Académique Documents

Professionnel Documents

Culture Documents

Panasonic

Transféré par

dinnhowCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Panasonic

Transféré par

dinnhowDroits d'auteur :

Formats disponibles

®

RT6908

PMIC for TFT LCD TV Panels

General Description Features

The RT6908 provides a complete set of programmable z 9V to 16V Input Supply Voltage

multi-functional power solution for TFT LCD panel. The z 4.4A Boost Regulator for AVDD with 12.7V to 19V

RT6908 contains a step-up converter for main power and Programmable Output

step-down controllers to provide the logic voltages for the z 1-CH Sync. Buck Converter for VI/O

system. Moreover, a positive charge pump regulator z 1-CH Sync. Buck Controller for VCORE

provides the adjustable gate-high voltage, VGH; a negative z Negative Charge Pump Regulator for VGL with

charge pump regulator provides the gate-low voltage, VGL. −8.1V to −1.8V Programmable Output

AVDD, VGH and VGL outputs and power sequence can be z Positive Charge Pump Regulator for VGH with 24.5V

programmable through I2C interface. to 40V Programmable Output

z Programmable Sequencing

With its high current capabilities, the device is ideal for

z Voltage Detection Output

large screen monitor panels and LCD TV applications with

z Over Temperature Protection

12V supply voltage. The RT6908 is available in a WQFN-

z I2C Compatible Interface for Register Control

40L 5x5 package.

z Thin 40-Lead WQFN Package

z RoHS Compliant and Halogen Free

Ordering Information

RT6908 Applications

Package Type z TFT LCD TV Panel

QW : WQFN-40L 5x5 (W-Type)

Lead Plating System Pin Configurations

Z : ECO (Ecological Element with (TOP VIEW)

Halogen Free and Pb free)

EN_I2C

BOOT1

VINB1

AGND

Note :

LXB1

LXB1

AVIN

NC

EN

VL

Richtek products are :

40 39 38 37 36 35 34 33 32 31

` RoHS compliant and compatible with the current require-

PGND 1 30 BOOT2

ments of IPC/JEDEC J-STD-020. FBB1 2 29 LXB2

COMP1 3 28 DHB2

` Suitable for use in SnPb or Pb-free soldering processes.

RSTB 4 27 NC

SDA 5 26 DLB2

PGND

SCL 6 25 ILIMIT2

Marking Information VDET 7 24 FBB2

AVDD 8 23 COMP2

RT6908ZQW : Product Number 41

GD 9 22 CRST

RT6908 YMDNN : Date Code LXI 10 21 DRVN

ZQW 11 12 13 14 15 16 17 18 19 20

A0

VGL

PGND

PGND

VGH

COMP

LX

LX

LX

DRVP

YMDNN

WQFN-40L 5x5

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

1

RT6908

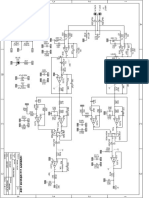

Typical Application Circuit

L1

6.8µH D1

VIN Q1 AVDD

12V C1 C2 15.6V

22µF 10µF C3 C4 C5

14, 15, 16 2.2nF 4.7nF 120µF

LX 10

35 AVIN LXI

9

C6 GD

1µF 8

AVDD

33 VL C30

R22 330pF

RT6908 220k

COMP 11

C7

1µF

36 VINB1 R1

C8 100k

10µF AVDD

C9

DRVP 20 Q2 1µF

L2 10µH

VI/O 39, 40 LXB1

D2 R7

3.3V C11 C10 C14 6.8

C13 C12 R2 0.1µF 47nF 0.22µF

22µF x 100pF 47k 38 BOOT1 R8

2 LXB1

2 FBB1 6.8

D3

C19

R3 R4

15k 470pF

120k 3 COMP1 R9

C15 D4

C16 6.8

0.1µF 0.22µF

R5 C17

VL 31 EN_I2C 22nF R10 LX

6.8

R6 32 EN CRST 22 D5

VL

30 BOOT2

VIN M1 C18

C21 R27 10µF

C20

28 DHB2

10µF

VGH

VGH 19

L3 R10

0.22µF 20k

4.7µH 35.5V

VCORE 29 LXB2 A0 12

1.1V C24 C22 VI/O

R14

22µF 1.2k 1nF M2 26 DLB2

x3 R11

10k R13 R16 R17 R18

C23 1.5 4.7k 4.7k 4.7k

470pF 24 FBB2 SCL 6 SCL

R12 C25 R23 SDA 5 SDA

24k 1nF 24k 4

RSTB RSTB

23 COMP2

Q3

C26 10pF C27

DRVN 21 47nF D6

C28

R20

6.8

R24 33k R19 0.22µF

25 ILIMIT2

100k R21 LXB1

6.8

R25 47k 7 D7

VI/O VDET

VGL 18 VGL

R26 C29 -6V

15k 10µF

AGND PGND

34 1, 13, 17,

41 (Exposed Pad)

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

2

RT6908

Timing Diagram

12V

VEN or VL

12V

VEN_I2C or VL

300µs

VCORE 1.1V

300µs

VI/O 3.3V

VDET

TCRST

VRSTB

2

I C Bus

TCON Program

Control Byte

(Internal Register) 0xFF=0x55

DLY1,DLY2 begins start up

VGL

TDLY1

Q1 VSG 3ms

TDLY2 4V

(VLXI - VGD)

TCGD

AVDD TSS

TDLY3

VGH

4ms

2

Figure 1. I C Mode Power Sequence (VEN_I2C = 1)

12V

VEN or VL

VEN_I2C 0V

300µs

VCORE 1.1V

300µs

VI/O 3.3V

VDET

TCRST

VRSTB

2

I C Bus

3ms

VGL

TDLY1

(Default : 200ms) (Default voltage : -6V)

Q1 VSG TDLY2 4V

(VLXI - VGD) (Default : 400ms)

TCGD (Default voltage : 15.6V)

TSS

AVDD (Default : 2ms)

(Default voltage : 35.5V)

TDLY3

(Default : 10ms)

VGH

4ms

Figure 2. Default Mode Power Sequence (VEN_I2C = 0)

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

3

RT6908

SDA

tSU, DAT tSU, STA tBUF

tLOW tHD, STA tSP

tHD, DAT tSU, STO

SCL tHIGH

tHD, STA

tR tF

START Repeated Start STOP START

Condition Condition Condition Condition

Figure 3. I2C Interface Timing Diagram

Functional Pin Description

Pin No. Pin Name Pin Function

1, 13, 17, Power Ground. The exposed pad must be soldered to a large PCB and

PGND

41(Exposed Pad) connected to PGND for maximum thermal dissipation.

2 FBB1 Feedback Input for Buck1 Converter.

Compensation Pin for Buck1 Converter. This pin is the output node of the

3 COMP1

error amplifier.

4 RSTB Voltage Detector Open-Drain Output.

2

5 SDA I C Compatible Serial Data Input/Output.

2

6 SCL I C Compatible Serial Clock Input.

7 VDET Voltage Detector Input.

8 AVDD Output Sense Pin for Boost Converter AVDD.

Gate Drive. Used to control an external MOSFET switch to provide input to

9 GD

output isolation of AVDD.

10 LXI Isolation Switch Input.

Boost Converter (AVDD) Compensation. Connect a compensation network

11 COMP

to ground.

2

12 A0 I C Compatible Device Address Bit 0.

Boost Converter (AVDD) Switch. Connect an inductor between this pin and

14, 15, 16 LX input voltage source.

18 VGL Output Sensing Pin of VGL Negative Charge Pump.

19 VGH Output Sensing Pin of VGH Positive Charge Pump.

20 DRVP Base Drive of External PNP Transistor for VGH Positive Charge Pump.

21 DRVN Base Drive of External NPN Transistor for VGL Negative Charge Pump.

Voltage Detector Delay Capacitor Connection. Connect capacitor from this

22 CRST

pin to ground.

23 COMP2 Compensation Pin for Buck2 Converter.

24 FBB2 Feedback Input for Buck2 Converter.

Current Limit Adjustment for Buck2 Converter. Connect a resistor from

25 ILIMIT2

ILIMIT2 to AGND to adjust the current limit threshold below 300mV.

26 DLB2 Low Side Gate Driver Output for Buck2 Converter.

27, 37 NC Not Internal Connected. Should be floating or connected to GND

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

4

RT6908

Pin No. Pin Name Pin Function

28 DHB2 High Side Gate Driver Output for Buck2 Converter.

Buck2 Converter Switch node Between High Side MOSFET and Low Side

29 LXB2

MOSFET.

N-MOSFET Gate Drive Voltage for Buck2 Converter. Connect a capacitor

30 BOOT2

from the switch node LXB2 to this pin.

2 2

31 EN_I2C Enable for I C Control. AVDD, VGL, VGH enabled by I C Control.

32 EN Chip Enable (Active High). Tie to VL to enable the device.

Internal Logic Regulator Output. Connect this pin with a decoupling

33 VL

capacitor.

34 AGND Analog Ground.

Analog Input Voltage of the Device. This is the input for the analog circuits.

35 AVIN

Connect this pin with a decoupling capacitor.

36 VINB1 Power Input Voltage Pins for the V I/O Buck Converter.

N-MOSFET Gate Drive Voltage for Buck1. Connect a capacitor from the

38 BOOT1

switch node LXB1 to this pin.

39 LXB1 Buck1 Switch node Between High Side MOSFET and Low Side MOSFET.

40 LXB1 Buck1 Switch node Between High Side MOSFET and Low Side MOSFET.

Function Block Diagram

LX

AVIN Internal LXI

VL Regulator GD

BOOST

AVDD

COMP

BOOT1

EN

VINB1 EN_I2C

Sequence

Sync. Control DC/DC 2 SDA

LXB1 I C

Buck1 DAC SCL

REG Interface A0

FBB1 DRVP

COMP1 VGH

VL AGND

Regulator

VGL

Regulator

DRVN VGH

VGL

CRST

BOOT2 VL Voltage

RSTB

DHB2 Detector

LXB2 Sync. VDET

DLB2 Buck2

PGND

FBB2

COMP2 ILIMIT2

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

5

RT6908

Absolute Maximum Ratings (Note 1)

z EN, EN_I2C, AVIN, VINB1, LXI, GD, AVDD, LX, LXB1, LXB2,

BOOT1, BOOT2, DHB2, VDET to PGND ----------------------------------------------------------------------------- −0.3 to 26V

z SDA, SCL, A0, RSTB, CRST, VL, COMP, COMP1, COMP2, FBB1,

FBB2, ILIMIT2, DLB2, DRVN to PGND -------------------------------------------------------------------------------- −0.3 to 6V

z BOOT1 to LXB1 ------------------------------------------------------------------------------------------------------------- −0.3 to 6V

z BOOT2, DHB2 to LXB2 --------------------------------------------------------------------------------------------------- −0.3 to 6V

z DRVP, VGH to PGND ----------------------------------------------------------------------------------------------------- −0.3 to 44V

z VGL to PGND --------------------------------------------------------------------------------------------------------------- −26V to 26V

z PGND to AGND ------------------------------------------------------------------------------------------------------------- ±0.3V

z Power Dissipation, PD @ TA = 25°C

WQFN-40L 5x5 ------------------------------------------------------------------------------------------------------------- 2.778W

z Package Thermal Resistance (Note 2)

WQFN-40L 5x5, θJA -------------------------------------------------------------------------------------------------------- 36°C/W

WQFN-40L 5x5, θJC ------------------------------------------------------------------------------------------------------- 6°C/W

z Lead Temperature (Soldering, 10 sec.) -------------------------------------------------------------------------------- 260°C

z Junction Temperature ------------------------------------------------------------------------------------------------------ 150°C

z Storage Temperature Range --------------------------------------------------------------------------------------------- −65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Model) ----------------------------------------------------------------------------------------------- 2kV

MM (Machine Model) ------------------------------------------------------------------------------------------------------ 200V

Recommended Operating Conditions (Note 4)

z Junction Temperature Range -------------------------------------------------------------------------------------------- −40°C to 125°C

z Ambient Temperature Range -------------------------------------------------------------------------------------------- −40°C to 85°C

Electrical Characteristics

(Typical values VIN = VAVIN = VINB = 12V, VAVDD = 15.6V, VI/O = 3.3V, VCORE = 1.1V, VGH = 35.5V, VGL = −6V, TA = 25°C, unless

otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Supply Current

Input Voltage Range VIN 9 -- 16 V

AVIN Quiescent Current IQIN LX, LXBx Not Switching -- 3.5 -- mA

VIN Rising -- 8.6 9

Under Voltage Lockout Threshold VUVLO VIN Falling 7.2 7.6 -- V

VIN Falling Latch Reset -- 5 --

VL Output Voltage VL -- 5 -- V

Fault Detection

Fault Trigger Duration -- 50 -- ms

Thermal Shutdown Threshold Temperature Rising -- 150 -- °C

Thermal Shutdown Hysteresis -- 50 -- °C

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

6

RT6908

Parameter Symbol Test Conditions Min Typ Max Unit

Logic Inputs (SDA, SCL, EN, EN_I2C)

Input High Voltage VIH 1.7 -- -- V

Input Low Voltage VIL -- -- 0.6 V

Input Leakage Current IIH, IIL VIN = 0 or 3.3V −1 0.01 1 μA

Input Capacitance -- 5 -- pF

SDA Output Low Voltage VOL I SINK = 6mA -- 0.3 -- V

2

I C Timing Characteristics

Serial-Clock Frequency fSCL 0 -- 400 kHz

Bus Free Time Between STOP

tBUF 1.3 -- -- μs

and START Conditions

Hold Time (Repeated) START

tHD, STA 0.6 -- -- μs

Condition

SCL Pulse-Width Low tLOW 1.3 -- -- μs

SCL Pulse-Width High tHIGH 0.6 -- -- μs

Setup Time for a Repeated

tSU, STA 0.6 -- -- μs

START Condition

Data Hold Time tHD, DAT 0 -- 800 ns

Data Setup Time tSU, DAT 100 -- -- ns

SDA and SCL Receiving Rise 20 +

tR -- 300 ns

Time 0.1CB

20 +

SDA and SCL Receiving Fall Time tF -- 300 ns

0.1CB

20 +

SDA Transmitting Fall Time tF -- 250 ns

0.1CB

Setup Time for STOP Condition tSU, STO 0.6 -- -- μs

Bus Capacitance CB -- -- 400 pF

Pulse Width of Suppressed Spike tSP -- -- 50 ns

Reset Voltage Detector

AVIN Minimum Voltage for

Minimum Operating Voltage 2.2 -- -- V

RSTB

VDET Detecting Threshold VTH VDET Falling -- 0.6 -- V

VDET Threshold Hysteresis ΔVTH -- 100 -- mV

RSTB Output Low Voltage VOL I SINK = 500μA -- -- 0.3 V

RSTB Leakage Current ILEAK VRSTB = 5.0V -- 0.01 0.1 μA

CRST Charge Current ICRST -- 8 -- μA

CRST Threshold VCRST -- 1.25 -- V

Boost Converter (AVDD)

Register Address = ”00h”, 6

Adjustable Output Voltage Range VAVDD bits, AVDD = (12.7V to 19V) 12.7 -- 19 V

[00h to 3Fh]

AVDD Regulation Voltage

VAVDD No load 15.444 15.6 15.756 V

(Default)

Oscillator Frequency fOSC 600 750 900 kHz

Maximum Duty Cycle -- 90 -- %

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

7

RT6908

Parameter Symbol Test Conditions Min Typ Max Unit

N-MOSFET On-Resistance RDS(ON) ILX = 500mA -- 120 -- mΩ

N-MOSFET Switch Current

ILIM 4.4 5.6 -- A

Limit

Switch Leakage Current Ileak VLX = 19V -- 1 10 μA

LXI Over Voltage Protection VOVP VLX Rising, Hysteresis = 1V 19.5 20 -- V

AVDD Line Regulation 9V ≤ VIN ≤ 16V, IOUT = 1mA -- 0.004 -- %/V

AVDD Load Regulation 1mA ≤ IOUT ≤ 2A -- 0.1 -- %/A

Trans-Conductance of Error

gm -- 100 -- μA/V

Amplifier

VAVDD VAVDD VAVDD

AVDD Fault Trip Level VFT_AVDD VAVDD Falling V

x 76% x 80% x 84%

Isolation Switch Control

GD Pull Down Voltage VLXI − VGD 5 6 7 V

GD Sink Current IGD 8 12 16 µA

GD Pull Up Resistance RGD 8 12 16 kΩ

Short-Circuit Trigger Duration IAVDDD ≥ ILIMGD / RON, PMOS -- 200 -- μs

Buck1 Controller (VI/O )

FBB1 Regulation Voltage VFBB1 No Load 0.788 0.8 0.812 V

Oscillator Frequency fOSC 400 500 600 kHz

Phase Shift Between Buck1

-- 180° -- --

and Buck2

Maximum Duty Cycle -- 86 -- %

Trans-Conductance of Error

gm -- 100 -- μA/V

Amplifier

LXB1 to VINB1 N-MOSFET

RDS(ON) ILXB1 = 500mA -- 200 -- mΩ

On-Resistance

LXB1 to PGND N-MOSFET

ILXB1 = 500mA -- 150 -- mΩ

On-Resistance

Soft-Start Period TSS_I/O -- 300 -- μs

FBB1 Fault Trip Level VFBB1 Falling 0.6144 0.64 0.6656 V

LXB1 Positive Current Limit ILIM 3 3.8 -- A

Buck2 Controller (VCORE)

FBB2 Regulation Voltage VFBB2 No Load 0.788 0.8 0.812 V

Oscillator Frequency fOSC 400 500 600 kHz

Phase Shift Between Buck1

-- 180° -- --

and Buck2

Maximum Duty Cycle -- 50 -- %

BOOT2 to DHB2 P-MOSFET

RUG(ON)_DHB2 ILXB2 = 100mA -- 1.8 -- Ω

On-Resistance

DHB2 to LXB2 N-MOSFET

RLG(ON)_DHB2 ILXB2 = 100mA -- 0.6 -- Ω

On-Resistance

LXB2 to DLB2 P-MOSFET

RUG(ON)_DLB2 ILXB2 = 100mA -- 2 -- Ω

On-Resistance

DLB2 to PGND N-MOSFET

RLG(ON)_DLB2 ILXB2 = 100mA -- 0.5 -- Ω

On-Resistance

Soft-Start Period TSS_CORE -- 300 -- μs

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

8

RT6908

Parameter Symbol Test Conditions Min Typ Max Unit

FBB2 Fault Trip Level VFBB2 Falling 0.6144 0.64 0.6656 V

FBB2 Short Trip Level VFBB2 Falling -- 0.16 -- V

ILIMIT2 Source Current -- 40 -- μA

Low Side Switch Current VILIMIT2

Cycle by Cycle -- -- V

Limit /8

Maximum ILIMIT2

-- 2.4 -- V

Voltage Setting

Negative Charge Pump Controller (VGL)

VGL Adjustable Output Register Address = ”02h”, 6 bits, VGL

VGL −8.1 -- −1.8 V

Voltage Range = (−1.8V to −8.1V) [00h to 3Fh]

VGL Regulation Voltage

VGL VDRVN = 0.6V, IDRVN = −100μA −6.3 −6 −5.7 V

(Default)

DRVN Sink Current Limit IDRVN,MAX VDRVN = 0.6V -- 3.5 5 mA

DRVN Short Circuit

IDRVN,SC VGL > −0.5V -- 300 -- μA

Current

VGL Load Regulation VDRVN = 0.6V,

-- 60 -- mV/mA

Error −50μA < IDRVN < −1mA

Soft-Start Period TSS -- 3 -- ms

VGL VGL

VGL Fault Trip Level VGL Rising -- V

+ 1.5 + 2.5

VGL Short Trip Level VGL Rising −0.5 V

Positive Charge Pump Controller (VGH)

VGH Adjustable Output Register Address = ”01h”, 5 bits,

VGH 24.5 -- 40 V

Voltage Range VGH = (24.5V to 40V) [00h to 1Fh]

VGH Regulation Voltage

VGH VDRVP = 15.6V, IDRVP = 100μA 34.79 35.5 36.21 V

(Default)

DRVP Source Current

IDRVP,MAX VDRVP = 15.6V -- 3.5 5 mA

Limit

DRVP Short Circuit

IDRVP,SC VGH < 20% -- 80 -- μA

Current

VGH Load Regulation

VDRVP = 15.6V, 50μA < I DRVP < 1mA -- 300 -- mV/mA

Error

Soft-Start Period TSS -- 4 -- ms

VGH VGH VGH

VGH Fault Trip Level VGH Falling %

x 70 x 75 x 80

VGH Short Trip Level VGH Falling -- 20 -- %

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θJA is measured at TA = 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

measured at the exposed pad of the package.

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

9

RT6908

Typical Operating Characteristics

Boost Efficiency vs. Load Current Buck1 Efficiency vs. Load Current

100 100

90 90

Efficiency (%)

Efficiency (%)

80 80

70 70

60 60

VIN = 12V, VAVDD = 15.6V VIN = 12V, VI/O = 3.3V

50 50

0 0.4 0.8 1.2 1.6 2 0 0.4 0.8 1.2 1.6 2

Load Current (A) Load Current (A)

Buck2 Efficiency vs. Load Current Boost Output Voltage vs. Load Current

100 17.0

16.5

90

Output Voltage (V)

Efficiency (%)

16.0

80

15.5

70

15.0

60

14.5

VIN = 12V, VCORE = 1.1V VIN = 12V, VAVDD = 15.6V

50 14.0

0 0.4 0.8 1.2 1.6 2 0 0.5 1 1.5 2

Load Current (A) Load Current (A)

Buck1 Output Voltage vs. Load Current Buck2 Output Voltage vs. Load Current

3.9 1.3

3.6 1.2

Output Voltage (V)

Output Voltage (V)

3.3 1.1

3.0 1.0

2.7 0.9

VIN = 12V, VI/O = 3.3V VIN = 12V, VCORE = 1.1V

2.4 0.8

0 0.5 1 1.5 2 0 0.5 1 1.5 2

Load Current (A) Load Current (A)

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

10

RT6908

VGH Output Voltage vs. Load Current VGL Output Voltage vs. Load Current

38 -3

37 -4

Output Voltage (V)

Output Voltage (V)

36 -5

35 -6

34 -7

VIN = 12V, VGH = 35.5V VIN = 12V, VGL = −6V

33 -8

0 15 30 45 60 75 0 15 30 45 60 75

Load Current (mA) Load Current (mA)

Boost Output Voltage vs. Temperature Buck1 Output Voltage vs. Temperature

17.0 3.5

16.5

3.4

Output Voltage (V)

Output Voltage (V)

16.0

3.3

15.5

3.2

15.0

3.1

14.5

VIN = 12V, VAVDD = 15.6V VIN = 12V, VI/O = 3.3V

14.0 3.0

-50 -25 0 25 50 75 100 125 -50 -25 0 25 50 75 100 125

Temperature (°C) Temperature (°C)

Buck2 Output Voltage vs. Temperature VGH Output Voltage vs. Temperature

1.3 38

1.2 37

Output Voltage (V)

Output Voltage (V)

1.1 36

1.0 35

0.9 34

VIN = 12V, VCORE = 1.1V VIN = 12V, VGH = 35.5V

0.8 33

-50 -25 0 25 50 75 100 125 -50 -25 0 25 50 75 100 125

Temperature (°C) Temperature (°C)

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

11

RT6908

VGL Output Voltage vs. Temperature Power On Sequence 1

-3

-4 VEN

(5V/Div)

Output Voltage (V)

-5

V CORE

(1V/Div)

-6

VI/O

(2V/Div)

VRSTB

-7 (2V/Div)

VIN = 12V, VGL = −6V VIN = 12V, VCORE = 1.1V, VI/O = 3.3V, C17= 22nF

-8

-50 -25 0 25 50 75 100 125 Time (1ms/Div)

Temperature (°C)

Power On Sequence 2 Boost Load Transient Response

VAVDD VAVDD_ac

(10V/Div) (500mV/Div)

VGH

(20V/Div)

VGL

(5V/Div)

IAVDD

(1A/Div)

VRSTB

(2V/Div) VIN = 12V, VAVDD = 15.6V, VIN = 12V, VAVDD = 15.6V,

VI/O = 35.5V, VGL = -6V, C17= 22nF R22 = 220kΩ, C30 = 330pF, C31= 10pF

Time (100ms/Div) Time (500μs/Div)

Buck1 Load Transient Response Buck2 Load Transient Response

VI/O_ac VCORE_ac

(100mV/Div) (100mV/Div)

I I/O I CORE

(1A/Div) (1A/Div)

VIN = 12V, VCORE = 1.1V, R23 = 24kΩ,

VIN = 12V, VI/O = 3.3V, R4 = 120kΩ, C19 = 470nF C25 = 1nF, C26 = 10pF, R14 = 1.2kΩ, C23 = 470pF

Time (500μs/Div) Time (500μs/Div)

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

12

RT6908

Application Information

I2C Command

Slave Address

7 6 5 4 3 2 1 0 = LSB

1 1 0 1 0 0 A0 R/W

Single I2C Register Write Protocol

Stop 1 1 0 1 0 0 A0 0 Slave

ACK Register Address Slave D7 D6 D5 D4 D3 D2 D1 D0 Slave Stop

ACK ACK

Slave Address

Single I2C Register Read Protocol

Stop 1 1 0 1 0 0 A0 0 Slave

ACK Register Address Slave Re- 1

ACK Start 1 0 1 00 A0 1 Slave

ACK

Slave Address Slave Address

D7 D6 D5 D4 D3 D2 D1 D0 Master

NACK

Stop

Multiple I2C Register Write Protocol

Stop 1 1 0 1 0 0 A0 0 Slave

ACK Register Address Slave D7 D6 D5 D4 D3 D2 D1 D0 Slave

ACK ACK

Slave Address

D7 D6 D5 D4 D3 D2 D1 D0 Slave

ACK D7 D6 D5 D4 D3 D2 D1 D0 Slave

ACK Stop

Multiple I2C Register Read Protocol

Stop 1 1 0 1 0 0 A0 0 Slave

ACK Register Address Slave Re- 1

ACK Start 1 0 1 00 A0 1 Slave

ACK

Slave Address Slave Address

D7 D6 D5 D4 D3 D2 D1 D0 Master

ACK D7 D6 D5 D4 D3 D2 D1 D0 Master

NACK

Stop

Register Map

Address Name Description Default Value Resolution Range

00h AVDD [5 : 0] Boost 15.6V (1Dh) 0.1V 12.7V to 19V (00h to 3Fh)

01h VGH [4 : 0] VGH 35.5V (16h) 0.5V 24.5V to 40V (00h to 1Fh)

02h VGL [5 : 0] VGL −6V (2Ah) −0.1V −1.8V to −8.1V (00h to 3Fh)

03h VIO [3 : 0] VIO adjustment 0% (07h) 1% −7% to 7% (00h to 0Eh)

04h VCORE [3 : 0] VCORE adjustment 0% (07h) 1% −7% to 7% (00h to 0Eh)

05h DLY1 [3 : 0] VGL Delay Time 200ms (01h) DLYR1 0 to 15 x DLYR1 (00h to 0Fh)

06h DLY2 [3 : 0] AVDD Delay Time 400ms (02h) DLYR2 0 to 15 x DLYR2 (00h to 0Fh)

07h DLY3 [3 : 0] VGH Delay Time 10ms (01h) DLYR3 0 to 15 x DLYR3 (00h to 0Fh)

08h DLYR1 [1 : 0] DLY1 Resolution 200ms (02h) 1ms, 10ms, 200ms

09h DLYR2 [1 : 0] DLY2 Resolution 200ms (02h) 1ms, 10ms, 200ms

0Ah DLYR3 [1 : 0] DLY3 Resolution 10ms (01h) 1ms, 10ms, 200ms

0Bh SS [3 : 0] AVDD Soft-Start Time 2ms (02h) 1ms 0ms to 15ms (00h to 0Fh)

[3 : 0] Isolation Switch Disable, 100mV to 800mV

0Ch ILIMGD Disable (00h) 50mV

Current Limit (00h to 0Fh)

[7 : 0] ’’55h’’ Start Power On

FFh CTRL 00h

Sequence

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

13

RT6908

Output Code Table (unit : V)

Register

AVDD VGH VGL VIO VCORE DLY1 DLY2 DLY3 DLYR1 DLYR2 DLYR3 SS ILIMGD

Code

00h 12.7 24.5 −1.8 −7% −7% 0ms 0ms 0ms 1ms 1ms 1ms 0ms disable

01h 12.8 25.0 −1.9 −6% −6% 1ms 1ms 1ms 10ms 10ms 10ms 1ms 100mV

02h 12.9 25.5 −2.0 −5% −5% 2ms 2ms 2ms 200ms 200ms 200ms 2ms 150mV

03h 13.0 26.0 −2.1 −4% −4% 3ms 3ms 3ms 3ms 200mV

04h 13.1 26.5 −2.2 −3% −3% 4ms 4ms 4ms 4ms 250mV

05h 13.2 27.0 −2.3 −2% −2% 5ms 5ms 5ms 5ms 300mV

06h 13.3 27.5 −2.4 −1% −1% 6ms 6ms 6ms 6ms 350mV

07h 13.4 28.0 −2.5 0 0 7ms 7ms 7ms 7ms 400mV

08h 13.5 28.5 −2.6 1% 1% 8ms 8ms 8ms 8ms 450mV

09h 13.6 29.0 −2.7 2% 2% 9ms 9ms 9ms 9ms 500mV

0Ah 13.7 29.5 −2.8 3% 3% 10ms 10ms 10ms 10ms 550mV

0Bh 13.8 30.0 −2.9 4% 4% 11ms 11ms 11ms 11ms 600mV

0Ch 13.9 30.5 −3.0 5% 5% 12ms 12ms 12ms 12ms 650mV

0Dh 14.0 31.0 −3.1 6% 6% 13ms 13ms 13ms 13ms 700mV

0Eh 14.1 31.5 −3.2 7% 7% 14ms 14ms 14ms 14ms 750mV

0Fh 14.2 32.0 −3.3 15ms 15ms 15ms 15ms 800mV

10h 14.3 32.5 −3.4

11h 14.4 33.0 −3.5

12h 14.5 33.5 −3.6

13h 14.6 34.0 −3.7

14h 14.7 34.5 −3.8

15h 14.8 35.0 −3.9

16h 14.9 35.5 −4.0

17h 15.0 36.0 −4.1

18h 15.1 36.5 −4.2

19h 15.2 37.0 −4.3

1Ah 15.3 37.5 −4.4

1Bh 15.4 38.0 −4.5

1Ch 15.5 38.5 −4.6

1Dh 15.6 39.0 −4.7

1Eh 15.7 39.5 −4.8

1Fh 15.8 40.0 −4.9

20h 15.9 −5.0

21h 16.0 −5.1

22h 16.1 −5.2

23h 16.2 −5.3

24h 16.3 −5.4

25h 16.4 −5.5

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

14

RT6908

Register

AVDD VGH VGL VIO VCORE DLY1 DLY2 DLY3 DLYR1 DLYR2 DLYR3 SS ILIMGD

Code

26h 16.5 −5.6

27h 16.6 −5.7

28h 16.7 −5.8

29h 16.8 −5.9

2Ah 16.9 −6.0

2Bh 17.0 −6.1

2Ch 17.1 −6.2

2Dh 17.2 −6.3

2Eh 17.3 −6.4

2Fh 17.4 −6.5

30h 17.5 −6.6

31h 17.6 −6.7

32h 17.7 −6.8

33h 17.8 −6.9

34h 17.9 −7.0

35h 18.0 −7.1

36h 18.1 −7.2

37h 18.2 −7.3

38h 18.3 −7.4

39h 18.4 −7.5

3Ah 18.5 −7.6

3Bh 18.6 −7.7

3Ch 18.7 −7.8

3Dh 18.8 −7.9

3Eh 18.9 −8.0

3Fh 19.0 −8.1

40h

If register data out of spec, IC will be into default value.

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

15

RT6908

The RT6908 is a programmable multi-functional power Boost Short Circuit Protection

solution for TFT LCD panels. The RT6908 contains a step- The main boost converter has a short circuit protection.

up converter for main power, a synchronous buck This function disables the boost converter and isolation

converter and a synchronous buck controller to provide P-MOSFET if the difference voltage between the LXI and

the logic voltages for timing controller, voltage detector AVDD pin larger than ILIMGD I2C register 0Ch [3:0] setting.

for the system. Moreover, a positive charge pump regulator The IC will shut down if this difference voltage remains

provides the adjustable gate-high voltage and a negative above setting value after 200μs. Besides, IC will also shut

charge pump regulator provides the gate low voltage. down if input voltage below UVLO threshold at AVDD short

circuit period. Only input voltage below 5V (typ.) then re-

Boost Converter

power on and remove fault condition, IC can return to normal

The boost converter is high efficiency PWM architecture. operation.

It performs fast transient responses to generate source

driver supplies for TFT LCD display. The high operation Boost Under Voltage Fault Protection

frequency allows use of smaller components to minimize The main boost converter has a fault protection. This

the thickness of the LCD panel. The output voltage can be function disables the boost converter if AVDD is detected

achieved by setting the I2C register 00h [5:0]. The Boost to be below 80%. The IC will shut down if AVDD remains

minimum gain ratio depends on minimum on time. It below 80% after 50ms.

suggested that AVDD higher than 1.14XVIN for better

performance. Boost Inductor Selection

The inductor value depends on the maximum input current.

Boost Soft-Start As a general rule the inductor ripple current is 20% to

The main boost converter has an internal soft-start function 40% of maximum input current. If 40% is selected as an

to reduce the input inrush current. The soft-start time can example, the inductor ripple current can be calculated

be achieved from 0ms to 15ms by setting the I2C register according to the following equation :

0Bh [3:0]. VOUT × IOUT(MAX)

IIN(MAX) =

η × VIN

Boost Over Voltage Protection

IRIPPLE = 0.4 × IIN(MAX)

The main boost converter has an over voltage protection

where η is the efficiency of the boost converter, IIN(MAX) is

to protect the main switch at the LXI pin. When the LXI

the maximum input current and IRIPPLE is the inductor ripple

pin voltage rises above 20V, the boost converter turns the

current. The input peak current can be obtained by adding

switch off. As soon as the output voltage falls below the

the maximum input current with half of the inductor ripple

over voltage threshold, the converter will resume operation.

current as shown in the following equation :

Boost Over Current Protection IPEAK = IRIPPLE + IIN(MAX) = 1.2 IIN(MAX)

The RT6908 senses the inductor current that is flowing

Note that the saturated current of inductor must be greater

into the LX pin. The internal N-MOSFET will be turned off

than IPEAK. The inductance can eventually be determined

if the peak inductor current reaches 5.6A (typ.). Thus, the

according to the following equation :

output current at the current limit boundary, denoted as

η × ( VIN ) × ( VOUT − VIN )

2

IOUT(LIM), can be calculated according to the following L=

0.4 × ( VOUT ) × I OUT(MAX)×fOSC

2

equation :

V ⎛ V × (VOUT − VIN ) TS ⎞

IOUT(LIM) = η × IN × ⎜ ILIM − 1 × IN ×

L ⎟⎠

where fOSC is the switching frequency. For better system

VOUT ⎝ 2 VOUT

performance, a shielded inductor is preferred to avoid EMI

where η is the efficiency of the boost converter, ILIM is the problems.

value of the current limit and TS is the switching period.

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

16

RT6908

Boost Diode Selection

The schottky diode is a good choice for any asynchronous

ΔIL

boost converter due to the small forward voltage. However,

when selecting a schottky diode, important parameters Input Current Inductor Current

such as power dissipation, reverse voltage rating, and

pulsating peak current must all be taken into

consideration. A suitable schottky diode's reverse voltage

Output Current

rating must be greater than the maximum output voltage,

Time

and its average current rating must exceed the average

output current. (1-D)TS Output Ripple

Voltage (ac)

Boost Input Capacitor Selection

Time

Low ESR ceramic capacitors are recommended for input ΔVOUT1

capacitor applications. Low ESR will effectively reduce

the input ripple voltage caused by the switching operation.

Figure 4. The Output Ripple Voltage without the

Another consideration is the voltage rating of the input

Contribution of ESR

capacitor, which must be greater than the maximum input

voltage.

Boost Loop Compensation

Boost Output Capacitor Selection The voltage feedback loop can be compensated with an

external compensation network consisted of R22 and C30.

Output ripple voltage is an important index for estimating

Choose R22 to set the high frequency integrator gain for

the performance. A 120μF low ESR OS-CAP is sufficient

fast transient response. And choose C30 to set the

for most applications. This portion consists of two parts,

integrator zero to maintain stability.

one is the product of IIN and ESR of output capacitor, another

part is formed by charging and discharging process of

VI/O Synchronous Buck Converter

output capacitor. As shown in Figure 4, ΔVOUT1 can be

The buck converter is a high efficiency PWM architecture

evaluated based on the ideal energy equalization.

with 500kHz operation frequency and fast transient

According to the definition of Q, the Q value can be

response. The converter drives an internal N-MOSFET,

calculated as the following equation :

connected between the VINB1 and LXB1 pin. Connect a

⎡ ⎤

Q = 1 × ⎢⎛⎜ IIN + 1 ΔIL − IOUT ⎞⎟ + ⎛⎜ IIN − 1 ΔIL − IOUT ⎞⎟ ⎥ 100nF low ESR ceramic capacitor between the BOOT1

2 ⎣⎝ 2 ⎠ ⎝ 2 ⎠⎦ pin and LXB1 pin to provide gate driver voltage for the high

V

× IN × 1 =COUT × ΔVOUT1 side MOSFET.

VOUT fOSC

Where fOSC is the switching frequency and the ΔIL is the VI/O Buck Output Voltage Setting

inductor ripple current. Move COUT to the left side to The regulated default output voltage is as shown in the

estimate the value of ΔVOUT1 as the following equation : following equation :

D × IOUT VI/O = VFBB1 × ⎛⎜ 1 + R2 ⎞⎟ , where VFBB1 = 0.8V (typ.)

ΔVOUT1 =

η × COUT × fOSC ⎝ R3 ⎠

Finally, the output ripple voltage can be determined as The recommended value for R2 should be up to 10kΩ

following equation : without some sacrificing. To place the resistor divider as

D × IOUT close as possible to the chip can reduce noise sensitivity.

ΔVOUT = IIN × ESR+

η × COUT × fOSC The output voltage also can be adjusted from −7% to 7%

by setting the I2C register 03h [3:0].

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

17

RT6908

VI/O Buck Soft-Start The recommended value for R11 should be up to 10kΩ

The step-down converter has an internal soft-start to reduce without some sacrificing. Place the resistor divider as

the input inrush current. When the buck converter is close as possible to the chip can reduce noise sensitivity.

enabled, the output voltage rises slowly from zero to the The output voltage also can be adjusted from −7% to 7%

regulated voltage. The typical soft-start time is around by setting the I2C register 04h [3:0].

300μs.

VCORE Buck Soft-Start

VI/O Buck Over Current Protection The synchronous buck converter has an internal soft-start

The IC senses the inductor current that is flowing out the to reduce the input inrush current. When the converter is

LXB1 pin. The internal MOSFET will be turned off if the enabled, the output voltage rises slowly from zero to the

peak inductor current reaches 3.8A (typ.). regulated voltage. The typical soft-start time is around

300μs.

VI/O Buck Short Circuit Protection

To limit the short circuit current, the device has a cycle- VCORE Buck Over Current Protection

by-cycle current limit. To avoid the short circuit current The IC has a cycle-by-cycle low side source current

from rising above the internal current limit when the output sensing algorithm that uses the on-resistance of the low

is shorted to GND, the switching frequency is reduced as side MOSFET as a current sensing element, so that costly

well. The switching frequency is reduced to one-half of sense resistors are not required. The DHB2 and DLB2 will

original frequency when the output voltage is below 80% be turned off if the low side MOSFET source current

and to one-fourth of the original frequency when the output reaches setting value. Moreover, IC will restart after 50ms

voltage is below 20%. If the “short” is removed, the buck if over current remains 7 cycles. Low side source peak

converter will resume operation. If the voltage remains current limit threshold is 1/8 voltage at the ILIMT2 pin.

below 80% after 50ms, the IC will shut down. Meanwhile, the real current limit value need consider the

on-resistance of the low side MOSFET.

VI/O Buck Loop Compensation

VILIMIT2

ILIM_M2 = (A)

The voltage feedback loop can be compensated with an 8 × RON (switch)

external compensation network consisted of the R4 and

when ILIM_M2 is “Low side switch current limit”.

C19. Choose R4 to set high frequency integrator gain for

fast transient response. And choose the C19 to set the VCORE Buck Short Circuit Protection

integrator zero to maintain stability.

To limit the short circuit current, the device has a cycle-

VCORE Synchronous Buck Controller by-cycle current limit. To avoid the short circuit current

from low side MOSFET source current limit when the

The synchronous buck controller is a high efficiency PWM

output is shorted to GND, the switching operation will be

architecture with 500kHz operation frequency and fast

stop. The switching operation will stop when the output

transient response. The controller need external high side

voltage is below 20%. If the short is removed, the buck

and low side N-MOSFET as synchronous rectifier and does

converter will resume operation. If the voltage remains

not required Schottky diode on the LXB2 pin. The high

below 80% after 50ms, the IC will shut down.

side MOSFET is connected between VIN and the LXB2

pin, while the low side MOSFET is connected between VCORE Buck Loop Compensation

the LXB2 pin and GND.

The voltage feedback loop can be compensated with an

VCORE Buck Output Voltage Setting external compensation network consisted of R23 and C25

and C26. Choose R23 to set high frequency integrator

The regulated default output voltage as shown in the

gain for fast transient response, C25 and C26 to set the

following equation :

VCORE = VFBB2 × ⎛⎜ 1 + R11 ⎞⎟ , where VFBB2 = 0.8V (typ.)

integrator zero to maintain stability.

⎝ R12 ⎠

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

18

RT6908

VCORE Buck External MOSFET Selection Buck Output Capacitor Selection

The VCORE buck controller drives two external N-MOSFETs The selection of COUT is determined by the required ESR

as the switch. There are some considerations to choose to minimize voltage ripple. Moreover, the amount of bulk

the external MOSFET. It includes MOSFET drain to source capacitance is also a key for COUT selection to ensure

voltage stress, on-resistance, total gate charge that the control loop is stable. Loop stability can be

characteristics and power dissipation for thermal checked by viewing the load transient response as

performance. described in a later section. The output ripple, VOUT, is

determined by :

Buck Inductor Selection

ΔVOUT = ΔIL × ⎛⎜ ESR + 1 ⎞

The inductor value and operating frequency determine the ⎝ 8 × fOSC × COUT ⎟⎠

ripple current according to a specific input and output

The output ripple will be highest at the maximum input

voltage. The ripple current, ΔIL, will increase with higher

voltage since IL increases with input voltage. Multiple

VIN and decrease with higher inductance, as shown in

capacitors placed in parallel may be needed to meet the

below equation :

ESR and RMS current handling requirement. Suitable

ΔIL = ⎛⎜ OUT ⎞⎟ × ⎛⎜ 1− OUT ⎞⎟

V V

⎝ fOSC × L ⎠ ⎝ VIN ⎠ candidates such as dry tantalum, special polymer,

Having a lower ripple current reduces not only the ESR aluminum electrolytic and ceramic capacitors are all

losses in the output capacitors but also the output voltage available in surface mount packages. Special polymer

ripple. High frequency with small ripple current can achieve capacitors offer very low ESR value. However, it provides

the highest efficiency operation. However, it requires a lower capacitance density than other types. Although

large inductor to achieve this goal. For the ripple current tantalum capacitors have the highest capacitance density,

selection, the value of IL(MAX) = 0.4 is a reasonable starting it is important to only use types that pass the surge test

point. The largest ripple current occurs at the highest VIN. for use in switching power supplies. Aluminum electrolytic

To guarantee that the ripple current stays below the capacitors have significantly higher ESR. However, it can

specified maximum, the inductor value should be chosen be used in cost-sensitive applications requiring high ripple

according to the following equation : current rating and long term reliability. Ceramic capacitors

⎛ VOUT ⎞ ⎛ VOUT ⎞ have excellent low ESR characteristics but can have a

L= ⎜ ⎟ × ⎜ 1− ⎟

f

⎝ OSC × Δ IL(MAX) ⎠ ⎝ VIN(MAX) ⎠ high voltage coefficient and audible piezoelectric effects.

The high Q of ceramic capacitors with trace inductance

Buck Input Capacitor Selection can also lead to significant ringing. Nevertheless, higher

The input capacitance, C IN, is needed to filter the value, lower cost ceramic capacitors are now becoming

trapezoidal current at the source of the high-side MOSFET. available in smaller case sizes. Their high ripple current,

To prevent large ripple current, a low ESR input capacitor high voltage rating and low ESR make them ideal for

sized for the maximum RMS current should be used. The switching regulator applications. However, care must be

RMS current is given by : taken when these capacitors are used at the input and

V VIN output. When a ceramic capacitor is used at the input,

IRMS = IOUT(MAX) × OUT × −1

VIN VOUT VIN, and the power is supplied by a wall adapter through

This formula has a maximum at VIN = 2VOUT, where IRMS long wires, a load step at the output can induce ringing at

= IOUT / 2. This simple worst-case condition is commonly the input. At best, this ringing can couple to the output

used for design because even significant deviations do and be mistaken as loop instability. At worst, a sudden

not offer much relief. Choose a capacitor rated at a higher inrush of current through the long wires can potentially

temperature than required. Several capacitors may also cause a voltage spike at VIN large enough to damage the

be paralleled to meet size or height requirements in the part.

design. For the input capacitor, a 10μF low ESR ceramic

capacitor is recommended.

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

19

RT6908

VGL Negative Regulator The 1V (typ.) hysteresis prevents supply transients from

The VGL negative regulator controller provides low level causing a shutdown. Once the input voltage exceeds the

voltage for gate driver. The linear regulator can provide a UVLO rising threshold, start-up begins. When the input

programmable output voltage. The output voltage can be voltage falls below the UVLO falling threshold, all switch

adjusted by setting the I2C register 02h [5:0]. The VGL will be turned off and latched. Otherwise, input voltage

negative regulator controller has a fault protection. This need below 5V (typ.), the IC can be reset.

function can disable the VGL negative regulator controller

Over Temperature Protection

when the VGL voltage is detected to be above VGL + 2V.

If the voltage remains above VGL + 2V after 50ms, the IC The RT6908 equips an Over Temperature Protection (OTP)

will shut down. Moreover, If VGL voltage above −0.5V, the circuitry to prevent overheating due to excessive power

IDRVN source current will be limited to 300μA for short dissipation. The OTP will shut down switching operation

circuit protection. when junction temperature exceeds 150°C. Once the

junction temperature cools down by approximately 50°C,

VGH Positive Regulator the RT6908 will resume operation. To maintain continuous

The VGH positive regulator controller provides high level operation maximum, the junction temperature should be

voltage for gate driver. The linear regulator can provide a prevented from rising above 125°C.

programmable output voltage. The output voltage can be

Thermal Considerations

adjusted by setting the I2C register 01h [4:0]. The VGH

positive regulator controller has a fault protection. This For continuous operation, do not exceed absolute

function can disable the VGH regulator controller when maximum junction temperature. The maximum power

the VGH voltage is detected to be below 75%. If the VGH dissipation depends on the thermal resistance of the IC

voltage remains below 75% after 50ms, the IC will shut package, PCB layout, rate of surrounding airflow, and

down. Moreover, If VGH voltage remains below 20%, the difference between junction and ambient temperature. The

IDRVP sink current will be limited to 80μA for short circuit maximum power dissipation can be calculated by the

protection. following formula :

PD(MAX) = (TJ(MAX) − TA) / θJA

Voltage Detector

where TJ(MAX) is the maximum junction temperature, TA is

The voltage detector monitors the VDET voltage to generate

the ambient temperature, and θJA is the junction to ambient

the RSTB pin signal. The RSTB pin will be floating and

thermal resistance.

pulled high by VI/O if VDET is higher than the detecting

level. Moreover, the detector power on delay can be For recommended operating condition specifications of

determined by connect capacitor to the CRST pin and the RT6908, the maximum junction temperature is 125°C

ground. The detecting level and delay time can be and TA is the ambient temperature. The junction to ambient

determined as the following equations : thermal resistance, θ JA , is layout dependent. For

WQFN-40L 5x5 package, the thermal resistance, θJA, is

Detect voltage, falling = VDET × ⎛⎜ 1 + R25 ⎞⎟ ,

⎝ R26 ⎠ 36°C/W on a standard JEDEC 51-7 four-layer thermal test

where VDET =0.6V (typ.) board. The maximum power dissipation at TA = 25°C can

Detector delay time = 0.1563 × C17 × 109 (ms) be calculated by the following formula :

PD(MAX) = (125°C − 25°C) / (36°C/W) = 2.778W for

Under Voltage Lockout Protection WQFN-40L 5x5 package

The UVLO circuit compares the input voltage at the AVIN

The maximum power dissipation depends on the operating

pin with the UVLO threshold (8.6V rising, typ.) to ensure

ambient temperature for fixed T J(MAX) and thermal

that the input voltage is high enough for reliable operation.

resistance, θJA. For the RT6908 package, the derating

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com DS6908-01 March 2013

20

RT6908

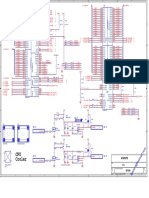

curve in Figure 5 allows the designer to see the effect of Layout Consideration

rising ambient temperature on the maximum power For high frequency switching power supplies, the PCB

dissipation. layout is important to get good regulation, high efficiency

3.2 and stability. The following descriptions are the guidelines

Maximum Power Dissipation (W)1

Four-Layer PCB

2.8 for better PCB layout.

2.4 ` For good regulation, place the power components as

2.0

close as possible. The traces should be wide and short

enough especially for the high current loop.

1.6

` The compensation circuit should be kept away from

1.2

the power loops and be shielded with a ground trace to

0.8 prevent any noise coupling.

0.4

` Minimize the size of all LX nodes and keep them wide

0.0 and shorter.

0 25 50 75 100 125

` The exposed pad of the chip should be connected to a

Ambient Temperature (°C)

strong ground plane for maximum thermal consideration.

Figure 5. Derating Curve for the RT6908 Package

Place the power components as close as Separate power ground (PGND) and analog ground

possible. The traces should be wide and (AGND). Connect the AGND and the PGND islands

AGND

short especially for the high current loop.

VIN

VIN

at a single end. Make sure that there are no other

C11 connections between these separate ground planes.

VI/O L2

VIN

EN_I2C

BOOT1

VINB1

AGND

C21

LXB1

LXB1

AVIN

NC

EN

C13

VL

C12 R2 C20 Place the power components

AGND 40 39 38 37 36 35 34 33 32 31 as close as possible.

R3

PGND 1 30 BOOT2

R4 FBB1 2 29 LXB2 VCORE

C19 M1

COMP1 3 28 DHB2 L3

RSTB 4 27 NC

M2 C24

SDA 5 26 DLB2

The compensation circuit PGND

should be kept away from the SCL 6 25 ILIMIT2 PGND

power loops and should be VDET 7 24 FBB2 R11

shielded with a ground trace AVDD AVDD 8 23 COMP2

to prevent any noise coupling. 41 R12 AGND

GD 9 22 CRST

LXI 10 21 DRVN R23 C25

The compensation circuit should be

11 12 13 14 15 16 17 18 19 20 kept away from the power loops and

AGND C28 R38 should be shielded with a ground

COMP

A0

PGND

LX

LX

LX

PGND

VGL

VGH

DRVP

C26

trace to prevent any noise coupling.

C54 The exposed pad of the chip

should be connected to ground

D1 L1 plane for thermal consideration.

Q1

AVDD VIN Place the power components as

close as possible. The traces should

C5 C2 be wide and short especially for the

high-current loop.

C1

PGND VIN

The power ground (PGND) consists of input and output

capacitor grounds, the components's ground of charge

pump. The PGND should be wide and short enough to

connect to a ground plane.

Figure 6. PCB Layout Guide

Copyright © 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS6908-01 March 2013 www.richtek.com

21

RT6908

Outline Dimension

SEE DETAIL A

D D2

L

1

E E2

1 1

2 2

e b

DETAIL A

A Pin #1 ID and Tie Bar Mark Options

A3

A1 Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.150 0.250 0.006 0.010

D 4.950 5.050 0.195 0.199

D2 3.250 3.500 0.128 0.138

E 4.950 5.050 0.195 0.199

E2 3.250 3.500 0.128 0.138

e 0.400 0.016

L 0.350 0.450 0.014 0.018

W-Type 40L QFN 5x5 Package

Richtek Technology Corporation

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

www.richtek.com DS6908-01 March 2013

22

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Serial Index CaterpillarDocument260 pagesSerial Index CaterpillarRamón Mangles90% (10)

- Payment InstructionDocument2 pagesPayment InstructionNeel PatelPas encore d'évaluation

- Taramps++ts1200+1+x4 R1 PDFDocument7 pagesTaramps++ts1200+1+x4 R1 PDFdinnhowPas encore d'évaluation

- 14 Bernardo Soustruhy deDocument40 pages14 Bernardo Soustruhy deTanase Constantin0% (1)

- ID 2051814.1 Oracle Support Sample SetupDocument9 pagesID 2051814.1 Oracle Support Sample SetupFerasHamdanPas encore d'évaluation

- Digital Image Processing Concepts, Algorithms, and Scientific Applications Second Edition by Bemd Jahne PDFDocument413 pagesDigital Image Processing Concepts, Algorithms, and Scientific Applications Second Edition by Bemd Jahne PDFdinnhowPas encore d'évaluation

- Lenovo IdeaPad 310-15ISK 510-15ISK LCFC DIS CG411 CG511 NM-A751 Discrite r1.0Document60 pagesLenovo IdeaPad 310-15ISK 510-15ISK LCFC DIS CG411 CG511 NM-A751 Discrite r1.0dinnhow100% (1)

- Online Bank SynopsisDocument7 pagesOnline Bank SynopsisPrashant VermaPas encore d'évaluation

- HP Pavilion g4 g6 g7 Quanta r33 Laptop SchematicsDocument43 pagesHP Pavilion g4 g6 g7 Quanta r33 Laptop Schematicstrutlept100% (5)

- Accounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualDocument26 pagesAccounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualKimberlyMendezyptr98% (40)

- 01.2 Small-Cell Report - Full ReportDocument31 pages01.2 Small-Cell Report - Full Reportwalia_anujPas encore d'évaluation

- LTN173KT02 T01 SamsungDocument31 pagesLTN173KT02 T01 SamsungdinnhowPas encore d'évaluation

- K3868 ToshibaSemiconductorDocument6 pagesK3868 ToshibaSemiconductordinnhowPas encore d'évaluation

- Nl40cu-Nl41cu 61025055Document88 pagesNl40cu-Nl41cu 61025055dinnhowPas encore d'évaluation

- Asus Eee PC 900 - Rev 1.2Document21 pagesAsus Eee PC 900 - Rev 1.2dinnhowPas encore d'évaluation

- Lp173wd1 Tla1 LGDocument32 pagesLp173wd1 Tla1 LGdinnhowPas encore d'évaluation

- Vinafix - VN K43E RGDocument11 pagesVinafix - VN K43E RGdinnhowPas encore d'évaluation

- Panasonic SA-HT75GDocument127 pagesPanasonic SA-HT75GdinnhowPas encore d'évaluation

- Datasheeet Yd2030Document4 pagesDatasheeet Yd2030dinnhowPas encore d'évaluation

- Sony Hbd-E2100 E3100 E3200 E4100 E6100 Ver1.7 PDFDocument94 pagesSony Hbd-E2100 E3100 E3200 E4100 E6100 Ver1.7 PDFdinnhow100% (1)

- Description: 40 V, 3.5 A Quad Power Half-BridgeDocument21 pagesDescription: 40 V, 3.5 A Quad Power Half-BridgedinnhowPas encore d'évaluation

- cd4047b Mil PDFDocument21 pagescd4047b Mil PDFdinnhowPas encore d'évaluation

- Tda 8563Document20 pagesTda 8563dinnhowPas encore d'évaluation

- Esq Nobreak T0738702 Net Station ΜST700BiFXDocument1 pageEsq Nobreak T0738702 Net Station ΜST700BiFXdinnhowPas encore d'évaluation

- Caderno de ÓticaDocument77 pagesCaderno de ÓticadinnhowPas encore d'évaluation

- 50pk550-Sa Chassis Pb01aDocument81 pages50pk550-Sa Chassis Pb01adinnhowPas encore d'évaluation

- Compal La-6582p r1.0 Schematics PDFDocument49 pagesCompal La-6582p r1.0 Schematics PDFdinnhowPas encore d'évaluation

- Fish DiseaseDocument22 pagesFish DiseasedinnhowPas encore d'évaluation

- Greatwall E66 Fic Mr040t Rev0.4Document56 pagesGreatwall E66 Fic Mr040t Rev0.4dinnhowPas encore d'évaluation

- Airframe Essay QuestionsDocument12 pagesAirframe Essay QuestionsRaul DeonarainPas encore d'évaluation

- Set 2 Unit 2 PDF FreeDocument13 pagesSet 2 Unit 2 PDF FreeASHWATH G (RA2111018010045)Pas encore d'évaluation

- PQ070XF02SZH: Features Outline DimensionsDocument4 pagesPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloPas encore d'évaluation

- Ms 95-2018 Solved AssignmentDocument15 pagesMs 95-2018 Solved AssignmentPramod ShawPas encore d'évaluation

- Gen Target-2017Document22 pagesGen Target-2017SundeepPas encore d'évaluation

- 1 Pre-Lab: Lab 07: Sampling, Convolution, and FIR FilteringDocument12 pages1 Pre-Lab: Lab 07: Sampling, Convolution, and FIR Filteringdemetrickn0% (1)

- Hitman Contracts PC ManualDocument14 pagesHitman Contracts PC ManualChernoll MendoncaPas encore d'évaluation

- On Pressure and Velocity Boundary Conditions For The Lattice Boltzmann BGK ModelDocument9 pagesOn Pressure and Velocity Boundary Conditions For The Lattice Boltzmann BGK Modelamin110110Pas encore d'évaluation

- Implementing The IBM Storwize V7000 V6.3: Front CoverDocument630 pagesImplementing The IBM Storwize V7000 V6.3: Front CoverMimiLakicPas encore d'évaluation

- Accounts Payable by ORACLEUGDocument164 pagesAccounts Payable by ORACLEUGPraveenReddyBPas encore d'évaluation

- 200+ Network Management Tools - Open Source, Free and Commercial SoftwareDocument29 pages200+ Network Management Tools - Open Source, Free and Commercial SoftwarenscintaPas encore d'évaluation

- DC Voltage & Current Digital Panel Meter, Model 451A: Quick ManualDocument23 pagesDC Voltage & Current Digital Panel Meter, Model 451A: Quick ManualdedekeetPas encore d'évaluation

- Manual Ni Usrp 2920Document56 pagesManual Ni Usrp 2920Anghye Plata100% (1)

- DBMS-LM Kavi With MinipjtDocument56 pagesDBMS-LM Kavi With Minipjtkavi_mithuPas encore d'évaluation

- Tutorial Joint Push Pull - English - V1.1 - 20 Feb 08Document31 pagesTutorial Joint Push Pull - English - V1.1 - 20 Feb 08shadownrunPas encore d'évaluation

- DPP Series 1 PDFDocument1 pageDPP Series 1 PDFsukainaPas encore d'évaluation

- Waste Management in Selected Hotels in GoaDocument11 pagesWaste Management in Selected Hotels in GoaSyna SoaresPas encore d'évaluation

- V8 Pro BRDocument20 pagesV8 Pro BRwtn2013Pas encore d'évaluation

- Fi SlingDocument4 pagesFi SlingSony TogatoropPas encore d'évaluation

- Canalta Parts CatalogueDocument25 pagesCanalta Parts Cataloguellando1Pas encore d'évaluation

- Redesigning Boilers Solves Problems and Saves MoneyDocument9 pagesRedesigning Boilers Solves Problems and Saves MoneyfelramPas encore d'évaluation

- En 10268Document4 pagesEn 10268Alex LacerdaPas encore d'évaluation

- 1743 LKWActrosXXXXXX 954frDocument4 pages1743 LKWActrosXXXXXX 954frgeothermal3102100% (1)