Académique Documents

Professionnel Documents

Culture Documents

Project 5

Transféré par

Neophyte1Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Project 5

Transféré par

Neophyte1Droits d'auteur :

Formats disponibles

'TVansterJe,1h

Ptoject #5 Soda Can Project from Stewart Co,!culus i €.artV

9 lzwarl t P' ttz

a

T H E S H A P EO F A C A N

In this project we investigate the most economical shape for a can. We first interpret this to mean

that the volume V of a cylindrjcal can is given and we need to find the height h and radius r that

minimrze the cost of the metai to make the can (see the figure). If we disregard any waste metal

in the manufacturing process, then the problem is to minimize the surface area of the cylinder.

I We solved this problem in Example 2 in Sectron 4.'l and we found that h : 2r; that is, the height

should be the same as the diameter. But if you go to your cupboard or your supermarket with a

I

I

j

ruler, you wiil discover that the height is usually greater than the diameter and the :atio hf r vuies

l :

from 2 up to about 3.8. Let's seeif we can explain this phenomenon.

\:'

I

..;

L The material for: the cans is cut from sheetsof metal. The cylindrical sides are formed by

rV

bending rectangles; these rectangles are cut from the sheet with little or no waste. But if the

top and bottom discs are cut from squaresof side 2r (as in the f,gure), this leaves considerable

waste metal, which may be recycled but has little or no value to the can makers. If this is the

case, show that the amount of metal used is minimized when

h8

2.55

r7f

2. A more efficient packing of the discs is obtained by dividing the metal sheet into hexagonsand

cutting the circular hds and bases from the hexagons (see tle figure). Show that if this strategy

Discs cut from squares

is adopted, then

,'/;

n '+\,/3

- a ar

rTr

The values of h/r that we found in Problems I and 2 are a little closer to the ones that

aclr-rallyoccur on supermarket shelves, but they still don't account for everything If we

Iook more closely at some real cans, we see that the lid and the base are formed from discs

with radius larger than r that are bent over the ends of the can. If we allow for this we would

increase hf r. More significantly, in addition to the cost of the metal we need to incorporatethe

Discscut from hexagons

manufacturing of the can into the cost. Let's assumethat most of the expense is incurred in

joining the sides to the rims of the cans. If we cut the discs from hexagons as in Problem 2,

then the total cost is proportional to

4J3 12 * 2nrh + k(4nr + h)

whele k is the reciprocai of the length that can be joined for the cost of one unit area of metal.

Show that this expression is minimized when

w: nh 2n - h/r

k r ;ii -nJT

Wc. Plotilk a s a f u n c t i o no f x : h l r anduseyourgraphtoarguethatwhenacanislargeor

joining is cheap, we should make hf r approximately 2.21 (as in Problem 2). But when the can

is small or joining is costiy, h/r should be substantiallylarger.

5. Our analysis shows that large cans should be almost square but small cans should be tall and

thnn.Take a look at the relative shapesof the cans in a supermarket. Is our conclusion usually

true rn practice? Are there exceptions? Can you suggestreasons why small cans are not aiways

tall and thin?

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Hydroponic Cheat SheetDocument3 pagesHydroponic Cheat SheetNarcisMarin100% (12)

- GORE Automotive Vents Exterior Lighting Datasheet ENDocument4 pagesGORE Automotive Vents Exterior Lighting Datasheet ENAaron HuangPas encore d'évaluation

- Common SSR For The Year 2019-20 (For All AP Power Utilities)Document48 pagesCommon SSR For The Year 2019-20 (For All AP Power Utilities)SIVA NAGA SUDHEER SIDDANIPas encore d'évaluation

- Atom, Molekul, Dan IonDocument28 pagesAtom, Molekul, Dan IonFelix V SPas encore d'évaluation

- Phase Equilibrium Study in The CaODocument5 pagesPhase Equilibrium Study in The CaOsattiricPas encore d'évaluation

- Simple DistillationDocument5 pagesSimple DistillationJheian Christian TublePas encore d'évaluation

- Hardness TestDocument2 pagesHardness TestjorgekarlosprPas encore d'évaluation

- Zanussi ZWS 510801Document20 pagesZanussi ZWS 510801LoreelayPas encore d'évaluation

- Lec14 PDFDocument18 pagesLec14 PDFRohan sharmaPas encore d'évaluation

- Polymer Chemistry For B.SC - Sem-6th PDFDocument49 pagesPolymer Chemistry For B.SC - Sem-6th PDFSohel Ansari0% (1)

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemPas encore d'évaluation

- Elog Brazil Lightweight Equipment - CompressedDocument51 pagesElog Brazil Lightweight Equipment - CompressedMarcelo SouzaPas encore d'évaluation

- Chemistry For Engineers: Assignment 1Document4 pagesChemistry For Engineers: Assignment 1Thanh Tan PhamPas encore d'évaluation

- Effect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelDocument6 pagesEffect of Pitting Corrosion On The Mechanical Properties of 316 Grade Stainless SteelAnilPas encore d'évaluation

- Corrosion Science: M.J. Muñoz-Portero, J. García-Antón, J.L. Guiñón, R. Leiva-GarcíaDocument11 pagesCorrosion Science: M.J. Muñoz-Portero, J. García-Antón, J.L. Guiñón, R. Leiva-GarcíaFadli IkhsanPas encore d'évaluation

- 12CHEM Long Response Dot PointsDocument11 pages12CHEM Long Response Dot PointsJane YooPas encore d'évaluation

- Fluid Bed PPT End Ar - pptx1Document20 pagesFluid Bed PPT End Ar - pptx1Yaqeen MutanPas encore d'évaluation

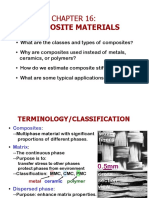

- 10 Chapter 16 Composite MaterialsDocument27 pages10 Chapter 16 Composite MaterialsZain FarhanPas encore d'évaluation

- НАУЧНОЕ НАСЛЕДИЕ АКАДЕМИКА КАШГАЯ PDFDocument364 pagesНАУЧНОЕ НАСЛЕДИЕ АКАДЕМИКА КАШГАЯ PDFAnver AkperovPas encore d'évaluation

- PhysicsDocument4 pagesPhysicsNelmart SolteoPas encore d'évaluation

- Formation Constants of Complex IonsDocument1 pageFormation Constants of Complex IonsIuliaHortPas encore d'évaluation

- Presentation 1Document5 pagesPresentation 1Eziah Pearl Joy AlaveraPas encore d'évaluation

- Pre-Final Bill Supplimentary works-MVGR 02.07.2019Document112 pagesPre-Final Bill Supplimentary works-MVGR 02.07.2019Anonymous ImoZI0363Pas encore d'évaluation

- Bentogliss 121 enDocument2 pagesBentogliss 121 enAdityaPas encore d'évaluation

- tnd14v 221kb00aaa0Document56 pagestnd14v 221kb00aaa0jombo123Pas encore d'évaluation

- Deewane: IES & GATE: Material ScienceDocument33 pagesDeewane: IES & GATE: Material ScienceMayank SaxenaPas encore d'évaluation

- Mtech ThesisDocument85 pagesMtech ThesisSuman BasakPas encore d'évaluation

- Icu - Main Drawing - Pb-ModelDocument1 pageIcu - Main Drawing - Pb-ModelLeanna Abdul WahabPas encore d'évaluation

- Slide 11 Extrusion and Wire DrawingDocument53 pagesSlide 11 Extrusion and Wire Drawingjohn doePas encore d'évaluation

- Johnson Rajkot Elite Plus Elite WallDocument148 pagesJohnson Rajkot Elite Plus Elite WallSiddhartha AgnihotriPas encore d'évaluation