Académique Documents

Professionnel Documents

Culture Documents

Method Statement For Installation of Fire Pump Set: Document Approval

Transféré par

Jayya PrakashTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Method Statement For Installation of Fire Pump Set: Document Approval

Transféré par

Jayya PrakashDroits d'auteur :

Formats disponibles

Method Statement for Installation of Fire Pump set

Document Approval:

Responsible Name Signature Date

Prepared by

Reviewed by

Approved by

1. Reference

Mechanical Specification volume-3-part-3 ( Section 6.15 Page 142/174,143/174,144/174).

2. Purpose

This method statement provides a standardized framework for the installation of GRP Water tank to ensure

compliance with the conditions of contract and contract specification.

3. Scope

This method statement is prepared to describe the method by which ARJ ENGINEERING L.L.C intends to

execute the installation of GRP Water tank.

4. Plant and Equipment

In order to carry out the scope of work, appropriate machinery, plant and equipment shall be used as

mentioned below

No Description Quantity

As per site

1. Drill Machine

requirement

2. Adjustable wrench ,,

3. Tool Box Set ,,

4. Bolts and nuts, washers ,,

Document ref.#: ARP-P083-MS-PL-____ Rev.0

Document ref.#: ARJ-PJ227-MS-PL-017 Rev.0

Page 1 of 3

©2009 Al RostamaniPegel LLC

5. Materials

No Description Specification Source MSD available

1 GRP Storage Tank

2 Access ladders. Mechanical

Specification

3 Ball float Valves, Automatic admittance vent valves volume-3-

part-3

Strainers & Flanges, studded pads ,pipe fittings, (Section 6.15

4

gasket of synthetic rubber, tie rods. Page

142/174,143/

5 Man holes, tank covers. 174,144/174).

6 Glass tube level indicator

7 Float Switches.

6. Human Resources

No Job function Quantity Special competencies/skills

1 Velmurugan Project Engineer

2 Babu Samuel Supervisor

7. Work Methodology

7.1 Storage

7.1.1 GRP water tank be stored on a flat surface in well ventilated storage area.

7.1.2 Inlet and outlet flange blanks shall not be removed until ready for connection to pipe work.

7.1.3 Manufacturer’s instructions shall be strictly followed as applicable.

7.1.4 The stored GRP water tank are to be inspected periodically for obvious conditions such as

standing water, parts theft, excess dirt build up or any other abnormal condition.

7.1.5 Storekeeper will be responsible for proper storage and maintenance of records, as required.

7.2 Preparation

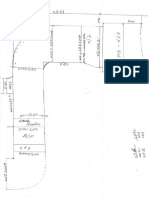

7.2.1 The GRP Water tank foundation shall be as per approved Drawings and details.

7.2.2 Check and ensure that the shop drawings used are latest and approved for construction.

7.2.3 ARJ will coordinate the location of foundation as per approved shop drawings.

7.2.4 The foundation surface shall be flat and level and smoothly finished top surface.

7.2.5 Check the piping support locations in coordination with piping layout and ensure they are not

obstruction the space around tank.

7.2.6 Ensure easy access and sufficient clearance for servicing and maintenance i.e. for replacement of

GRP Water tanks.

Document ref.#: ARP-P083-MS-PL-____ Rev.0

Document ref.#: ARJ-PJ227-MS-PL-017 Rev.0

Page 2 of 3

©2009 Al RostamaniPegel LLC

7.3 Installation

7.3.1 GRP Water tanks shall be installed on the concrete beams as per approved foundation drawings,

ensure adequate space is available for valves ,piping and for future maintenance.

7.3.2 Steel skid base shall be fixed on the concrete beams.

7.3.3 Drill the suitable size holes in the Foundations.

7.3.4 The tanks and the other associated accessories including the piping manifold are pre-assembled

on a steel skid base. Shift the water tanks to the place of installation in safe manner. Use fork-

lift / crane as applicable / required as per site conditions.

7.3.5 Position the water tank frame assembly on the foundation and fix the anchor fasteners.

7.3.6 Steel skid base shall be leveled properly as required to drain off the tanks water.

7.3.7. Side panels shall be installed on the base panels.

7.3.8. Gasket shall be put in between the panels for preventing water leakage from joints.

7.3.9. Tank panels should be jointed as per manufacturers recommendations by bolts.

7.3.10 locations of the panels for inlet, outlet, drain &overflow pipe shall be as per approved shop

drawing.

7.3.11 Installation of the internal accessories is carried out after side panels installation.

7.3.12 panels shall be tied internally by steel tie rod for side panels reinforcement and externally by

stay plates as per manufacture's recommendations.

7.3.13 Inlet, outlet, drain& overflow nozzles shall be connected to tanks with flange connection.

7.3.14 UPVC pipe support shall be provided for roof panels block supports.

7.3.15 ladder shall provided externally and internally.

7.3.16 All nut bolts to be securely tide with washer.

7.3.17 Air vent shall be installed on each tanks.

7.3.18 Tanks shall be allowed for water leak test as per manufacture's recommendations.

7.3.19 For testing, all openings shall be closed, water shall be filled in the tanks by temporary water

supply line .

7.3.20 water shall be kept inside the tanks for 24 hours an leak shall be checked ,if any leak found, it

shall be rectified and again offered for the same for consultant approval.

8. Inspection

8.1 After the GRP storage tanks installation consultant shall inspect the complete .

8.2 Request for inspection shall be raised for consultant’s inspection.

9 Health, Safety and Environmental Risk

Please refer the attached Risk Assessment

10 Records

The following records shall be maintained as documentary evidence of the establishment of the Method

Statement.

Minimum retention

Record no. & name Responsibility Disposition

period

Site Engineer/MEP

Request for Inspection

Coordinator

Site Engineer/MEP

Test Reports

Coordinator

------------------------------------------

Document ref.#: ARP-P083-MS-PL-____ Rev.0

Document ref.#: ARJ-PJ227-MS-PL-017 Rev.0

Page 3 of 3

©2009 Al RostamaniPegel LLC

Vous aimerez peut-être aussi

- Compliance Statement: Project: P085/R533 Jumeirah Plot D DevelopmentDocument2 pagesCompliance Statement: Project: P085/R533 Jumeirah Plot D DevelopmentJayya PrakashPas encore d'évaluation

- Block B 1 20.02.17 As Per ShopdrwDocument1 pageBlock B 1 20.02.17 As Per ShopdrwJayya PrakashPas encore d'évaluation

- Ducting For 5th Floor Supply2Document9 pagesDucting For 5th Floor Supply2Jayya PrakashPas encore d'évaluation

- 04-06-2017Document5 pages04-06-2017Jayya PrakashPas encore d'évaluation

- A.R.J. ENGINEERING L.L.C - Project: - Golden Tulip Hotel (PJ-223) (21AUGUST To 20 SEPTEMBER) 2016Document15 pagesA.R.J. ENGINEERING L.L.C - Project: - Golden Tulip Hotel (PJ-223) (21AUGUST To 20 SEPTEMBER) 2016Jayya PrakashPas encore d'évaluation

- Big TicketDocument1 pageBig TicketJayya PrakashPas encore d'évaluation

- Abdul Aleem CV - Updated Autocad 2017Document4 pagesAbdul Aleem CV - Updated Autocad 2017Jayya PrakashPas encore d'évaluation

- 01-WIS5 Terms 306Document30 pages01-WIS5 Terms 306Jayya PrakashPas encore d'évaluation

- CSWIP 3.1 Welding InspectionDocument12 pagesCSWIP 3.1 Welding InspectionJayya PrakashPas encore d'évaluation

- IRCTC LTD, Booked Ticket PrintingDocument2 pagesIRCTC LTD, Booked Ticket PrintingJayya PrakashPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- British Std. 3293-1960Document18 pagesBritish Std. 3293-1960Ranjan KumarPas encore d'évaluation

- Chilled Water DistibutionDocument56 pagesChilled Water DistibutionorganicspolybondPas encore d'évaluation

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaPas encore d'évaluation

- Gaskets: Frame Plate End Plate II Channel Plates End Plate I Pressure PlateDocument3 pagesGaskets: Frame Plate End Plate II Channel Plates End Plate I Pressure PlateSergei KurpishPas encore d'évaluation

- Installation, Assembly and Test Procedure: Kamos Patented Kammprofil GasketDocument16 pagesInstallation, Assembly and Test Procedure: Kamos Patented Kammprofil Gasketjayhuacat7743Pas encore d'évaluation

- Turbashed EmersonDocument2 pagesTurbashed EmersonGERARDO JARDON ZAMBRNOPas encore d'évaluation

- Maschio Gaspardo SeeddrillsDocument9 pagesMaschio Gaspardo SeeddrillsAnonymous 1XBCMXPas encore d'évaluation

- BOQ - Firefighting WorkDocument22 pagesBOQ - Firefighting WorkDIGAMBAR SINGHPas encore d'évaluation

- D 100017 X 012Document24 pagesD 100017 X 012ErnestoPas encore d'évaluation

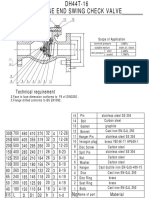

- Flanged End Swing Check Valves DIN3202 F6Document2 pagesFlanged End Swing Check Valves DIN3202 F6AndiniPermanaPas encore d'évaluation

- Specs Sheet Duplicate 9655021-3-4 & AD993180Document8 pagesSpecs Sheet Duplicate 9655021-3-4 & AD993180Fathan KarimanPas encore d'évaluation

- Doublepipe and Multipipe Heat ExchangerDocument21 pagesDoublepipe and Multipipe Heat Exchangerpec21102002Pas encore d'évaluation

- Piping Course هام جداDocument206 pagesPiping Course هام جداMohamed Ibrahim100% (1)

- Ref Data Guide Help 409Document352 pagesRef Data Guide Help 409vasu_msa123Pas encore d'évaluation

- SDG100S 3a1 3a5Document66 pagesSDG100S 3a1 3a5КонстантинPas encore d'évaluation

- Cummins KTA19 Engine Spare Parts Catalog: Part Number DescriptionDocument22 pagesCummins KTA19 Engine Spare Parts Catalog: Part Number Descriptionsaeedt538100% (1)

- Ef1000b 7XD2 2003Document25 pagesEf1000b 7XD2 2003CRISTIAN BARRIOSPas encore d'évaluation

- Design of A Shell and Tube Heat Exchanger Ijariie6039Document15 pagesDesign of A Shell and Tube Heat Exchanger Ijariie6039Evans Azka FPas encore d'évaluation

- AAHE Bibo BrochureDocument16 pagesAAHE Bibo BrochureBANGUN RAHMAT TEKNIKPas encore d'évaluation

- Stubbe DHV-712 Pressure Relief Valve Operating and Maintenace Instructions ManualDocument12 pagesStubbe DHV-712 Pressure Relief Valve Operating and Maintenace Instructions ManualTrEnD SeT vicky rioPas encore d'évaluation

- Engine Mechanical: SectionDocument156 pagesEngine Mechanical: SectionAutoservicio FullerPas encore d'évaluation

- Automotive Servicing Grade 11: TVL/Industrial ArtsDocument10 pagesAutomotive Servicing Grade 11: TVL/Industrial ArtsOliver Talip100% (2)

- Placing Concrete by Pumping Methods: ACI 304.2R-96Document25 pagesPlacing Concrete by Pumping Methods: ACI 304.2R-96منير أحمدPas encore d'évaluation

- EmishieldingDocument225 pagesEmishieldingBurak KarakaşPas encore d'évaluation

- Escorts Construction Equipment: Parts CatalogueDocument392 pagesEscorts Construction Equipment: Parts CatalogueMM SparesPas encore d'évaluation

- Hop So Clack 4261309 - 15.5HR36432-18 - TPL-1298 - 2015-09-28Document74 pagesHop So Clack 4261309 - 15.5HR36432-18 - TPL-1298 - 2015-09-28ANH LÊPas encore d'évaluation

- Emission Measurements of Industrial Valves According To TA Luft and en ISO 15848-1-Riedl - LRDocument3 pagesEmission Measurements of Industrial Valves According To TA Luft and en ISO 15848-1-Riedl - LRnelshingodoiPas encore d'évaluation

- Manual Peças 935HDocument143 pagesManual Peças 935HWeverton PereiraPas encore d'évaluation

- Shaft SinkingDocument10 pagesShaft SinkingAnonymous 340A7vnwV1Pas encore d'évaluation

- JIS Standard Table GasketsDocument4 pagesJIS Standard Table GasketsDaoPas encore d'évaluation