Académique Documents

Professionnel Documents

Culture Documents

GR SM TDS0376 - e PDF

Transféré par

Jan HendriksTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

GR SM TDS0376 - e PDF

Transféré par

Jan HendriksDroits d'auteur :

Formats disponibles

Agip GR SM

PRODUCT DATA SHEET

Special lubricating grease based on lithium soap with MoS2.

Characteristics (typical figures):

Agip GR SM Unit Test method

NLGI consistency class 2 DIN 51 818

Thickener Li 12 Hydroxistearat with MoS2

Working temperature range °C -35 to +130

Drop point °C ca. 185 DIN ISO 2176

Behaviour against water Step 1 - 90 DIN 51 807 T. 1

Rating at test temperature

Designation KPF 2K -30 DIN 51 502

Properties and Performance:

Agip GR SM is based on a high-quality lithium soap grease that is used as carrier for the solid

lubricant component MoS2. It excels with an extreme water resistance, so it is suitable for

lubrication points, which are exposed to the ingress of water or humidity. Its worked stability,

the high ageing resistance as well as suitable oxidation inhibitors take care, that the regreasing

intervals can be prolonged by a multiple.

The solid component MoS2 complements the properties of the lubricating grease in the area of

the mixed friction.

Molybdenum disulphide has the property to anchor itself at the sliding surfaces and to form an

absolutely pressure and temperature resistant sliding film, which prevents a metallic contact of

the friction faces and therefore significantly reduces friction and wear.

Applications:

Agip GR SM is suitable for highly loaded, slow running sliding bearings, which work under

most difficult conditions. Also for roller bearings, especially for bevel and pendulum roller

bearings, which are naturally loaded with a higher sliding portion. Proven as uniform lubricant

on construction sites for the heaviest machines and for unapproachable lubrication points,

which cannot be regreased during the operation and require dry running properties.

Furthermore for lubrication points that are located in the area of the mixed friction, e. g.

oscillating movements of vibration stressed bearings at vibration rollers etc. Furthermore for

intermittent loads at unfavourable active agent pairing, like steel on steel. As break-in grease

it shortens the break-in process with an outstanding smoothing effect.

If possible a mixture with greases of different soap basis has to be avoided since the special

qualities can be lost.

Please observe the manufacturer’s specifications when selecting products.

Eni Schmiertechnik GmbH TK1

Paradiesstraße 14 07/2013

97080 Würzburg 0376e

Tel. 0931 90098-0 Page 1 of 2

Agip GR SM

PRODUCT DATA SHEET

Additional physical-technical data:

Agip GR SM Unit Test method

Worked penetration 0,1 mm 265 - 295 DIN ISO 2137

Corr. protection properties Corr.-grade 0 and 0 DIN 51 802

accord. to the SKF-Emcor-procedure

Corrosion effect on Corr.-grade 1 - 100 DIN 51 811

copper at 120°C

Testing with the SKF-roller bearing °C 120 DIN 51 806

grease test machine: Running test B

passed at test temperature

VKA welding test N 4200 DIN 51 350 T. 4

Designation KPF 2 K -30 DIN 51 502

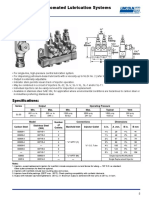

Specifications:

DIN 51 825 T.3

KPF 2K -30

Eni Schmiertechnik GmbH TK1

Paradiesstraße 14 07/2013

97080 Würzburg 0376e

Tel. 0931 90098-0 Page 2 of 2

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- D21a P 8Document6 pagesD21a P 8Jan HendriksPas encore d'évaluation

- E SpecCMP15 18 20sDocument6 pagesE SpecCMP15 18 20sJan HendriksPas encore d'évaluation

- Catalog Komatsu PDFDocument202 pagesCatalog Komatsu PDFJan Hendriks82% (11)

- 340 7 PDFDocument8 pages340 7 PDFJan HendriksPas encore d'évaluation

- Diesel or LPG Engine Pneumatic Tires: CMP50 CMP60 CMP70 CMP50Document6 pagesDiesel or LPG Engine Pneumatic Tires: CMP50 CMP60 CMP70 CMP50MA TotalforkliftPas encore d'évaluation

- C15-20 Gen-2 PDFDocument6 pagesC15-20 Gen-2 PDFJan HendriksPas encore d'évaluation

- BR350JG 1Document8 pagesBR350JG 1Jan HendriksPas encore d'évaluation

- Brochure ZW310 5Document20 pagesBrochure ZW310 5Jan HendriksPas encore d'évaluation

- I60O 150930 Trilithic CT 4 KKDocument2 pagesI60O 150930 Trilithic CT 4 KKJan HendriksPas encore d'évaluation

- Despiece Motor Kubota V-2203-DI PDFDocument43 pagesDespiece Motor Kubota V-2203-DI PDFMario Aguirre100% (2)

- Kubota z482 d722Document81 pagesKubota z482 d722jaumegusPas encore d'évaluation

- 51468Document6 pages51468Jan HendriksPas encore d'évaluation

- Teleboom HandlersDocument8 pagesTeleboom HandlersArturo AndPas encore d'évaluation

- Wheel Loaders: Innovative Drivetrain SolutionsDocument4 pagesWheel Loaders: Innovative Drivetrain SolutionsAli Tavakoli NiaPas encore d'évaluation

- 299D XHP Compact Track Loader AEHQ6565-01Document2 pages299D XHP Compact Track Loader AEHQ6565-01Jan HendriksPas encore d'évaluation

- 120 H GraderDocument20 pages120 H GraderSuyash Kumar Labh100% (1)

- Bomag Technical DataDocument4 pagesBomag Technical DataJan HendriksPas encore d'évaluation

- Peterbilt Heavy Duty Body Builder Manual 2017Document290 pagesPeterbilt Heavy Duty Body Builder Manual 2017Jan Hendriks100% (2)

- PN Infosheet Compressors K-Series en May18 LQDocument1 pagePN Infosheet Compressors K-Series en May18 LQJan HendriksPas encore d'évaluation

- 299D XHP Compact Track Loader AEHQ6565-01Document2 pages299D XHP Compact Track Loader AEHQ6565-01Jan HendriksPas encore d'évaluation

- Max Lifting Height 16.35mDocument4 pagesMax Lifting Height 16.35mJan HendriksPas encore d'évaluation

- 12M Motorgrader PDFDocument28 pages12M Motorgrader PDFJan HendriksPas encore d'évaluation

- 12M Motorgrader PDFDocument28 pages12M Motorgrader PDFJan HendriksPas encore d'évaluation

- TL35 70Document1 pageTL35 70Jan HendriksPas encore d'évaluation

- CD60R - 1A Brochure PDFDocument4 pagesCD60R - 1A Brochure PDFJan HendriksPas encore d'évaluation

- D350ahg - D400ahg - en PDFDocument69 pagesD350ahg - D400ahg - en PDFJan HendriksPas encore d'évaluation

- BR500JG 1a PDFDocument8 pagesBR500JG 1a PDFJan HendriksPas encore d'évaluation

- Telescopics: DimensionsDocument10 pagesTelescopics: DimensionsJan HendriksPas encore d'évaluation

- Grease 15-16 PDFDocument1 pageGrease 15-16 PDFJan HendriksPas encore d'évaluation

- 1275 EnuDocument2 pages1275 EnuJan HendriksPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Mitsubishi CB76-A PDFDocument6 pagesMitsubishi CB76-A PDFAdriawan AnnesPas encore d'évaluation

- J IndexDocument4 pagesJ Indexapi-3820466Pas encore d'évaluation

- Trombone Studio HandbookDocument19 pagesTrombone Studio Handbookapi-405690949100% (1)

- Stanvac National Price List DT 01-08-2012Document22 pagesStanvac National Price List DT 01-08-2012kmanikec67% (3)

- Grease Injectors LincolnDocument6 pagesGrease Injectors LincolnnelsonPas encore d'évaluation

- Guide Bearing Lubrication Freq QtyDocument3 pagesGuide Bearing Lubrication Freq Qtyrifal1990Pas encore d'évaluation

- Cat 943 EnsambleDocument134 pagesCat 943 Ensamblejose luis juarezPas encore d'évaluation

- Manual de Servicio NaviDocument240 pagesManual de Servicio NaviJavier100% (1)

- Manual Drill Collar S-R-LDocument6 pagesManual Drill Collar S-R-LJAVIER EDUARDO MANTILLA BUITRAGOPas encore d'évaluation

- B+V-Manual - Tongs BV & WRT Models PDFDocument58 pagesB+V-Manual - Tongs BV & WRT Models PDFYina Useche100% (2)

- 00 EP Lubricant ManuualDocument50 pages00 EP Lubricant Manuualpln up3Pas encore d'évaluation

- Elring Sealing Compound Dirko HT: Technical DatasheetDocument3 pagesElring Sealing Compound Dirko HT: Technical Datasheetperico_Pas encore d'évaluation

- Handbook GreaseDocument46 pagesHandbook Greasepcbyk_mro75% (4)

- T54125ADocument64 pagesT54125ARaúl FroddenPas encore d'évaluation

- Dismantling and Assembly GuideDocument44 pagesDismantling and Assembly GuideRadu Babau100% (1)

- Conversion Chart AgricultureDocument2 pagesConversion Chart Agricultureiescobar0702Pas encore d'évaluation

- SD Slip ManualDocument9 pagesSD Slip ManualGregory StewartPas encore d'évaluation

- FAG Motion Guard - The Intelligent Lubricators: Compact, Champion, Concept 6Document6 pagesFAG Motion Guard - The Intelligent Lubricators: Compact, Champion, Concept 6Renzo Jo LaurentPas encore d'évaluation

- CAT M316D MaintenanceDocument66 pagesCAT M316D MaintenanceHenwy Dickinson75% (4)

- Cat. NICEDocument32 pagesCat. NICEnelson santosPas encore d'évaluation

- SKF Cage MaterialsDocument2 pagesSKF Cage MaterialsKamolwan WeerachatsakulPas encore d'évaluation

- Yamaha 2019-2020 Grizzly Service ManualDocument440 pagesYamaha 2019-2020 Grizzly Service ManualRodolfo Godoi QueirozPas encore d'évaluation

- Manual de Máquina de Coser JukiDocument243 pagesManual de Máquina de Coser JukiDavid Jesus Ludewig OrtegaPas encore d'évaluation

- Power-Lock As Series: Instruction ManualDocument1 pagePower-Lock As Series: Instruction ManualJona SiahaanPas encore d'évaluation

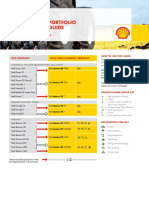

- TDS Shell Gadus S2 OGH 0 00 TDS Open GearDocument2 pagesTDS Shell Gadus S2 OGH 0 00 TDS Open GearBenedict KargboPas encore d'évaluation

- Tds-Ind-Gearz-Ep 052715Document2 pagesTds-Ind-Gearz-Ep 052715sebastianPas encore d'évaluation

- MSCC ManualDocument11 pagesMSCC ManualBoochuckPas encore d'évaluation

- Pis Taski Spiral HDDocument2 pagesPis Taski Spiral HDMaddyPas encore d'évaluation

- Oil & Fuel Transfer Pumps: 02 Farm 51 - 107 7/3/07 10:42 AM Page 51Document57 pagesOil & Fuel Transfer Pumps: 02 Farm 51 - 107 7/3/07 10:42 AM Page 51Brad PaynePas encore d'évaluation

- C2104pe Smo SMXDocument6 pagesC2104pe Smo SMXapi-295828551Pas encore d'évaluation