Académique Documents

Professionnel Documents

Culture Documents

WallSystems PDF

Transféré par

Eiz Zu DeenDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WallSystems PDF

Transféré par

Eiz Zu DeenDroits d'auteur :

Formats disponibles

Bars G2 (evenly spaced) Backfill

Bars F

4" Min.

Bars A (F.S.) Front Face

of Wall

Bars A (paired with Bars J)

Wall Cover

(Typ.)

H eight Bars G2 (evenly

H eight

spaced)

Bars F (N.S.) Slope

NOTE:

Backwall

See Plans for Retaining Wall Data

Bars J & K

Bars K (F.S.)

Dsoil

(1’-0" Min.) Const. Jt.

L Bars H

toe

Bars M (N.S.) Bars J (F.S.) Footing Cover (Typ.)

D

D

A

key

key

Bars Z (N.S.)

dgn

*D

*D

\d\projects\standards\structures\current\ready4release\2012book_draft\06010-1of2.

Bars G1

Bars H Bars G1

L *L Footing Cover (bottom only)

Bars Z toe key

(Showing Near Side) (Showing Far Side)

Bars M (paired with Bars F)

L

VIEW A-A foot

(Shear key shown dashed)

* Shear Key is required only when

specified by the Engineer

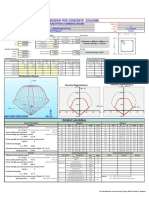

TYPICAL SECTION

NOTES

DESIGN SPECIFICATIONS:

Design according to FDOT Structures Manual (current edition).

BENDING DIAGRAM

MATERIALS:

Total Length

All reinforcing steel shall conform to ASTM A615 Grade 60.

1’-0" Lap Splice (Typ.)

SURFACE FINISH:

A Class 5 Applied Finish Coating shall be applied to the top of the wall and the exposed face above ground line.

ARCHITECTURAL SURFACE TEXTURES:

Alternate Architectural Surface Textures may be substituted for the Striated Pattern shown when approved by the Engineer. BARS G1

Concrete required for Architectural Surface Textures is not included in the quantities.

C:

TRAFFIC RAILING BARRIER: 1

If there is a Traffic Railing Barrier on the wall, Wall Joints and Barrier V-Grooves shall align and Wall Expansion Joints

and Barrier Open Joints shall align.

A

Slope

rd960rh

Backwall

FOUNDATION: Prepare the soil below the footing in accordance with the requirements for spread footings in Specification

A

Section 455. 90

PAYMENT:

41 AM

B B

All Retaining Wall costs, including all miscellaneous costs, shall be paid for at the unit contract price for

34:

either Class II, III or IV Concrete (Retaining Walls) (CY) and Reinforcing Steel (Retaining Walls) (lbs.).

9:

Retaining Wall quantities shall not include concrete nor reinforcing steel for Traffic Railings/Junction Slab. BARS J & K BARS M

Traffic Railing/Junction Slab shall be paid for under Concrete Traffic Railing Barrier with Junction Slab. NOTE:

12/30/2011

All bar dimensions are out-to-out

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

C-I-P CANTILEVER RETAINING WALL

01/01/11 FY 2012/2013 6010 1

**Wall joint spacing 25 ft. maximum.

At minimum, every fourth wall joint

to be an expansion joint. W

**Wall Joint Spacing »¿˘" V-Groove across top and »¿˘" x ˘" chamfers (

See Plans for actual wall joint spacing

front face of wall at joint (Typ.).

and expansion joint location.

Extend V-Groove down back of wall

All exposed wall surfaces 6" to 6" min. below ground.

6"

shall receive a Class 5 (see ’V-Groove Detail’)

Applied Finish Coating A

»¿˘" V-Gr

(see ’V-Groove Detail)

Wall Joint

A B B

(required at footing step)

Thickness of form liner

Ground Line (including striations)

6" 6"

Const. Joint permitted

SECTION A-A Top of Footing

(keyway not required)

)

-0" M ax.

D

Top of Footing

Thickness of form liner

step

Level (Typ.)

Striated Surface shall (including striations)

2’

1’-0"

V

consist of uniform vertical

»¿˘" V-Gr

(

3" PVC Drain Pipe at »¿grooves of ˘" t 6" 6" (see ’V-Groove

10 ft. max. spacing (Typ.) See ’Detail A’

At Contractor’s option, depth and spacing

Detail’)

See ’Typical Backfill Detail’

D

Striations may terminate at

6" min. below ground line

Traffic Railing (Index No. 420,

Bars R Optional Shear Key

32" F-Shape shown, see Plans Wall Joint

FRONT ELEVATION Stem Offset (paired with

for Traffic Railing type)

Bars G1)

Top of Coping Stem as constructed

Junction Slab (See Vertical Line

Index Series 6100) SECTION B-B DETAIL A

Top of Front Face

dgn

CIP Wall

\d\projects\standards\structures\current\ready4release\2012book_draft\06010-2of2.

of Wall

-3"

45 (Typ.) Stem Offset (in.) = H(Ft.)/16

9" 1’

H eight Varies

H

Front Face »¿ Wall

of Wall

6"

»

1 b" »¿˘" V-Groove (T

(see ’V-Groove Detail’)

» ¿

4"

»

Bars D @ 1’-0"

"

(Max. spacing)

Varies

V-GROOVE DETAIL STEM OFFSET VALUES

4"

» ¿*

( for H < 20 Ft.) Front Face

of Wall

4

»

TRAFFIC RAILING/JUNCTION SLAB DETAIL

"

Bars D

V

(32" F-Shape Shown, other Traffic Railings similar)

a

»¿

r

(field bend)

ie

»¿

Varies

(for 32" F-Shape Traffic Railing (as shown), see Index No. 420;

s

Backfill layers to be sloped both 9"

for 32" Vertical Shape Traffic Railing, see Index No. 423;

transversely and longitudinally as

for 42" Vertical Shape Traffic Railing, see Index No. 422)

necessary to drain and prevent TYPICAL CORNER JOINT DETAIL

ponding during backfilling.

WALL JOINT DETAIL

Front Face of Wall See Roadway Plans for Backfilling shall comply with

*Key to stop at top of footing and 6" from top of wall.

drainage requirement FDOT Specifications.

Joint across footing and top of wall to be straight line.

3" PVC Drain Pipe. Slope down

b" from back to front of wall

»¿ Wall

and extend b" beyond both Front Face

of Wall 1 b"

front face and back face of wall.

C:

» ¿

b" Preformed Joint Filler

»

Bars D @ 1’-0"

(Max. spacing)

1" Cl.

rd960rh

Excavation shall comply with

4"

FDOT Specifications.

» ¿*

Final Groundline. Plastic sleeve

»

Drain shall be continuous 1.5’ x 1.5’ clean, broken stone or gravel,

»

41 AM

Varies

Inside ends of weep holes graded and placed to allow free drainage.

shall be covered with 1.0 Place geotextile fabric, meeting requirements of FDOT Specification

34:

»¿

Geotextile fabric, 1’-0" wide and full height of fill,

985 and Type D-3 of Index No. 199, around the perimeter to 9"

9:

square foot of galvanized

meeting requirements of Specification 985

»¿mesh with ˘" open prevent fill from washing out.

and Type D-5 of Index No. 199.

EXPANSION JOINT DETAIL Apply an adhesive approved by the Engineer to

12/30/2011

TYPICAL BACKFILL DETAIL

the back of wall for attachment of fabric material.

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

C-I-P CANTILEVER RETAINING WALL

01/01/11 FY 2012/2013 6010 2

GENERAL NOTES

:1 s

1 ie

r

1. Gravity walls constructed as extensions of reinforced

a

ESTIMATED QUANTITIES FOR WALL

V

Bars B concrete retaining walls, except walls of proprietary

8"

.

e

x

p

(Typ.)

lo

a

designs, shall have the same face texture and finish

M

PER LINEAR FOOT OF WALL

S

WEEP as the reinforced concrete retaining wall.

3"

»¿˘" Cha HEIGHT HOLES

»¿ ˘" V- CLASS NS CONCRETE (CY) REINF. 2. Concrete for Gravity Wall shall be Class NS per Section 347.

(Typ.) (FT.) & DRAIN Concrete for Scheme 3 Junction Slab and Traffic Railing shall

STEEL

6"

General Note 5)

SCHEME SCHEME SCHEME REQD.

Joint Seal, see

(LB.) be Class II per Section 346, unless otherwise specified in

3" Cl.

1 2 3

the plans.

3. Reinforcing steel shall be ASTM A615, Grade 40 or 60

-0"

1’ 0.08 0.11 (0.20*) 0.03 3 (4*) No

provided at the max. spacings shown. ASTM A185 Smooth or

1’

Joint Seal

2’ 0.14 0.20 (0.32*) 0.09 4 (5*) No

ASTM A497 Deformed Welded Wire Reinforcement (WWR) may be

3" Cl.

)

Typ.

M ax.

)

W all Joints equally spaced

-0" M ax.

4b" 3’ 0.22 0.32 (0.47*) 0.29 5 (6*) Yes substituted on an equal area basis. Do not increase bar/wire

9"

spacing for Grade 60 reinforcing steel or WWR.

(

Varies

(

4’ 0.32 0.47 (0.65*) 0.43 6 (7*) Yes

3" Cl. Bar A 4. When required, for adjunct guiderail see the plans,

Bars A (Typ.)

(Typ.) 5’ 0.43 0.65 (0.85*) 0.60 7 (8*) Yes Index No. 870 or 880 as appropriate. For adjunct Type B

Keyway

5’

)

-6" sp.

30’M ax.

12

Bars B @

Bar B fence see Index No. 802.

H eight (

5. Joint seal to be two layers of 30# smooth roofing paper

ESTIMATED QUANTITIES NOTES:

or Type D-5 geotextile fabric in accordance with Index

1’

8" Varies 6"

) No. 199. Mop all contact surfaces of concrete and roofing

p.

(

For Scheme 3 Junction Slab and Traffic Railing see the

Ground Ty

( paper or geotextile fabric with cut-back asphalt. Stop

referenced Design Standards for estimated quantities.

Surface Bars A & roofing paper or geotextile fabric 6" below top of wall).

M ax.

» ¿

General Note 5)

Joint Seal, see

B @ 1’-6"

9"

» »¿ » 6. Provide a continuous 1’x1’ clean gravel or crushed rock

1" Cl. * Quantity for 2’-0" Toe Depth in Scheme 2.

Ctrs. (Max.) drain for wall heights 3 ft. and higher. Wrap drainage layer

Weep

-0"

as shown, with Type D-3 geotextile fabric in accordance

Hole

with Index No. 199. Provide 8"x8" galvanized mesh with

1’

Depth)

Varies

»¿ ˘" openings, at the inside end of the PVC Drain P

Drainage Layer

Toe

Provide 2" PVC Drain Pipe (Sch. 40) at 10 ft. max.

One layer And PVC Drain

(

4b"

(

spacing (When Drainage Layer required). Locate minimum

of 30# Smooth (See Note 6)

2’-0" clear of wall joints.

Roofing Paper

7. Cost of reinforcing steel, face texture, finish, joint seal,

(Typ.) 6" Cl. (– 2" Prepare Foundation Per drain pipes, drainage layer, galvanized mesh and geotextile

dgn

Tolerance) Spec. 455 (Spread Footings) fabric to be included in the Contract Unit Price for Concrete

\d\projects\standards\structures\current\ready4release\2012book_draft\06011-1of1.

Class NS, Gravity Wall. Cost of concrete for Junction Slab in

Scheme 3, to be included in Contract Unit Price for Concrete

KEYWAY & WALL JOINT DETAIL

TYPICAL SECTION Traffic Railing Barrier With Junction Slab. Adjunct railings or

(TOP VIEW)

fences to be paid for separately.

BILL OF REINFORCING STEEL

MARK SIZE LENGTH

A 4 As Reqd.

Edge of paved shoulder B 4 As Reqd.

1:1b < Slopes = 1:1 3’-6" Min. Offset or face of curb Traffic Railing (Index No. 420,

1:6 < Slopes = 1:1b 32" F-Shape shown, see Plans

Edge of paved shoulder 3’-6" = Offset < 7’-3"

or face of curb

for Traffic Railing type) BAR BENDING DIAGRAM

Slopes = 1:6 3’-6" = Offset < 6’-6"

1:6 < Slopes = 1:1b 7’-3" Min. offset 3b"

Scheme 3

Live Load Limit Scheme 1 & 2

Slopes = 1:6 6’-6" Min. offset

Live Load Limit

1

-0"

Soil Reinforcement

"

See General Wall Joint spacing - 4"

H eight + Toe Depth - 9"

R

H eight + Toe Depth - 2’

.

Note 4 when required Junction Slab (See (29’-8" Max.)

Top of

See General (See Plans) Index Series 6100)

Coping

Note 4

C:

-3"

BAR A

)

5’M ax.

1’

Slopes up Slopes up

to Max. 1:1 to Max. 1:1

rd960rh

H eight (

1’-0" Min. to SHW

)

9

5’M ax.

5’M ax.

H eight

H eight

(Except for slopes 1’-0" Min. to SHW

1’-0" For Slopes = 1:1b for Wall Height = 2’-0" 9" 12

steeper than 1:2

2’-0" For Slopes > 1:1b 2’-0" Min. to SHW

with wall heights > 3’, 5 9

(

then 2’-0" Min.) for Wall Height > 2’-0"

42 AM

12 1’-0" Min. 12

to SHW NOTES:

34:

1. All bar dimensions are BAR B

9:

out to out.

1’-0" 1’-0" For Wall Height = 2’-0"

2. Lap splices for Bars A

SCHEME 1 SCHEME 2 2’-0" For Wall Height > 2’-0" SCHEME 3

12/30/2011

must be a minimum of 1’-6".

(No Traffic Loading Effects) (With Traffic Loading or Slopes > 1:1b) (With Traffic Railing)

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

C-I-P GRAVITY WALL

01/01/11 FY 2012/2013 6011 1

C-I-P Traffic Railing

NOTES Limit of Class 5

Applied Finish Coating

SPECIFICATIONS:

C-I-P Junction Slab

1. General Specifications: 9. All exposed concrete surfaces will receive a Class 5 Applied Finish Coating Top of Shoulder or

(See Index Series

The Florida Department of Transportation "Standard Specifications for Road in accordance with Specification Section 400. Refer to Typical Section on Coping Elevation Roadway Pavement

6100)

and Bridge Construction", Current Edition and Supplements as Amended. this sheet and the following notes for limits of applied finish:

2. Design Specifications: a. The inside, backside and top of Traffic Railings and Pedestrian/Bicycle

a. Florida Department of Transportation (FDOT) "Structures Design Guidelines", Railings. Concrete Coping

Current Edition. b. Exposed surfaces of coping on top of retaining wall. Other coatings,

b. American Association of State Highway and Transportation Officials (AASHTO) colors or textures will be applied as required in the Wall Control

"LRFD Bridge Design Specifications", Current Edition. Drawings.

Soil Reinforcement (Typ.)

c. AASHTO-AGC-ARTBA Task Force 27 (Ground Modification Techniques), 10. For concrete facing panel surface treatment, see Wall Control Drawings.

"Insitu Soil Improvement Techniques", January 1990. Extend surface treatment a minimum of 6" below final ground line.

11. Drive piles located within the soil volume prior to construction of the Surface treatment when

DESIGN CRITERIA: retaining wall, unless a method to protect the structure, acceptable to both required (See Construction

1. Design is based on the assumption that the material contained within the the Engineer and Wall Company, is proposed and approved in writing. The Note 10) Limits of

reinforced soil volume, methods of construction and quality of prefabricated portion of piles or drilled shafts extensions within the soil volume will be Soil Volume

materials are in accordance with Specification Section 548 and Chapter 3 wrapped with polyethylene sheeting in accordance with Specification 1’-0" Min.

4’-0" Min.

of the FDOT Structures Design Guidelines. Section 459.

2. It is the responsibility of the Engineer of Record to determine that the 12. A structural extension of the connection of the retaining wall panel to soil

Proposed Final

maximum factored bearing pressure shown for the wall does not exceed reinforcement will be used whenever necessary to avoid cutting or excessive

Ground Line

the factored bearing resistance of the foundation for that specific wall location. skewing (greater than 15) of the soil reinforcement around obstructions

3. The Wall Company is responsible for internal stability of the wall. External (i.e., piles, pipes, manholes, drop inlets, etc.).

stability design, including foundation and slope stability, is the responsibility 13. Steps in leveling pads will occur at MSE Wall panel interfaces. Panels will not

of the Engineer of Record. cantilever more than 2" past the end of the upper tier leveling pad.

Top of

4. If there are manholes and/ or drop inlets present, design and analysis for both 14. The top of the leveling pad or footing will be 2’-0" minimum below final

Leveling Pad

internal and external stability shall be considered. ground line.

2’-0" Min. Elevation

15. Top of leveling pad elevations shown in the Wall Control Drawings are maximum

Interior Face of

SOIL PARAMETERS: elevations. The constructed leveling pad elevations may be deeper based on

Concrete Leveling Pad Concrete Facing Panels

1. See Wall Control Drawings for soil characteristics of foundation material to be the panel layout shown in the shop drawings.

used in the design of the wall system. 16. The height of panels in the bottom course of MSE Walls must not be less

dgn

2. The Contractor will provide soil design parameters for backfill material based than half the height of a standard panel. TYPICAL MSE RETAINING WALL SECTION

\d\projects\standards\structures\current\ready4release\2012book_draft\06020-1of1.

on the actual soil characteristics utilized at the site. 17. Work this Index with Index 6100 & 6200 Series. WITH A TRAFFIC RAILING

(Showing Limits of the Reinforced Soil Volume)

MATERIALS: SHOP DRAWING REQUIREMENTS:

1. Concrete Class: See Wall Control Drawings. See Specification Section 548 for shop drawing requirements.

2. See Specification Section 548 for material requirements.

3. For additional material requirements see the Wall Company’s General Notes.

10’-0" min. C.I.P. Coping 12’-0" min. Precast Coping/Traffic Railing

CONSTRUCTION:

1. Walls will be constructed in accordance with Specification Section 548 and

the Wall Company’s instructions. 12" 2’-0" 6"

2. For location and alignment of retaining walls, see Wall Control Drawings. Coping

Top of Coping

3. If present, consider in design and analysis and locate manholes and drop Transition

inlets as shown on wall elevations.

FDOT MSE RETAINING WALL CLASSIFICATION TABLE

4. Refer to Wall Control Drawings of individual walls for minimum reinforcement

strip/mesh length, factored bearing resistance’s, minimum wall embedment Durability Requirements Other Allowable FDOT Wall Types

Precast

Coping

Coping

P.

-0"

-3"

and anticipated long term and differential settlements.

I.

Applicable Concrete Concrete Pozzolan Soil

2’

2’

C.

5. The Contractor is responsible for controlling water during storm events as

needed during construction. FDOT Wall Cover Class Additions? Reinforcement 2A 2B 2C 2D 2E 2F

6. It is the Contractor’s responsibility to determine the location of any Type * (in.) for Panels ** Type

guardrail posts behind retaining wall panels. Prior to placement of the top

layer of soil reinforcement, individual reinforcing strips/mesh may be Type 2A 2 II No Metal

3"

skewed (15 maximum) to avoid the post locations if authorized by b" Preformed

Type 2B 2 IV No Metal

the Engineer. No cutting of soil reinforcement is allowed unless shown Joint Filler

on Shop Drawings and approved by the Engineer. Any damage done to Provide Supplemental Type 2C 3 IV No Metal

C:

the soil reinforcement due to installation of the guardrail will be repaired #4 Bar with 3" concrete Type 2D 3 IV Yes Metal

by the Contractor at the Contractor’s expense. Repair method will be cover

approved by the Engineer. Type 2E 3 IV No Plastic

7. If existing or future structures, pipes, foundations or guardrail posts Type 2F 3 IV Yes Plastic

rd960rh

within the reinforced soil volume interfere with the normal placement of ELEVATION VIEW OF

soil reinforcement and specific directions have not been provided on the * See Data Table in Contract Plans.

COPING HEIGHT TRANSITION

plans, the Contractor will notify the Engineer to determine what course ** Silica fume, metakaolin or ultrafine fly ash.

of action shall be taken.

(Railing Not Shown For Clarity)

8. The Contractor is responsible for gradually displacing upper layer(s) of

46 AM

soil reinforcement downward (15 maximum from horizontal) to avoid

34:

cutting soil reinforcement and conflicts with paving and subgrade preparation.

9:

The Contractor’s attention is directed especially to situations where roadway

superelevation and/or soil mixing are anticipated.

12/30/2011

GENERAL NOTES AND DETAILS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

PERMANENT MSE RETAINING WALL SYSTEMS

01/01/12 FY 2012/2013 6020 1

NOTES

SPECIFICATIONS:

1. General Specifications:

The Florida Department of Transportation "Standard Specifications for

Road and Bridge Construction", Current Edition and Supplements as

Amended.

Secondary Reinforcement

2. Design Specifications:

Top of Wall as required

a. Florida Department of Transportation (FDOT) "Structures Design

Guidelines", Current Edition.

b. American Association of State Highway and Transportation Officials

(AASHTO) "LRFD Bridge Design Specifications", Current Edition. Primary Reinforcement

c. AASHTO-AGC-ARTBA Task Force 27 (Ground Modification Techniques),

"Insitu Soil Improvement Techniques", January 1990.

Reinforced

Fill

DESIGN CRITERIA:

1. Design is based on the assumption that the material contained within the

reinforced soil volume, methods of construction and quality of prefabricated

Geotextile Wrap

materials are in accordance with Specification Section 548 and FDOT

Structures Design Guidelines Section 3.13.2. Wire Facing

Limits of

2. It is the responsibility of the Engineer to determine that the factored or Basket

Soil Volume

bearing pressure shown for the wall does not exceed the factored

bearing resistance of the foundation for that specific wall location.

3. The Wall Company is responsible for internal stability of the wall. External

stability design, including foundation and slope stability, is the responsibility

of the Engineer.

4"-0" Min.

4. If present, consider in design and analysis and locate manholes and drop

inlets as shown on wall elevations.

1"-0" Min.

SOIL PARAMETERS: Foundation Soil

1. See wall control drawings for soil characteristics of foundation material

dgn

to be used in the design of the wall system. The Contractor must provide Soil Reinforcement Length

\d\projects\standards\structures\current\ready4release\2012book_draft\06030-1of1.

soil design parameters for backfill material based on the actual soil

characteristics utilized at the site. Provide the values of unit weight,

cohesion and internal friction angle in the Shop Drawings. TYPICAL RETAINING WALL SECTION

(Showing Limits of the Reinforced Soil Volume)

MATERIALS:

1. Provide soil reinforcement in accordance with Specification Section 548.

2. For additional material notes, see Wall Company General Notes.

CONSTRUCTION:

1. Walls must be constructed in accordance with Specification Section 548 and

the Wall Company’s instructions.

2. For location and alignment of retaining walls, see Wall Control Drawings. Varies (See Index No. 414

2’-0" Min. and Wall Control Drawings)

3. Refer to Plan and Elevation sheets of individual walls for minimum

reinforcement strip/mesh length, factored bearing resistance’s, minimum

wall embedment and anticipated long term and differential settlements.

Type K Temporary

4. If existing or future structures, pipes, foundations or guardrail posts within

Traffic Railing

the reinforced soil volume interfere with the normal placement of soil

Dropoff (See Index No. 414

reinforcement and specific directions have not been provided on the

for Details)

plans, the Contractor must notify the Engineer to determine what course

of action should be taken.

5. The Contractor is responsible for gradually deflecting upper layer(s) of

soil reinforcement downward (15 maximum from horizontal) to avoid

cutting soil reinforcement and conflicts with paving and subgrade

45

preparation. The Contractor’s attention is directed especially to

situations where roadway superelevation and/or soil mixing are Front Face of

C:

anticipated. Temporary

Retaining Wall

rd960rh

47 AM

TEMPORARY TRAFFIC RAILING

34:

PLACEMENT DETAIL

9:

12/30/2011

GENERAL NOTES AND DETAILS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

TEMPORARY MSE RETAINING WALL SYSTEMS

01/01/11 FY 2012/2013 6030 1

Bulkhead Cap

SHEET PILE DESIGN CRITERIA AND NOTES

(See Bulkhead Plans

for actual Cap outline)

DESCRIPTION:

This Design Standard includes details for three types of piles with two thicknesses.

Types "B" and "C" piles (corner piles) are of reinforced concrete construction, and Type "A" is of prestressed

concrete construction. The piles shall be manufactured, cured and installed in accordance with the requirements

of the contract documents.

)

-0"

M in.

1’

MATERIALS: (for materials not listed refer to the Specifications)

(

Compacted Fill

CONCRETE

Class: V (Special) for slightly and moderately aggressive environments

V (Special w/ Silica Fume) for extremely aggressive environment

Unit weight: 150 pcf

Plastic Filter Fabric Modulus of Elasticity: Based on the use of Florida limerock concrete

(Continuous) Sheet pile

REINFORCING STEEL

ASTM A615 Grade 60

PRESTRESSING STEEL

Existing Ground ASTM A416 Grade 270 (Low-Relaxation Strand)

(Mud Line)

CROSS REFERENCES: DESIGN PARAMETERS:

For Dimensions L and X see Sheet Type "A"

Pile Data Table in Structures Plans. Concrete Compressive Strength at release of prestressing: 4000 psi minimum

-8"

Uniform compression after prestressing losses: 1000 psi minimum

1’

Pick-up, Storage and Transportation: 0.0 psi tension with 1.5 times pile self weight

Types "B" & "C"

Bottom of Dim. X

Pick-up, Storage and Transportation: Minimum compressive strength f’ci = 4000 psi required.

and Filter Fabric

ENVIRONMENT:

The pile designs are applicable to all Environments.

dgn

SECTION THRU BULKHEAD

\d\projects\standards\structures\current\ready4release\2012book_draft\06040-1of4.

PLASTIC FILTER FABRIC:

(Showing Plastic Filter Fabric)

The plastic filter fabric shall extend to the bottom of the "X" dimension.

PILE PICK-UP AND HANDLING:

Grout (Typ.) (See Specifications) Type "A"

Pick-up of pile may be either a single point pick-up or a two point pick-up as shown below.

~

Types "B" & "C"

2’-6"

Two point pick-up for lifting out of forms & two point support for storage & transportation.

Type "A" (Typ.)

Single point pick-up for installation only.

PILE FIT-UP:

90

~

The 2’-6" Sheet Pile dimension is nominal. This dimension may be shortened by the Manufacturer up to b" to

allow for Sheet Pile fit-up in its final position. Minimum Sheet Pile width is 2’-5b". No changes shall be made

to the tongues or grooves.

Type "A"

Type "A"

Type "C" Type "A" Type "B"

Starter Pile Plastic Filter Fabric

DETAIL "A"

(Cap and Anchoring System Not Shown)

(Section Taken Above Dimension X)

NOTE: Detail "A" shows a Part-Plan View of an assumed bulkhead.

See Bulkhead plans for actual Plan View.

C:

1’-3"

»¿ Pile and

Starter Pile

2 Point Pick-up, Tie Down and Support Points Single Point

rd960rh

Pick-up

0.21 L 0.58 L 0.21 L

il r

"

s

48 AM

o pi ’-3

e

l

1

n ca

P

34:

r

e

y

9:

1’-3" L

T

DETAIL "A"

C

(Section Taken Below Dimension X) PILE STORAGE AND TRANSPORTATION SUPPORT DETAILS

12/30/2011

NOTES AND DETAILS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

PRECAST CONCRETE SHEET PILE WALL

01/01/11 FY 2012/2013 6040 1

L

BAR BENDING DIAGRAMS

4" (Typ.)

11" X

(Typ.)

Slope only on the tongue side

10"

DIMENSION A

(Typ.)

A Prestressed

2 ~ Bars A B S1 1’-11 "

Strands

M in. Lap)

S2 1’-9b "

-3"

S3 2’-2"

)

11"

Typ.

Pick-up Strand(S)

A

1’

Varies S4 1’-6 "

(

1

Bars Bars

(

S5 1’-10 "

’-

0

S1 S2

"

S6 11"

45

"

Bar S5 S7 1’-7 "

-0

Bar S4

BAR A

1’

DIMENSION B

T=10 in. 4"

B B T=12 in. 6"

7"

B

A 2-PIECE 1-PIECE

BAR S

4b " 6 sp. @ 4" Spaced at 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for

Bars S

NOTES:

TYPICAL PILE 1. Intermediate Prestress Strands not shown in Elevations and Sections.

2. All bar dimensions are out-to-out.

SHEET PILE DIMENSIONS

L 3. Bars A are #5 and Bars S are #4.

T(in.) 10 12 4. At the Contractor’s option Bars S may be fabricated as a two piece bar

Y(in.) » » as shown in the Bar Bending Diagram.

dgn

11" X

\d\projects\standards\structures\current\ready4release\2012book_draft\06040-2of4.

Z(in.) 3 4 5. The Contractor may use Deformed Welded Wire Reinforcement conforming to

(Typ.) specification ASTM A497 in lieu of Bars A and Bars S if the wire size and

spacing provide the same area of reinforcing steel per foot as the Bars shown.

10"

6. For Dimensions L and X see Sheet Pile Data Table in Structures Plans.

(Typ.)

C Prestressed

2" Cover

2" Cover

2 ~ Bars A B T T T

2" Cover

Strands

See Detail "D" See Detail "E" See Detail "D"

2 "

11"

2 "

)

Typ.

Pick-up

Strand(S)

(

Bars Bars

S3 S2 Bars A Bars A

Strands)

Strands)

Strands)

D

D

"

-6"

-6"

Bar S7

n sp. @

n sp. @

n sp. @

Bars S1 Bars S2 Bars S3

-6"

-0

2’

2’

Bar S6 3" Cover 3" Cover 3" Cover

1’

2’

(

(

(

(Typ.) (Typ.) (Typ.)

Bars A

2 "

Cover

7"

Cover

2 ~ Bars A

Cover

B

C

2"

2"

2"

4b " 6 sp. @ 4" Spaced at 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for

SECTION A-A SECTION B-B SECTION C-C

Bars S

STARTER PILE Y 3 " Y Z 4" Z

C:

b" 2 " b" b" 3" b"

Wall STRAND DIA. MAXIMUM D TOTAL # OF SECTION * STRESS

n

Thickness (in.) L (in.) STRANDS MODULUS (in.‡) (psi)

rd960rh

T=10 in. 0.5 28’-0" 6 3 14 500 1150

2"

0.6 27’-0" 4 5 10 500 1160

2 "

T=12 in. 0.5 31’-0" 7 2 16 720 1100

49 AM

0.6 30’-0" 5 4 12 720 1160

34:

9:

* Unit Prestress after losses.

DETAIL "D" DETAIL "E"

(Typical Tongue) (Typical Groove)

12/30/2011

TYPE "A" STANDARD SECTION

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

PRECAST CONCRETE SHEET PILE WALL

01/01/11 FY 2012/2013 6040 2

L

See Detail "D"

11" Slope is to Slope only on tongue side

this point 11" 2’-2" X 7"

C Bars A3 B

T Bars A2 Bars A1 Bars A2

A Bars A1

Bars A2

Bars A1

Bars A3 Bars A3

1’

Bars A3 Bars A3

-3

Bars S3

Bars A4 Bars A4

"

S2 S1 Bars A4 Bars A4

Bars S1 Bars S2

Bars A4 Bars A4

4"

Pick-up Strand(s)

Bars A4 Bars A4

Bars S4 Bars A4 Bars A4

Bars A4 Bars A4

"

-3

3" Cover (Typ.) 3" Cover

1’

(Typ.)

SECTION A-A SECTION B-B

T

C B Bars A4 A

10" T

bT

VIEW C-C bT

Y

4 " 6 sp. @ 4" Spaced @ 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for

» ¿

Bars S b"

Y

ELEVATION 2

2"

"

(TYPE "B" PILE) b"

r

2"

ve

Co

dgn

BAR BENDING DIAGRAMS

\d\projects\standards\structures\current\ready4release\2012book_draft\06040-3of4.

Bars A2 Bars S

STIRRUP DIMENSIONS (T = 10") STIRRUP DIMENSIONS (T = 12")

BAR MARK R1 R2 R3 R4 R5 R6 R7 R8 BAR MARK R1 R2 R3 R4 R5 R6 R7 R8

SHEET PILE DIMENSIONS

1’-6b " 2b " 5b " 4 " 10" 3b " Bars A1 or A4

S1 11 " 9 " 5" 4 " S1 11b " 1’-6" 7" 4 " 5 " 6"

T (in.) 10 12

S2 1’-1b " 9 " 1’-8 " 2b " 4b " 5b " 5 " 4 " S2 1’-1 " 10" 1’-8 " 3b " 6b " 5 " 5 " 6"

2

30 30

Y (in.) 3 4

Co

2"

S3 11 " 8" 1’-6" 1 " 5" 4b " 4b " 5" S3 11b " »¿ 1’-5 " 2" 4 " 4b " 7 "

"

7"

ve

Z (in.) 3 4

1 "

r

S4 11 " 4 " 1’-1 " 5" 3 " 2b " 6 " S4 11b " 4" 1’-1 " 2 " 7" 3 " 2b " 8 "

S1 11b " 8" 1’-4" 4" 5b " 6b " 8" 4" S1 1’-0" 8b " 1’-3 " 5 " 7b " 6 " 8b " 5 " b"

1’-5 " 4" 8" 4" S2 8b " 5 " 3"

S2 1’-1 " 8" 4b " 7b " 1’-2 " 1’-5b " 6b " 7 " 8b " 5 "

b" Z

45 45

S3 11b " 6 " 1’-4" 2 " 5b " 6 " 6 " 5b " S3 1’-0" 7" 1’-4" 3" 7b " 6 " 7" 7 " 4"

Z bT

S4 11b " 3b " 1’-0" 3" 5b " 5" 3b " 7" S4 1’-0" 3b " 11 " 3 " 7b " 5" 3b " 9"

bT

S1 1’-0" 6" 1’-0 " 5 " 6" 7 " 10 " 3" S1 1’-0b " 6 " 11 " 7" 8" 6 " 10 " 4" T

S2 1’-2" 6" 1’-2 " 5 " 4 " 8 " 10b " 3" S2 1’-2 " 6 " 1’-2" 7" 6 " 8" 10 " 4"

60 60

S3 1’-0" 4 " 1’-1b " 3 " 6" 8" 8 " 5 " S3 1’-0b " 5" 1’-1b " 4" 8" 8" 9" 7"

DETAIL "D"

S4 1’-0" 2b " 10" 4b " 6" 5 " 4" 7b " S4 1’-0b " 2b " 9b " 5b " 8" 5b " 4 " 9 "

NOTES:

1. This drawing includes details for precast concrete corner piles for 10"

C:

)

Typ.

and 12" thick sheet pile systems. The details apply equally to both thicknesses.

Typ.

R5 R6 R5 R6

4"

R5 R6

4"

2. The bar configurations shown in Sections A-A and B-B shall be used for

(

angles between 15 and 75. For angles not shown, the reinforcing bar

dimensions may be interpolated or extrapolated from the stirrup dimensions shown.

rd960rh

R1

R1

3. All bar dimensions are out-to-out.

R1

Varies

R3

R3

4. Bars A are #8 and Bars S are #4.

R3

5. Values for Stirrup Dimensions are shown for equal to 30, 45 & 60 only.

6. At the Contractor’s option Bars S may be fabricated as a 2 piece bar with

R2

50 AM

R2

R2

a minimum lap length of 1’-6", as shown in Bar Bending Diagrams.

45

R4

7. If Type "B" pile is used as a Starter Pile show tongue on both sides of pile

R4

34:

1

’-

R4

9:

0

" from Dim. X down. Show dimensions for Bars S2, S3 & S4 in shop drawings.

R7 R8 R7 R8 8. If tongue must be on the opposite side from that shown all dimensions and Bars A,

R7 R8 BAR A2

S2, S3 and S4 will be the same but opposite hand.

12/30/2011

9. For Dimensions L, X and Angle , see Sheet Pile Data Table in Structures Plans.

1 - PIECE 2 - PIECE BARS S3 & S4

BARS S1 & S2 TYPE "B" - VARIABLE ANGLE CORNER PILE

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

PRECAST CONCRETE SHEET PILE WALL

01/01/11 FY 2012/2013 6040 3

L

For 10" Pile

For 12" Pile

1’-4" 10 " 2’-2" X

This A4 bar ends See

T

here if T=12"

)

Section C-C

Typ.

Bars A1 See Section C-C

C B 2 ~ Bars A2

2"

10" T S2 T

D Bar A4 A

(

Bars S3 (Typ.) Bars A1 3" Cover

* Bar A4 * Bar A4

Bars S1 Bar A5

Bar A5

-8"

-9"

Bars S5 Bars A2

-8"

-9"

** Bar A4

** Bar A4

1’

1’

Bars S4 Bar A6

1’

1’

T

T

Pick-up Bar A6

Strand(s)

Bars A5 Bars A3 7" Bars A3 Bars A3

3" 2" (Typ.)

1’-8" D A

(Typ.) C B 3" Cover

For 10" Pile

For 12" Pile

1’-9"

Bars S2 Bars S1

1’-8" For 10" Pile

END VIEW 1’-9" For 12" Pile

4" 6 sp. @ 4" Spaced @ 1’-0" Maximum 6 sp. @ 4" 3 " Spacing for

SECTION A-A SECTION B-B

Bars S

ELEVATION

(TYPE "C" PILE) * This Bar A4 shall be 1’-2" shorter than other A4 bars for T = 12".

Bars A2

** This Bar A4 (not shown in elevation) is included only if T = 12".

Bar A4 BAR BENDING DIAGRAMS

Bar S2

3 "

dgn

Y Y

\d\projects\standards\structures\current\ready4release\2012book_draft\06040-4of4.

Bar S3 R2 R3

Bar A5 STIRRUP DIMENSIONS

b" 2 " b"

R2

Bar S4 T (in.) BAR MARK R1 R2 R3

Bars

Bar S5 S1 7" 5 " 7"

R1

A3

2"

2"

4"

S2 7" 8" 4 "

10 S3 6 " 7 " 4 "

Bar A6

4"

*Bar A4 S4 5b " 6b " 4 "

S5 4 " 5 " 4 "

4b "A2 & A6

Bar A5 Bars A2 90 STIRRUPS S

-3"

-3"

S1 9" 4 " 9"

1’

1’

** Bar A4

2b " A4

0" A5

3b "A3

S2 9" 7" 6 "

SECTION D-D (T=10") 1’-2" Varies

b"

Bars A3

12 S3 8 " 6 "

Z

6 "

Bars S2

Bars A2

Bar A6 S4 7b " 5b " 6 "

45

4"

3"

T

1

S5 6 " 4 " 6 " - (Bars A2 only)

’

0

"

5"

6"

BARS A

b"

Bar A4

Bar S2

Z

For 10" Pile

For 12" Pile

Bar S3

Bar A5

»¿ Bul Note: All Bar dimensions are out-to-out.

2 " SHEET PILE DIMENSIONS

C:

For 10" Pile 1’-3" 5" Bar S4 T (in.) 10 12 NOTES:

For 12" Pile 1’-3" 6" Bar A4 Bar S5 1. All bar dimensions are out-to-out.

Bars

Y (in.) 3 4

2. Bars A are #8 and Bars S are #4.

A3

Z (in.) 3 4 3. This drawing includes information for precast Corner Piles for 10" and 12"

rd960rh

thick Sheet Pile systems. The details apply to both thicknesses but the bar

SECTION C-C (T=10" or 12") Bar A6

configurations change slightly according to the thickness values used.

4. If Type "C" pile is used as a Starter Pile show tongue on both sides of

pile from Dim. X down. Show dimensions for Bars S2, S3, S4 & S5 in

51 AM

shop drawings.

5. If tongue must be on opposite side (Groove Side) from that shown,

34:

all dimensions and reinforcement shall follow the corresponding Tongue

9:

or Groove side.

SECTION D-D (T=12") 6. For Dimensions L and X see Sheet Pile Data Table in Structures Plans.

12/30/2011

TYPE "C" - RIGHT ANGLE CORNER PILE

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

PRECAST CONCRETE SHEET PILE WALL

01/01/11 FY 2012/2013 6040 4

» b " Open Joint

Dim. A

0"Mi n)

.

» b " Open Joint 1

l (0-

’

"Typc

ia

0-

’0

Spacn

ig~ 3

nJon

it Bars 4B (follows top of * 2" Min. Cover (Typ.)

b"Ope

Top of C-I-P Retaining Wall Panel) (Typ.) ** 3" Min. Cover (Typ.) Drainage Ditch when

Bars 4A (follows Coping required (See Wall Control

Bars 4U1 @ 1’-6" Max. Slope of C-I-P Bars 4U1

Drawings for details)

sp. (lap with Dowel Coping)

A

" Chamfer Bars 4A

Bars 4D) (Typ.) (Typ.)

Varies

Dowel Bars 4D (1’-3" Max.,

2" Min.)

-0"

(Typ.) (See

2’

Note 2)

Bars 4B shown as ( )

Top of Retaining

Wall Panel (Typ.) Dowel Bars 4D

(See Note 2)

6"

Clearance

Bottom of Varies

C-I-P Coping Retaining Wall Panel

Retaining Wall (See Wall Company

Panels (Typ.) Drawings for Details)

Smooth or Textured Face of Panel

A

PRECAST AND C-I-P COPING NOTES:

1. Provide Class II concrete for slightly aggressive environments

SECTION A-A

dgn

or Class IV for moderately or extremely aggressive environments.

C-I-P COPING - PARTIAL ELEVATION VIEW

\d\projects\standards\structures\current\ready4release\2012book_draft\06100-1of2.

C-I-P COPING Panel width

2. Dowel Bars 4D extend 1’-0" above the top of retaining

Dim. A

+ 6"

wall panel. Field cut as necessary to maintain 2" minimum

Panel width

cover. See Wall Company Drawings for number and spacing

Dim. B

+ 1’-0" Min.

of Dowel Bars 4D.

3. Payment for Dowel Bars 4D, Buildup Concrete and Coping will

be made under Retaining Wall System (Permanent).

» b " Open Joint Dim. B

* 2" Min. Cover (Typ.)

» b " Open Joint Drainage Ditch when

n.) Top of Retaining ** 3" Min. Cover (Typ.)

5

g(’-0"Mi required (See Wall

stCopn

i

alPreca Wall Panel (Typ.)

0"Typc

i Control Drawings

10-

’

Top of C-I-P * For Slightly and Moderately Bars 4U2

Bars 4A for details)

2" Cover

Buildup Concrete Aggressive environments

(Typ.)

B

)

" Chamfer (Typ.)

-0" M ax.

Top of Precast

Coping ** For Extremely Aggressive

Varies

environments.

2" Cover

1’

Min.

(

-0"

2’

-3"

C-I-P Buildup Concrete

1’

(1’-0" Max.)

Provide 3b " x 3b " preservative

treated timber blocking @ 5’ Max.

Bars 4U2 @ Spacing for gaps > 1"

C:

1’-4" sp. (Typ.)

Varies (1’-3" Max., Dowel Bars 4D

Bars 4A

Clearance "

2" Min.) (See Note 2)

Dowel Bars 4D (Typ.) Varies

Bottom of " Std.

(See Note 1) 6" 6"

rd960rh

Precast Coping (

b " Min. ~ 2b " Max.)

Min. Min.

Retaining Wall

Retaining Wall Panel

Panels (Typ.)

Smooth or Textured Face of Panel (See Wall Company

B

Drawings for Details)

52 AM

34:

9:

SECTION B-B

PRECAST COPING - PARTIAL ELEVATION VIEW PRECAST COPING

12/30/2011

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

MSE WALL COPING (PRECAST OR C-I-P)

01/01/12 FY 2012/2013 6100 1

REINFORCING STEEL BENDING DIAGRAMS - PRECAST AND C-I-P COPINGS Dim. B

BILL OF REINFORCING STEEL REINFORCING STEEL NOTES: * 2" Min. Cover (Typ.)

1. All bar dimensions in the bending diagrams are out to out. ** 3" Min. Cover (Typ.) Drainage Ditch when

LENGTH LENGTH 2. All reinforcing steel at the open joints will have a 2" minimum cover. required (See Wall

MARK SIZE

* S or M * E 3. Bars 4A may be continuous or spliced at the construction joints. Lap splices for Bars 4A will Bars 4U2 Control Drawings

Bars 4A

be a minimum of 1’-8". for details)

3

A 4 AS REQD. AS REQD. 4" Chamfer (Typ.) (Typ.)

4. The Contractor may use Welded Wire Reinforcement when approved by the Engineer. Welded Wire

Reinforcement will conform to ASTM A 497.

B 4 AS REQD. AS REQD.

Recess Varies

Varies

D 4 2’-0" 2’-0" * S = Slightly Aggressive (1’-3" Max., 2" Min.)

-0"

M = Moderately Aggressive

U1 4 Panel width + 4" Panel width + 3" E = Extremely Aggressive

2’

** 6" M in.

* 8" M in.

U2 4 Panel width + 8" Panel width + 6"

Varies Varies Dowel Bars 4D

(See Note 2, Sheet 1)

U3 4 Panel width + 4" Panel width + 3"

Varies

Ground

4A Length as Required

Line 6" 6"

-6"

-6"

-0"

-8"

-8"

Min.

** 1’

** 1’

2’

-0" M in.

* 1’

* 1’

4B Length as Required (Match

Precast

Field cut as

Dimensions)

2’

required to maintain

2" minimum cover Retaining Wall Panel

BARS 4A & 4B DOWEL BAR 4D BAR 4U1 BAR 4U2 BAR 4U3 Leveling Pad for (See Wall Company

MSE Wall Shown Drawings for Details)

C-I-P COPING USED WITH PRECAST COPING

Note: When precast coping units do not fit the entire length of the retaining

wall, use this similar C-I-P coping for short portions between precast

dgn

\d\projects\standards\structures\current\ready4release\2012book_draft\06100-2of2.

coping units. This C-I-P coping may also be used for vertical copings.

Dim. C

* For Slightly and Moderately

Aggressive environments

Top of Coping

Top of Retaining

* 2" Cover (Top & Sides)

Wall End Panel ** For Extremely Aggressive

** 3" Cover (Top & Sides)

environments.

C 3

Begin or End 4" Chamfer (Typ.)

Bars 4A (follows Slope

Bars 4B

Spacing

Retaining Wall

of C-I-P Coping Enclosure)

Bars 4B (Horizontal) (Field

cut as required to maintain Panel width

minimum cover) Bars 4A (Typ.) Dim. B

+ 1’-0" Min.

Panel width

Bottom of Coping Dim. C

+ 6"

-6" M ax.

Eq. sp. @

Varies

Retaining Wall End Panel

Edge of C-I-P Bars 4B shown

(See Wall Company

1’

Coping Enclosure as ( ) (Typ.)

Drawings for details)

Bars 4U3

-0" M in.

Bars 4U3 @ 1’-6"

C:

Edge of Retaining

Max. sp. (Typ.)

Wall End Panel

6"

2’

rd960rh

412"

Bars 4B (Horizontal) C

4" Cover Leveling Pad for

(Bottom) MSE Wall Shown

53 AM

3" Min. Overlap

Varies SECTION C-C

34:

9:

C-I-P COPING ENCLOSURE DETAIL

12/30/2011

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS

NO. NO.

MSE WALL COPING (PRECAST OR C-I-P)

01/01/12 FY 2012/2013 6100 2

1" Dowel Load Transfer

Devices (See Typical Sections Top of

Bars 5C @ 8" sp. Expansion Joint (See

for details) Junction Slab b" V-Groove (See 2" Cover (tie to Bars 4A) "Expansion Joint Detail" 1" Dowel Load

Bars 5B2 Bars 4A @

4 ~ Bars 5F Note 7 & Detail "A") Sides (Typ.) (Typ.) this sheet and Detail "A") Transfer Devices

4" (Typ.)

(Top of Slab)

Approved metal (Required only

or fiber cap when Junction

Slab is skewed)

Bottom of "

Lap Splice

Junction Slab

-0" M in.

3"

" Preformed Expansion Approach Slab 3s

p.

@

(See Note 12) 6"

Joint Filler

2’

Gutter Line

1’-0" 1’-0"

»¿ Expansion

Bars 4L @ 8" sp.

(Typ.)

EXPANSION JOINT DETAIL

(Junction Slab expansion joints are to coincide Field cut reinforcing as required Bars 5V2 (Typ.) Coping

" Open Joint Bars 5S Bars 5B1

with " open joints in Traffic Railing) 3" to maintain minimum cover (Typ.)

in Precast Coping

Spacing Bars 5V2 8" Spacing (Typ.) (See Note 1 & 9)

CROSS REFERENCE: For Detail "A", see Sheet 2. 2" Cover @

2" Cover @ Expansion Joints

b " V-Groove Spacing 30’-0" Max. (See Note 7)

Open Joints

dgn

» " Open Joint in Precast

Begin or End Retaining Wall »¿˘" Expansion Joint Spacing ~ 30’-0" Min., 90’-0" Max. (See Not

\d\projects\standards\structures\current\ready4release\2012book_draft\06110-1of6.

Coping and C-I-P Traffic

and Precast or C-I-P Coping

Railing to coincide with "

" Open Joint PARTIAL PLAN VIEW FOR F-SHAPE TRAFFIC RAILING Expansion Joint in Junction

Slab.

(Skewed Approach Slab Shown, Perpendicular Approach Slab Similar)

(Precast Coping Shown, C-I-P Coping Similar) (Traffic Railing not Shown for Clarity)

JUNCTION SLAB NOTES: ny(

l 5-

’0"Min)

.

»¿ ˘" Open Jo ecastCo pn

igO

10-

’0"Typc

ial Pr

1. APPLICATIONS: This junction slab is only applicable for a TL-4 crash test rating. Precast Coping and Seci

tons*

l

iing & Copn

ig

Top of ecastTraffc Ra

i

For TL-5 crash test rating increase Expansion Joint Spacing to 60’-0" minimum and provide Bars 5C at 6" max. Precast Traffic Railing 12-

’0"Minmu

i m Pr

Traffic

spacing within 6’-0" of Open Joints for precast coping with the 42" F-Shape Traffic Railing.

Railing Top of Precast Coping

2. CONSTRUCTION REQUIREMENTS: Construct the Junction Slab level transversely and expansion joints plumb;

do not construct the junction slab or C-I-P coping perpendicular to the roadway surface. Slip forming of Coping

Traffic Railing

and/or junction slab is not permitted. Mortar Plug

Varies

3. Provide Class II concrete for slightly aggressive environments or Class IV for moderate or extremely (See Note 5)

2" Cover M in.

Top of C-I-P

aggressive environments.

Buildup Concrete

4. Dowel Load Transfer Devices will be ASTM A 36 smooth round bar and hot-dip

)

9" M ax.

galvanized in accordance with Specification Section 962. Install Dowel Load Transfer Devices in accordance

Top of Retaining

Varies

with Specification Section 350.

Wall Panel (Typ.)

3"

»¿5. Construct ˘" Expansion Joints in junction slabs and C-I-P copings plumb and perpendicular or radial to

Gutter Line. Provide at 90’-0" maximum intervals as shown. Provide 3"x3" Mortar plugs in open joints at the

Precast

Coping

-3"

base of traffic railings to contain runoff.

6. Provide and install Preformed Expansion Joint Filler in accordance with Specification Section 932.

2’

7. Construct b" V-Grooves in junction slabs and C-I-P copings plumb and provide at 30’-0" maximum intervals as

C:

»¿ shown. Space V-Grooves equally between ˘" Expansion Joints and/or Begin or End Junction Slab. V-Gr

locations are to coincide with V-Groove locations in the Traffic Railing.

8. Shoulder or Roadway Pavement is required on top of the junction slab for its entire length on the traffic Clearance

side of the Traffic Railing. See Typical Sections on Sheet Nos. 2 and 3 for details. Varies

rd960rh

9. Spacing shown is along the Gutter Line. Bottom of Dowels 4D (Typ.)

10. On MSE Walls provide, Dowel Bars 4D and extend to 7" above the top of retaining wall panel. Field cut as Precast Coping (See Note 9)

necessary to maintain 2" minimum cover to the top of the buildup concrete. See Wall Company Drawings for

number and spacing of Dowel Bars 4D.

53 AM

11. Work this Index with the following: Retaining Wall (MSE Shown,

Index No. 420 - Traffic Railing - (32" F-Shape) Other Types Similar) (Typ.)

34:

Index No. 425 - Traffic Railing - (42" F-Shape). PARTIAL ELEVATION VIEW

9:

12. The following Indexes contain details of the intersection of the retaining wall at approach slabs:

(Precast Coping and Junction Slab Reinforcing not Shown for Clarity) * C-I-P End Section must

Index No. 20900 - Approach Slabs (Flexible Pavement Approaches)

(Precast Coping Shown, C-I-P Coping Similar) be = 12’-0".

12/30/2011

Index No. 20910 - Approach Slabs (Rigid Pavement Approaches)

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS WALL COPING WITH TRAFFIC RAILING/JUNCTION NO. NO.

01/01/12 FY 2012/2013 SLAB 6110 1

1

6’-6 2"

1’-2b " (32" F-Shape) 3 1

5’-0" 5" 8 4" 2 2"

1’-5" (42" F-Shape)

Cover

(C-I-P Junction Slab)

»¿

Bars 4N @ 8" sp.

2"

Top of Precast Coping »¿1˘" C-I-P F-Sh (Tied to Bars 5P)

312"

»¿3˘" Precast 32" F-S

Traffic Bars 5P

-0"

4 "

Railing

714"

@ 8" sp.

Precast Traffic Railing

Min. Embed. (32" F-Shape)

1’

Bars 5C @ 8" sp.

-0" M in. Length)

Min. Embed. (42" F-Shape) Bars 5S

-10"

Bars 5S (Field Bent) Coping (Tied to alternate Bars 4A)

(Typ.)

312"

1’

6"

8"

1" Dowel Load 2"Co

-8"

Bars 5V Construction ver

114"

Transfer Devices at

2’

(Rotated) Joint Permitted

3" 4 2"

214"

expansion joints (Typ.)

for C-I-P 10 114"

1

"R

Bars 4A @ 4" sp. Sections*

12’

End Stirrup Bar 5V Shoulder or Roadway

Precast Coping 2" Cover (Top) Bars 5V2

7"

(Bars 5V2 may be Pavement (Full depth

4"

@ 8" sp. 3

(

3 4"

8"

substituted) asphalt or See Note 3) Sl

ope Vari

es Top of

3

1

(

Se Coping

3"

e Note1)

Bars 5S

PARTIAL END VIEW OF TRAFFIC RAILING END

3

TRANSITION FOR GUARDRAIL ATTACHMENT

4"

3 4"

812"

Precast Coping)

(Showing Bars 5V and Bars 5S) (See Note 2)

-0"

2" Cover

(Precast Coping Shown, C-I-P Coping Similar)

1’

-0"

6"

-3"

1’

NOTE: See Index No. 420 and Index No. 425, Detail "A" for details. 3" Cover

6"

Bars 4L @ 8" sp.

2’

-114"

6"

Utility Conduit

(

permitted

Bars 5B2 @ 1’-0" sp. (Typ.)

1’

dgn

» ¿

ESTIMATED QUANTITIES FOR PRECAST COPING Slope Permitted See Note 7

\d\projects\standards\structures\current\ready4release\2012book_draft\06110-2of6.

Two Layers 30Lb. Roofing Felt

ITEM UNIT QUANTITY Varies (2" min.)

2" Min. Cover

Spacing Bars 5B1

Optional widening & extension for Precast Coping (See Note 6) 514"

Concrete (Precast Coping Only) CY/LF 0.079

Retaining Wall (Type Varies)

Dowel Bars 4D (MSE Walls only)

Concrete (Precast Barrier & Coping) CY/LF 0.165 6"

Spacing 1" 1’-3" 3 sp. @ 1’-0" = 3’-0" Spacing 6"

C-I-P Buildup Concrete

Concrete (C-I-P Junction Slab) CY/LF 0.185 Dowels Bars 5S

»¿ » (MSE Walls only)

b" Min. ~ 2b" Max. Gap Smooth or Textured

Reinforcing Steel (Precast Coping & Traffic

LB/LF 52.67 Face of Wall

Railing) 3" 4 sp. @ 1’-0" = 4’-0" (5B2) 2 sp. @ 1’-0"– (5B1) 3"

Spacing

Bars 5B

Reinforcing Steel (C-I-P Junction Slab) (Typ.) LB/LF 12.52

TYPICAL SECTION THRU PRECAST* 32" F-SHAPE

Additional Reinf. @ Expansion Joints LB 21.36 TRAFFIC RAILING AND COPING WITH C-I-P JUNCTION SLAB

* C-I-P Traffic Railing and Coping Sections using precast dimensions

(The above concrete quantities are based on a max. superelevation of 6.25%

and reinforcement are permitted at End Sections, Drainage Inlets and

and a 32" F-Shape Traffic Railing.

Light Pole Pedestals if slip forming is not used.

NOTES:

1. Match Cross Slope of Travel Lane or Shoulder.

»¿2. The 3˘" dimension corresponds to a maximum superelevation of 6.

C:

For steeper superelevations increase this dimension to match roadway

superelevation.

b " V-Groove (Typ.) b " V-Groove (Typ.)

3. For Rigid Pavement (Concrete), Junction Slab may be thickened to match

finish grade.

rd960rh

4. Minimum length of Junction Slab between expansion joints is 30’-0".

5. At the Contractor’s option, mechanical couplers may be used to splice

»¿˘" Preformed Expan »¿˘" Preformed Expan

Joint Filler Joint Filler reinforcing. Complete details, including reinforcement lengths are required

in the Shop Drawings. Provide mechanical couplers in accordance with

Specification Section 415. Mechanical couplers shall develop 125% of the bar

55 AM

yield strength.

C-I-P COPING

34:

6. Contractor to maintain stability of precast coping/traffic railing prior to

9:

PRECAST COPING junction slab completion. In the Shop Drawings, show reinforcement for

optional extension required for stability, shipping and handling. Maintain

DETAIL "A" 2" minimum concrete cover.

12/30/2011

7. Angle varies ~ 0 min., 20 max.

(Showing Locations of b " V-Grooves and " Preformed Expansion Joint Filler)

F-SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS WALL COPING WITH TRAFFIC RAILING/JUNCTION NO. NO.

01/01/12 FY 2012/2013 SLAB 6110 2

REINFORCING STEEL BENDING DIAGRAMS 6’-6b" (32" F-Shape)

3’-9"

6’-9" (42" F-Shape) »¿

BILL OF REINFORCING STEEL

5’-0" 5" 1034" b" (32" F-Shape)

8"

LENGTH (C-I-P Junction Slab) »¿1’- (42" F-Shape)

Cover

»¿

Spacing Bars 5S (32" F-Shape)

MARK SIZE PRECAST COPING

2"

Shoulder or Roadway

COPING & Spacing Bars 8S1 (42" F-Shape)

BARS 4L Pavement (Full depth

3b "

3b "

32" F-SHAPE C-I-P Precast

asphalt or See Note 3)

32" F-Shape)

42" F-Shape)

6 " (32" F-Shape) Bars 5P

-0"

A 4 5’-7" 8’-0" 5’-7"

(42" F-Shape) @ 8" sp.

8b "

8b "

9"

1’

Optional Bar 5C @ 8" sp.

C-I-P Traffic Railing

3"

32" F-Shape)

42" F-Shape)

(32" F-Shape)

-0" M in. Length)

B1 5 11’-6" N/A 9’-6" for Precast Coping Bars 5S

(42" F-Shape) »¿

or 8S1 (Typ.)

B2 5 AS REQD. AS REQD. AS REQD.

1" Dowel Load

2" 3 4"

» ¿

3"Co

-10" (

ve

-8" (

r

114"

1

Transfer Devices at

C 5 4’-8" N/A 4’-8"

expansion joints (Typ.)

3b " 9"

2’

114"

1’

10

32" F-Shape)

42" F-Shape)

-8" (

-6" (

Construction "R

3" 4

F 5 4’-8" 4’-8" 4’-8"

Bars 4A @ 4" sp. Joint Reqd.

30’

2’

3’

L 4 4’-5" 4’-5" 4’-5" 2" Cover (Top)

Bars 5V2

7"

(

@ 8" sp.

134"

8"

8"

N 4 2’-6" N/A N/A Sl

ope Vari

es

Top of

134"

3"

(

See Note1)

-5" (

-3" (

Bars 5S Coping

P 5 5’-7" 5’-7" 5’-7"

C-I-P or Precast Coping)

» ¿

2’

3’

4"

S 5 11’-6" AS REQD. 9’-6"

4"

3

2" Cover

3

-0"

8

S1 8 N/A AS REQD. 9’-6" See Note 7

1’

-0"

V2 5 5’-10" 5’-10" 5’-10"

-3"

6"

1’

3" Cover

6"

1

52"

2’

Smooth

1" Dowel 2’-0" 2’-0" 2’-0"

"

Bar Bars 4L @ 8" sp.

Varies

1’-

6"

1˘

STIRRUP BAR 5P

dgn

)

Two layers 30Lb. Roofing Felt

2" m in.

(1’-

Bars 5B2 @ 1’-0" sp. (Typ.)

»¿

9’-6" (Precast Coping only),

\d\projects\standards\structures\current\ready4release\2012book_draft\06110-3of6.

5b "

5B1 11’-6" (Precast Traffic Railing)

»¿

Expanded Polystyrene (b" Side) (for C-I-P only)

(

5B2 Length as Required

Optional widening & extension for Precast Coping (See Note 6)

5C Precast Coping ~ 4’-8" (See Note 7) Contractor’s

Retaining Wall (Type Varies)

option Spacing 6" 512" (C-I-P) Spacing Bars

"

9

Bars 5S 5B1 ~ Precast,

6" 514" (Precast)

5F 4’-8"

2’-0" Spacing 1" 1’-3" 3 sp. @ 1’-0" = 3’-0" 5B2 ~ C-I-P Coping

)

45

F

Precast Coping, ~ 11’-6" (with Dowels

Smooth or Texture

)

"

F

2

5S 32" F-Shape), 9’-6" (Coping Only)

32" F-Shape)

42" F-Shape)

Face of Wall

(3

"

2

Spacing 3" 4 sp. @ 1’-0" = 4’-0" 2 sp. @ 1’-0"– 3"

"

(4

8S1 C-I-P Coping ~ Length as Required

-2

"

’

Bars 5B2

-5

1

Construction Joint Permitted

1

1" DOWEL TYPICAL SECTION THRU C-I-P TRAFFIC RAILING Optional Keyway

WITH C-I-P JUNCTION SLAB AND C-I-P COPING

BARS 5B, 5C, 5F & 5S 5" Buildup for

-8b " (

-1b " ( (PRECAST COPING SIMILAR WITH C-I-P BUILDUP)

stepped MSE

5430’

ping~

ecastCo Wall Panels

Pr

1"

5& 6)

M ax.

412"

-1b "

2’

3’

M in.

e Note (0" min.,

Se

6"

9"(

2"

3-

’

" »¿11˘" m

10"

’-2

g ~6 45

1’

P Copn

i

C-I-

Coping

412"

Expanded

-10"

Polystyrene (b")

86 10" (32" F-Shape) 6"

1’

6"

1’-0b" (42" F-Shape) ESTIMATED QUANTITIES FOR C-I-P COPING BUILDUP FOR STEPPED MSE WALL PANELS

C:

BAR 4A STIRRUP BAR 4N NOTES: AND C-I-P COPING

STIRRUP BAR 5V2 1. Match Cross Slope of Travel Lane or Shoulder.

REINFORCING STEEL NOTES:

ITEM UNIT QUANTITY »¿2. The 3˘" dimension corresponds to a maximum superelevatio

1. All bar dimensions in the bending diagrams are out to out.

rd960rh

6.25%. For steeper superelevations increase this dimension to match

2. All reinforcing steel at expansion and open joints will have a 2" minimum cover.

roadway superelevation.

3. Lap splices for Bars 5B & 5S will be a minimum of 2’-0". Concrete (Traffic Railing not Included) CY/LF 0.264

3. For Rigid Pavement (Concrete), Junction Slab may be thickened to

4. For Precast Copings only, lap splice Bars 4A with Bars 5C. Lap splices will be a minimum of 2’-0".

match finish grade.

5. The Contractor may use either full length Bars 4A or lap splice with Bars 5C at alternate Bars 4A

Reinforcing Steel (Typical) excluding 4. Minimum length of Junction Slab between expansion joints is 30’-0".

LB/LF 30.89

56 AM

for C-I-P Copings.

Bars 5V2 and 5S (Typ.) 5. See Index No. 420 & 425 for additional Traffic Railing Details.

6. Dimension shown is for lap splice option. For mechanical coupler option, this dimension is 1’-4b"

34:

6. Contractor to maintain stability of precast coping prior to junction

(32" F-Shape) or 1’-7" (42" F-Shape).

9:

Additional Reinf. @ Expansion Joint LB/LF 21.36 slab completion. In the Shop Drawings, show reinforcement for

7. Dimension shown is for lap splice option. For mechanical coupler option, this dimension is 4’-8".

optional extension required for stability, shipping and handling.

8. The Contractor may use Welded Wire Reinforcement when approved by the Engineer. Welded

Maintain 2" minimum concrete cover.

(The above concrete quantities are based on a max. superelevation

12/30/2011

Wire Reinforcement will conform to ASTM A 497.

7. Angle varies ~ 0 min., 20 max.

of 6.25%, beneath a 32" F-Shape Traffic Railing on an MSE Wall).

F-SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS WALL COPING WITH TRAFFIC RAILING/JUNCTION NO. NO.

01/01/12 FY 2012/2013 SLAB 6110 3

Bars 5C @ 8" sp. b" V-Groove

4 ~ Bars 5F 3" Expansion Joint (See Expansion

2" Cover (Tie to Bars 4A) 4L Bars @ (See Detail "A" 1" Dowel Load

(Top of Slab) 3s

p.

@ Joint Detail & Detail "A")

6" Bars 5B2 Sides (Typ.) (Typ.) 8" sp. (Typ.) & Note 7, Sheet 1) Transfer Devices

(Required only

when Junction

Slab is skewed)

Field cut reinforcement

as required to maintain

minimum concrete

cover (Typ.)

-0" M in.

Lap Splice

Approach Slab

(See Note 12

Sheet 1)

2’

Begin or End Skew Bars 7P1 & Bars 4L @ 8" (Typ.) Bars 7P1 & 4V1 (Typ.) Bars 5B1

Gutter Line Coping Line Bars 7P1 &

Approach Slab 4V1 as required

dgn

Bars 4A @ 4" (Typ.)

4V1 (Typ.)

\d\projects\standards\structures\current\ready4release\2012book_draft\06110-4of6.

" Open Jt. 5’-0" End Post Varies 2’-6" (Typ.) 5’-0" Interior Post (Typ.) 2’-6" (Typ.) Varies ~ 5’-0" (Typ.) 5’-0" End Post 5’-0" End Post

(2’-6" Min., 5’-0" Max.) (2’-6" Min., 5’-0" Max.) @ Expansion Joint @ Expansion Joint

2" Cover @

» " Open Joint in Precast

b" V-Groove Spacing ~ 30’-0" Max. (See Note 7, Sheet 1) Open Joints

Coping and C-I-P Traffic

Railing to coincide with "

»¿˘" Expansion Joint Spacing ~ 30’-0" Min., 90’-0" Max. (See Note 5, Shee

Expansion Joint in Junction

Slab.

PLAN VIEW

(Skewed Approach Slab shown, Perpendicular Approach Slab similar) CROSS REFERENCES:

(Precast Coping shown, C-I-P Coping similar) 1. For Detail "A" see Sheet 2.

(Traffic Railing reinforcement not shown, except for Bars 7P1 & 4V1) 2. For "Expansion Joint Detail" see Sheet 1.

3. For "Junction Slab Notes" see Sheet 1.

Bars 5C @ 8" sp. Bars 5C @ 8" sp.

Bars 5B2 (Tie to Bars 4A) (Typ.) (Tie to Bars 4A) (Typ.) Bars 5B2

Guardrail

Gutter Line Gutter Line

4b " Taper

(Typ.)

C:

Face of Curb

Bars 4L (Typ.) Bars 4A (Typ.)

Begin or End

rd960rh

Retaining Wall

Coping and Bars 7P1 & 4V1 (Typ.) Bars 5B1 Bars 4L Bars 4P5 (Typ.) Bars 7P1 & 4V1 (Typ.) Bars 4R3 (Typ.)

Traffic Railing Bars 4A

3’-0" Taper Varies (12’-6" Min.) 3’-0" Taper Coping Line 2’-6" (Typ.) 5’-0" Interior Post (Typ.) 2’-6" (Typ.) Coping Line

(Inside Face) (Inside Face)

56 AM

PARTIAL PLAN VIEW OF GUARDRAIL TRANSITION AT BEGIN OR END RETAINING WALL PARTIAL PLAN VIEW OF COPING WITH CURB

34:

9:

(Precast Coping shown, C-I-P Coping similar) (Precast Coping shown, C-I-P Coping similar)

(Traffic Railing reinforcement not shown, except for Bars 7P1 & 4V1) (Traffic Railing reinforcement not shown, except for Bars 4P5, 4R3, 7P1 & 4V1)

12/30/2011

CORRAL SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS WALL COPING WITH TRAFFIC RAILING/JUNCTION NO. NO.

01/01/12 FY 2012/2013 SLAB 6110 4

»¿ Interior Post (C 1

6 4"–

rs4A) Joint permitted in rail) P1 & 4V1

i oa

et t

lernate Ba Spacn

ig Bars7

4 " paced@ 8–(

" T 5sp.

Bars7P1 & 4V1 s 5sp.

11 " 5–

"

5 " @ 4" Curb)

nst

iion @ 4" acn

ig Bars4P5 (

GuardralT

i ra 2sp. Sp

8"

7-

’3 " 6-

’6–

"

u-BoltSpacing –

" 2sp. "

6-

’3" Thr 5 @ 8

Guardrail Thrie Beam 1-

’1b" "

@ 8 Bars 4S3

attachment shown, Shift Bars 4A & 4L to A

W-Beam similar clear precast opening C

Top of C-I-P b" V-Groove Curb (Precast

Traffic Railing rs7 T

P1 (yp)

. permitted for or C-I-P)

D Ba

T

V1 (yp)

. C-I-P Curb

Bars4

Bars 4P5 (Typ.) Bars 4R3

C-I-P

Transition

2’

-3"

re

is A 2-

’6" 2-

’6"

Va p)

.

5-

’0 T

"(y

C n

"Mi., 2-

’6"

Bars 4L (Typ.) per 0

(’-0 st

Bars 4A (Typ.) 3-

’0 "Ta Intero

ir Po

Begin or End 4"

n.) -6"Max)

. Ba

"( rs4L)

D Vare

i 2

s(’-6"Mi

nsd

i e Face) 2’ 4" s 4A) & 14 sp.@ 8

Retaining Wall (I 8sp.@ 4 B

"( ar

2

3-

’0"Taper 8"(Bars 4L)

Coping, and –

" 4" s4A)& 14s p.@

4 8sp.@ 4 Ba

"( r

ce) 2

Traffic Railing I

(nsd

ie Fa "sp. pn

ig

.& Bars4L@ 8 ypc

ialPrecastCo » " Open Joint

Bars4A@ 4"sp 10-

’0"T

4" ranst

iion Copn

ig wih Cu

t rb in Precast Coping

10-

’0"BegnT

i

tion Copn

ig and Precast Curb

n.)EndTransi

Vare

i 8

s(’-6"Mi

PARTIAL ELEVATION VIEW OF OUTSIDE FACE OF COPING

dgn

\d\projects\standards\structures\current\ready4release\2012book_draft\06110-5of6.

(End Transition and Typical Precast Coping with Curb shown, C-I-P Coping similar)

»¿ Interior Post (C

»¿ Expansion Joi Joint permitted in rail)

6 "

Begin/End Approch Slab

5sp.

V1 5sp.

a cn

ig Bars7 P1 & 4

Sp @ 4"

» " Open Joint in 4b" "

P1 & 4V1 ars o

t @ 4 B

Bars7 (Tiea t

lernate b

Coping & Traffic Railing

6sp.@ 8" Ba rs4 Aor4 L )

Top of C-I-P

Traffic Railing A

Bars7 T

P1 (yp)

.

Bars4 T

V1 (yp)

.

Post (Precast or C-I-P)

Top of Precast Coping

Bars 4S3 (Typ.)

Bars 4S3 (Typ.)

Post (Precast or C-I-P) (Typ.)

Bars 4L (Typ.)

Bars 4A (Typ.)

2-

’6"

2-

’6"

5-

’0 T

"(yp)

.

yp)

. 2-

’6"

ies~ 5-

’0"(T st

Var n

I e

t ro

ir Po

C:

5-

’0"End Post

d Post n.,5-

’0"Ma x)

. 4"

5-

’0"En 2

(’-6"Mi Ba

"( rs4L)

p )

. p.Jon

it) 4" A)& 14sp.@ 8

Varies~ 5 -

’0"(Ty T

(ypc

ial@ Ex 8sp.@ 4 Ba

"( rs4

p.Jon

it) 2

2-

’6" T

( ypc

ial@ Ex Ba

"( rs4L)

n,

. 5-

’0" Max.) s4A)& 14sp.@ 8

2

(’-6"Mi 28sp.@ 4 Ba

"( r

4" ecastCopn

ig

7’-6"Typ )

. A 10-

’0"Typc

ialPr » " Open Joint

pe nn

ig Va re

is(

tO

rd960rh

End Pos )

.

pansionJ oint(7-

’6"Min

t

wihoutCurb B in Precast Coping

n,7

. -

’6"Ma x)

. 10-

’0"Typc

ialEx

(5-

’0"Mi

o n

it(7’-6 n

"Mi.) g without Curb & Precast Curb

picalEx pansionJ PrecastCopin

» " Open Joint 10-

’0"T y "M

-0 n

i .,9’

0-0"

ntspacing ~3’

0

h

t outC urb xa

pn i

s onJoi

in Precast Coping PrecastCo ping wi »¿˘ "E NOTE: Wall Panels not shown for clarity.

-0"Min.,90’-0"

nt p

saci g

n ~30’

i

57 AM

xpansionJo

˘ "E

»¿

CROSS REFERENCES:

34:

1. For Sections A-A, B-B, C-C & D-D, see

PARTIAL ELEVATION VIEW OF OUTSIDE FACE OF COPING

9:

Sheet 6.

(Precast Coping at Expansion Joint and Typical Precast Coping without Curb shown, C-I-P Coping similar)

2. For Junction Slab Notes, see Sheet 1.

12/30/2011

CORRAL SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS WALL COPING WITH TRAFFIC RAILING/JUNCTION NO. NO.

01/01/12 FY 2012/2013 SLAB 6110 5

1’-6b"

Coping 1’-6b" 1’-6b"

Gutter Line

Coping Coping

Gutter Line Gutter Line

Index No. 424

Index No. 424 Index No. 424

P. Only

Traffic Railing -

P. Only

Rail)

(Corral Shape) Traffic Railing - Traffic Railing -

4 "

Rail)

(Corral Shape) (Corral Shape)

Bars 7P1 4 "

I.

(

Post & Rail)

C.

(See Note 4) Bars 7P1

I.

(

1b "

P. Only

C.

(See Note 4) 1b " 1b "

I.

C.

P.

Precast

Post)

(

Curb

I.

Bars 4S3

or C.

Const. Bars 4S3 Bars 4P5 (See Note 4)

(See Note 4) See "Curb Joint

Joint Const.

(

(See Note 4)

Sealant Detail"

1’-2" permitted Joint

1’-2" required 1’-2" 3b " 6" Precast

or C.I.P. Curb

Bars 4A

6" Bars 4A Bars 4A

Embed. 6" 6"

Bars 5C Embed. Embed.

Bars 4V1 Bars 5C

Bars 5B2 Bars 4R3

(See Note 4) Bars 5B2 Bars 4V1 Bars 5B2

(See Note 4) (See Note 4)

Bars 4L

Bars 5B1 (Typ.) Bars 4L Bars 4L Const. Joint permitted

See Sheet 2 Bars 5B2 (Typ.)

for Junction Slab and

See Sheet 3 Bars 5B1 (Typ.)

Precast Coping Details

for Junction Slab and See Sheet 2 or 3

C.I.P. Coping Details for Junction Slab

and Coping Details Trim Bars 4P5 as

required to clear

Const. Joint

1’-6b" Min.

dgn

1’-6b" Min.

(See Note 3)

\d\projects\standards\structures\current\ready4release\2012book_draft\06110-6of6.

SECTION A-A (See Note 3)

SECTION A-A

(TYPICAL SECTION C.I.P. COPING WITHOUT CURB)

(TYPICAL SECTION PRECAST COPING WITHOUT CURB) SECTION B-B

1’-6b"

1’-6b"

Gutter Line Coping (TYPICAL SECTION WITH CURB)

Coping (Precast Coping Shown, C.I.P. Coping Similar)

Gutter Line

Index No. 424

Traffic Railing -

Index No. 424

(Corral Shape)

Traffic Railing - 7 " 4 "

(Corral Shape)

Transition)

P. Only

Top of Curb

Transition)

4b " 1b "

P. Only

Bars 7P1 Bars 7P1

(See Note 4) (See Note 4)

1b " Low Modulus

I.

Silicone Sealant

I.

C.

C.

(Type A)

(

»¿˘" (T JOINT NOTE:

(

Joint sealant required at

4b" Taper Const. all expansion joints and

4b" Taper Const.

Joint between precast and

Joint

1’-2" required C.I.P. curb openings.

11" required

" Preformed Expansion

Bars 4A Joint Filler (See Detail "A"

Bars 4A

6" Sheet 2)

Embed. 1" Foam

Bars 5C

Bars 5C Bars 4V1 Backer Rod

Bars 5B2

C:

Bars 4V1 2"

Bars 5B2 (See Note 4)

(See Note 4)

Bars 4L Min.

Bars 4L Bars 5B1 (Typ.)

Bars 5B1 (Typ.)

CURB JOINT SEALANT DETAIL

See Sheet 2 or 3 See Sheet 2 or 3

rd960rh

for Junction Slab for Junction Slab

and Coping Details and Coping Details

NOTES:

1. See Sheets 2 & 3 for Junction Slab and additional Coping details.

58 AM

2. Slip Forming of C.I.P. Traffic Railiing is not permitted.

1’-6b" Min.

34:

1’-6b" Min. 3. Actual width varies depending on type of Retaining Wall used.

9:

(See Note 3)

(See Note 3) 4. See Index No. 424 for Traffic Railing details and Bars 7P1, 4P5,

SECTION C-C END VIEW D-D 4R3, 4S3 & 4V1. Bars 5R2 and 5U are not required in Retaining

Wall Coping.

12/30/2011

(TYPICAL SECTION TRANSITION COPING) (TYPICAL SECTION TRANSITION COPING)

(Precast Coping shown, C.I.P. Coping similar) (Precast Coping shown, C.I.P. Coping similar)

CORRAL SHAPE TRAFFIC RAILINGS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

REVISION FDOT DESIGN STANDARDS WALL COPING WITH TRAFFIC RAILING/JUNCTION NO. NO.

01/01/12 FY 2012/2013 SLAB 6110 6

1" Dowel Load Expansion Joint (See

b " V-Groove (See 2" Cover

1" Dowel Load Transfer Bars 5B2 Bars 4C @ 6" sp. (tie Bars "Expansion Joint Detail "

Note 6 & Detail "B") Transfer Devices

Sides (Typ.)

Devices (See Typical Sections 4C to Bars 5A) (Typ.) this sheet and Detail "B")

Top of Raised

for details) Sidewalk

4 ~ Bars 5F

(Top of Slab)

Approved metal (Required only

or fiber cap when Raised

Sidewalk is

skewed)

Lap Splice

-0" M in.

3"

Approach Slab 3s

p.

@

(See Note 10) 6"

Edge of

2’

Precast Coping

Gutter Line

" Bar 5T

Bottom of

Raised Sidewalk

" Preformed Expansion

Bars 5L @ 6" sp.

Joint Filler (tied to alternating

Bars 5T and 5X)

1’-0" 1’-0"

Field cut reinforcing " Open Joint Alternating Bars Coping (Typ.)

Begin or End Retaining Wall as required to maintain Bars 5S in Precast Coping 5T and 5X @ Bars 5B1

»¿ Expansion

& Precast or C-I-P Coping minimum cover (Typ.) 1’-0" sp. (Typ.) Bars 5A @ 6" sp.

2b "

(tied to Bars 5U1) (Typ.)

EXPANSION JOINT DETAIL Spacing Bars 6" Spacing (Typ.) (See Note 7) 2" Cover @ 2" Cover @

5T and 5X Open Joints Expansion Joints

(Raised Sidewalk expansion joints are to coincide

with " open joints in Traffic Railing) b " V-Groove Spacing 30’-0" Max. (See Note 6)

dgn

»¿˘" Expansion Joint Spacing ~ 30’-0" Min., 90’-0" Max. (See Not

\d\projects\standards\structures\current\ready4release\2012book_draft\06120-1of3.

»¿ ˘" Open Jo

»¿˘" Open J PARTIAL PLAN VIEW FOR VERTICAL SHAPE TRAFFIC RAILING

Precast Coping and

(Skewed Approach Slab Shown, Perpendicular Approach Slab Similar) C-I-P Traffic Railing

RAISED SIDEWALK NOTES: (Precast Coping Shown, C-I-P Coping Similar) (Traffic Railing not Shown for Clarity) »¿to coincide with