Académique Documents

Professionnel Documents

Culture Documents

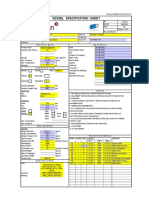

Mechanical Data Sheet - Air Filter (031-GN-002AB)

Transféré par

Gaurav PandeyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mechanical Data Sheet - Air Filter (031-GN-002AB)

Transféré par

Gaurav PandeyDroits d'auteur :

Formats disponibles

(RATHCHAKRA

PROJECT, PARADIP)

Mechanical Datasheet - Air

Filter

(031-GN-002A/B)

Project No.

Page 3 of 7

ThyssenKrupp PPOS

Industrial Solution (India)

Table of Contents

Sl. No. Description No. of sheets

1 Cover Sheet 2

2 Table of Contents 3

3 Design Data 4

4 Material & Testing Requirements 5

5 Nozzle Schedule 6

6 Design Notes 7

Client Document No. :PPOS-8430-DS-031-6017 Rev-1

(RATHCHAKRA

PROJECT, PARADIP)

Mechanical Datasheet - Air Filter

(031-GN-002A/B)

Project No. PPOS Page 4 of 7

ThyssenKrupp

Industrial Solution (India)

Design Data

1 Number of Units Two Rev.

2 Units Shell Jacket/ Coil

3 Type Cartridge

4 Cleaning method Offline

5 Toxic / Lethal (Yes / No) No

6 Sour Service (Yes / No) No

7 Cyclic Service (Yes / No) No

8 Fluid Air

9 Density kg/m³ 7.31

10 Viscosity @ Temp Amb°C cP 0.01

11 Flow (Max/ Normal) kg/h 307.1/ 279.2

12 Inlet temperature °C Ambient

13 Inlet pressure kg/cm²g 6.5

14 Design temperature °C 70

15 Design pressure kg/cm²g 10.5

16 Nature of particles to be

Dust

17 removed

18 Corrosive/ Erosive agents Nil

19 Particle size of solids to be

microns ≥5

20 removed

21 Filter efficiency % 99

22 Total filtration area m² 0.127

23 Filter flux rate m³ / m² N.A.

24 Pressure drop across filter (at Nor. Flow) kg/cm² 0.1

25 Maximum allowable

kg/cm² 0.1

26 pressure drop (clean)

27 Maximum allowable

(at max flow) kg/cm² 0.2

28 pressure drop (dirty)

29 (At Site - Hot & Corroded) kg/cm2 g 64.55

Hydrotest Pressure

30 (At Shop - New & Cold) kg/cm2 g 67.72

31 Corrosion Allowance (Body/ Filter Element) mm 3.00/ NIL

32 MDMT °C 11.3

33 MAWP kg/cm2 g 49.66

34 Orientation (Vertical/ Horizontal) Vertical

35 Vessel Diameter (ID/ OD) mm OD 200 DN 1

36 Weld to Weld Length mm 960

37 Minimum Length (Face-Face)( Inlet & Outlet) mm 630

38 Thickness (Shell/ Head) mm Sch. 60

39 Operating Volume m3 0.02

40 Insulation/ Fire proofing No/ No

41 FOUNDATION LOADING DATA

42 Wind Design Code IS-875, Part-3 1987 (Reaffirmed 2003) Weights (in kgs)

43 Basic Wind Speed (m/s) 65 Fabricated 225

44 Wind Design Factors Empty 228

45 a) K1, K3 1, 1 Shipping 250

46 b) Zone No. 6 Operating 233

47 b) Terrain Category 2 Hydrotest (At Site) 260

48 Seismic Design Code IS-1893, Part 4 (RSM) Hydrotest (At Shop) 260

49 Earthquake Factor Note 6.6 Internals (Including Packing) 5

50 a) Importance Factor 2 (vertical) / DELETED 1

51 b) Zone No. 3

52 Base Shear (kN) 1

53 Base Moment (N-m) 274

54 Note: Wind & Seismic Analysis shall be carried out as per Project Specification PDRP-8310-SP-0001.

Client Document No. :PPOS-8430-DS-031-6017 Rev-1

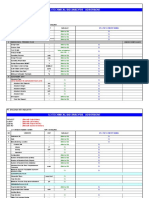

(RATHCHAKRA

PROJECT, PARADIP)

Mechanical Datasheet - Air Filter

(031-GN-002A/B)

Project No.

ThyssenKrupp Page 5 of 7

PPOS

Industrial Solution (India)

Material & Testing Requirements

1 MATERIALS OF CONSTRUCTION Rev.

2 Shell ASTM A 106 Gr. B Bolts (external) ASTM A 193 B7

3 Heads ASTM A 234 Gr. WPB Nuts (external) ASTM A 194 2H

4 Boot NA Bolts (internal) NA

5 Shell / Boot Cladding NA Nuts (internal) NA

6 Heads Cladding NA Gaskets (External) SS 316 spiral wound / Graphite

7 Jacket/ Coil Shell NA Gaskets (Internals) NA

8 Jacket/ Coil Head NA Cover Gasket SS 316 spiral wound / Graphite

9 Nozzle Flanges ASTM A 105N

10 Nozzle Necks (Size <12") ASTM A 105N / External Welded Supports ASTM A 516 70N

11 ASTM A 106 GR. B Internal Welded Supports ASTM A 516 70N

12 Nozzle Necks (Size >12") NA 1 Baffle NA

13 Nozzle RF Pads ASTM A 516 70N Screen NA

14 Nozzles Cladding/ Overlay NA Filter Element SS 304 L (Note 6.9)

15 Girth Flanges ASTM A 105N Internal Pipe Fittings NA

Girth Flanges Cladding/

16 NA Internal Flanges NA

Overlay

17 Skirt (Top Side) NA Packing NA

18 Skirt (Lower Side) NA Internal Pipe NA

19 Basering NA Internal Bed NA

20 Support Legs ASTM A 283 C Vortex Breaker NA

21 Saddles NA Impingement Baffles NA

22 Base Plate ASTM A 283 C Coalescer NA

23 Wear/ Wrapper Plate NA Coalescer Distributor NA

24 Stiffening Rings NA Demister NA

25 Lifting Lugs (w/o RF Pad) ASTM A 516 70N

26 Insulation Supports NA Lifting Lugs (w/ RF Pad) NA 1

27 Fireproofing Cleats NA Tailing Lugs NA

28 Anchor Bolts ASTM A 36

29

30 FABRICATION/ TESTING REQUIREMENTS

31

32 ASME SEC.VIII, Div.1, Radiography Per Code & Spec.

Design Code

33 Ed. 2015 Magnetic Particle Per Code & Spec.

34 Project Specification PDRP-8430-SP-0001 Dye Penetrant Per Code & Spec.

35 Code Stamp (Yes/ No) No Ultrasonic Per Code & Spec.

36 Stress Relieving/ PWHT Yes Gas Leak Testing NA

37 Special Heat Treatment NO PMI For SS Material Only

38 Surface Finish (Internal) Clean & Dry Other NDE Per Code & Spec.

39 Surface Finish (External) PDRP-8440-SP-0006 Hardness Tests Per Code & Spec.

40 Painting PDRP-8440-SP-0006 Impact Testing Per Code & Spec.

41 Lining NA IOCL inspection- Free

42 Per Code + Specs. PDRP-8440- access to Vendor's and

Welding Standard Required

43 SP-0010 their Sub- Vendor's works

44 Surveillance Grade 1B (as per PDRP-8440-SP-0024)

for IOCL representatives

45 Design Life (Excluding Visual and dimensional

20 Years

46 elements) inspection (at Final Required

47 inspection)

48

49

50

Client Document No. :PPOS-8430-DS-031-6017 Rev-1

(RATHCHAKRA

Mechanical Datasheet - Air Filter PROJECT, PARADIP)

(031-GN-002A/B)

Project No.

ThyssenKrupp Page 6 of 7

PPOS

Industrial Solution (India)

Nozzle Schedule

1 Rev.

2 Sch./ Flanges

Size, Pad/ Insert Plate Projections

Nozzle Plate

No. Service NB Rating Size, Dia. x Thk (mm) Remarks

3 Tag Thk. Type Face Finish Note 5.1

(mm) (#) (mm)

(mm)

4 Process Nozzles

5 N1 1 Inlet 80 160 300 WN RF 180 OD X 10 Thk 315

6 N2 1 Outlet 80 160 300 WN RF 180 OD X 10 Thk 315

125 ~

7 N3 1 Vent 50 16.6 300 LWN RF - 360

250

8 N4 1 Drain 50 160 300 WN RF - 315

AARH

9 N5 1 Drain 50 16.6 300 LWN RF 360

10

11 BODY FLANGE

125 ~

REFER

12 1 Bolted Access 200 60 300 WN RF 250 - Note 5.1 1

GAD

AARH

13

14 Notes :

15 5.1) Nozzle projections shall be as per Engineering Standard " Nozzle Details, PDRP-8430-SP-0018". (200mm from vessel outer wall to flange

16 face for WN nozzles & 300mm from vessel outer wall to flange face for LWN nozzles).

17 5.2) All nozzles with companion flange are required with gasket & bolting. 1

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Client Document No. :PPOS-8430-DS-031-6017 Rev-1

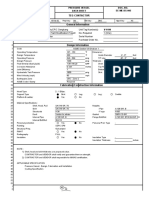

(RATHCHAKRA

Mechanical Datasheet - Air Filter PROJECT, PARADIP)

(031-GN-002A/B)

Project No.

ThyssenKrupp Page 7 of 7

PPOS

Industrial Solution (India)

Design Notes

1 Vessel Design Notes: Rev.

2 6.1) All dimensions are in millimetres unless otherwise stated.

3 6.2) All anchor bolt holes shall straddle the principal center line of vessel, unless otherwise indicated. All bolt holes of nozzle flanges

4 shall straddle the principal center lines of vessel, unless otherwise indicated.

5 6.3) Vendor shall perform stress analysis as per applicable Design Codes complying to all requirements of Design Code and applicable

6 project specifications

6.4) Gaskets: Spiral wound graphite filled gaskets with type 316 SS windings and SS 316 inner & CS outer ring conforming to ASME

7 1

B16.20.

8 6.5) Impact testing requirements shall be fulfilled for all materials as per code at the given MDMT.

9 6.6) Earthquake data as per Sec. 3.9 of document no. PDRP-8820-SP-0001.

10 6.7) All Carbon steel material shall be killed carbon steel. Hardness in KCS welds not to exceed 200BHN.

11 6.8) Chloride content in water for hydrostatic test shall be as per applicable project specification.

12 6.9) Filter element shall be removable and reusable type.

13 6.10) Internal bypass around filter element not acceptable.

14 6.11) Screwed connections & Slip on connections are not permitted.

15 6.12) Filter must be be capable of being depressurised and completely drained / flushed prior to opening.

16 6.13) Asbestos in any form is probhibited.

17 6.14) Tolerances on the plate thicknesses shall be +ve side only.

18 6.15) Mechanical Datasheet abbreviations:

19 VTA- Vendor To Advise SS- Stainless Steel

20 IOCL- Indian Oil Corporation Limited NA- Not Applicable

21 CS- Carbon Steel

22 6.16) Model No. of filter elements.: NOT Applicable

23 6.17) filter operation is alone.

24 6.18) Molecular weight is 28.97 kg/kmol.

25 6.19) Backwashing is not applicable for this filter.

26 6.20) Solid content of fluid (nor/ max) shall be defined later.

27 6.21) Particle size (average) is 5 microns.

28 6.22) estimated time between element change-out (during commissioning/ normal operation)'.: It will depend upon the quantity of

29 incoming 'dust & particle distribution size.

30 6.23) No. of banks and no. of filters per bank.: Total 3 Nos. of elements are fixed in filter housing on single plate.

31 6.24) Bolted filter cover (removable for cleaning), davit arrangement is required for the cover.

32 6.25) Package shall comply with the requirements of the local regulations and standards including those specified in the

33 Environmental Design Basis PDRP4280-8150-PH-0002.

34 6.26) Health,Safety,Security and Environmental instructions as per 3210-8560-SP-0004.

35 6.27) filter size : Dia 54 X 250Lg. & and clean pressure drop: 0.1 Kg/cm2

36 6.28) Nitrogen purging along with pressure indicators is required for transportation and storage of all stainless steel and duplex stainless

37 steel equipment & equipment with stainless steel components.

38 6.29) This datasheet is prepared/ revised based upon Process Data Sheet : PPOS-8110-DS-031-0029, Rev.0 for Air Filter (031-GN-002

39 A/B).

40

41

42

43

44

45

46

47

48

49

50

51

52

Client Document No. :PPOS-8430-DS-031-6017 Rev-1

Vous aimerez peut-être aussi

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaPas encore d'évaluation

- PACE Structured Column Packings: Datasheet For Existing ColumnDocument2 pagesPACE Structured Column Packings: Datasheet For Existing ColumnAabbhas GargPas encore d'évaluation

- De MisterDocument2 pagesDe MisterLaxman G GalipelliPas encore d'évaluation

- Filter Design Data (24 Oct20)Document2 pagesFilter Design Data (24 Oct20)Hedi Ben MohamedPas encore d'évaluation

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaPas encore d'évaluation

- Vessel Specification SheetDocument2 pagesVessel Specification Sheetangel gabriel perez valdezPas encore d'évaluation

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalPas encore d'évaluation

- DcrerweDocument1 pageDcrerwesri9987Pas encore d'évaluation

- B 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUDocument10 pagesB 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUYusri FakhrizalPas encore d'évaluation

- 1308-306-MEC-DTS-001 - Rev.1 - Cryogenic Flexible HoseDocument3 pages1308-306-MEC-DTS-001 - Rev.1 - Cryogenic Flexible HoseKira RaPas encore d'évaluation

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDPas encore d'évaluation

- IPS MBD21907 in 522 Datasheet of Emergency Relief Valve ADocument3 pagesIPS MBD21907 in 522 Datasheet of Emergency Relief Valve ANikhil KarkeraPas encore d'évaluation

- 16 B 06 HDocument20 pages16 B 06 HVaibhav Bhoir0% (1)

- TBA - AdsorbentDocument4 pagesTBA - AdsorbentTifano KhristiyantoPas encore d'évaluation

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolawePas encore d'évaluation

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoPas encore d'évaluation

- 1.0 J1415 QF200-2 PSA DatasheetDocument2 pages1.0 J1415 QF200-2 PSA DatasheetCarlos MagPas encore d'évaluation

- 96 CH Report DHI 96 2021-22 (LPG Bullet)Document114 pages96 CH Report DHI 96 2021-22 (LPG Bullet)Gilberto YoshidaPas encore d'évaluation

- Table-1 Scope of Work Supply (MR For ACHE)Document6 pagesTable-1 Scope of Work Supply (MR For ACHE)Avinash ShuklaPas encore d'évaluation

- 769-E-1102 Propane Chiller - P2 PDFDocument8 pages769-E-1102 Propane Chiller - P2 PDFamit8808Pas encore d'évaluation

- 08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankSamer ArousPas encore d'évaluation

- Vessel Process Data Sheet1Document3 pagesVessel Process Data Sheet1AJAY1381Pas encore d'évaluation

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocument38 pagesNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalPas encore d'évaluation

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1Pas encore d'évaluation

- Instrument Hookup Drawing OF LEVEL SWITCHDocument1 pageInstrument Hookup Drawing OF LEVEL SWITCHEdafe DicksonPas encore d'évaluation

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CAgus MarpaungPas encore d'évaluation

- Design of Incinerator Plant For Vasai-Virar RegionDocument4 pagesDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRIPas encore d'évaluation

- Mechanical Tender CNG PDFDocument161 pagesMechanical Tender CNG PDFAWANI SRIVASTAVAPas encore d'évaluation

- Ejma7r2 Bellows Worksheet 1Document8 pagesEjma7r2 Bellows Worksheet 1NamıkPas encore d'évaluation

- Tendernotice 5 PDFDocument148 pagesTendernotice 5 PDFAbhijit BhandarkarPas encore d'évaluation

- Pumps Final TeDocument48 pagesPumps Final Tegharsallah mounaPas encore d'évaluation

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayPas encore d'évaluation

- Guideline For Preparing IPDS - Instrument Process Data SheetDocument3 pagesGuideline For Preparing IPDS - Instrument Process Data Sheetbalaji krishnanPas encore d'évaluation

- Gear Pump Datasheets 1Document12 pagesGear Pump Datasheets 1MauliPas encore d'évaluation

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasPas encore d'évaluation

- Sov - 1Document1 pageSov - 1biswasdipankar05Pas encore d'évaluation

- Pages From g446 0828 2810 Itp 0100 0046 Rev 05 Final Approved 2Document4 pagesPages From g446 0828 2810 Itp 0100 0046 Rev 05 Final Approved 2Vinay YadavPas encore d'évaluation

- Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument6 pagesConsultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2Pas encore d'évaluation

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDocument2 pagesACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelPas encore d'évaluation

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayPas encore d'évaluation

- 202366-VP10-DWG-002 - Rev.1 Detail Drawing For Inlet Compressor Filter Separator F-1011Document6 pages202366-VP10-DWG-002 - Rev.1 Detail Drawing For Inlet Compressor Filter Separator F-1011Pham LanphuongPas encore d'évaluation

- National Oil Corporation: Rev Date Description Checked ApprovedDocument21 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobPas encore d'évaluation

- HD Tanque ATM PDFDocument1 pageHD Tanque ATM PDFAtomic JPas encore d'évaluation

- Onshore Terminal For KG DWN 98/2 Development Project: Pramod KhotDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: Pramod Khotsumit kumarPas encore d'évaluation

- Limpet With Jacket Nozzle OrientationDocument1 pageLimpet With Jacket Nozzle OrientationArunkumar MyakalaPas encore d'évaluation

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADocument4 pagesMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanPas encore d'évaluation

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocument12 pagesSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoPas encore d'évaluation

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Document6 pages1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoPas encore d'évaluation

- Data Sheet For Flare Package (PK-720)Document3 pagesData Sheet For Flare Package (PK-720)samynatha PrasathPas encore d'évaluation

- 08572-Trht-Ms-Ppfm003-A06-003 - e General Arrangement Drawing Filtered Raw Water Storage TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-003 - e General Arrangement Drawing Filtered Raw Water Storage TankSamer ArousPas encore d'évaluation

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 pagesN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridPas encore d'évaluation

- Data Sheet WB RU VDocument5 pagesData Sheet WB RU VMaharani Putri IndrianurPas encore d'évaluation

- 1503F003ADocument6 pages1503F003AMinh Tường NguyễnPas encore d'évaluation

- Compress Report For Pressure VesselDocument394 pagesCompress Report For Pressure VesselgaurangPas encore d'évaluation

- PEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ADocument30 pagesPEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ARokan PipelinePas encore d'évaluation

- Data Sheet For T-8101.RevCDocument5 pagesData Sheet For T-8101.RevCSuresh SjPas encore d'évaluation

- Standard Specification 3-26-2: 1. GeneralDocument2 pagesStandard Specification 3-26-2: 1. Generalhlagos123Pas encore d'évaluation

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPPas encore d'évaluation

- VP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPDocument10 pagesVP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPMinh PhamPas encore d'évaluation

- WPS 7018+70S2Document5 pagesWPS 7018+70S2rajuPas encore d'évaluation

- 9Mm As Per DrawingDocument20 pages9Mm As Per DrawingGaurav PandeyPas encore d'évaluation

- Type of EquipmentDocument1 pageType of EquipmentGaurav PandeyPas encore d'évaluation

- 4 GP 1486 SKT 19Document1 page4 GP 1486 SKT 19Gaurav PandeyPas encore d'évaluation

- 8Mm As Per DrawingDocument20 pages8Mm As Per DrawingGaurav PandeyPas encore d'évaluation

- 2.13 Including Static HeadDocument19 pages2.13 Including Static HeadGaurav PandeyPas encore d'évaluation

- 501 G 108Document27 pages501 G 108Gaurav PandeyPas encore d'évaluation

- Elevated TemperatureDocument10 pagesElevated TemperatureVirgil SorcaruPas encore d'évaluation

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiPas encore d'évaluation

- FEA CAlDocument20 pagesFEA CAlGaurav PandeyPas encore d'évaluation

- Design of Tooth-Locked Quick Open-Die PR PDFDocument4 pagesDesign of Tooth-Locked Quick Open-Die PR PDFGaurav PandeyPas encore d'évaluation

- GI-0175-TDC-06 R0 For CS Plates - HIC Tested - Plate For Shell & HeadDocument3 pagesGI-0175-TDC-06 R0 For CS Plates - HIC Tested - Plate For Shell & HeadGaurav PandeyPas encore d'évaluation

- Technical Requirements For The Supply of Components in 6mo Austenitic, 22Cr Duplex and 25Cr Super Duplex Stainless SteelDocument45 pagesTechnical Requirements For The Supply of Components in 6mo Austenitic, 22Cr Duplex and 25Cr Super Duplex Stainless SteelGaurav PandeyPas encore d'évaluation

- Design Engineer JDDocument2 pagesDesign Engineer JDGaurav PandeyPas encore d'évaluation

- FRBD MES DL D2 067 - 804 V 01 - Rev.01 - Latest1 PDFDocument1 pageFRBD MES DL D2 067 - 804 V 01 - Rev.01 - Latest1 PDFGaurav PandeyPas encore d'évaluation

- Grand Prix Engineering PVT LTD: 2 17-May-2018 PPC Tpi-Dnv-Tuv-Abs-,Ll Oyds PLOT NO.82, SECTOR 25, FARIDABAD, 121004Document1 pageGrand Prix Engineering PVT LTD: 2 17-May-2018 PPC Tpi-Dnv-Tuv-Abs-,Ll Oyds PLOT NO.82, SECTOR 25, FARIDABAD, 121004Gaurav PandeyPas encore d'évaluation

- Technical Requirements For The Supply of Components in 6mo Austenitic, 22Cr Duplex and 25Cr Super Duplex Stainless SteelDocument45 pagesTechnical Requirements For The Supply of Components in 6mo Austenitic, 22Cr Duplex and 25Cr Super Duplex Stainless SteelGaurav PandeyPas encore d'évaluation

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Document14 pagesSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITPas encore d'évaluation

- Wash ColumnDocument10 pagesWash ColumnAna Mariel VenturaPas encore d'évaluation

- L2. Closure To Effect of Bentonite Slurry Pressure On Interface Friction of Pipe Jacking by Mucahit Namli and Erol GulerDocument4 pagesL2. Closure To Effect of Bentonite Slurry Pressure On Interface Friction of Pipe Jacking by Mucahit Namli and Erol GulerAna Maria Garcia EscandonPas encore d'évaluation

- Water Filteration Summary 1Document2 pagesWater Filteration Summary 1api-526691999Pas encore d'évaluation

- Basket FilterDocument1 pageBasket FilterShreya TrikhaPas encore d'évaluation

- NB20003 Mechanical Separation 2018Document30 pagesNB20003 Mechanical Separation 2018Jing Yi PangPas encore d'évaluation

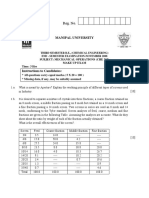

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- Drinking Water Treatment MethodsDocument9 pagesDrinking Water Treatment MethodsCretu DanPas encore d'évaluation

- Eaton BECO Standard Range TechnicalDataSheet enDocument4 pagesEaton BECO Standard Range TechnicalDataSheet enElio Tueros melgaPas encore d'évaluation

- Are1024 (Eng) CH07Document62 pagesAre1024 (Eng) CH07AmiRul SaLimi SAyutiPas encore d'évaluation

- SESSION - 2021-22 Revision Booklet Term - I Science Grade - 6Document17 pagesSESSION - 2021-22 Revision Booklet Term - I Science Grade - 6hasneekPas encore d'évaluation

- Glycol PumpsDocument13 pagesGlycol PumpsJackPas encore d'évaluation

- BS en 12461-1998 - (2018-06-27 - 04-42-12 Am)Document14 pagesBS en 12461-1998 - (2018-06-27 - 04-42-12 Am)Rankie ChoiPas encore d'évaluation

- FMP Series: High Pressure Fi LtersDocument14 pagesFMP Series: High Pressure Fi LtersДаниіл ЩигельськийPas encore d'évaluation

- 1296 Stock Report 26-01-2020 PDFDocument20 pages1296 Stock Report 26-01-2020 PDFSANJAY KUMAR SINGHPas encore d'évaluation

- Solubility Lab ReportDocument3 pagesSolubility Lab ReportJampathippong SorraveePas encore d'évaluation

- Science-PT Research PaperDocument12 pagesScience-PT Research PaperMarv SaysonPas encore d'évaluation

- Sewerage System Enviornmental EngineeringDocument32 pagesSewerage System Enviornmental EngineeringShivam SharmaPas encore d'évaluation

- A Risk-Based Approach To Setting Sterile FiltrationDocument10 pagesA Risk-Based Approach To Setting Sterile FiltrationAngus CHUPas encore d'évaluation

- Gove Operations Process Flow Single PageDocument4 pagesGove Operations Process Flow Single PageMayke Cezar WippelPas encore d'évaluation

- 1790 Visual Inspection of InjectionsDocument20 pages1790 Visual Inspection of InjectionsAbdelkarim Belkebir100% (2)

- 230120164K1UN4PKEIAReport PDFDocument74 pages230120164K1UN4PKEIAReport PDFVinay kumarPas encore d'évaluation

- RPT Ms BRG HM 1000Document1 pageRPT Ms BRG HM 1000kemrosokkPas encore d'évaluation

- ch.9 Slurry Displacement PilesDocument47 pagesch.9 Slurry Displacement PilesGiovanni ArangoPas encore d'évaluation

- Yeast ProductionDocument35 pagesYeast ProductionVu Hong ThangPas encore d'évaluation

- 10 PDFDocument5 pages10 PDFIndira BanerjeePas encore d'évaluation

- Activity 2Document6 pagesActivity 2yancysalinas.bermasPas encore d'évaluation

- Erbslöh Beer Compendium: Good Beer Demands The Best IngredientsDocument12 pagesErbslöh Beer Compendium: Good Beer Demands The Best IngredientsMarius NazarePas encore d'évaluation

- Report #2: The Disc FiltersDocument8 pagesReport #2: The Disc FiltersAli SharifPas encore d'évaluation

- Commissioning Report - FILTERDocument9 pagesCommissioning Report - FILTERGrace PentinioPas encore d'évaluation