Académique Documents

Professionnel Documents

Culture Documents

Lecture 12

Transféré par

Bharath Subramania RajaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lecture 12

Transféré par

Bharath Subramania RajaDroits d'auteur :

Formats disponibles

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

054414 Process Control System Design

LECTURE 12:

MODEL PREDICTIVE CONTROL

Daniel R. Lewin

Department of Chemical Engineering

Technion, Haifa, Israel

12-1 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Objectives

On completing this section, you should:

n Be able to explain to a layman how model predictive

control (MPC) works.

o Understand why MPC can improve on the performance

that can be expected from decentralized controllers.

p Be able to correctly tune MPC to obtain a good

response.

q Be able to implement MPC using MATLAB.

Refs: 1) Seborg, D. E., Edgar, T. F. and Mellichamp, D. A., Process

Dynamics and Control, 2

12-2 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

1 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Introduction

Thus far, digital controllers have been designed using relatively

simple models to predict the future values of the process

outputs. We shall now consider a more general form of model

predictive control in which:

n The set points are computed based on a constrained

optimization of a steady-state process model.

o A model-based predictive algorithm ensures that the process

outputs track the setpoints over a prespecified horizon.

d

e u +

+

Opt. control process y

ys -

y model - +

constraints

12-3 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Constrained Optimization

The most common approach is to perform constrained

optimization using a static process model at regular

intervals. This ensures that the process is maintained at

the optimal operating level when confronted with such

things as:

Changes in product demands.

Disturbances such as feedstock changes

Changes in equipment availability

Despite the fact that processes can be highly nonlinear,

the most commonly-used method is LP. This has been

covered in other courses (054374, 054402), so it will not

be discussed further here. This leaves MPC to cover…

12-4 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

2 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

MPC made simple…

MPC is a model-based control strategy using models in 2 ways:

Uses a reliable model to predict effect of past control

moves on P future outputs, assuming no future moves.

Uses the same model to compute the optimal M controller

moves. Implement first move and repeat procedure.

past Prediction horizon, P v

target YCL

v

yOL

yk

mk

k k+M k+P

Control horizon, M

12-5 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Discrete Convolution Models

Evidently, a discrete model describing the effect of inputs on

outputs is required. Commonly, discrete impulse response, or

convolution, models are used.

Consider the response of a typical process to a unit step input:

ai are the step response coefficients

hi are the impulse response coefficients

hi = ai − ai −1 , i = 1, …,H - model horizon.

h0 = 0 (what does this assume?)

H, the model horizon, is selected to

capture 99% of the transient.

H

A discrete convolution model is: yk +1 = ∑ hi mk +1−i

i =1

Predicted Manipulated

value of y variable at k + 1 - i

12-6 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

3 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Discrete Convolution Models

H

Discrete convolution model: yk +1 = ∑ hi mk +1−i (11.1)

i =1

yk +1 = h1mk + h2mk −1 + … + hH mk +1−H

(11.2)

where mk +1−H = 0 when k + 1 − H < 0

Define ∆mk = mk − mk −1 and substituting in (11.2):

yk +1 = h1mk + h2mk −1 + … + hH mk +1−H

= ( a1 − a0 ) mk + ( a2 − a1 ) mk −1 + … + ( aH − aH −1 ) mk +1−H

= a0mk + a1 ( mk − mk −1 ) + … + aH −1 ( mk +1−H − mk +1−H ) + aH mk +1−H

H

Hence: yk+1 = ∑ ai ∆mk +1−i (11.3)

i =1

Note that this assumes that ∆mk +1−H = mk +1−H − mk −H = mn +1−H

12-7 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Discrete Convolution Models

Applying Eq. (11.3), a step change in m at k = 0 ⇒ ∆m0 = m0 – m-1,

with ∆mk = 0, k > 0:

H

k = 0: y1 = ∑ ai ∆m1−i

i =1 0

= a1 ∆m0 + a2 ∆m−1 + … = a1 ∆m0

H

k = 1: y2 = ∑ ai ∆m2−i

i =1 0 0

= a1 ∆m1 + a2 ∆m0 + a3 ∆m−1 + … = a2 ∆m0

In general, yk = ak ∆m0 − predicted values are step response

coefficients multiplied by ∆m0.

12-8 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

4 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

ZT-Convolution Model Equivalence

We shall now see how these convolution models are equivalent

to transfer function models studied so far. As an example,

consider the process: p ( s ) = s +1 with a hold and T = 0.2.

1

Then HP ( z ) =

(1 − e ) z

−0.2 −1

=

0.1813z −1

1 − e −0.2z −1 1 − 0.8187z −1

By long division: HP ( z ) = 0.1813z −1 + 0.1484z −2 + 0.1215z −3

+0.0995z −4 + 0.0815z −5 + … (11.4)

To obtain unit step response: Yˆ ( z ) = HP ( z ) M ( z ) = HP ( z ) ⋅ 1 −1

1 −z

y(T) y(2T) y(3T)

By long division: Yˆ ( z ) = 0.1813z −1 + 0.3297z −2 + 0.4512z −3

+0.5507z −4 + 0.6321z −5 + … (11.5)

This is identical to the response: y (kT ) = 1 − e

− kT

12-9 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

ZT-Convolution Model Equivalence

H

Note that Eq. (11.3) is yk+1 = ∑ ai ∆mk +1−i

i =1

Taking Z-transforms of this equation gives:

H

ˆ ( z ) z k +1 = a ∆Mˆ ( z ) z k +1−i Ŷ ( z ) H

Y ∑i = ∑ ai z −i (11.6)

i =1 ∆Mˆ ( z ) i =1

Hence, when ∆mo = 1 ( ∆Mˆ ( z )), Eq. (11.6) is equivalent to Eq.

(11.5), so coefficients a1 = 0.1813, a2 = 0.3297, etc., can be

obtained by measuring the unit-step response.

H

Furthermore, we can write Eq. (11.1): yk +1 = ∑ hi mk +1−i

i =1

Ŷ ( z ) H

in the Z-domain: = HP (z ) = ∑ hi z −i (11.7)

Mˆ ( z ) i =1

Hence, Eq. (11.7) is equivalent to Eq. (11.4), whose coefficients

are h1, h2, etc. and we can check that hi = ai – ai-1.

12-10 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

5 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Matrix Form for Predictive Control

In general, at sample k, we will compute:

M future input changes - ∆mk , ∆mk +1 , …, ∆mk +M −1

input horizon

and P predicted future outputs - yk +1 , yk +2 , …, yk +P

prediction horizon

Generalizing Eq. (11.4):

H H

yk+1 = ∑ ai ∆mk +1−i = a1 ∆mk + ∑ ai ∆mk +1−i

i =1 i =2

future

past

H 2 H

yk+2 = ∑ ai ∆mk +2−i = ∑ ai ∆mk +2−i + ∑ ai ∆mk +2−i

i =1 i =1 i =3

future past

12-11 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Matrix Form for Predictive Control

M H

yk +M = ∑ ai ∆mk +M −i + ∑ ai ∆mk +M −i

i =1 i M

= +1

future past

P H

y k +P = ∑

i =P −M +1

ai ∆mk +P −i + ∑ ai ∆mk

i =P +1

+P −i

future past

In summary, at sample interval n + j :

j H

yk + j = ∑

i

ai ∆mk

=1

+ j −i + ∑ ai ∆mk

i j

= +1

+ j −i j ≤M

future adjustments past adjustments (11.8)

j H

yk + j = ∑

i = j −M +1

ai ∆mk + j −i + ∑ ai ∆mk

i = j +1

+ j −i M < j ≤P

future adjustments past adjustments

12-12 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

6 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Matrix Form for Predictive Control

Thus, in matrix form, the predicted trajectory is:

⎡y k0+1 ⎤

⎡yk +1 ⎤ ⎡a1 0 0 0 ⎤ ⎢ 0 ⎥ ⎡w k ⎤

⎢yk +2 ⎥ ⎢a2 a1 0 0 ⎥ ⎡ ∆mk ⎤ ⎢y k +2 ⎥ ⎢w k +1 ⎥

⎢ ⎥ ⎢ ⎥⎢ ⎥ ⎢ 0 ⎥ ⎢ ⎥

⎢yk +3 ⎥ ⎢a3 a2 a1 0 ⎥ ⎢ ∆mk +1 ⎥ ⎢y k +3 ⎥ ⎢w k +2 ⎥

⎢ ⎥=⎢ ⎥ ⎢ ∆mk +2 ⎥ + ⎢ ⎥+⎢ ⎥

⎢yk +M ⎥ ⎢aM aM −1 aM −2 a1 ⎥ ⎢ ⎥ ⎢y ⎥ ⎢w k +M −1 ⎥

0

⎢ ⎥ ⎢ ⎥⎢ ⎥ ⎢ k +M ⎥ ⎢ ⎥

⎢ ⎥ ⎢ ⎥ ⎣ ∆mk +M −1 ⎦ ⎢ ⎥ ⎢ ⎥

⎢⎣yk +P ⎥⎦ ⎢⎣aP aP −1 aP −2 aP −M +1 ⎥⎦ ⎢y 0 ⎥ ⎢⎣w k +P −1 ⎥⎦

⎣ k +P ⎦

y A ∆ m k

y

0

wk

k k

In the above, y k + j is the output predicted without further

0

H

control action: y k + j =

0

∑ ai ∆mk

i j= +1

+ j −i and wk is disturbance effect.

12-13 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Dynamic Matrix Control

That, is, in matrix form: y k = A ⋅ ∆m k + y k + w k

0

(11.9)

In DMC, the effect of disturbances on the output at k + 1 is

considered to be modeling error, and is estimated by using the

actual value of y measured at instant k :

wˆk = yk − yk (11.10)

Now, our objective is to obtain a desired trajectory, y k

*

Thus, we need to minimize the closed loop prediction error:

e *k = y k* − A ⋅ ∆m k − y k0 − wˆk

Rearranging: e *k (

= −A ⋅ ∆m k + y − y − wˆk

*

k

0

k ) (11.11)

Closed-loop Vector of Open-loop

prediction future control

error prediction

moves error

12-14 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

7 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Dynamic Matrix Control

Clearly, we would like to minimize the closed-loop prediction

error, e k . This can be formally stated as follows:

*

T

min φ = ⎡⎣e k0 − A ⋅ ∆m k ⎤⎦ ⎡⎣e k0 − A ⋅ ∆m k ⎤⎦ (11.12)

∆mk

where e k = y k − y k − wˆk is the open-loop prediction error.

0 * 0

Differentiating Eq. (11.12) with respect to ∆mk, and equating

to zero gives:

∂φ

= −AT ⎣⎡e k0 − A ⋅ ∆m k ⎦⎤ = 0

∂∆m k

( )

−1

Solving gives: ∆m k = A A AT e k0

T

(11.13)

A MxP matrix

of controller

gains

12-15 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Dynamic Matrix Control

The generic DMC algorithm is implemented as follows:

n The process output, yk, is measured, and used to

estimate the process model error using Eq. (11.10).

o The open-loop prediction error, e k = y k − y k − wˆk , is

0 * 0

updated (accounting for changes in setpoint and

effect of previous controller moves)

( )

−1

p Solve Eq. (11.13): ∆m k = AT A AT e k0

q ∆mk (first step only) is implemented.

r Counter is updated: k = k + 1.

12-16 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

8 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

MPC in Action

n The process output, yk, is measured, and used to

estimate the process model error using Eq. (11.10).

past

yk

mk

12-17 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

MPC in Action

o The open-loop prediction error, e k = y k − y k − wˆk , is

0 * 0

updated (accounting for changes in setpoint and

effect of previous controller moves)

past Prediction horizon, P

Target y k*

0

y

yk k

mk

k k+P

12-18 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

9 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

MPC in Action

( )

−1

p Solve Eq. (11.13): ∆m k = AT A AT e k0

q ∆mk (first step only) is implemented.

past Prediction horizon, P

Target y k*

0

y

yk k

mk

k k+M k+P

Control horizon, M

12-19 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

MPC in Action

r Counter is updated: k = k + 1.

past Prediction horizon, P

Target y k*

yk

mk

k k+M k+P

Control horizon, M

Problem. Control law can result in ringing in ∆mk. This occurs

when A A is ill-conditioned or singular.

T

12-20 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

10 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Dynamic Matrix Control

Solution. Modify the objective function, to penalize for

excessive control moves:

T

φMS = ⎡⎣e k0 − A ⋅ ∆m k ⎤⎦ ⎡⎣e k0 − A ⋅ ∆m k ⎤⎦ + ∆mTk W 2 ∆m k (11.14)

The inclusion of the positive definite matrix, W 2 , in the

objective function is refereed to as “move suppression.”

( )

−1

Minimizing with respect to ∆mk gives: ∆m k = A A +W 2 AT e k0

T

Example. Design MPC/DMC for the process: p ( s ) = e −s

1

(10 s +1)( 5s +1)

Use T = 2 min, and H = 40, and test: (a) M = 1, P = 3, and (b) M =

2, P = 4. Compare results with PID tuned by (c) ZN rule, and (d)

IMC-PID method. Test the performance of the designs for unit

step change in setpoint for nominal process model and for the

case with 50% gain and delay uncertainty.

12-21 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Comparing MPC with PID (SISO)

Nominal servo responses.

P=3,M=1

P=4,M=2

P=3,M=1

P=4,M=2

ZN tuning is: Kc = 4.2,τI = 6, τD = 4. IMC-PID tuning (with

λ = 2) is: Kc = 3.75,τI = 15, τD = 3.33. Note that IMC-PID

gives similar performance to MPC, superior to ZN (Is this

surprising?)

12-22 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

11 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Comparing MPC with PID (SISO)

Servo responses with 50% uncertainty in gain and delay.

P=3,M=1

P=4,M=2

P=3,M=1

P=4,M=2

Increasing M and P leads to more aggressive control

action and less robustness.

12-23 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

MIMO MPC

The results obtained so far are easily extended to cover MIMO

systems. Consider for example the 2x2 system described by

the following discrete convolution model:

H H

y1,k+1 = ∑ a11,i ∆m1,k +1−i + ∑ a12,i ∆m2,k +1−i

i =1 i =1

H H

y2,k+1 = ∑ a21,i ∆m1,k +1−i + ∑ a22,i ∆m2,k +1−i

i =1 i =1

This model can be transformed into the standard dynamic form:

* 0

E k = −A ⋅ ∆M k + E k

* 0

where E k and E k are vectors of length 2P and ∆Mk is a vector

of length 2M: * T

E k = ⎡⎣e1,*k +1 , e1,*k +2 , …, e1,*k +P , e2,*k +1 , e2,*k +2 , …, e2,*k +P ⎤⎦

T

∆M k = ⎡⎣ ∆m1,k , ∆m1,k +1 , …, ∆m1,k +M −1 , ∆m2,k , ∆m2,k +1 , …, ∆m2,k +M −1 ⎤⎦

12-24 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

12 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

MIMO MPC

In this 2x2 case, the matrix A has the following structure:

⎡A A 12 ⎤

A

A = ⎢ 11 ⎥ where each sub-matrix ij has the structure:

A

⎣ 21 A 22 ⎦

⎡aij ,1 0 0 0 ⎤

⎢a aij ,1 0 0 ⎥

ij ,2

⎢ ⎥

Aij = ⎢aij ,3 aij ,2 aij ,1 0 ⎥

⎢ ⎥

⎢ ⎥

⎣⎢aij ,P aij ,P −1 aij ,P −2 aij ,P −M +1 ⎦⎥

Even more general objective function is:

*T * T

φ = E k W 1 E k + ∆M k W 2 ∆M k

( )

−1 0

Minimizing gives: ∆M k = A W 1 A +W 2 AT W 1 E k

T

12-25 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Comparing MPC with PID (MIMO)

Example. Consider the Wood and Berry distillation column:

⎡ 12.8 −18.9 −3s ⎤

e −s e

⎡xD ⎤ ⎢ 16.7s + 1 21s + 1 ⎥ ⎡L ⎤

= ⎢ ⎥⎢ ⎥

⎣⎢xB ⎦⎥ ⎢ 6.6 e −7 s −19.4 −3s ⎣V ⎦

e ⎥

⎣⎢ 10.9s + 1 14.4s + 1 ⎥⎦

We will compare two MIMO control systems for the process:

(a) an MPC design for H=30, P=6, M = 3, T=3, and W 2 = 0;

(b) a diagonal IMC-PID control system, tuned with λ = [6, 2.5].

Results. The following slides indicate that: (a) Nominally, MPC

provides superior performance to decentralized PID, since it

decouples the process interactions; (b) It is more sensitive to

model uncertainties (50% in gain and delay) than PID.

12-26 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

13 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Comparing MPC with PID (MIMO)

Example: Wood and Berry Column (Nominal MPC)

P=6, M=3

12-27 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Comparing MPC with PID (MIMO)

Example: Wood and Berry Column (Nominal PID)

12-28 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

14 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Comparing MPC with PID (MIMO)

Example: Wood and Berry Column (MPC - Model Error)

P=6, M=3

12-29 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Comparing MPC with PID (MIMO)

Example: Wood and Berry Column (PID - Model Error)

12-30 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

15 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Tuning the MPC Controller

The following recommendations are often considered when

selecting the tunable parameters in MPC:

n H - model horizon.

HT should be selected so that it is greater than the open-loop settling

time (defined as 99 or 95% of response). Commonly 20 ≤ H ≤ 70.

o T – sampling period.

Should be selected to capture important dynamic information.

p P and M - prediction and control horizons.

Generally, P > M. Increasing M increases controller aggressiveness and

decreases robustness. A suitable first guess P ≈ t60/T (number of

samples to reach 60% of open-loop response).

q W1 and W2 – weighting matrices.

W2, generally defined as a diagonal matrix, permits selectively

penalizing particular manipulated variables for MIMO systems (“move

suppression”). W1 allows output scaling to be handled, and is referred

to as “equal concern error” in DMC.

12-31 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Process Constraints

In practice, the manipulated variables are constrained to

physical, or allowable limits. Furthermore, the output variables

may also be subject to constraints. Thus, in practice, a

constrained optimization problem is solved:

*T * T

min φ = E k W 1 E k + ∆M k W 2 ∆M k (11.15)

∆M k

subject to: ∆m ≤ ∆m k ≤ ∆m (move limits)

L H

mL ≤ mk ≤ mH (manipulated variable bounds)

y ≤ yk ≤ y

L H

(output variable bounds)

This type of problem can be solved using quadratic

programming. Nonlinear versions are solved using successive

quadratic programming (SQP).

12-32 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

16 Daniel R. Lewin, Technion

LECTURE TWELVE 054414 PROCESS CONTROL SYSTEM DESIGN

Why Model Predictive Control ?

Real processes are multivariable and often involve

significant interaction.

interaction Here’s a good analogy to convince

your future boss to implement MPC.

Driving a car down Haifa’s, Freud Street

When driving a car, we make coordinated use of:

Steering wheel

Brake pedal

Acceleration pedal

Gear stick

Consider how well you could maneuver a car at speed

down Freud Street using only the steering wheel, with

all other controls fixed? Equivalent to SISO control…

12-33 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

Summary

On completing this section, you should:

n Be able to explain to a layman how model predictive

control (MPC) works.

Recall that MPC uses a model in two ways: (a) to predict

the effects of past moves; (b) to optimize future moves.

o Understand why MPC can improve on the performance

that can be expected from decentralized controllers.

Recalling that MPC: (a) implicitly handles constraints and

thus maximizes DOF; (b) effectively decouples process

interactions.

p Be able to correctly tune MPC to obtain a good

response.

q Be able to implement MPC using MATLAB.

12-34 PROCESS CONTROL SYSTEM DESIGN - (c) Daniel R. Lewin Model Predictive Control

17 Daniel R. Lewin, Technion

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Electric Load Forecasting in Energy Power Systems Based On Online Gaussian Process Regression Coupled With Multilayer Perceptron Kernel MethodDocument5 pagesElectric Load Forecasting in Energy Power Systems Based On Online Gaussian Process Regression Coupled With Multilayer Perceptron Kernel MethodagbodoPas encore d'évaluation

- HW 09 SolDocument24 pagesHW 09 SolNanilyn TumlodPas encore d'évaluation

- Aparna Rathi SC E: Electronics & Radar Development Establishment (LRDE)Document91 pagesAparna Rathi SC E: Electronics & Radar Development Establishment (LRDE)muvin236Pas encore d'évaluation

- Lubich C (2) - RK Theory For Volterra Integrodifferential Equations (NumMat, 1982)Document17 pagesLubich C (2) - RK Theory For Volterra Integrodifferential Equations (NumMat, 1982)Александр ЛобаскинPas encore d'évaluation

- J.P. Rizal Ext. West Rembo, Makati CityDocument2 pagesJ.P. Rizal Ext. West Rembo, Makati CityQ Annang TomanggongPas encore d'évaluation

- KMNS - 2223 - Pre PSPM SM015 - Set 3Document4 pagesKMNS - 2223 - Pre PSPM SM015 - Set 3Nur ZuhayraPas encore d'évaluation

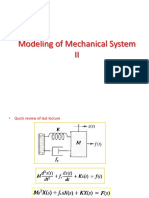

- Modeling of Mechanical System IIDocument11 pagesModeling of Mechanical System IIshrey saxenaPas encore d'évaluation

- (Unit-04) Part-01 - ML AlgoDocument49 pages(Unit-04) Part-01 - ML Algosuma varanasiPas encore d'évaluation

- EN1201: Introductory Mathematics: University of Colombo, Sri LankaDocument6 pagesEN1201: Introductory Mathematics: University of Colombo, Sri LankaJanaka Bandara100% (1)

- The Connectivity Index of A Weighted Graph: O. Araujo A.i, J.A. de La Pefia B.Document7 pagesThe Connectivity Index of A Weighted Graph: O. Araujo A.i, J.A. de La Pefia B.Krishan AcharyaPas encore d'évaluation

- Measures of Central TendencyDocument32 pagesMeasures of Central TendencyJanainah Diamla SaripadaPas encore d'évaluation

- McGill MATH - 133Document1 pageMcGill MATH - 133RafaPas encore d'évaluation

- Formal Truth & Material Truth Self Evidence Theory and Coherence TheoryDocument9 pagesFormal Truth & Material Truth Self Evidence Theory and Coherence TheoryAudhora IslammPas encore d'évaluation

- Digital Signal Processing: Classification of Discrete Time SignalDocument23 pagesDigital Signal Processing: Classification of Discrete Time Signaltamizh kaviPas encore d'évaluation

- Analyzing The Content of The Physics Books in Middle School For Iraq in Light of Science Standards For The Next Generation (NGSS)Document26 pagesAnalyzing The Content of The Physics Books in Middle School For Iraq in Light of Science Standards For The Next Generation (NGSS)emaPas encore d'évaluation

- WCE2014 pp1404-1409Document6 pagesWCE2014 pp1404-1409hykiPas encore d'évaluation

- Ncert Solutions Class 8 Math Chapter 2 Ex 2 4Document11 pagesNcert Solutions Class 8 Math Chapter 2 Ex 2 4Vinayak MauryaPas encore d'évaluation

- A Class of Hankel ConvolutionsDocument17 pagesA Class of Hankel ConvolutionsLouis DoroteoPas encore d'évaluation

- Implicit and Explicit DiffDocument19 pagesImplicit and Explicit Diffjohnlery guzmanPas encore d'évaluation

- CH 10Document36 pagesCH 10LeonardoMadeira11100% (1)

- 3 To 8 Decoder Using Two 2 To 8 DecoderDocument14 pages3 To 8 Decoder Using Two 2 To 8 DecoderBineilKcThapa100% (1)

- Elements of Complex AnalysisDocument62 pagesElements of Complex AnalysisNaledi xuluPas encore d'évaluation

- Calculator Techniques NewDocument108 pagesCalculator Techniques NewNiel Nisperos100% (6)

- (Sem-4) Numerical Section of CVNM (Mech - Eng) : InterpolationDocument1 page(Sem-4) Numerical Section of CVNM (Mech - Eng) : InterpolationVivek ThakkarPas encore d'évaluation

- Lab11 - Autotuning PDFDocument26 pagesLab11 - Autotuning PDFEng. Ebrahim A. AlrohmiPas encore d'évaluation

- Nsejs Geometry Sa3Document6 pagesNsejs Geometry Sa3gobinda prasad barmanPas encore d'évaluation

- PHY103A: Lecture # 1: Semester II, 2017-18 Department of Physics, IIT KanpurDocument13 pagesPHY103A: Lecture # 1: Semester II, 2017-18 Department of Physics, IIT KanpurSABARI BALAPas encore d'évaluation

- Optimal Re-Entry Guidance of Space Vehicles Under Control and State Variable Inequality ConstraintsDocument11 pagesOptimal Re-Entry Guidance of Space Vehicles Under Control and State Variable Inequality ConstraintssssdaitPas encore d'évaluation

- Ann FLDocument102 pagesAnn FLdpkfatnani05Pas encore d'évaluation