDavid PomaPas encore d'évaluation

- API Spec S Petrol Engine FinalDocument1 pageAPI Spec S Petrol Engine FinalDavid PomaPas encore d'évaluation

- Waukesha Sentron LD 500011 1 10Document13 pagesWaukesha Sentron LD 500011 1 10David PomaPas encore d'évaluation

- Gulf Powertrac 4T Oct16 - 20161005040210Document1 pageGulf Powertrac 4T Oct16 - 20161005040210David PomaPas encore d'évaluation

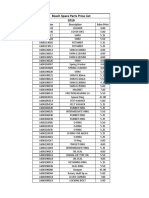

- Bosch Spare Parts Price List 2016Document113 pagesBosch Spare Parts Price List 2016David PomaPas encore d'évaluation

- Lube Points in Automobiles - FinalDocument2 pagesLube Points in Automobiles - FinalDavid PomaPas encore d'évaluation

- TDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDocument1 pageTDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDavid PomaPas encore d'évaluation

- Lube Points in Automobiles - Final PDFDocument1 pageLube Points in Automobiles - Final PDFDavid PomaPas encore d'évaluation

- Overview of Mitsubishi Services: Download All Pages PDFDocument27 pagesOverview of Mitsubishi Services: Download All Pages PDFiswandyPas encore d'évaluation

- Iso11500 PDFDocument13 pagesIso11500 PDFDavid PomaPas encore d'évaluation

- 'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDocument5 pages'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDavid PomaPas encore d'évaluation

- Gulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228Document1 pageGulf-Syngear-Fe-75w-80 - 20-Dec-16 - 20161222052228David PomaPas encore d'évaluation

- 2013 Chevrolet Captiva Sport Owners PDFDocument374 pages2013 Chevrolet Captiva Sport Owners PDFDavid PomaPas encore d'évaluation

- Overview of Mitsubishi Services: Download All Pages PDFDocument27 pagesOverview of Mitsubishi Services: Download All Pages PDFiswandyPas encore d'évaluation

- Sewer Cleaning Parts & Accessories - PipeHunter EquipmentDocument32 pagesSewer Cleaning Parts & Accessories - PipeHunter EquipmenthanePas encore d'évaluation

- Thermoplastic Tubing: Catalogue 5210/UKDocument15 pagesThermoplastic Tubing: Catalogue 5210/UKGeo BuzatuPas encore d'évaluation

- Automatic Lubrication Systems 3 Edition CatalogueDocument34 pagesAutomatic Lubrication Systems 3 Edition CataloguetitiPas encore d'évaluation

- Copper Nickel Pipe Fittings CatalogDocument8 pagesCopper Nickel Pipe Fittings CatalogAli FarzadmaneshPas encore d'évaluation

- Finetrol Rotary Control Valve: Added SecurityDocument14 pagesFinetrol Rotary Control Valve: Added SecurityAmine KhPas encore d'évaluation

- Gen II Automated Transmissions - TRTS0062 EN-US PDFDocument314 pagesGen II Automated Transmissions - TRTS0062 EN-US PDFsherzadPas encore d'évaluation

- Havells PumpsDocument8 pagesHavells PumpsNAVEEN JATPas encore d'évaluation

- Lasac. Assignment 4. Ce43s4Document9 pagesLasac. Assignment 4. Ce43s4Karyme MendezPas encore d'évaluation

- Single Compression Cable Glands - Comet PDFDocument2 pagesSingle Compression Cable Glands - Comet PDFdip461Pas encore d'évaluation

- Reviewer'sComment Pre Chap3Document198 pagesReviewer'sComment Pre Chap3HISHAMPas encore d'évaluation

- 3in Elamr Drawing Illustration in One FileDocument43 pages3in Elamr Drawing Illustration in One FileusamakhattakPas encore d'évaluation

- Rexroth: Spare Parts ListDocument26 pagesRexroth: Spare Parts ListRafael RodriguezPas encore d'évaluation

- COMPLETE Report (Braking Department)Document30 pagesCOMPLETE Report (Braking Department)Dinie Abdullah ZamawiPas encore d'évaluation

- BS 1139-2-2Document14 pagesBS 1139-2-2murali krishPas encore d'évaluation

- KasdkfjDocument10 pagesKasdkfjPravallika KolliparaPas encore d'évaluation

- Polyfort FPP 40 T: Engineering PlasticsDocument3 pagesPolyfort FPP 40 T: Engineering PlasticsFida GhanmiPas encore d'évaluation

- Mihir's Handbook of Chemical Process Engineering (Excerpts)Document74 pagesMihir's Handbook of Chemical Process Engineering (Excerpts)Mihir Patel100% (4)

- Safe Operation of ForkliftDocument44 pagesSafe Operation of Forkliftkarvad100% (1)

- DA42 VI SystemsDocument188 pagesDA42 VI SystemsBen DoverPas encore d'évaluation

- 7 Flight Mech-Drift-Down and Landing PDFDocument23 pages7 Flight Mech-Drift-Down and Landing PDFchess kingsPas encore d'évaluation

- The Concrete Producer Article PDF - Comparing The Options For Cooling ConcreteDocument4 pagesThe Concrete Producer Article PDF - Comparing The Options For Cooling Concretearangar1100% (1)

- Sambungan Chapter 2.2Document57 pagesSambungan Chapter 2.2iffahPas encore d'évaluation

- Design and Configure SAG Mill Liners For Maximum Tonnage PerformanceDocument12 pagesDesign and Configure SAG Mill Liners For Maximum Tonnage PerformanceDiegoAlvarezHuguezPas encore d'évaluation

- Kadix Clima Manual Baxi Duo Tec MP 35-110 Engl PDFDocument5 pagesKadix Clima Manual Baxi Duo Tec MP 35-110 Engl PDFVasil PascuPas encore d'évaluation

- Fujitsu Cassete InverterDocument32 pagesFujitsu Cassete InverterAdrian NascimentoPas encore d'évaluation

- Heat and Mass Transfer (Subject Code: KME 501) Unit Introduction To Heat TransferDocument2 pagesHeat and Mass Transfer (Subject Code: KME 501) Unit Introduction To Heat TransferRajeev100% (2)

- Halton TsaDocument9 pagesHalton TsaNetri KrisztiánPas encore d'évaluation

- Oxygen Sensor Certification ManualDocument20 pagesOxygen Sensor Certification ManualSR BangashPas encore d'évaluation

- Katalog en StandaradaDocument78 pagesKatalog en Standaradahebasignal100% (1)

- Datasheet SMA05 Ha7212 enDocument18 pagesDatasheet SMA05 Ha7212 enTom JotPas encore d'évaluation