Académique Documents

Professionnel Documents

Culture Documents

Improved Seismic Performance of Gusset Plate Connections

Transféré par

Gokul PrabuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Improved Seismic Performance of Gusset Plate Connections

Transféré par

Gokul PrabuDroits d'auteur :

Formats disponibles

Improved Seismic Performance of Gusset Plate Connections

Dawn E. Lehman1; Charles w. Roeder2; David Herman3; Shawn Johnson4; and Brandon Kotulka5

Abstract: Current design practices use a strength-based design approach to design gusset plate connections in special concentrically

braced frames 共SCBFs兲, in which the expected tensile and compressive capacities of the brace are used to design the gusset plate and the

weld used to connect the brace to the frame. To achieve brace end rotation, the gusset plate is sized using a linear offset rule, and large,

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

uneconomical gusset plate connections may result. A research program was undertaken to improve the economy and performance of

gusset plate connections. A new approach is proposed in which the gusset plate design is based on a balanced design approach in which

the yield mechanisms of the brace are balanced with the yield mechanisms of the connection and the failure modes of the system to

achieve a target yielding hierarchy and suppress unwanted failure modes. Full-scale one-story, one-bay frames were designed and tested

to investigate the seismic performance of current and proposed design methods. In the test program, variations in balance factors between

the brace, gusset plate, and weld were considered to study the proposed method, to evaluate possible yield mechanisms and failure modes,

and to obtain the desired yielding hierarchy. Comparison of the observed and measured performance of each specimen is made and

specific design expressions to improve the seismic engineering of SCBF systems are proposed.

DOI: 10.1061/共ASCE兲0733-9445共2008兲134:6共890兲

CE Database subject headings: Earthquake engineering; Frames; Bracing; Plates; Connections.

Introduction Gusset plate connections have been used for many years, and they

are designed using the Whitmore width and the AISC Uniform

Concentrically braced frames 共CBFs兲 are economical, and their Force Methods 共UFM兲 共Whitmore 1952, Thornton 1991; AISC

strength and stiffness assist in achieving serviceability limit states 2005b兲. These methods are not based on seismic design prin-

for performance-based seismic design 共PBSD兲. During severe, in- ciples, which add to the uncertainty in the design method. How-

frequent earthquakes, brace yielding and buckling occur, and this ever, they are backed by significant experimental data 共e.g.,

behavior provides the deformation and energy dissipation capaci- Bjorhovde and Chakrabarti 1985; Hu and Cheng 1987; Brown

ties to satisfy life-safety and collapse-prevention performance ob- 1988; Rabinovich and Cheng 1993; Cheng et al. 1994; Grondin et

jectives. The special concentrically braced frame 共SCBF兲 design al. 2000兲. A recent literature review 共Chambers 2004兲 of gusset

requirements in the AISC Seismic Design Provision 共AISC plate connection research identified more than a hundred refer-

2005a兲 address these objectives. SCBFs have increased in usage ences; however these studies do not accurately simulate the seis-

in recent years, because of these advantages and uncertainty as to mic behavior of gusset plate connections.

the performance of special moment resisting frames after the Most past experiments evaluate gusset plate behavior to failure

1994 Northridge Earthquake 共Roeder 2002兲. but few employ inelastic cyclic deformation demands. The pre-

The seismic behavior of SCBFs is not well understood by vious tests ignore complete frame action and exclude the de-

engineers. The design and performance of gusset plate connec- formation demands resulting from cyclic inelastic axial and

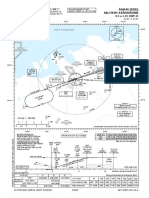

tions, which join the brace to beams and columns as schemati- postbuckling deformation of the brace. Past experimental results

cally shown in Fig. 1, are primary concerns in SCBF design. were compared to analytical and design models for connection

performance 共Roeder et al. 2004, 2005兲. The comparison showed

1

Assistant Professor, Dept. of Civil and Environmental Engineering, great variability in the accuracy of current design models, and

Univ. of Washington, Seattle, WA 98103. E-mail: delehman@ suggests that improvements are needed to accurately predict the

u.washington.edu connection resistance and system behavior. Recent tests show that

2

Professor, Dept. of Civil and Environmental Engineering, Univ. of

the seismic performance of these is different from that postulated

Washington, Seattle, WA 98103.

3

Structural Engineer, Magnusson Klemencic Associates, 1301 Fifth in the SCBF design assumptions, and suggest that a broader, ho-

Ave., Suite 3200, Seattle, WA 98101-2699. listic perspective of gusset plate connection design and behavior

4

Structural Engineer, Magnusson Klemencic Associates, 1301 Fifth is required 共Uriz and Mahin 2004兲.

Ave., Suite 3200, Seattle, WA 98101-2699. This broader perspective was the focus of a recent research

5

Structural Engineer, Magnusson Klemencic Associates, 1301 Fifth study, which was aimed at developing such a design method.

Ave., Suite 3200, Seattle, WA 98101-2699. Experiments were carried out to evaluate and improve the seismic

Note. Associate Editor: James S. Davidson. Discussion open until response of SCBF gusset plate connections. Results from 13

November 1, 2008. Separate discussions must be submitted for individual large-scale tests are presented. The test specimens simulated a

papers. To extend the closing date by one month, a written request must

single-story, single bay of a low-to-mid-rise building. The speci-

be filed with the ASCE Managing Editor. The manuscript for this paper

was submitted for review and possible publication on February 5, 2007; mens were integrated component tests, which included beams,

approved on July 31, 2007. This paper is part of the Journal of Struc- columns, a brace, and two gusset-plate connections, and were

tural Engineering, Vol. 134, No. 6, June 1, 2008. ©ASCE, ISSN 0733- conducted to assure a realistic simulation of the demand on and

9445/2008/6-890–901/$25.00. performance of the gusset-plate connection. The results showed

890 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:890-901.

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 1. Schematic of SCBF gusset plate connections and design checks 共a兲 welded tube brace; 共b兲 bolted angle connection; 共c兲 gusset plate welds;

and 共d兲 free edge buckling

clear limitations in the current design methods and potential im- based upon the work point of the brace and the frame geometry.

provements needed for seismic design. The results were compiled Failure modes that must then be considered, as suggested in Fig.

and analyzed to develop design expressions that assure that the 1, include tearing or fracture of the brace, net section fracture of

gusset plate rotation resistance and stiffness meet the require- the brace or gusset plate, weld fracture of the gusset plate welds,

ments of the SCBF system. Implementing these improvements in shear fracture of the bolts, block shear, excessive bolt bearing

design practice will result in more compact and economical con- deformation, and buckling of the gusset plate. The primary design

nections with increased inelastic deformation capacity and im- steps for a gusset-plate connection, which take these failure

proved performance. modes into consideration, are as follows.

• The welds or bolts used to attach the brace to the gusset plate

must be designed to provide the expected tensile yield resis-

Current AISC Design Method for SCBF Frames tance of the brace, and the weld length or bolt group must also

be checked using the block shear design expression.

The CBF and UFM design methods 共AISC 2005b兲 assume that

• The yield and buckling strengths of the plate are calculated

the frame acts as an in-plane truss, and neglect effects associated

using the Whitmore width and modified Thornton design ex-

with frame bending and brace buckling. The truss assumption is

pressions and compared with the tensile and compressive

made by designers and is explicitly stated in the current AISC

Specification 共2005b兲. Gusset-plate connections are designed to strengths of the brace, respectively. 共Fig. 1 shows these rel-

assure that the factored resistance, Rn, for each connection de- evant variables for bolted and welded connections, respec-

sign failure mode exceeds the axial demand of the brace, Pu. The tively.兲 The Whitmore width is defined by a 30° projected

axial demand, Pu, is a factored design load for most nonseismic angle from the start to the end of the bolted or welded joint. In

applications. For seismic design 共AISC 2005a兲, Pu is defined as addition, an edge buckling check 共Brown 1988; Astaneh-Asl

the expected tensile yield force 共RyAgFy兲 or expected compres- 1998兲 is often employed, as suggested in Fig. 1共c兲, but com-

sive buckling force 共RyAgFcr兲, respectively. In the products, parison with past test results shows poor correlation between

Ry⫽ratio of the expected yield stress to the minimum specified edge buckling predictions and experimental results 共Roeder

yield stress; Ag⫽gross area of the brace; and Fy⫽minimum speci- et al. 2005兲.

fied yield stress of the steel. • The welds, which are fillet or complete joint penetration 共CJP兲

For connection design, the geometric proportions 关dimensions welds, attaching the gusset plate to the beam and column are

a and b shown in Figs. 1共a and b兲兴 of the gusset plate are initially sized 共the interface welds兲 for design forces determined using

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 891

J. Struct. Eng. 2008.134:890-901.

Fig. 2. Photos of damaged CBF gusset plate connections 共a兲 fracture

of beam adjacent to gusset plate; 共b兲 premature bucking of gusset

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 3. 共a兲 Yield mechanisms; 共b兲 failure modes for SCBFs

equilibrium methods with the expected tensile force in the However, where the capacity-design method assures that the duc-

brace. tile element yields first, the proposed balanced design method

The AISC seismic design provisions require allowances for the maximizes the system ductility and inelastic deformation capac-

brace end rotation, and a 2t p-linear clearance at the end of and ity, because it controls the sequence of yielding and maximizes

parallel to the axis of the brace is commonly employed 共Fig. 1兲, the inelastic deformation. In most cases, greater ductility is

where t p⫽thickness of the gusset plate. This requirement can re- achieved with the proposed method by assuring that multiple,

sult in very large gusset plates which can lead to uneconomical desirable yield mechanisms are developed prior to fracture or

seismic design and inferior seismic performance. failure of the connection 共Roeder 2002兲.

Several design concerns are apparent when past research is This process satisfies serviceability design limits, as each

considered. First, there are significant inconsistencies between de- member has a resistance greater than a specified seismic design

sign model predictions and past experimental results 共Roeder et requirement. The required capacities of the connection must then

al. 2004, 2005兲. Second, substantial variations in design practice exceed the expected plastic resistances of these members.

are noted, because the requirements of the UFM were not specifi- Collapse-prevention and life-safety design objectives require that

cally developed for seismic design and has several variations in the system sustain a significant ductility demand without exhibit-

application. Third, economy and performance of these connec- ing undesirable failure modes, and this is assured by a sequence

tions is uncertain. These issues are exacerbated by results from of yielding before the target failure mode is permitted and unde-

two recent experimental research studies 共Uriz and Mahin 2004; sirable failure modes are suppressed. Some failure modes have

Chen et al. 2004兲 which have shown premature damage to beams, more severe consequences than others, and the balancing method

columns, and braces adjacent to the gusset plate connections such accounts for this by providing greater separation between the less

as the beam fracture shown in Fig. 2共a兲 and gusset plate buckling, desirable failure modes and the primary yield resistance thereby

which occurred at relatively small deformations, shown in Fig. assuring that these undesirable behaviors will not occur.

2共b兲. These recent test results show that the seismic performance Fig. 3 illustrates the possible yield mechanisms and failure

of SCBF gusset-plate connections is different from those postu- modes for SCBFs, and the following equation expresses the pro-

lated in the design assumptions and that brittle and unexpected posed yield mechanism balance procedure used to establish this

failures can result at moderate story drifts, which are well below yielding hierarchy:

the performance required by SCBF design. The goal of seismic

design must be to assure that adequate strength, stiffness, energy Ryield,mean = RyRyield ⱕ y1Ry1Ryield,1 ⱕ y2Ry2Ryield,2 ⱕ ¯

dissipation or ductility, and inelastic deformation capacities are

achieved. Further, for PBSD, these criteria must be achieved to ⱕ yiRyiRyield,i 共1兲

satisfy the multiple performance states. These goals are the focus The nominal yield resistances, Ryield,i, for the identified desirable

of this research. yield mechanisms are separated by balance factors, yi, to control

the resistance of secondary yield mechanisms and to achieve the

yielding hierarchy. The primary yield mechanism, Ryield,mean, is

Overview of Balanced Design Method to Improve followed by secondary yield mechanism 1, which are followed by

Performance secondary yield mechanism 2, etc. The  values, which define the

separations, are based on the ductility and experimental perfor-

A design methodology based on balancing the yield mechanisms mance of the various yield mechanisms and the separation re-

and preventing undesirable failure modes is proposed to address quired to achieve the performance goals. These  have similar

the inadequacies in current SCBF gusset-plate connection design. characteristics to the resistance factors, , commonly used in

Members initially are designed to meet the design seismic force load and resistance factor design, but they are fundamentally dif-

demands, and specific yielding elements 共e.g., braces in SCBFs兲 ferent, because  values are selected to achieve ductility and

are designed to sustain the inelastic deformation demands. Capac- inelastic deformation capacity rather than strength.

ity design principles are used to avoid premature failure and to Failure modes cause fracture, tearing, reduction of resistance,

achieve a progression of inelastic behaviors directed toward a or deterioration of performance. A single failure mode typically

preferred yield sequence and selected failure mode. These two will not result in collapse or total failure of the connection or the

objectives are achieved by balancing the relative resistances of all system, because multiple failure modes are usually required to

of the yield mechanisms and failure modes. achieve this extreme condition. However, a single failure mode

This approach is an extension of the capacity-design approach. causes significant, irrecoverable damage. The following addi-

892 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:890-901.

N⫽number of plate thicknesses, t p, that the elliptical line is to be

offset from the intersection of the beam and the gusset plate.

To study the impact of the gusset plate design on the frame

performance, the study parameters that were investigated in-

cluded: 共1兲 Plate thickness, 共2兲 brace clearance requirement 共stan-

dard or elliptical兲, 共3兲 weld type and dimensions, 共4兲 taper of the

gusset plate, and 共5兲 strength and stiffness of the beams. The last

parameter was included to test the hypothesis that the stiffness of

the framing element also influences the cyclic response 共Yoo

2006兲.

Thirteen specimens were tested and designated as HSS 共indi-

cating that the brace was a hollow steel section兲. Fig. 5 shows a

typical test specimen. Table 1 lists salient details of all specimens.

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Nominally identical sections were used for the beams 共W16

⫻ 45兲, columns 共W12⫻ 72兲, and brace 共HSS 5 ⫻ 5 ⫻ 3 / 8兲, as in-

dicated in Fig. 5. Specimen HSS-11 was the exception since a

larger beam section was used, as indicated in Table 1. The frame

centerline dimensions measured 3.66 m 共12 ft兲 high by 3.66 m

共12 ft兲 wide. The gusset plate was attached to the beam and col-

umn using a fillet weld on both sides 共F兲 or CJP weld. The brace

was connected to the gusset plate using a fillet weld. All welds

were E71T-8 flux core arc welds satisfying the toughness require-

Fig. 4. Proposed elliptical-clearance requirement and associated ments for AISC Seismic Provisions demand critical welds 共AISC

geometry 2005a兲. The length of the interface weld between the gusset and

beam or column were approximately 30– 40 mm less than the

variables a and b, which indicate the length between the gusset

tional balancing expressions are used to separate and balance plate and the flange of the beam or column, respectively. 共This

critical failure mode resistances, and to assure that multiple yield difference results from the clipped corner of the gusset plate at the

mechanisms occur. bam and column flange intersections.兲 The thickness of the fillet

weld used for each specimen is specified in Table 1.

Ryield,mean = RyRyield ⱕ fail,1Rfail,1 ⱕ fail,2Rfail,2 ⱕ ¯ ⱕ yield Each specimen or subseries of specimens were designed to

study a specific parameter. Specimen HSS-1 was designed to re-

⬍ fail 共2a兲 flect current seismic design specifications and practice and served

or if multiple yield mechanisms are desired as a reference; HSS-12 was nominally identical to HSS-1 but

detailed with a CJP weld. These were the only specimens de-

Ry,1Ryield,1 ⱕ fail,1Rfail,1 ⱕ fail,2Rfail,2 ⱕ ¯ 共2b兲 signed using the 2t p linear offset. The gusset plates of the remain-

ing specimens were designed using the proposed elliptical

Eq. 1共a兲 assures that the resistances of all failure modes, Rfail, clearance with additional variations in the elliptical offset dis-

exceed the primary yield resistance, Ryield,mean. Combining Eqs. tance, the interface weld, and the degree of taper, as defined in

共1兲 and 共2b兲 assures that the resistances of all of the failure modes Table 2. The gusset plate of HSS-2 was modified to meet a 6t p

exceed the primary yield resistance and the first secondary yield elliptical clearance requirement and the interface weld used to

mechanism. The magnitude of fail,i is determined such that less connect the plate to the beams and columns was sized to meet the

favorable failure modes have greater separation 共i.e., smaller  plastic capacity of the plate. The thickness of each gusset plate

values兲 than more favorable failure behaviors and smaller prob- used for Specimens HSS-2 and HSS-7 was varied. The offset

ability of occurrence. An earlier paper 共Roeder et al. 2005兲 de- distance used for the elliptical clearance was varied from 3t p

scribes this balance procedure and the rationale used to establish 共HSS-8兲 to 9t p 共HSS-4兲. Taper was studied by using nominally

the  actors. identical plates for Specimens HSS-2 and HSS-10 with a 0 or 15°

taper, respectively. To study the influence of the weld type, the

following pairs of companion, nominally identical specimens

Test Program were detailed with fillet and CJP welds, respectively: HSS-1/

HSS-12, HSS-2/HSS-9, and HSS-10/HSS-13.

Previous tests that have focused on the cyclic behavior of braces The test setup was designed to simulate, to the extent possible,

or connections have neglected the influence of the coupled behav- the boundary and loading conditions present on a one-story, one-

ior of the components of a braced frame and nonlinearity in the bay frame in a SCBF building. Fig. 6 shows the setup and indi-

framing elements. In this test program, the test specimens and cates the components of the test rig. The frame was placed

setup were designed incorporate these important response mecha- horizontally 共parallel to the laboratory floor兲. A horizontal,

nisms. The primary focus of the test program was the influence 1,468 kN 共330 kip兲 actuator applied the cyclic lateral load to the

of the gusset plate design on the overall cyclic lateral response of specimen through a load beam; the load beam extended over ap-

SCBFs. To improve both the constructability and performance of proximately one-third of the specimen width to ensure a uniform

the connections, the 2t p linear clearance distance discussed earlier transfer of the load without excessive restraint of the beam rota-

was replaced using an elliptical clearance requirement, shown in tion. The specimen reactions were distributed to the reaction wall

Fig. 4, for most tests. As shown in the figure, the ellipse is offset through a pair of channels which was securely attached to the

from the beam and column faces a distance of Ntp, where wall. The specimen was supported by direct bearing on the chan-

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 893

J. Struct. Eng. 2008.134:890-901.

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 5. Typical test specimen

nels in compression and a series of bolts provided shear transfer Instrumentation was placed to monitor loads, global displace-

from the lower beam to the channels. A pair of rods was used to ments, and local strains and deformations in the brace, framing

apply a 1,557 kN 共350 kip兲 axial load to each column of the elements, and the gusset plate. Load cells monitored the applied

specimen. This axial load simulated gravity loads from upper sto- lateral and axial loads. Potentiometers monitored the movement

ries and limited column uplift during the test. A series of steel of the specimen and test rig. Additional potentiometers monitored

assemblies fitted with lubricated nylon sliding on polished metal local rotations and translations of the beams, columns, and gusset

surfaces provided out-of-plane restraint with minimal frictional plates as well as elongation of the brace. Strain gauges were at-

resistance. tached to beams, columns, and the brace in regions where limited

Table 1. Test Specimen Properties

Yield and ultimate strengths 共MPa兲 Gusset plate geometry 共mm兲

Brace

Specimen Beam Column Brace Gusset length Weld t2

designation 共A992兲 共A992兲 共A500兲 共A572兲 tp a b Offset Lb共m兲 type 共mm兲

HSS-1 410 516 414 505 483 529 821 876 12.8 863.6 762.0 2t 3.42 F 4.76

HSS-2 405 388 388 516 483 529 454 552 12.4 635.0 533.4 E-6t 4.01 F 12.70

HSS-3 376 503 412 532 483 529 354 503 12.5 635.0 304.8 E-6t 4.01 F 11.11

HSS-4a 396 508 380 514 505 549 354 503 12.5 647.7 543.1 E-9t 3.90 F 11.11

HSS-5 395 501 409 522 505 549 447 602 9.5 635.0 533.4 E-8t 4.01 F 7.94

HSS-6 376 503 412 532 446 481 446 599 9.6 635.0 304.8 E-8t 4.01 F 7.94

HSS-7 395 501 409 522 446 481 407 531 22.0 723.9 622.3 E-6t 3.79 F 19.05

HSS-8 419 532 396 525 446 481 509 621 9.6 596.9 495.3 E-3t 4.12 F 11.11

HSS-9 421 531 392 519 446 481 473 603 12.9 635.0 533.4 E-6t 4.01 CJP —

HSS-10b 412 524 408 524 454 490 473 672 12.9 476.3 415.9 E-7t 3.99 F 7.94

HSS-11c 396 512 404 516 454 490 435 547 22.6 723.9 622.3 E-6t 3.79 CJP —

HSS-12 414 510 414 524 455 490 414 552 12.8 863.6 762.0 2t 3.42 CJP —

HSS-13b 414 510 414 524 455 490 414 552 12.7 476.3 415.9 E-7t 3.79 CJP —

a

Brace splice length was reduced to 349 mm 共from 374 mm兲.

b

Gusset plate detailed with 15° taper for HSS-10 and HSS-13.

c

W16⫻ 89 section used for beams in Specimen HSS-11.

894 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:890-901.

Table 2. Global Experimental Results

Drift ratio 共%兲 Load 共kN兲

Specimen

Specimen tp nt p tw / t p description ⌬max ⌬min ⌬comp,tear Range Max Min

HSS-01 12.78 n/a 0.4 Ref. 2t w / 1 / 2 in. pl 1.3 −1.6 −1.0 2.9 1,483 −860

HSS-02 12.42 6 1.0 6t w / 1 / 2 in. pl 1.5 −2.1 −2.0 3.6 1,514 −757

HSS-03 12.50 6 0.9 6t w / 3 / 8 in. pl 1.5 −3.0 −2.2 4.5 1,635 −757

HSS-04 12.50 9 0.9 9t w / 3 / 8 in. pl 1.5 −2.9 −2.5 4.4 1,483 −766

HSS-05 9.53 8 0.8 HSS-03 w / 5 / 16 in. weld 1.7 −3.1 −1.7 4.8 1,586 −721

HSS-06 9.55 8 0.8 HSS-05 w/reinf. weld 1.7 −3.0 −1.9 4.8 1,577 −712

HSS-07 22.02 6 0.9 6t w / 7 / 8 in. pl 1.3 −2.8 −2.7 4.0 1,595 −927

HSS-08 9.63 3 1.2 3t w / 3 / 8 in. pl 2.3 −2.6 −1.7 4.9 1,519 −771

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

HSS-09 12.85 6 cjp 6t w / 1 / 2 in. pl & cjp weld 1.3 −2.4 −1.8 3.7 1,631 −762

HSS-10 12.85 7 0.6 HSS-02 w/15° taper 1.9 −2.5 −2.2 4.5 1,564 −708

HSS-11 22.58 6 cjp HSS-07 w/large beam 1.1 −1.5 −1.5 2.6 1,841 −896

HSS-12 22.78 n/a cjp Ref. 共HSS-01兲w/CJP 1.4 −2.1 n/a 3.5 1,671 −806

HSS-13 12.70 7 cjp Tapered w/CJP 1.9 −2.1 n/a 4.0 1,564 −788

yielding was expected to monitor axial load, shears, and mo- testing protocol 共ATC 1992兲. Fig. 7 shows the target history. The

ments. For some specimens, biaxial strain gauges were used to magnitude of each cycle was a multiple of the yield drift, y, but

monitor local yielding of the gusset plate. Additional details of the different drifts corresponding to buckling and tensile yielding of

test setup may be found elsewhere 共Johnson 2005; Herman 2006兲. the brace are expected. As a result, the number of cycles applied

in these tests was larger than normally required by the ATC pro-

tocol in order to fully capture the performance of yielding and

Experimental Response

buckling in both directions of loading. Differences in the applied

The specimens were tested to observe the cyclic, nonlinear re- drift history and that actually sustained by the frame resulted from

sponse with increasing amplitude drift cycles based on the ATC slip, column uplift, and local bearing deformations. These effects

Fig. 6. Test configuration

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 895

J. Struct. Eng. 2008.134:890-901.

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 7. Normalized displacement history

were measured and the data was corrected to obtain the actual

drift history of the frame.

One of the primary objectives of the test program was to de-

velop PBSD tools for SCBFs. Therefore, the primary and second-

ary yield mechanisms and all failure modes, which are indicated

in Fig. 3, were carefully observed and the frame drifts and local

deformations at which they occurred were noted. Similar mecha-

nisms and modes were observed for most test specimens.

In all specimens, the initial yield mechanism was brace buck-

ling, as shown in Fig. 8共a兲, and it occurred at drift ratios ranging

from −0.2 to −0.5%. Tensile yielding of the brace occurred under

load reversal at drift ratios ranging from 0.4 to 1%. With addi-

tional drift demand, the brace buckling increased to a moderate

Fig. 8. Brace buckling progression 共a兲 initial; 共b兲 moderate; and 共c兲 level 关Fig. 8共b兲兴. In most test specimens, severe brace buckling

pinching occurred in which local pinching and cupping of the tube was

observed towards the center of the brace 关Figs. 8共c兲 and 9兴. The

drift at which severe buckling occurred varied depending on

the connection design. This response was followed by tearing of

the brace, as shown in Fig. 9共b兲.

Although a brace is typically idealized as a pin-ended 共truss兲

member analytically, the test results show that this may not be

accurate. Out-of-plane movement of the brace caused rotation of

the gusset plate, which in some cases resulted in gusset plate

yielding, as shown in Fig. 10. With cycling, yielding of the plate

in tension occurred in the specimens with thinner or tapered gus-

Fig. 9. Brace failure progression set plates. In some specimens, the large rotation demands on the

Fig. 10. Progression of yielding in gusset plate 共a兲 formation of yield line; 共b兲 significant yielding

896 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:890-901.

Fig. 11. Progression of weld damage 共a兲 initial tearing; 共b兲 separation; and 共c兲 complete fracture

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

plate led to ductile tearing 共drift levels for initial weld tearing are drift ranges 共⌬tens,max − ⌬comp,max兲 are also provided for each speci-

noted in Table 2兲, or complete fracture of the weld 共HSS-1 only兲, men, because this range represents a better measure of total

as shown in Figs. 11共a and b兲, respectively. ductility.

In some specimens, large frame deflections led to yielding or Only Specimen HSS-1 failed as a result of complete fracture

local buckling of the beams and columns adjacent to the gusset of the gusset-plate interface weld. Specimen HSS-1 was designed

plate because of bending moments in the beams or columns in- for weld forces obtained using the UFM and based on the ex-

duced by frame action, as depicted in Fig. 12. pected brace yield force. Failure of the other specimens was a

result of brace fracture, which was the more ductile and desirable

failure mode. The maximum drift in compression was achieved

Influence of Study Parameters by HSS-5 and HSS-6, which were detailed with thin 共9.5 mm兲

plates using an 8t p elliptical offset clearance requirement. The

Fig. 13 shows the measured normalized force-drift response of six maximum drift 共brace in tension兲 was sustained by Specimen

specimens, specifically: HSS-8, which was detailed with a thin plate and a 3t p elliptical

• HSS-1—reference specimen designed using current AISC offset. Specimens HSS-5, HSS-6, and HSS-8 achieved the maxi-

specification; mum drift ranges. In contrast, the minimum drift capacities in

• HSS-2—elliptical, 6t p clearance requirement with t p tension and compression, and the smallest drift range were

= 12.7 mm 共1 / 2 in.兲; achieved by Specimen HSS-11, which was designed using a large

• HSS-5—elliptical, 8t p clearance requirement with t p = 9.5 mm beam and thick gusset plate. These results show the importance of

共3 / 8 in.兲; the connection flexibility on the global frame response.

• HSS-7—elliptical, 6t p clearance requirement with t p A more detailed evaluation of specific behaviors permits

= 22.2 mm 共7 / 8 in.兲; evaluation of several gusset plate design parameters and issues

• HSS-10—elliptical, 7t p clearance requirement tapered to meet including plate flexibility, use of and variation in the elliptical

Whitmore width; and clearance requirement, weld geometry, and impact of frame

• HSS-11—nominally identical to HSS-7 with larger 共W16 stiffness. The following subsections evaluate each of these

⫻ 89兲 beams parameters.

In the plots, the measured shear force was normalized by the

shear force corresponding to the design yield strength of the brace

共RyFyAg兲. Curves of the remaining specimens are similar and Offset Distance Using Elliptical Clearance

may be found elsewhere 共Johnson 2005; Herman 2006兲. Table 2

Figs. 13共a and b兲 show Specimen HSS-1, the reference specimen,

provides maximum drifts achieved for the brace in compression

and Specimen HSS-2, designed using the elliptical clearance with

⌬comp,max 共given as a negative percentage兲, and the brace in ten-

a 6t p offset. The comparison suggests that the elliptical clearance

sion ⌬tens,max, as well as the corresponding story-shear forces. The

provides improved system drift capacity, but HSS-1 failed prema-

turely because of the inadequate capacity of the gusset plate weld.

Specimen HSS-12 was nominally identical to HSS-1 expect that a

CJP weld was used, which prevented all weld cracking. Table 2

shows that HSS-12 had somewhat comparable performance to

HSS-2 共same plate thickness with different offset criteria兲, but its

performance was inferior to HSS-5 and HSS-8, which had

slightly larger elliptical offsets. These results clearly show that the

elliptical clearance model provides equal or better performance

than the 2t p linear clearance model if the proper design param-

eters are employed.

Selection of the proper elliptical offset distance 共Ntp兲 depends

on the performance objectives of interest. Comparison of HSS-04

共9t p兲, HSS-05 共8t p兲, and HSS-08 共3t p兲 permits evaluation of the

Fig. 12. Local yield mechanisms in beams and columns 共a兲 extensive influence of the offset distance on the brace and system perfor-

yielding; 共b兲 severe local buckling mance. Table 2 presents measured global drift and load data as

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 897

J. Struct. Eng. 2008.134:890-901.

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 13. Normalized force-deflection responses for selected specimens

well as the compressive drift demand corresponding to initial achieved, simultaneously delaying weld tearing and nonlinear

weld tearing, ⌬comp,tear. Each specimen had the same specified analyses support these experimental findings 共Yoo 2006兲. Thus,

gusset-plate thickness of 9.7 mm 共3 / 8 in.兲. The “compressive” 8t p is the recommended clearance limit.

drift capacity 共brace in compression兲 is smallest for Specimen

HSS-8 共3t p兲. Conversely, the “tensile” drift capacity 共brace in Plate and Beam Geometries

tension兲 was smallest for Specimen HSS-4 共9t p兲. Specimen Fig. 14共b兲 presents measured drift ranges for three approximate

HSS-5 had the maximum drift range 共8t p兲 before fracture of the gusset plate thicknesses, 9.5, 12.5, and 22 mm. Figs. 13共c and d兲

brace. provide a comparison of specimens with 22 and 9.7 mm thick

Compiling all of the experimental results shows a similar gusset plates. The test data indicate that initial buckling capacity

trend. Fig. 14共a兲 indicates the compressive drift at the onset of was largest for Specimen HSS-7, because the thick gusset plate

weld tearing, which was lowest for the 3t p offset specimen resulted in additional end rotation restraint. However, the speci-

共Specimen HSS-08兲. Fig. 14共b兲 plots the maximum drift range as mens with thinner plates achieved larger tension drifts and drift

a function of the elliptical clearance. These results indicate that ranges. This improved response is likely a result of the increased

using an offset of 8t p permitted the maximum drift range to be flexibility and secondary yielding of the gusset plate.

898 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:890-901.

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Fig. 14. Impact of elliptical offset distance on 共a兲 compressive drift at weld tearing, 共b兲 total drift range

The drift capacities were smallest for Specimen HSS-11, Engineering Recommendations

which had a thick plate and larger beam, because of the increased

stiffness of the gusset plate and beam. This increased end restraint Experimentally the effective length factor was determined using

increased the local deformation demand in the brace for a given the buckling capacity of the brace and the total brace length 共Lb兲.

inelastic drift demand thereby reducing the ductility of the frame. On average, the experimental results indicate that an effective

Fig. 13共f兲 shows the limited inelastic deformation range of this length coefficient, k, of 1 used with this true brace length is ap-

specimen. The drifts at initial yielding and brace fracture are larg- propriate for design. Specific values are presented elsewhere

est for the specimens with the thinnest 共HSS-5兲 and tapered 共Johnson 2005, Herman 2006兲.

共HSS-10兲 gusset plates. This increased capacity results from the The elliptical design criterion was developed to achieve large

flexibility, deformability, and yielding of the plate and reduced frame postbuckling drift capacities without excessive weld tear-

strain concentration in the buckled brace. The use of the flexible ing. The experimental results indicate that using an offset distance

gusset plate clearly permitted larger deformation of the brace, and of approximately eight 共8兲 times the plate thickness 共t p兲 meets this

therefore the frame, prior to brace fracture, a direct result of the performance objective. This elliptical clearance model provided

balanced design method. brace rotational capacity and cyclic, inelastic performance that

exceeded that achieved with the current linear clearance model,

simultaneously providing a thinner, more compact gusset plate.

Weld Size and Type The thinner, more compact gusset plate had added benefits in that

they induced less damage in the welds and faming members ad-

Three pairs of specimens were designed to compare the impact of jacent to the gusset plate. With this model, a clear 共8t p wide兲

using complete joint penetration and fillet welds. These were elliptical band is maintained, as shown in the shaded area of Fig.

HSS-1/HSS-12, HSS-2/HSS-9, and HSS-10/HSS-13. The results 4. The actual dimensions of the elliptical band are easy to visu-

indicated that CJP welds either eliminate 共in the case of HSS-12, alize, and they can be determined graphically from the gusset

reference specimen, and HSS-13, specimen with tapered plate, plate dimensions. Although the offset can not be expressed by a

which did not exhibit weld tearing兲 or reduce 共in the Specimen single equation, an approximate analytical solution may be useful

HSS-9, which sustained only initial weld tearing兲 the extent of to the designer and has been developed using the geometric no-

weld tearing over that noted with specimen design using fillet tation shown in Fig. 4. The additional terms are needed for this

welds sized to achieve the plastic capacity of the plate 共Herman approximate derivation:

2006兲. • ␣ is the inclination angle of the brace from the horizontal;

Fig. 14共a兲 presents the drifts corresponding to weld tearing, • c is maximum distance from the centroidal axis to the extreme

⌬comp,tear, as observed during testing, as a function of the ratio of fiber of the brace; and

the weld size 共tw兲 to the plate thickness 共t p兲. Table 2 provides the • l⬘ is the length from the imaginary corner of the rectangular

elliptical clearance distances 共3t p – 9t p兲, weld-to-plate thickness gusset plate to the end of the square cut of the brace. This

ratios, and degree of plate taper for all specimens. Specimens length must include the length of the weld or bolt group as

with a 3t p offset or a weld-to-plate thickness ratio, tw / t p, less than well as the corner that is typically cut from the gusset.

0.9 sustained weld tearing at less than 2% drift. Specimens with a The dimensions a and b should be selected so that the imagi-

3t p offset or tw / t p ⬍ 0.9, sustained additional weld damage to nary corner of the gusset intersects the centroidal axis of the brace

achieve the maximum drift capacity of the frame, but the tough- as shown in Fig. 4. The radii of the ellipse are established as

ness of the welds prevented dramatic weld fracture and assured

reasonable inelastic deformation capacity of the SCBF system.

The acceptability of weld tearing at a given drift level depends on a⬘ = a − 8t p ; b⬘ = b − 8t p 共3兲

the design criteria, however, it is noted that larger fillet welds and

offset distances delay this damage state. and

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 899

J. Struct. Eng. 2008.134:890-901.

a⬘ Table 3. Comparison of Drift Capacities for Various Design ww Values

= 共4兲

b⬘ Specimen Study parameter ww ⌬max共%兲 ⌬range共%兲

HSS-05 HSS-03 w/5/16 in. weld 1.0 1.7 4.8

Then, x⬘ and y ⬘ 共as shown in Fig. 4兲 are established as the exact

HSS-06 HSS-05 w/reinf. wield 1.0 1.7 4.8

centerline dimensions to assure the 8t p elliptical clearance

HSS-03 6t w/ 3/8 in. pl 1.0 1.5 4.5

HSS-10 HSS-02 w/15° taper 0.8 1.9 4.5

y ⬘ = a⬘ sin共arctan共 tan共␣兲兲兲 共5a兲

HSS-09 6t w/ 1 / 2 in. pl & cjp wield 0.8 1.3 3.7

and HSS-02 6t w/ 1 / 2 in. pl 0.8 1.5 3.6

HSS-01 Ref. 2t w/ 1 / 2 in. pl 0.8 1.3 2.9

x⬘ = a⬘ 冑 冉 冊

1−

y⬘

b⬘

2

共5b兲

HSS-07

HSS-11

6t w/7/8 in. pl

HSS-07 w/large beam

0.4

0.4

1.3

1.1

4.0

2.6

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

The x⬘ and y ⬘ dimensions 共measured from the imaginary cor-

ner兲 are the exact clearance dimensions for the brace if the brace Conclusions and Recommendations for Future

had no width. However, the brace has finite width, and the goal is Work

to assure that the extreme corners of the brace also clear the

elliptical zone. An approximate solution is required here based The experimental program presented studied the inelastic, seismic

upon the slope of the ellipse at the centroid of the brace performance of SCBF gusset plate connections to improve the

performance relative to the current AISC design provisions, si-

= arctan 冉 冑 冊

−2

a ⬘2

x ⬘2

共6a兲

multaneously improving the constructability of SCBF systems.

The study focused on the gusset plate clearance needed to accom-

modate brace end rotation, the size and type of weld used to

connect the gusset plate to the framing elements, and the impact

Corr = c sin共兲cos共␣兲 共6b兲 of the gusset plate stiffness, thickness and geometry and the con-

nection and system performance. The study indicates that:

and finally • The elliptical gusset plate clearance model with an 8t p offset

distance provides greater system ductility and deformation ca-

l⬘ = 冑x⬘2 + y ⬘2 + Corr 共7兲 pacity, simultaneously delaying or limiting fracture of the

welds or brace.

This procedure was evaluated for different brace angles and cross • Use of the elliptical clearance model results in more compact,

sections, and gusset plate sizes and dimensions. The results show flexible gusset plates, reduced damage to the welds and beams

that it provides a corner intersection of the brace that approxi- and columns than the current linear offset model.

mates the 8t p band, except in cases where the brace angle be- Design recommendations appropriate for SCBF systems were

comes very flat or very steep. developed and include:

The weld size requirements were studied both experimentally • Use of an effective length 共K兲 coefficient of 1 共one兲 for tubular

and analytically 共Johnson 2005; Yoo 2006兲. The results indicate braces with gusset plate connections to provide a good esti-

that for a matching electrode, the fillet weld size should be equal mate of the brace buckling capacity.

to or greater than the thickness of the gusset plate. Yoo 共2006兲 • An approximate expression for the elliptical 8t p offset.

presents an equivalent expression for a different electrode; how- • Use of interface fillet welds, which connect the gusset plate to

ever the expression has not been verified experimentally. the beams and columns, with a thickness equal to the gusset

The experimental results indicate that yielding and flexibility plate thickness and an electrode that matches the gusset plate

of the gusset plate permits increased SCBF drift capacity, and metal to prevent premature weld cracking. Using a CJP weld at

reduced cracking of the weld and yielding of the beams and col- this location also reduces the potential for weld cracking.

umns adjacent to the connection. To quantify the benefit of bal- • The thickness of a rectangular gusset plate with welded HSS

ancing the tensile strength of the brace and the plate, the balance tube braces should be sized using Eq. 共8兲 which is based on the

factor for the plate strength based on the Whitmore width, ww, Whitmore width for the expected tensile capacity of the plate

was calculated using the expression provided in and the brace with ww = 1 for rectangular plates.

The research results still leave unanswered questions regarding

Ry,bFy,bAb other aspects of the SCBF frame design including alternative

ww = 共8兲 brace sections, beam-to-column connection and bolted connec-

Ry,gpFy,gpbwt p

tions. Additional research is needed to address issues regarding

The overstrength factors used were Ry,b = 1.4 and Ry,gp = 1.1 for the system response including brace configuration, geometry, and

the materials specified. The variables Fy,b and Fy,gp indicated the three dimensional effects. Future research by the writers and oth-

specified yield strengths for the brace and gusset plate, respec- ers is planned to explore these topics.

tively 共345 MPa兲, and the variable bw⫽Whitmore width. Table 3

provides the calculated balance factors for all specimens designed

using the 8tp elliptical clearance requirement and the reference Acknowledgments

共HSS-1兲 specimen. Specimens HSS-05, HSS-06, HSS-03, and

HSS-10 achieved the maximum drift range. For the rectangular The research results presented here were the result of studies

specimens, the balance factor, ww, was approximately 1. Only funded by the National Science Foundation, Grant No. CMS-

Specimen HSS-10, which was designed using a tapered plate, 0301792, Performance-Based Design of Concentrically Braced

sustained equivalent drift capacities with a lower ww factor. Frames 共Dr. Steven McCabe, Program Manager兲 and the Ameri-

900 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008

J. Struct. Eng. 2008.134:890-901.

can Institute of Steel Construction 共Mr. Tom Schlafly, Research strength of gusset plate connections.” J. Struct. Eng., 120共2兲, 538–

Director兲. The structural steel shapes were donated by Nucor- 559.

Yamato steel 共coordinated by Mr. Michael Engstrom兲 and the Grondin, G. Y., Nast, T. E., and Cheng, J. J. R. 共2000兲. “Strength and

high-strength steel tubes were donated by Columbia Structural stability of corner gusset plates under cyclic loading.” Proc., Annual

Tubing 共coordinated by Mr. Engstrom兲. The writers gratefully ac- Technical Session and Meeting, Structural Stability Research Council.

Herman, D. 共2006兲. “Further improvements on and understanding of

knowledge this support. SCBF systems.” MS thesis, Univ. of Washington, Seattle.

Hu, S. Z., and Cheng, J. J. R. 共1987兲. “Compressive behavior of gusset

plate connections.” Structural Engineering Rep. No. 153, Univ. of

References Alberta, Alberta, Ont., Canada.

Johnson, S. 共2005兲. “Improved seismic performance of special concentri-

American Institute of Steel Construction 共AISC兲. 共2005a兲. “Seismic pro- cally braced frames.” MS thesis, Univ. of Washington, Seattle.

visions for structural steel buildings.” AISC/ANSI Standard341-05, Rabinovitch, J. S., and Cheng, J. J. R. 共1993兲. “Cyclic behavior of steel

gusset plate connections.” Structural Engineering Rep. No. 191, Univ.

Downloaded from ascelibrary.org by COLUMBIA UNIVERSITY on 02/17/13. Copyright ASCE. For personal use only; all rights reserved.

Chicago.

of Alberta, Alberta, Ont., Canada.

American Institute of Steel Construction 共AISC兲. 共2005b兲. Steel construc-

Roeder, C. W. 共2002兲. “Connection performance for seismic design of

tion manual, 13th Ed., Chicago. steel moment frames.” J. Struct. Eng., 128共4兲, 517–525.

Applied Technology Council 共ATC兲. 共1992兲. “Guidelines for cyclic seis-

Roeder, C. W., Lehman, D. E., and Yoo, J. H. 共2004兲. “Performance

mic testing of components of steel structures.” ATC 24.

based seismic design of braced-frame connections.” 7th Pacific Struc-

Astaneh-Asl, H. 共1998兲. Seismic behavior and design of gusset plates,

tural Steel Conf.

Steel Tips, Structural Steel Education Council, Moraga, Calif. Roeder, C. W., Lehman, D. E., and Yoo, J. H. 共2005兲. “Improved seismic

Bjorhovde, R., and Chakrabarti, S. K. 共1985兲. “Test of full size gusset design of steel frame connections.” Int. J. Steel Struct., 5共2兲, 141–

plate connections.” J. Struct. Eng., 111共3兲, 667–684. 153.

Brown, V. L. S. 共1988兲. “Stability of gusseted connections in steel struc- Thornton, W. A. 共1991兲. “On the analysis and design of bracing connec-

tures.” Ph.D. thesis, Dept. of Civil Engineering, Univ. of Delaware, tions.” Proc., National Steel Construction Conf., AISC, Section 26,

Del. 1–33.

Chambers, J. 共2004兲. Brace frame gusset plate research—Phase I litera- Uriz, P., and Mahin, S. 共2004兲. “Seismic performance of concentrically

ture review, Univ. of Utah, Salt Lake City. braced steel frame buildings.” Proc., 13th World Conf. on Earthquake

Chen, C., Lai, J., Lin, M., Weng, Y., and Tsai, K. C. 共2004兲. “Pseudo- Engineering, Paper 1639.

dynamic test of a full-scale cft/bfb frame: Part 2—Construction and Whitmore, R. E. 共1952兲. “Experimental investigation of stresses in gusset

testing.” Proc., 13th World Conf. on Earthquake Engineering, Paper plates.” MS thesis, Univ. of Tennessee, Knoxville, Tenn.

2175, Canadian Association for Earthquake Engineering, International Yoo, J. H. 共2006兲. “Analytical investigation on the seismic performance

Assocaition of Earthquake Engineering. of special concentrically braced frames.” Ph.D. dissertation, Univ. of

Cheng, J. J. R., Yam, M. C. H., and Hu, S. Z. 共1994兲. “Elastic buckling Washington, Seattle.

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JUNE 2008 / 901

J. Struct. Eng. 2008.134:890-901.

Vous aimerez peut-être aussi

- Improved Seismic Performance of Gusset Plate ConnectionsDocument12 pagesImproved Seismic Performance of Gusset Plate ConnectionsPrateek PandaPas encore d'évaluation

- 10 1016@j JCSR 2017 07 022Document17 pages10 1016@j JCSR 2017 07 022Siti Aisyah NurjannahPas encore d'évaluation

- Journal of Constructional Steel Research: Charles W. Roeder, Eric J. Lumpkin, Dawn E. LehmanDocument13 pagesJournal of Constructional Steel Research: Charles W. Roeder, Eric J. Lumpkin, Dawn E. LehmanSantiago MonroyPas encore d'évaluation

- Journal of Constructional Steel ResearchDocument17 pagesJournal of Constructional Steel ResearchNaomi PratiwiPas encore d'évaluation

- Thin-Walled Structures: Son Tung Vy, Mahen Mahendran, Thananjayan SivaprakasamDocument18 pagesThin-Walled Structures: Son Tung Vy, Mahen Mahendran, Thananjayan SivaprakasamLidya DewiPas encore d'évaluation

- Experimental Investigation of Inelastic Cyclic Buckling and Fracture of Steel BracesDocument14 pagesExperimental Investigation of Inelastic Cyclic Buckling and Fracture of Steel BracesMacPas encore d'évaluation

- 1 s2.0 S0263823122010709 MainDocument16 pages1 s2.0 S0263823122010709 MainSerban IacobPas encore d'évaluation

- Engineering Structures: Nattapat Wongpakdee, Sutat Leelataviwat, Subhash C. Goel, Wen-Cheng LiaoDocument9 pagesEngineering Structures: Nattapat Wongpakdee, Sutat Leelataviwat, Subhash C. Goel, Wen-Cheng LiaoPhilip Amsal Apriano GintingPas encore d'évaluation

- Design of Unstiffened Extended Single Plate Shear ConnectionsDocument14 pagesDesign of Unstiffened Extended Single Plate Shear ConnectionsGonzalo ContrerasPas encore d'évaluation

- Experimental Performance of Steel Braced Frames Subjected To Bidirectional LoadingDocument12 pagesExperimental Performance of Steel Braced Frames Subjected To Bidirectional Loadingfranjc79Pas encore d'évaluation

- Bennett - 2015 - Design Parameters For Masonry Wall - Stiffness PredictionDocument14 pagesBennett - 2015 - Design Parameters For Masonry Wall - Stiffness PredictionJhon Smit Gonzales UscataPas encore d'évaluation

- Journal of Constructional Steel ResearchDocument16 pagesJournal of Constructional Steel ResearchfankenstainPas encore d'évaluation

- 6.-Structural Testing and Design of Wire Arc Additively Manufactured Square Hollow SectionsDocument19 pages6.-Structural Testing and Design of Wire Arc Additively Manufactured Square Hollow SectionsJosé RiquelmePas encore d'évaluation

- On Global Equilibrium in Design of Geosynthetic Reinforced WallsDocument7 pagesOn Global Equilibrium in Design of Geosynthetic Reinforced WallsssheafiPas encore d'évaluation

- Han - 2006 - General Analytical Framework For Design of FlexibleReinforced Earth StructuresDocument9 pagesHan - 2006 - General Analytical Framework For Design of FlexibleReinforced Earth StructuresStefano VignaPas encore d'évaluation

- Optimization and Sensitivity of Retaining Structures: by A KM Sarlba L and Fuat ErbaturDocument8 pagesOptimization and Sensitivity of Retaining Structures: by A KM Sarlba L and Fuat ErbaturIngénieurCivilPas encore d'évaluation

- (Asce) ST 1943-541X 0001789Document11 pages(Asce) ST 1943-541X 0001789surafel abebawPas encore d'évaluation

- Girder Load Distribution For Seismic Design of Integral BridgesDocument11 pagesGirder Load Distribution For Seismic Design of Integral BridgesAkhmad Immamul AzizPas encore d'évaluation

- A Study On Detailing Gusset Plate and Bracing Members in Concentrically Braced Frame StructuresDocument35 pagesA Study On Detailing Gusset Plate and Bracing Members in Concentrically Braced Frame StructuresRavindraKhandelwalPas encore d'évaluation

- Influence of Gusset Plate Stiffeners On The SeismicDocument6 pagesInfluence of Gusset Plate Stiffeners On The SeismicSang NguyenPas encore d'évaluation

- Experimental Study On Shear Strength of High-Strength Concrete BeamsDocument8 pagesExperimental Study On Shear Strength of High-Strength Concrete BeamsHuda JawadPas encore d'évaluation

- Design of Unstiffened Extended Single-Plate ShearDocument15 pagesDesign of Unstiffened Extended Single-Plate ShearM. Murat ErginPas encore d'évaluation

- Performance of Damage-Protected Beam-Column Joints Subjected To Bi-Directional Lateral Loading Kevin Solberg, Luoman Li, Brendon Bradley, John B. Mander, Rajesh P. DhakalDocument10 pagesPerformance of Damage-Protected Beam-Column Joints Subjected To Bi-Directional Lateral Loading Kevin Solberg, Luoman Li, Brendon Bradley, John B. Mander, Rajesh P. DhakalThulasirajan KrishnanPas encore d'évaluation

- Strength Prediction For Discontinuity Regions by Softened Strut-and-Tie ModelDocument8 pagesStrength Prediction For Discontinuity Regions by Softened Strut-and-Tie ModelAbi IlamvazhuthiPas encore d'évaluation

- International Conference On "Structural Engineering & Construction Management" SECM-2016Document8 pagesInternational Conference On "Structural Engineering & Construction Management" SECM-2016VishwanadhPas encore d'évaluation

- Comparison of Available Shear Strength Models For Non ConformingDocument16 pagesComparison of Available Shear Strength Models For Non ConformingSaad KhanPas encore d'évaluation

- Efficient Seismic Design of 3D Asymmetric and Setback RC Frame Buildings For Drift and Strain LimitationDocument12 pagesEfficient Seismic Design of 3D Asymmetric and Setback RC Frame Buildings For Drift and Strain LimitationAristotle MedinaPas encore d'évaluation

- Determination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsDocument3 pagesDetermination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsklllPas encore d'évaluation

- 1 s2.0 S2352012422003502 MainDocument19 pages1 s2.0 S2352012422003502 Mainali salekifardPas encore d'évaluation

- Full-Scale Testing For Composite Slab/Beam Systems Made With Extended Stud SpacingDocument9 pagesFull-Scale Testing For Composite Slab/Beam Systems Made With Extended Stud SpacingvardhangargPas encore d'évaluation

- 12.-Flexural Buckling of Wire Arc Additively Manufactured Tubular ColumnsDocument14 pages12.-Flexural Buckling of Wire Arc Additively Manufactured Tubular ColumnsJosé RiquelmePas encore d'évaluation

- (Asce) 0733-9445 (2007) 133 9 (1195)Document10 pages(Asce) 0733-9445 (2007) 133 9 (1195)gopa dasPas encore d'évaluation

- Seismic Performance Evaluation and Retrofit of Fixed Jacket Offshore Platform StructuresDocument11 pagesSeismic Performance Evaluation and Retrofit of Fixed Jacket Offshore Platform StructuresIoanna DiamPas encore d'évaluation

- Optimal Design of Cold-Formed Steel Lipped Channel Beams - Combined Bending, Shear, and Web CripplingDocument12 pagesOptimal Design of Cold-Formed Steel Lipped Channel Beams - Combined Bending, Shear, and Web Cripplingdinesh lakshmananPas encore d'évaluation

- Beushausen e AlexanderBondstrengthdevelopmentbetweenconcretesofdifferentagesDocument11 pagesBeushausen e AlexanderBondstrengthdevelopmentbetweenconcretesofdifferentagesLuis Felipe VerasPas encore d'évaluation

- EqS - Roeder2012 - Steel - CBF - Seismic PerformDocument19 pagesEqS - Roeder2012 - Steel - CBF - Seismic PerformfaisaladePas encore d'évaluation

- Finite Element Analyses Applied in Design of Foundations and Anchors For Offshore StructuresDocument14 pagesFinite Element Analyses Applied in Design of Foundations and Anchors For Offshore StructuresNhân NguyễnPas encore d'évaluation

- Parastesh 2021Document16 pagesParastesh 2021Luiz AlmeidaPas encore d'évaluation

- Shear Failure Mechanism of Reinforced Concrete Haunched BeamsDocument16 pagesShear Failure Mechanism of Reinforced Concrete Haunched BeamsalpegambarliPas encore d'évaluation

- Gusset Plate Connections For Seismic DesignDocument15 pagesGusset Plate Connections For Seismic DesignIndah Permata YeniPas encore d'évaluation

- Inspection, Planning of Offshore JacketDocument3 pagesInspection, Planning of Offshore JacketsaulolmPas encore d'évaluation

- 2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteDocument18 pages2022 Capacity Design of Coupled Composite Plate Shear Wall ConcreteHamid GoodarziPas encore d'évaluation

- Bayrak SeikhDocument13 pagesBayrak SeikhArthur DahokloryPas encore d'évaluation

- Llaves de CorteDocument12 pagesLlaves de CorteJose Luis Martinez SaavedraPas encore d'évaluation

- 047 P2 (Asce) 1090 0268 (2005) 9 - 6Document10 pages047 P2 (Asce) 1090 0268 (2005) 9 - 6Novia MerisaPas encore d'évaluation

- Engineering Structures: J. Ramon Gaxiola-Camacho, Hamoon Azizsoltani, Francisco J. Villegas-Mercado, Achintya HaldarDocument11 pagesEngineering Structures: J. Ramon Gaxiola-Camacho, Hamoon Azizsoltani, Francisco J. Villegas-Mercado, Achintya Haldarsriram narendranPas encore d'évaluation

- (Asce) ST 1943-541X 0002538 PDFDocument13 pages(Asce) ST 1943-541X 0002538 PDFJayti GuptaPas encore d'évaluation

- 2002c-Dhakal Maekawa PDFDocument10 pages2002c-Dhakal Maekawa PDFdmep25Pas encore d'évaluation

- Infill of HCBDocument17 pagesInfill of HCBTesfayePas encore d'évaluation

- بسیار مهمDocument18 pagesبسیار مهمh.ezatisazehPas encore d'évaluation

- Aashto Excerpt Specification CH9Document8 pagesAashto Excerpt Specification CH9CyrilPas encore d'évaluation

- Web Slenderness For Longitudinally Stiffened I-Girders Subjected To Patch LoadingDocument15 pagesWeb Slenderness For Longitudinally Stiffened I-Girders Subjected To Patch LoadingGogyPas encore d'évaluation

- S B RCC V T C: Eismic Ehavior of Olumns With Arious IE Onfigurations by Y. L. Mo, Member, ASCE, and S. J. WangDocument9 pagesS B RCC V T C: Eismic Ehavior of Olumns With Arious IE Onfigurations by Y. L. Mo, Member, ASCE, and S. J. Wangdexter238Pas encore d'évaluation

- Hybrid Method For Analysis and Design of Slope Stabilizing PilesDocument14 pagesHybrid Method For Analysis and Design of Slope Stabilizing PilesPANKAJ GUPTAPas encore d'évaluation

- Seismic Design With BRBsDocument15 pagesSeismic Design With BRBsAlex MolinaPas encore d'évaluation

- Pile Design and Installation Specification Based On ConceptDocument4 pagesPile Design and Installation Specification Based On ConceptMoe Oo HtunPas encore d'évaluation

- 10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsDocument9 pages10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsmahdiPas encore d'évaluation

- Special Section: Balancing, Restoration, and Palinspastic ReconstructionDocument28 pagesSpecial Section: Balancing, Restoration, and Palinspastic ReconstructionБогдан ПлотниковPas encore d'évaluation

- Anbarasu 2021Document11 pagesAnbarasu 2021Suhail BabaPas encore d'évaluation

- A Correlation Study of Methods of Matrix Structural Analysis: Report to the 14th Meeting, Structures and Materials Panel Advisory Group for Aeronautical Research and Development, NATO, Paris, France, July 6, 1962D'EverandA Correlation Study of Methods of Matrix Structural Analysis: Report to the 14th Meeting, Structures and Materials Panel Advisory Group for Aeronautical Research and Development, NATO, Paris, France, July 6, 1962Évaluation : 5 sur 5 étoiles5/5 (1)

- NonDocument8 pagesNonGokul PrabuPas encore d'évaluation

- Welding SymbDocument22 pagesWelding SymbGokul PrabuPas encore d'évaluation

- CombinepdfDocument6 pagesCombinepdfGokul PrabuPas encore d'évaluation

- Welded Joints & Symbols: Learner GuideDocument33 pagesWelded Joints & Symbols: Learner GuideGokul PrabuPas encore d'évaluation

- Asm 0002Document7 pagesAsm 0002Gokul PrabuPas encore d'évaluation

- American Welding SocietyDocument1 pageAmerican Welding SocietyGokul PrabuPas encore d'évaluation

- Die Casting PDFDocument16 pagesDie Casting PDFGokul PrabuPas encore d'évaluation

- Toc Pmt1805-Eng MLD2018Document8 pagesToc Pmt1805-Eng MLD2018Gokul PrabuPas encore d'évaluation

- ValvveDocument8 pagesValvveGokul PrabuPas encore d'évaluation

- Three Dimensional Printing (3DP) : Abbreviation: Material Type: MaterialsDocument2 pagesThree Dimensional Printing (3DP) : Abbreviation: Material Type: MaterialsGokul PrabuPas encore d'évaluation

- Helical Sweeps Creo 3Document6 pagesHelical Sweeps Creo 3brpnaidu2157Pas encore d'évaluation

- Mild Steel.5Document1 pageMild Steel.5Gokul PrabuPas encore d'évaluation

- Spec For FEM Stress AnalysisDocument1 pageSpec For FEM Stress AnalysisGokul PrabuPas encore d'évaluation

- Die Casting PDFDocument16 pagesDie Casting PDFGokul PrabuPas encore d'évaluation

- 06 June Month 2018Document32 pages06 June Month 2018Gokul PrabuPas encore d'évaluation

- Die Casting PDFDocument16 pagesDie Casting PDFGokul PrabuPas encore d'évaluation

- Die Casting PDFDocument16 pagesDie Casting PDFGokul PrabuPas encore d'évaluation

- Machine Vice Models and Drawings: Re. Fundamentals of Graphics Communication, Gary R. Bertoline, EtalDocument4 pagesMachine Vice Models and Drawings: Re. Fundamentals of Graphics Communication, Gary R. Bertoline, EtalGokul Prabu100% (1)

- MachiningDocument1 pageMachiningGokul PrabuPas encore d'évaluation

- MachiningDocument1 pageMachiningGokul PrabuPas encore d'évaluation

- Nodia and Company: Gate Solved Paper Mechanical Engineering 2004Document52 pagesNodia and Company: Gate Solved Paper Mechanical Engineering 2004murugeshmech22Pas encore d'évaluation

- Resccessed Handle.4Document1 pageResccessed Handle.4Gokul PrabuPas encore d'évaluation

- Various HR LettersDocument9 pagesVarious HR LettersshivaachantiPas encore d'évaluation

- Die Casting PDFDocument16 pagesDie Casting PDFGokul PrabuPas encore d'évaluation

- Application Form For Community CertificateDocument1 pageApplication Form For Community CertificateN Rakesh100% (1)

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Anonymous AJDL2y4ftPas encore d'évaluation

- Sgkjhsefsojfsaef A KN Aef Nkjbfehohijfo Lefrijejlefjlse Akfjo Njfaj Amd - Am Qpqiwde Nkuhgouhl/' ( ) Iohlj VjgfuyfgiDocument1 pageSgkjhsefsojfsaef A KN Aef Nkjbfehohijfo Lefrijejlefjlse Akfjo Njfaj Amd - Am Qpqiwde Nkuhgouhl/' ( ) Iohlj VjgfuyfgiGokul PrabuPas encore d'évaluation

- Book List - MR JambunathanDocument1 pageBook List - MR JambunathanVirendra Agarwal0% (1)

- Department of Electrical Engineering Minutes of The Meeting of The Departmental Research Committee (DRC)Document1 pageDepartment of Electrical Engineering Minutes of The Meeting of The Departmental Research Committee (DRC)Ravinder RangaPas encore d'évaluation

- s1fnmdl3sm PDFDocument26 pagess1fnmdl3sm PDFmn_aminPas encore d'évaluation

- Joraform JK Series Operating PrinciplesDocument6 pagesJoraform JK Series Operating Principlesapi-236782993Pas encore d'évaluation

- P45-69Z V3.0 Schematic DiagramDocument10 pagesP45-69Z V3.0 Schematic DiagramAhmed El SharkawyPas encore d'évaluation

- Modelsim TutorialDocument26 pagesModelsim Tutorialsachinshetty001Pas encore d'évaluation

- Kočnice Shimano BR-M422Document1 pageKočnice Shimano BR-M422salecello2113Pas encore d'évaluation

- Spring Support Used in PipingDocument7 pagesSpring Support Used in Pipingashish.mathur1Pas encore d'évaluation

- Shrinkage Strip Method Statment and Ther PDFDocument4 pagesShrinkage Strip Method Statment and Ther PDFhakim2020Pas encore d'évaluation

- HSE FRM 32 Final Incident ReportDocument6 pagesHSE FRM 32 Final Incident ReportDilshad aliPas encore d'évaluation

- Til 1213 R1Document6 pagesTil 1213 R1Hernan GirautPas encore d'évaluation

- 2017 Tel 1608Document47 pages2017 Tel 1608Alvaro Torres BozzoPas encore d'évaluation

- 20v4000enDocument266 pages20v4000enMario MartinezPas encore d'évaluation

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Document23 pagesData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainPas encore d'évaluation

- Euro Tempered Glass Industries Corp. - Company ProfileDocument18 pagesEuro Tempered Glass Industries Corp. - Company Profileunited harvest corpPas encore d'évaluation

- Control Lab ReportDocument11 pagesControl Lab ReportMariamMunirAhmad100% (1)

- PQP FormatDocument10 pagesPQP FormatMichael TeoPas encore d'évaluation

- Ac Repair Doha QatarDocument5 pagesAc Repair Doha QatarperfectsolutionqaseoPas encore d'évaluation

- Re-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Document6 pagesRe-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Vasilica BarbarasaPas encore d'évaluation

- Foxpro Treeview ControlDocument5 pagesFoxpro Treeview ControlJulio RojasPas encore d'évaluation

- FM GREASE AX EP SERIES - Data Sheet PDFDocument2 pagesFM GREASE AX EP SERIES - Data Sheet PDFricardo gomezPas encore d'évaluation

- I/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoDocument1 pageI/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoMIkołaj MorzePas encore d'évaluation

- Flying Qualities CriteriaDocument24 pagesFlying Qualities CriteriajoereisPas encore d'évaluation

- Baseline Processing ReportDocument17 pagesBaseline Processing ReportMAMAN MAMANPas encore d'évaluation

- Sony FDR AX1 - E ProDocument68 pagesSony FDR AX1 - E ProTodorPas encore d'évaluation

- Full Download Book Power Electronics Motor Drive Systems Fundamentals Experiments and Applications PDFDocument41 pagesFull Download Book Power Electronics Motor Drive Systems Fundamentals Experiments and Applications PDFrichard.desouza769100% (10)

- 6 - Reasoning PDFDocument5 pages6 - Reasoning PDFAgri CoachigPas encore d'évaluation

- Company Names and Number UAEDocument35 pagesCompany Names and Number UAESoju Suresh100% (1)

- 2021 Product Catalogue DTH - English - LOWDocument42 pages2021 Product Catalogue DTH - English - LOWEmrah MertyürekPas encore d'évaluation

- Metode Statement of Fabrication RebarDocument11 pagesMetode Statement of Fabrication RebararifPas encore d'évaluation

- Free and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongDocument18 pagesFree and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongRajesh KachrooPas encore d'évaluation

- Centrifugal PumpsDocument6 pagesCentrifugal Pumpsjerome fajardoPas encore d'évaluation