Académique Documents

Professionnel Documents

Culture Documents

Aashto R - 50-10

Transféré par

SonalMhaisalgikarTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Aashto R - 50-10

Transféré par

SonalMhaisalgikarDroits d'auteur :

Formats disponibles

Standard Practice for

Geosynthetic Reinforcement of the

Aggregate Base Course of Flexible

Pavement Structures

AASHTO Designation: R 50-091

American Association of State Highway and Transportation Officials

444 North Capitol Street N.W., Suite 249

Washington, D.C. 20001

Standard Practice for

Geosynthetic Reinforcement of the

Aggregate Base Course of Flexible

Pavement Structures

AASHTO Designation: R 50-09 1

1. SCOPE

1.1. This standard practice provides guidance to pavement designers interested in incorporating

geosynthetics for the purpose of reinforcing the aggregate base course of flexible pavement

structures. Geosynthetic reinforcement is intended to provide structural support of traffic loads

over the life of the pavement.

1.1.1. For the purpose of this guide, base reinforcement is the use of a geosynthetic within, or directly

beneath, the granular base course.

1.1.2. When referring to geosynthetics, the discussion is limited to geotextiles, geogrids, or

geogrid/geotextile composites.

2. REFERENCED DOCUMENTS

2.1. AASHTO Standard:

M 288, Geotextile Specification for Highway Applications

2.2. Other References:

Geosynthetics Materials Association (GMA) White Paper I—“Geosynthetics in Pavement

Systems Applications,” May 1999. Available at www.bookstore@ifai.com.

Geosynthetic Materials Association (GMA) White Paper II—“Geosynthetic Reinforcement of

the Aggregate Base Course of Flexible Pavement Structures,” June 2000. Available at

www.bookstore@ifai.com.

National Highway Institute (NHI) Participant Notebook—Geosynthetic Design and

Construction Guidelines, April 1999. Available at www.nhi.fhwa.dot.gov.

3. INTRODUCTION

3.1. Because the benefits of geosynthetic reinforced pavement structures may not be derived

theoretically, test sections are necessary to obtain benefit quantification. Studies have been done

that demonstrate the value added by a geosynthetic in a pavement structure. These studies,

necessarily limited in scope, remain the basis for design in this field.

3.2. This standard practice is very empirical in nature and restricted to applications already

demonstrated to be useful. The practitioner will need to consult the references and locate a tested

TS-4e R 50-1 AASHTO

© 2010 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

section similar to that which is expected in their own design. In that way, the experimentally

determined benefit may be applied to the project being designed.

4. TERMINOLOGY

4.1. Definitions:

4.1.1. base course reduction (BCR)—percentage of the base or subbase thickness in a reinforced

pavement, as compared to the base or subbase thickness in an unreinforced pavement with the

same material components, such that equal life cycles for a defined failure state result between

the two.

4.1.2. separation—use of a geotextile to prevent the mixing of a subgrade soil and an overlying

aggregate material.

4.1.3. stabilization—use of a geotextile in wet, saturated conditions to provide the functions of

separation and drainage.

4.1.4. traffic benefit ratio (TBR)—ratio of the number of load cycles of a reinforced pavement structure

to reach a defined failure state to the number of loads for the same unreinforced section to reach

the same defined failure state.

4.2. Discussion—Use of geotextiles for separation and stabilization applications is covered in M 288

and, therefore, is not included in this guide.

5. SUMMARY OF DESIGN METHOD

5.1. The purpose of this guide is to provide the practitioner with general information regarding the

use of a geosynthetic for reinforcement in a pavement structure. The guide will not provide

step-by-step procedures for the design of the geosynthetic in this application; instead, overall

design considerations are outlined.

5.2. Design procedures use experimentally derived input parameters that are often geosynthetic

specific. Thus, computed engineering designs and economic benefits are not easily translated to

other geosynthetics. Therefore, users of this document are encouraged to affirm their designs with

field verification of the reinforced pavement performance, both in engineering design and

economic benefits.

6. SIGNIFICANCE AND USE

6.1. Geosynthetics are used in the pavement structure for structural support of traffic loads over the

design life of the pavement. The geosynthetic is expected to provide one or both of these benefits:

(1) improved or extended service life of the pavement, or (2) reduced thickness of the structural

section.

6.2. Service life improvement may be in the form of extended performance periods or increased

reliability (1) so that the constructed pavement will support the actual versus designed equivalent

single-axle loads, or (2) to account for actual subgrade strengths lower than assumed designed

subgrade strength.

TS-4e R 50-2 AASHTO

© 2010 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

7. GENERAL DESIGN STEPS

7.1. In general terms, the design steps to be followed in determining the applicability of incorporating

geosynthetic reinforcement in a pavement design are shown below.

7.1.1. General design procedures may be found in the NHI Participant Notebook on this topic.

7.1.2. A general design procedure for the reinforcement application, detailing the steps summarized

below, is contained in GMA White Paper II.

7.1.3. Make an initial assessment of the applicability of a geosynthetic. This is based on an assessment of

the subgrade strength and the past performance in similar soils. Consideration should be given to

each type of geosynthetic appropriate for the installation.

7.1.4. Design the thickness of an unreinforced pavement section based on representative material

parameters for a pavement design unreinforced by geosynthetics.

7.1.5. Determine the benefits of using a geosynthetic. Refer to Section 6.1 to determine what the target

benefit or benefits should be.

7.1.6. The target benefits should indicate whether a TBR or BCR, or both, needs to be identified.

7.1.6.1. The TBR is defined as the ratio of the number of load cycles of a reinforced pavement structure to

reach a defined failure state, to the number of loads for the same unreinforced section to reach the

same defined failure state.

7.1.6.2. The BCR is defined as the percentage of the base or subbase thickness in a reinforced pavement,

as compared to the base or subbase thickness in an unreinforced pavement with the same material

components, such that equal life cycles for a defined failure state result between the two.

7.1.7. Develop a trial reinforced pavement design that reflects the desired target benefits. Though

the design procedures mentioned in Sections 7.1.1 and 7.1.2 can be used to estimate the

potential benefit of geosynthetic reinforcement, the accuracy of these methods for specific

applications is yet to be determined; hence, construction and performance monitoring as

discussed in Sections 7.1.11 and 7.1.12 is recommended. Similar case histories of pavement

reinforcement should also be used to help estimate the potential benefit of geosynthetic

reinforcement for the specific application being considered.

7.1.8. Perform a life-cycle cost analysis. A knowledge of the initial construction costs for both the

unreinforced and the reinforced options, the life-cycle costs for both options, and other benefits,

which may not be easily quantifiable, is needed in order to complete a life-cycle cost analysis.

7.1.9. Prepare material specifications. Based on the results of the above process, the engineer may want

to develop an approved list of products that are considered appropriate for this application, based

on successful past applications. The construction contractor then has the option, based on the

results of the design, to select products based on suitability, availability, and economics.

7.1.10. Prepare contract documents, specifications, and construction drawings. Specific attention needs to

be paid to installation guidelines, location within the pavement section, and quality assurance

procedures when preparing these documents and drawings.

TS-4e R 50-3 AASHTO

© 2010 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

7.1.11. Monitor the construction sequences to ensure that the correct geosynthetic is installed in the

correct locations, both vertically within the pavement section and horizontally along the project.

The installation procedures should also be monitored to eliminate any construction damage to the

geosynthetic and to ensure proper performance of the material.

7.1.12. Monitor long-term performance. Formal documentation of the pavement’s performance is

recommended to allow for a complete evaluation of the geosynthetic’s performance in relation to

the benefits that the section was designed to provide.

7.1.13. Users of this guide are encouraged to prepare an annual assessment regarding the performance of

the geosynthetic.

7.1.14. Based on the above assessment of performance, design procedures and/or material specifications

may be developed or revised to reflect the results of the study.

1

This standard was first published in 2001 as PP 46.

TS-4e R 50-4 AASHTO

© 2010 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

Vous aimerez peut-être aussi

- Working Platform For Tracked Plant - BR470 Guideline and Revised ApproachDocument6 pagesWorking Platform For Tracked Plant - BR470 Guideline and Revised ApproachDanny LamPas encore d'évaluation

- Aashto M288Document29 pagesAashto M288jong_hao_su5167% (3)

- Aashto M288Document29 pagesAashto M288jong_hao_su5167% (3)

- AASHTO M288 GeotextilesDocument2 pagesAASHTO M288 GeotextilesAaron_Gea0% (2)

- Aashto TP62-07Document18 pagesAashto TP62-07amin13177100% (1)

- Astm D1633-17 PDFDocument4 pagesAstm D1633-17 PDFRaúl Meza100% (1)

- SOIL MECHANICS AND FOUNDATION ENGINEERING, K.R. Arora, Delhi, 2004. 903p PDFDocument903 pagesSOIL MECHANICS AND FOUNDATION ENGINEERING, K.R. Arora, Delhi, 2004. 903p PDFMANUEL ARTURO FIGUEROA LEON85% (52)

- Pavement Deflection Measurements: Standard Method of Test ForDocument11 pagesPavement Deflection Measurements: Standard Method of Test Forsidiq7100% (2)

- Bailey Method For Gradation SelectionDocument39 pagesBailey Method For Gradation SelectionBijay Krishna Das100% (2)

- D 4751 - 99 Rdq3nteDocument5 pagesD 4751 - 99 Rdq3nteRonald VillegasPas encore d'évaluation

- Maccaferri Pavement Design With GeogridDocument15 pagesMaccaferri Pavement Design With GeogridMahesh KoppakaPas encore d'évaluation

- Geosynthetic Engineering - IntroductionDocument31 pagesGeosynthetic Engineering - IntroductionCatalin VeghiuPas encore d'évaluation

- Eurocode 7 Geotechnical Design Worked ExamplesDocument172 pagesEurocode 7 Geotechnical Design Worked ExamplesJevgenijs Kolupajevs100% (1)

- Eurocode 7 Geotechnical Design Worked ExamplesDocument172 pagesEurocode 7 Geotechnical Design Worked ExamplesJevgenijs Kolupajevs100% (1)

- D3398Document5 pagesD3398smanoj354Pas encore d'évaluation

- Design Flexible Roads Reinforced with Tenax Geogrids using TNXROAD SoftwareDocument32 pagesDesign Flexible Roads Reinforced with Tenax Geogrids using TNXROAD SoftwareJose LizarragaPas encore d'évaluation

- Index of Aggregate Particle Shape and Texture: Standard Test Method ForDocument4 pagesIndex of Aggregate Particle Shape and Texture: Standard Test Method ForLupita RamirezPas encore d'évaluation

- US 0702-3A Design and Execution-F3Document42 pagesUS 0702-3A Design and Execution-F3almirante_andrePas encore d'évaluation

- Astm D4695-96Document3 pagesAstm D4695-96Bridger WangPas encore d'évaluation

- Astm D 4254Document9 pagesAstm D 4254safak kahramanPas encore d'évaluation

- CBR-Index Soil PropertiesDocument5 pagesCBR-Index Soil PropertiesJagathChandraPas encore d'évaluation

- Design of Hot Mix Asphalt Using Bailey Method of GradationDocument8 pagesDesign of Hot Mix Asphalt Using Bailey Method of GradationInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- AASHTO Equation For Flexible Pavement.Document3 pagesAASHTO Equation For Flexible Pavement.Usama Fareed50% (2)

- Modelling Study On The Geotextile, Geogrid and Steel Strip Reinforced SlopesDocument15 pagesModelling Study On The Geotextile, Geogrid and Steel Strip Reinforced SlopesAnupEkbotePas encore d'évaluation

- Reclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForDocument5 pagesReclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForRed RedPas encore d'évaluation

- Mechanistic-Empirical Pavement Design GuideDocument3 pagesMechanistic-Empirical Pavement Design Guidelelu8210Pas encore d'évaluation

- Potholes:: Technical Guide To Their Causes, Identification and RepairDocument52 pagesPotholes:: Technical Guide To Their Causes, Identification and RepairTerrencePas encore d'évaluation

- Asphalt Pavements A PracticalDocument2 pagesAsphalt Pavements A PracticalMahmoudRadi0% (1)

- BISAR 3.0: Bitumen Business Group May 1998Document47 pagesBISAR 3.0: Bitumen Business Group May 1998rapax2450% (2)

- D 6916 - 03Document6 pagesD 6916 - 03luis-12Pas encore d'évaluation

- Determination of Degree of Saturation of Soil Samples by B Value MeasurementDocument5 pagesDetermination of Degree of Saturation of Soil Samples by B Value Measurementcamillelele100% (1)

- Marshall Mix Design ProcedureDocument31 pagesMarshall Mix Design Procedurebraackw100% (2)

- D7113 tcxp6531 DensityDocument3 pagesD7113 tcxp6531 DensityDasarathaPas encore d'évaluation

- D1073 PDFDocument2 pagesD1073 PDFArnold RojasPas encore d'évaluation

- Geocell 4Document54 pagesGeocell 4prabin kumar ashishPas encore d'évaluation

- Asphalt ConcreteDocument6 pagesAsphalt ConcretemechnsatheeshPas encore d'évaluation

- NCHRP RPT 598Document64 pagesNCHRP RPT 598destayegPas encore d'évaluation

- Tesis PavsGeotextiles PDFDocument204 pagesTesis PavsGeotextiles PDFDavid SupoPas encore d'évaluation

- Selection of Cutback Asphalts: Standard Practice ForDocument3 pagesSelection of Cutback Asphalts: Standard Practice ForD IZomer Oyola-GuzmánPas encore d'évaluation

- ACPA City Street Pavement DesignDocument8 pagesACPA City Street Pavement DesignFelipe Fernández100% (1)

- Hot-Mix Asphalt Paving HandbookDocument9 pagesHot-Mix Asphalt Paving HandbookCollin LegaspinaPas encore d'évaluation

- 5 D 4427 - 18 Klasifikasi-DikonversiDocument4 pages5 D 4427 - 18 Klasifikasi-DikonversiAlfonsus HasugianPas encore d'évaluation

- Design of Pavement Using Reinforced SoilDocument14 pagesDesign of Pavement Using Reinforced Soilmehul ranaPas encore d'évaluation

- Stone Matrix Asphalt Pavement 1Document26 pagesStone Matrix Asphalt Pavement 1JAYBHAY BHAGWATPas encore d'évaluation

- Astm C-42Document6 pagesAstm C-42Víctor M Fernández JiménezPas encore d'évaluation

- ASTM Volume 04.03 Road and Paving MaterialsDocument7 pagesASTM Volume 04.03 Road and Paving MaterialsVenu GopalPas encore d'évaluation

- Precision of Marshall Stability and Flow Test Using 6 Inch Diameter SpecimensDocument1 pagePrecision of Marshall Stability and Flow Test Using 6 Inch Diameter SpecimensProf. Prithvi Singh KandhalPas encore d'évaluation

- A Correlation Between Dynamic Cone Penetrometer Values and PDocument8 pagesA Correlation Between Dynamic Cone Penetrometer Values and PgaddargaddarPas encore d'évaluation

- Highway SpecificationDocument85 pagesHighway SpecificationAkaninyenePas encore d'évaluation

- Astm C1688C1688M.4631Document4 pagesAstm C1688C1688M.4631Thayane SoaresPas encore d'évaluation

- Aashto T 179 2005 (R 2009)Document6 pagesAashto T 179 2005 (R 2009)Ivan David JacomePas encore d'évaluation

- Aashto T 391Document9 pagesAashto T 391Ramy Hussein100% (1)

- Napa Is129Document21 pagesNapa Is129Felix GranadosPas encore d'évaluation

- Determining Fracture Energy of Asphalt-Aggregate Mixtures Using The Disk-Shaped Compact Tension GeometryDocument8 pagesDetermining Fracture Energy of Asphalt-Aggregate Mixtures Using The Disk-Shaped Compact Tension GeometryBrayan RomeroPas encore d'évaluation

- Is - 15462 PDFDocument20 pagesIs - 15462 PDFAnuradhaPatraPas encore d'évaluation

- Plastic Limit Plasticity Indext 090Document5 pagesPlastic Limit Plasticity Indext 090Jayson AbejarPas encore d'évaluation

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementD'EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementPas encore d'évaluation

- AASHTO R 50-09 Geosynthetic Reinforcement PDFDocument4 pagesAASHTO R 50-09 Geosynthetic Reinforcement PDFankitPas encore d'évaluation

- TN White PDFDocument7 pagesTN White PDFLord ScribdPas encore d'évaluation

- ABC-Draft - 03 Dated 18.07.13Document96 pagesABC-Draft - 03 Dated 18.07.13Ratul RanjanPas encore d'évaluation

- BR470 Review Summary 1Document2 pagesBR470 Review Summary 1junhe898Pas encore d'évaluation

- Control 5 - AASHTO IntroducciónDocument29 pagesControl 5 - AASHTO IntroducciónManuel Hugo Luarte JaraPas encore d'évaluation

- Design of Geocell Reinforced Flexible PavementDocument4 pagesDesign of Geocell Reinforced Flexible Pavementsundra0Pas encore d'évaluation

- Design of Rigid Pavement CC Road With M30Document108 pagesDesign of Rigid Pavement CC Road With M30Ajay Singh100% (1)

- Stone Matrix Asphalt Specification UpdatesDocument31 pagesStone Matrix Asphalt Specification UpdatesShaik Bademiya100% (2)

- Nelsen Thesis 2018Document190 pagesNelsen Thesis 2018SonalMhaisalgikarPas encore d'évaluation

- Fhwa Nhi 09 087 PDFDocument154 pagesFhwa Nhi 09 087 PDFSonalMhaisalgikarPas encore d'évaluation

- Fhwa 011367 2Document216 pagesFhwa 011367 2SonalMhaisalgikarPas encore d'évaluation

- Astm A 975 PDFDocument7 pagesAstm A 975 PDFSonalMhaisalgikarPas encore d'évaluation

- Irc SP 042 2014Document148 pagesIrc SP 042 2014roshanrsv100% (6)

- IS: 8009 (Part I) - 1976Document42 pagesIS: 8009 (Part I) - 1976SonalMhaisalgikarPas encore d'évaluation

- QIP123 Heavy-Duty Pavements 2e PDFDocument74 pagesQIP123 Heavy-Duty Pavements 2e PDFGANDHI JAY JITENDRAPas encore d'évaluation

- IS: 8009 (Part I) - 1976Document42 pagesIS: 8009 (Part I) - 1976SonalMhaisalgikarPas encore d'évaluation

- Ispitivanja PDFDocument100 pagesIspitivanja PDFajlaPas encore d'évaluation

- The Effective Contribution of Software Applications in Various Disciplines of Civil Engineering PDFDocument18 pagesThe Effective Contribution of Software Applications in Various Disciplines of Civil Engineering PDFawake.shugalPas encore d'évaluation

- Is.2720. (CBR Field Det) PDFDocument12 pagesIs.2720. (CBR Field Det) PDFAmeen SyedPas encore d'évaluation

- Astm A 975 PDFDocument7 pagesAstm A 975 PDFSonalMhaisalgikarPas encore d'évaluation

- IS: 8009 (Part I) - 1976Document42 pagesIS: 8009 (Part I) - 1976SonalMhaisalgikarPas encore d'évaluation

- Irc - SP 75 2008Document72 pagesIrc - SP 75 2008SonalMhaisalgikarPas encore d'évaluation

- Standard specifications for road bridge foundationsDocument110 pagesStandard specifications for road bridge foundationsopti123Pas encore d'évaluation

- FHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IIDocument404 pagesFHWA-NHI-10-024 Design & Construction of MSE Walls and Reinforced Soil Slopes - Volume IIKathleen NoonanPas encore d'évaluation

- BS 8009 - 2Document23 pagesBS 8009 - 2SonalMhaisalgikarPas encore d'évaluation

- IS: 8009 (Part I) - 1976Document42 pagesIS: 8009 (Part I) - 1976SonalMhaisalgikarPas encore d'évaluation

- BS 8009 - 2Document23 pagesBS 8009 - 2SonalMhaisalgikarPas encore d'évaluation

- Design Coastal Roads for Safety & SustainabilityDocument55 pagesDesign Coastal Roads for Safety & SustainabilityMohammedPas encore d'évaluation

- Chapter Three Stabilized Pavement MaterialsDocument35 pagesChapter Three Stabilized Pavement MaterialsIfa AsratPas encore d'évaluation

- Modified Binders and Superpave Plus SpecificationsDocument2 pagesModified Binders and Superpave Plus Specificationsingmdtz_1Pas encore d'évaluation

- PCA EB234 Guide To Full-Depth Reclamation (FDR) With CementDocument21 pagesPCA EB234 Guide To Full-Depth Reclamation (FDR) With Cementjaime_rbPas encore d'évaluation

- Stabilization of Soil by Plastic Waste I PDFDocument3 pagesStabilization of Soil by Plastic Waste I PDFDennis Vincent VillarPas encore d'évaluation

- Kerbs & Inl SpecDocument4 pagesKerbs & Inl Specabdulrehman731Pas encore d'évaluation

- MNDOT Rating Procedures OverviewDocument8 pagesMNDOT Rating Procedures OverviewcrojastPas encore d'évaluation

- DBM 507Document7 pagesDBM 507Mark Moni Mary ManoPas encore d'évaluation

- Triple Barrel Box Culvert Revised 2Document17 pagesTriple Barrel Box Culvert Revised 2John Ricky Exequiel CalaraPas encore d'évaluation

- 3.15 Roads and Pavings (Class Q)Document3 pages3.15 Roads and Pavings (Class Q)Ashiteru BestPas encore d'évaluation

- Central Level Project Implementation UnitDocument54 pagesCentral Level Project Implementation UnitDamodar ShresthaPas encore d'évaluation

- Han Giroud 3parts WebDocument36 pagesHan Giroud 3parts WebAlexPas encore d'évaluation

- Guide to soil load-bearing values and footing depthsDocument3 pagesGuide to soil load-bearing values and footing depthsKasimiro BukayoPas encore d'évaluation

- Construction and Building Materials: S.D. Capitão, L.G. Picado-Santos, F. MartinhoDocument9 pagesConstruction and Building Materials: S.D. Capitão, L.G. Picado-Santos, F. MartinhoShuddhashil GhoshPas encore d'évaluation

- Advanced Pavement DesignsDocument6 pagesAdvanced Pavement DesignsJackie CrowellPas encore d'évaluation

- Determining Degree of Pavement Compaction of Bituminous Aggregate MixturesDocument2 pagesDetermining Degree of Pavement Compaction of Bituminous Aggregate MixturesEvert RiveraPas encore d'évaluation

- Applicability of Biodegradable Fibres On The Geotechnical Properties of A Subgrade MaterialDocument18 pagesApplicability of Biodegradable Fibres On The Geotechnical Properties of A Subgrade MaterialHAMPO OBINNAPas encore d'évaluation

- CBR Test Procedure Determination of California Bearing Ratio For Road Design PDFDocument5 pagesCBR Test Procedure Determination of California Bearing Ratio For Road Design PDFMohamed AdelPas encore d'évaluation

- Different Coat Application For Flexible Pavement NewDocument38 pagesDifferent Coat Application For Flexible Pavement NewAvishya JaswalPas encore d'évaluation

- Rigid Pavement Design For: Any Airport Anywhere, USA Engineer's Are Us 3-XX-XXX-XXDocument15 pagesRigid Pavement Design For: Any Airport Anywhere, USA Engineer's Are Us 3-XX-XXX-XXKaterinePas encore d'évaluation

- Gravel Paser 02Document24 pagesGravel Paser 02Jesus SanovalPas encore d'évaluation

- Evaluation of FE Software For Pavement Stress Analysis PDFDocument126 pagesEvaluation of FE Software For Pavement Stress Analysis PDFSudipto PaulPas encore d'évaluation

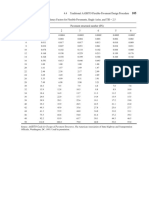

- Table 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5Document6 pagesTable 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5fadi eidPas encore d'évaluation

- Effects of Bad Road Conditions on Transportation in Mayapyap NorteDocument22 pagesEffects of Bad Road Conditions on Transportation in Mayapyap NorteDominic BautistaPas encore d'évaluation

- Chapter 4: Pavement Design GuideDocument53 pagesChapter 4: Pavement Design Guidecj salesPas encore d'évaluation

- Airport Product PortfolioDocument6 pagesAirport Product PortfolioRakesh ParaliyaPas encore d'évaluation

- Composition and Structure of Flexible PavementDocument2 pagesComposition and Structure of Flexible PavementlauropaniergoPas encore d'évaluation

- Pat303 Highway and Traffic Technology Laboratory WorksheetDocument14 pagesPat303 Highway and Traffic Technology Laboratory WorksheetDickson LingPas encore d'évaluation

- Fibre Reinforced Microsurfacing - V2.0 - Bovin KumarDocument11 pagesFibre Reinforced Microsurfacing - V2.0 - Bovin KumarMuralee MohanPas encore d'évaluation

- HighwayDocument20 pagesHighwayYashpal GangeshwarPas encore d'évaluation